Chevrolet Stovebolt engine

This article needs additional citations for verification. (December 2009) |

| Straight 6 | |

|---|---|

| Overview | |

| Manufacturer | General Motors Corporation |

| Production | 1929–1990 North America 2002–2009 (Atlas LL8) North America 1962–2001 Brazil |

| Layout | |

| Valvetrain | OHV |

| Combustion | |

| Fuel type | gasoline |

| Cooling system | water-cooled |

| Chronology | |

| Predecessor | 171 Straight-4 |

| Successor | General Motors 90° V6 engine |

The Chevrolet inline 6 otto engine was Chevrolet's sole engine from 1929 (when it replaced their first 4-cylinder engine, the 171-cubic-inch four), through 1954, and was the base engine starting in 1955 when they added the small block V8 to the lineup. It had finally been completely phased out by 1990 in North America, but in Brazil, GM held on to their fuel-injected version through the 1998 model year. It was replaced by more recently developed V6 and four-cylinder engines. Many popular cars and trucks, including the Chevrolet Camaro, Chevrolet Impala, and Chevrolet Suburban used the inline 6 as the base engine. Chevrolet did not offer another inline 6 until the 2002 General Motors Atlas engine's debut in the Chevrolet TrailBlazer.

1st Generation (1929 Stovebolt Era)

| First Generation | |

|---|---|

| |

| Overview | |

| Production | 1929–1936 |

| Layout | |

| Displacement | 194 cu in (3.2 L) 181 cu in (3.0 L) 207 cu in (3.4 L) |

| Cylinder bore | 3.3125 in (84 mm) |

| Piston stroke | 3.75 in (95 mm) |

| Valvetrain | OHV |

| Combustion | |

| Oil system | "splash" lubrication for the rod bearings and pressurized lubrication to the three main bearings. |

| Cooling system | Water-cooled |

| Output | |

| Power output | 50 hp (37 kW) 1929–1931 194 60 hp (45 kW) 1932–1933 194 80 hp (60 kW) 1934–1936 194 |

| Chronology | |

| Predecessor | 171 Straight-4 |

"A six for the price of a four"

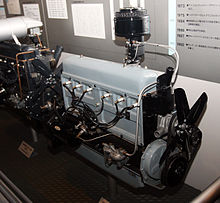

The first mass-produced GM inline 6 was introduced in 1929 on Chevrolet cars and trucks, replacing the company's first inline-4. Richard Grant (Chevrolet marketing executive) insisted that the new design boast overhead valves. Chevrolet had long been known for its "valve-in-head" four-cylinder engines. William S. Knudsen's cast-iron wonder was produced through 1936.

194

It was 193.9 cubic inches (3.2 L) in size and produced 50 hp (37 kW). This engine used a forged steel crankshaft with three bearings and cast-iron pistons. Bore and stroke was 3.3125 in (84.14 mm) by 3.75 in (95.25 mm). The 194 was shared with Chevrolet and GMC trucks for 1935 and 1936.

A balanced crankshaft was introduced for 1932, while a higher (5.2:1) compression ratio upped output to 60 hp (45 kW). Applications:

- 1929 Chevrolet Series AC International (Only $10 more than 1928s four-cylinder)

- 1930 Chevrolet Series AD Universal

This engine was used in all Chevrolet passenger cars 1929-1933, and the 1934 "Standard" models.

181

A 181-cubic-inch (3.0 L) (3.3125 x 3.5) version was used by Chevrolet and GMC trucks in 1935 and 1936.

207

206.8-cubic-inch (3.4 L) (3.3125 x 4) variant was used by Chevrolet and GMC trucks in 1934, 1935, and 1936. The 1934 Chevrolet "Master Deluxe" series used this engine, as did all 1935-1935 Chevrolet passenger cars. This newly revised engine put out 80 hp (60 kW).

Oldsmobile's flathead straight six in Chevrolet and GMC trucks

In 1935 and 1936, GMC and Chevrolet used an Oldsmobile 213 L-head engine. For 1937 and 1938, they used Oldsmobile's 230 L-head engine.

Second generation

The next-generation Chevrolet inline 6 was introduced in 1937 and phased out in 1963 in the US, and 1964 in Brazil. It is often known as the "Blue Flame" engine, although that name was only officially applied beginning in 1953, and then only for one certain model of the engine.[1]

| Second generation | |

|---|---|

| Overview | |

| Production | 1937–1963 US -1964 Brazil |

| Layout | |

| Displacement | 216 cu in (3.5 L) 235 cu in (3.9 L) 261 cu in (4.3 L) |

| Cylinder bore | 3.500 in (88.9 mm) 3.5625 in (90.5 mm) 3.750 in (95.2 mm) |

| Piston stroke | 3.750 in (95.2 mm) 3.9375 in (100 mm) |

| Valvetrain | OHV |

| Compression ratio | 6.5:1 6.6:1 7:1 |

| Combustion | |

| Cooling system | Water-cooled |

| Output | |

| Power output | 85 hp (63 kW) 90 hp (67 kW) 92 hp (69 kW) 123 hp (92 kW) 136 hp (101 kW) 150 hp (112 kW) |

216

This engine had a 216.48-cubic-inch (3.5 L) displacement with a 3.500” (88.90 mm) bore and a 3.750” (95.25 mm) stroke. A four-bearing crankshaft was added, along with 6.5:1 compression pistons, for 85 hp (63 kW). A new cylinder head in 1941 increased output to 90 hp (67 kW), and 6.6:1 compression gave the 1949 model 92 hp (69 kW). This generation did not use a fully pressurized oiling system. The connecting rods were oiled using an "oil trough" built into the oil pan that had spray nozzles that squirted a stream of oil at the connecting rods (which were equipped with "dippers"), thus supplying oil to the rod bearings.

Rod bearings were made of babbitt cast integral with the rod. The bearing was adjustable for wear by removing copper shims placed between the rod cap and connecting rod. In this way specified oil clearance could be maintained. If the crankshaft were to be turned undersized, or if the bearing was damaged or worn out, rod and bearing were replaced as a unit, typically at the dealership.[citation needed]

This engine was also used in GM's British Bedford truck. In the late 1930s rival Austin decided to get into the 2-3 ton truck ("lorry") market and in a crash program based the design—one might say shamelessly copied[citation needed] - on the basic architecture of this "Stove Bolt" engine, except that they added detachable shell main and con-rod bearings and pressurized lubrication. That Austin engine, in six-cylinder form, post war, went on to power cars such as the Austin Sheerline and Princess, and the Jensen Interceptor and 541. Austin also lopped off two cylinders and in that form various versions, with various capacities, powered cars such as the Austin 16, A70 Hampshire and Hereford, A90 Atlantic, the Austin-Healey 100-4 and the Austin Gipsy, plus a generation of commercial vans, plus the iconic London black taxi (FX3 and FX4).

235

In 1941, a 235.49 cu in (3,859 cubic centimetres) version of the 216 engine was introduced for use in large trucks. Both the bore (3.5625” or 90.49 mm) and stroke (3.9375” or 100.01 mm) were increased over the 216. This engine also had an oil "dipper system" as described above, in reference to the oiling system, as in the 216.

This 235-cubic-inch (3.9 L) version was added to cars in 1950 to complement the new Powerglide automatic transmission, and 3.55:1 rear differential. Hydraulic lifters were used in the Powerglide 235 and a fully pressurized lubrication system was introduced in 1953, but only in cars ordered with the "Powerglide" transmission. The 216-cubic-inch (3.5 L) continued to be standard powerplant for cars with the three-speed manual transmission until 1954, when the 235-cubic-inch (3.9 L) became the standard powerplant on all Chevrolet passenger cars. Two versions were used in 1953 cars - a solid-lifter version called the Thrift-King, with 123 hp (92 kW) for standard transmissions, and the hydraulic-lifter 136 hp (101 kW) version (the Blue-Flame) for Powerglide use. The "Blue Flame" moniker had been used in Chevrolet advertising since 1934. A blue rather than yellow flame within the cylinder meant that perfect combustion was achieved, promised GM's ad men.[1]

The major limitation for performance on the 235 was the design of the intake and exhaust ports. Unlike more modern straight sixes, the 235 had siamesed ports, with three intake ports and four exhaust ports. This meant the adjacent cylinders 2 and 3 and cylinders 4 and 5 shared a single exhaust port between them, whereas cylinders 1 and 6 had their own exhaust ports. Secondly, since there were only three intake ports, each port was divided between a pair of adjacent cylinders: 1 and 2, 3 and 4, and 5 and 6 shared an intake port. The design of the intake manifold also favored the middle port (and therefore the middle two cylinders). This ultimately caused the four end cylinders to receive less mixture, resulting in an unequal and unbalanced work load between the six cylinders.

From 1954 to 1963, the high-pressure 235 engine with mechanical valve lifters was used in some trucks. From 1956 to 1962, all 235 engines used in cars had hydraulic lifters.

The original 1953 Corvette engine was the high-pressure 235 engine equipped with mechanical lifters. A 150 hp 235 engine was used in the 1954 Corvette and into 1955 (until they were all sold). The Corvette 235 was equipped with the same slightly higher-lift camshaft as used in the 261 truck engine and used triple side draft, single barrel, Carter Model YH carburetors mated to a PowerGlide transmission and dual exhaust manifold.

The Chevrolet 235-cubic-inch is known as one of the great Chevrolet engines, noted for its power and durability. It was gradually replaced by the third generation 230, beginning in 1962.

Canadian production GMC trucks used the 216 and 235 Chevrolet straight six engines as their base light duty truck powerplant in the late 1940s and early 1950s in Canada, not USA. The 216 was used from 1947 to 1953, and the 235 was used in 1954 light duty trucks only. Medium duty GMC trucks used US built GMC engines in the 248, 270, and up sizes prior to 1954.

Toyota built the similar 236-cubic-inch Toyota F engine from 1955 to 1974, although it used a modified head from the previous "stovebolt" engine.

261

In 1954, a 260.9-cubic-inch (4.3 L) truck engine was introduced as an optional Jobmaster engine for heavy-duty trucks. This engine was very similar to the 235 engine, except for a different block casting with a larger piston bore of 3.750” or 95.25 mm, two extra coolant holes (in the block and head) between three paired (siamesed) cylinders, and a slightly higher lift camshaft. This engine was offered as a step up from the 235 starting in 1954. It was offered in parallel with the GMC V6 engine in 1960 until 1963, when it was discontinued. The 261 USA truck engine had mechanical lifters and was available from 1954 to 1962.

The 235 and 261 truck engines were also used by GMC Truck of Canada (GMC truck 6-cylinder engines were also used in Canada). The 1955–1962 Canadian full-size Pontiac car had a standard 261-cubic-inch engine that had hydraulic lifters. This engine was not sold in the USA, but was very similar to the USA truck 261.

The 261 engines were also used in light trucks and the Chevrolet Veraneio from 1958 to 1979 in Brazil.

Third generation

| Third generation | |

|---|---|

| |

| Overview | |

| Production | 1962—1990 1964—2001 (Brazil) |

| Layout | |

| Displacement | 194 cu in (3.2 L) 230 cu in (3.8 L) 250 cu in (4.1 L) 292 cu in (4.8 L) |

| Cylinder bore | 3.563 in (90.5 mm) 3.875 in (98.4 mm) 3.875 in (98.4 mm) 3.875 in (98.4 mm) |

| Piston stroke | 3.250 in (82.6 mm) 3.250 in (82.6 mm) 3.530 in (89.7 mm) 4.120 in (104.6 mm) |

| Valvetrain | OHV |

| Combustion | |

| Cooling system | Water-cooled |

| Dimensions | |

| Length | 32.5 in (830 mm) |

Chevrolet's third-generation inline six was introduced in 1962 (two years after rival Chrysler introduced its Slant Six as a replacement for the long-obsolete Chrysler 90hp 230 cubic-inch flat-head six-cylinder engine), and was produced through 1988. Although the exterior dimensions were similar to previous Chevrolet OHV inline six-cylinders, this generation was lighter and had a different cast-in bell housing pattern it shares with all Chevrolet engines designed and produced after 1954, including the modern LS-series "small-block" Chevy V8s and the 8.1L "big-block" Chevy V8s. The first three third-generation engines with 230, 250 and 292 cubic inches share the 3.875" bore with the first three small-block V8 engines, which are the 265, 283 and 307 cubic inch V8s.

Some of the many third-generation engines have bores and/or strokes in common with other Chevrolet engines, while others have bores and/or strokes unique to themselves. Since Chevrolet produced its "first-generation" small-block V8s and third-generation inline 6-cylinders during a period of several decades and for many General Motors and outside OEM manufacturers in several different factories, most situations where the V8s share parts or dimensions with the 6-cylinders are happenstance or coincidence rather than the result of a concerted effort to maximize commonality, which wasn't confined to the 6-cylinders and small-block V8s. There are certain parts and dimensions some 6-cylinder engines share with big-block Chevy V8s, which is another case of convenience and coincidence rather than design.

By the time the third-generation 6-cylinders were being designed and developed, Chevrolet was the most popular brand of vehicles in the world, and sales and production of vehicles and engines were into the millions of units per year with increasing markets for Chevrolet engines both within General Motors and outside the company in the industrial/commercia/agricultural/military/transportation markets both in the U.S. and worldwide.

As Chevrolet's first engine family produced with both Chevrolet and General Motors use and applications in mind and for widespread marketing and sales to other OEMs who purchased engines for applications ranging from marine propulsion to powering agricultural machinery to use by other motor vehicle manufacturers in their own vehicles, Chevrolet engineers concentrated on making the engines as interchangeable with the small-block and big-block V8s as possible without wasting time, money and personnel resources building the new 6-cylinders with as many off-the-shelf V8 parts as possible.

The huge success of Chevrolet since the introduction of the small-block V8s for the model year and the W-series big-block introduction in the 1958 model year had resulted in a huge increase in engine production and Chevrolet engineers had subsequently recognized mistakes or weaknesses in the V8 engines, had improved the engines and had developed new processes and technologies that in some ways made the third-generation 6-cylinders descendants of the V8s and in others made them ancestors of improved V8 engines when even more was learned from the 6-cylinders and was then applied to existing and new V8 engines.

There was no need to pinch pennies and spend dollars trying to save dimes by making a V8 part fit a 6-cylinder or vice versa when a better part designed and produced specifically for either family resulted in a better finished product and the larger initial investment was repaid many times over as a result. General Motors in general and Chevrolet Division in particular had learned much from Ford's fall from dominance and a near monopoly of the U.S. auto industry, which primarily resulted from reluctance to change and resistance to outside opinions and criticisms from potential, existing and former customers who generally supported Henry Ford and his company and products, but felt that Ford produced the products it thought best for Ford while paying little attention to what was wanted and needed by those who paid the bills with their purchases of Ford products. General Motors and Chevrolet were determined to be the antithesis of Ford Motor Company and its perceived "take it or leave it" attitude.

A 153 cubic-inch inline 4-cylinder engine with bore and stroke identical to the 230 cubic-inch inline 6-cylinder was produced and many internal parts were common to both engines.

There were other major differences between the third-generation 6-cylinder/153 4-cylinder and previous Chevrolet inline OHV engines.

The Gen-3 crankshafts had 7 main bearings (increased from 4). . The 230 reduced stroke to 3.25" from the comparable 235 design's 3.9375". The combustion chamber changed to a conventional wedge design much like the V8. The harmonic damper gained cast-in pulley provisions. Air-conditioned vehicles had a stamped-steel pulley bolted up front. Stamped and stud-mounted rocker arms were introduced, similar to the V8, and the ratio was close to the one used in the Chevrolet GEN IV big block (1.75:1 ratio) rather than the shaft-mounted earlier rockers at 1.477:1. The HEI (High Energy Ignition) system with an electronic pickup replacing the points and the coil locate in the distributor cap became standard equipment for the 6-cylinder engines concurrent with its use in the small-block and big-block V8s.

Two variants of the third generation six were produced - the 194/230/250 cid short deck (used in passenger cars, light trucks, and vans), and the tall deck 292 (used with some light trucks, vans, and commercial vehicles, which retained the dimensions of the previous generation "Stovebolt" six-cylinders, which were so-named due ).

The first use was in the newly introduced 1962 Chevy II; the following year, Chevrolet passenger cars adopted it (alongside Checker Marathons since 1965) and used this powerplant until 1977 (1979 for Camaros, Novas, and full size Chevrolets). Chevrolet/GMC trucks, which previously used the stovebolts (235 and 261), also used some members (with the tall deck 292 with both the light duty and medium duty trucks, C40-C60) of this family from 1963 through 1984 (short deck motors), as did Pontiac in 1964 and 1965. A 153-cubic-inch inline-4 version of this engine was offered in the Chevy II/Nova line through the 1970 model year. After several years of steadily declining sales (just 3,900 units in the 1972 model year),[2] the straight six was dropped from Chevrolet's full-sized cars for 1973, for the first time since 1928; it would be restored in 1977.[2] Sidenote: the base six cost about US$334 less than a V8, and weighed some 188 lb (85 kg) less.[2]

By the mid-1970s, the compact V-design (e.g. Buick 231) led to inline six engines being phased out in passenger cars, but they continued to be installed in trucks and vans until 1988.

Overseas, the third generation of the inline six was mass-produced in Brazil. It was used in the Chevrolet Opala from 1969 (230) to 1992 (250). It was already used in light trucks as the A and Chevrolet Veraneio. The Brazilian version of the GMT400 – the Brazilian Chevrolet Silverado – is powered with a 4.1 instead of the Vortec 4300 V6. Brazilian produced sixes manufactured to the 2001 model year gained multipoint fuel injection unlike the USA-manufactured sixes which retained the Rochester Monojet one barrel carburetor. These inline sixes and their four-cylinder siblings were converted for marine usage by Mercruiser and Volvo Penta, and also used in stationary applications (such as power generation) and in Clark forklifts.[citation needed][dubious – discuss] Aftermarket port fuel injection and re-engineered cylinder heads have been the norm although parts for the six e.g. aftermarket intake manifolds (from a three carburetor setup or a single 4-barrel carburetor), exhaust headers, and/or hybrid cylinder heads based on the small block are costlier than the Small Block Chevrolet unlike the rival AMC inline six (which has a cult following with Jeep enthusiasts, especially with the 4.0L).

194

The 194 (3,185 cc or 3.2 L) was shared between Chevrolet and GMC trucks.

Applications:

- 1962–1967 Chevy II

- 1962–1974 Chevrolet 400 (Argentina)

- 1962–1974 Chevrolet 400 Special (Argentina)

- (Circa 1965-66) Holden HD (South Africa)[3]

- (Circa 1966-67) Holden HR (South Africa)[4]

- 1968–1974 Chevrolet 400 Rally Sport (Argentina)

- 1964–1967 Chevrolet Chevelle

- 1965–1966 Studebaker Commander, Daytona ('66 only), Cruiser and Wagonaire (built by McKinnon Industries in Canada)

- 1973-1978 Chevrolet 4100 (South Africa)

215

Pontiac's 215 (1964–1965) was a smaller bore (3.75") version of the 230 cu in (3.8 L) Chevrolet straight-6 engine.

230

The 230 (3,768 cc or 3.8 L) replaced the long-stroke, second generation 235 cu in (3.9 L) version. Bore and stroke are 3.875 in (98.43 mm) and 3.25 in (82.55 mm) respectively. It was also used by Chevrolet and GMC trucks, primarily for the half-tons. It produced 140 hp (100 kW). The 230 had a firing order of 1-5-3-6-2-4 rotating clockwise. It was also built in Latin America and was in production in South Africa until at least 1982, where it powered a multitude of different cars. A four-cylinder version of this engine was also built, as the Chevrolet "153" engine.

This engine was used on the following vehicles:

- 1973-1979 Chevrolet 3800 (South Africa)

- 1963–1969 Chevrolet Chevelle/Malibu

- 1965–1968 Checker Marathon

- 1965 Chevrolet El Camino

- 1964–1970 Chevrolet Chevy II / Nova

- 1966 Studebaker Commander, Wagonaire, Daytona and Cruiser

- (Circa 1966-67) Holden HR (South Africa) [4]

- 1967 Chevrolet Camaro

- 1962–1974 Chevrolet 400 Special (Argentina)

- 1964–1974 Chevrolet 400 Super (Argentina)

- 1972–1974 Chevrolet 400 Rally Sport (Argentina)

- 1969 Chevrolet Camaro

- 1978-1982 Chevrolet Commodore (South Africa)[5]

- 1968–1971 Chevrolet Opala (Brazil)

- 1963–1967 Pontiac (fullsize, Canada)

Pontiac 3.8

The Pontiac 3.8 was a special SOHC version of the standard 230 cu in (3,768 cc) inline six which shared very little with the Chevrolet: the block was different and used shaft drive outside of the engine for water pump and distributor drive and the famous OHC with a fiberglass reinforced timing belt, first introduced for the 1966 Tempest and used in two versions, one with a single one barrel carburetor and 165 hp, and a second Sprint version with a quadrajet 4 bbl. at 207 hp.[6] An optional W53 version for the Firebird produced 215 hp (160 kW). The Pontiac 3.8 was replaced by a 250 cu in version for 1968-69. The Sprint version of the 250 OHC made 230 HP.

This engine was used on the following vehicles:

- 1967-69 Pontiac Firebird

- 1966-1969 Pontiac Tempest

250

The stroked 250 version produced 155 hp (116 kW) for Chevrolet and GMC, with a 37/8 in bore and 317/32 in stroke. Between 1975 and 1984, an integrated cylinder head was produced (intake manifold and cylinder head were a single casting with a bolt on exhaust manifold), with one-barrel intakes for passenger cars, and two-barrel intakes for trucks after 1978.

During the mid-1970s, the Buick 231 and Chevrolet 90-Degree 4.3L V6 engine (essentially a 350 cubic-inch small-block Chevy V-8 with the two rear cylinders removed) were replacing the Chevrolet 250 for use in passenger cars and light duty trucks/vans. Passenger car use of the 250 cu in (4,093 cc) engine was discontinued after the 1979 model year for North America (along with the Chevrolet 292), since the six was restricted to light truck usage (the 4.1 was discontinued after 1984 in North America, where the Vortec 4.3 V6 became the base engine). Brazil held on to the 250 (known as the 4.1 there) until 1998 for passenger cars, when the Chevrolet Omega A was replaced by rebadged Australian Holdens. It was used in Brazil until 2001 in Chevrolet Silverado when the engine line was discontinued. The Brazilian produced sixes gained multipoint fuel injection and redesigned cylinder heads which had smaller intake ports. It would be GM's final inline six until the introduction of the GM Atlas engine in late 2001. It was also used for a number of large sedans by Chevrolet of South Africa.

This engine was used on the following vehicles:

- 1966–1984 Chevrolet (passenger cars to 1979, trucks/vans to 1984)

- 1968–1974 Chevrolet 400 Super Sport (Argentina)

- 1972–1974 Chevrolet 400 Rally Sport (Argentina)

- 1970–1976 Pontiac Firebird

- 1970 Pontiac Tempest

- 1970–1976 Pontiac LeMans

- 1968–1969 Buick Special

- 1968–1972 Oldsmobile F-85

- 1975–1976 Oldsmobile Cutlass

- 1971–1975 Pontiac Ventura

- 1968–1971 Buick Skylark

- 1973–1975 Buick Apollo

- 1967–1979 Chevrolet Camaro

- 1969–1979 Checker Marathon

- 1970–1974 Puma GTB (Brazil)

- 1971–1992 Chevrolet Opala (Brazil)

- Chevrolet Constantia (South Africa)

- 1973-1982 Chevrolet Commodore (South Africa)[5]

- 1979-1982 Chevrolet Senator (South Africa)[5]

- 1979–1994 Chevrolet Veraneio (Brazil)

- 1988–1992 Puma AMV (Brazil)

- 1995–1998 Chevrolet Omega A (Brazil)

- 1998–1999 Chevrolet Tahoe (Argentina)

- 1998–1999 Chevrolet Silverado - (GMT400) (Brazil)

250-S

When the long duration races restarted in Brazil, in 1973, the Opala found a great competitor, the Ford Maverick, which was powered by an engine almost one liter larger in displacement. It took Bob Sharp and Jan Balder, who shared a ride to second place in the "24 Hours of Interlagos" in August of that year in an Opala, to pressure GMB to field a more powerful racing engine.

By coincidence, engine development manager Roberto B. Beccardi was working on this engine hop-up project out of his own initiative, but lacked factory support or approval. This impulse came right from these two pilots.

Thus, in July 1974, GM started to offer the 250-S engine as an option for the Opala 4100. It was slightly different from the version launched two years later: the project engine was similar to the four-cylinder units, did not get a vibration damper, and used the cooling fan from the standard 2500, with four blades instead of six.

The Opala was now much faster than the Maverick GT and Ford did not waste time. It quickly homologated a version with four-barrel carburetor, called "Quadrijet" in Brazil (no relationship to GM's own Rochester Quadrajet), with performance roughly equivalent to the 250.[citation needed]

The 250-S has 171 Horsepower and 229.7 lb.-ft. at 2,400 rpm.

- 1974–1980 Chevrolet Opala SS (Brazil)

- 1977–1980 Chevrolet Opala Caravan SS (Brazil)

- 1981–1988 Chevrolet Opala - All Line (Brazil)

- 1974–1987 Puma GTB (Brazil)

- 1978–1988 Santa Matilde SM4.1 (Brazil)

L22

The L22 was a 250-cubic-inch (4.1 L) I6 engine produced from 1967 to 1979. The '78 Camaro had 105 horsepower (78 kW) and 190 ft⋅lbf (260 N⋅m) of torque with the 250.

LD4

The LD4 was a 250-cubic-inch (4.1 L) I6 engine produced strictly in 1978.

LE3

The LE3 was a 250-cubic-inch (4.1 L) I6 engine produced from 1979 to 1984.

292

The 292 cu in (4.8 L) engine was used in Chevrolet and GMC trucks as well as some full-sized Chevrolet cars beginning in the early 1960s; the block deck is taller, along with a relocated passenger-side engine mount. Flywheel bolt pattern is the same as the six and V8 - with 1/2" bolts for the flywheel if produced after the 1966 model year. Production of the engine was shifted to Mexico in 1980, and later variants of this engine were marketed as the "L25". The 292 retained the separate intake (with a Rochester Monojet carburetor) and exhaust manifolds as used with the short deck motors (194-250). It was GM's last pushrod straight-six engine used from 1977 to 1988 in Chevrolet trucks, including UPS truck chassis. Outputs in 1988 (only): 165 hp at 3,800 rpm and 280 lb. ft. at 1,600 rpm.

Eventually the L25 was replaced by the 4.3 L 90-degree V6.

GMC engines

It has been suggested that this section should be split into a new article titled GMC straight-6 engine. (discuss) (May 2016) |

GMC as a marque really only produced a few engine designs, the straight six, a V8, and a V6 which was also available as a V12 for a brief period. GMC used many engines from other GM divisions, as noted below.

228

GMC replaced the Pontiac 223 with their own 228-cubic-inch (3.7 L) 228 in 1939. This OHV (overhead-valve) engine was produced through 1953. This is the smallest low-deck engine, all three of which have 3.8125" stroke and 3.5625" bore, with 7" connecting rods.

236

GMC also developed an OHV/pushrod engine in 1939. The 236-cubic-inch (3.9 L) 236 was produced through 1955. This is a low-deck engine. The bore was 3.625".

248

Those same years (1939–1955), GMC produced a 248-cubic-inch (4.1 L) engine, the 248, which was similar to the 236. This is the largest low-deck engine. The bore was 3.71875".

256

The 256-cubic-inch (4.2 L) 256 was different from the 236 and 248. It was also an OHV/pushrod engine, and was built for just two years, 1940 and 1941. This is the smallest raised-deck engine, all three of which have 4" stroke and 7" connecting rods. The bore was 3.6875".

270

The last GMC-only straight six was the 270-cubic-inch (4.4 L) 270. It was produced from 1941 through 1963, and was an OHV/pushrod engine. This is a raised-deck engine. The bore was 3.78125".

302

The 301.6 (4.9L) GMC inline six was produced from 1952 to 1960, when it was replaced by the V6. It has a 4.00" bore and a 4.00" stroke. This is the largest raised-deck engine. It was originally designed for the GMC military M135 and M211. It was used in military 2.5 ton trucks with the HydraMatic transmission; however, the engine was a sealed engine for snorkel/submersion use, had an electric fuel pump, and other features such as a deep sump oil pan. From 1952 to 1959, GMC manufactured the civilian 302 engine, which was not sealed, had a mechanical fuel pump, and used a "standard" oil pan. This engine was popular with hotrod enthusiasts because it delivered tremendous power for an inline six engine at the time (although now obsolete), is truck built with a heavy cast block, and can take quite a bit of abuse.

426

The 425.6 (7.0L; 4.25"x5.0") GMC inline six appeared in 1940s 4x4 Cab Over Engine (COE) trucks made in Pontiac, MI. It also appeared in large GMC trucks in the 1950s.

503

The 502.7 (8.2L; 4 9/16" x 5 1/8") GMC inline six was more numerous than the 426 inline six, but beginning and ending dates are unknown. The GMC 630 Series of the early 1950s offered the 550.

Atlas

In 2002, GM announced a new family of straight six engines, the Atlas. Branded by GM under the Vortec name, the Vortec 4200 or Atlas LL8 is currently the only straight six available to the GM family of vehicles.

See also

References

- ^ a b Leroux, Bruno (2012-11-15). "Le saviez-vous?". La Vie de l'Auto (in French) (1533). Fontainebleu Cedex, France: Éditions LVA: 8.

{{cite journal}}: Unknown parameter|trans_title=ignored (|trans-title=suggested) (help) - ^ a b c Flory, p.881.

- ^ Holden Abroad, Restored Cars #220, Sep-Oct 2013, page 45

- ^ a b 1970 Holden HT Brougham, Restored Cars #174, Jan-Feb 2006, pages 27 to 28

- ^ a b c Mastrostefano, Raffaele, ed. (1985). Quattroruote: Tutte le Auto del Mondo 1985 (in Italian). Milano: Editoriale Domus S.p.A. pp. 186–187. ISBN 88-7212-012-8.

- ^ Gunnell, John; Kowalke, Ron (1995). Standard Catalog of Pontiac, 1926-1995. Iola, WI: Krause Publications, Inc. pp. 92–93. ISBN 0-87341-369-5.

- FAQ Stovebolt.com — What is a Stovebolt?

- Chevrolet "Stovebolt" Six by Jack Nerad — The story of the Chevrolet "Stovebolt" Six.

- Classic definition of a Stovebolt — by the Mid State Antique Stock Car Club

External links

- Sheridan's 1946 Chevy Truck — 1941–46 Chevrolet truck photos; lots of information.

- Stovebolt.com — Online information resource and discussion forums for pre-'73 Chevrolet & GMC trucks.

- 67–72chevytrucks.com — Founded for the 67-72 trucks, it is now an online forum community devoted to all years & models full size Chevy/GMC Trucks. From stock originals, to mud trucks, to show stoppers… our members have them all.

- chevytrucks.org — Specializing in information on 1941–59 Chevrolet trucks; how-to articles, pictures, history, etc.

- "The Art Deco Series" — This site is dedicated to the history and preservation of the Chevrolet & GMC commercial haulers that were produced just before, during, and just after World War II, 1941–46.

- OldTruckNetwork.com — The No. ? online information resource for old trucks and politics.