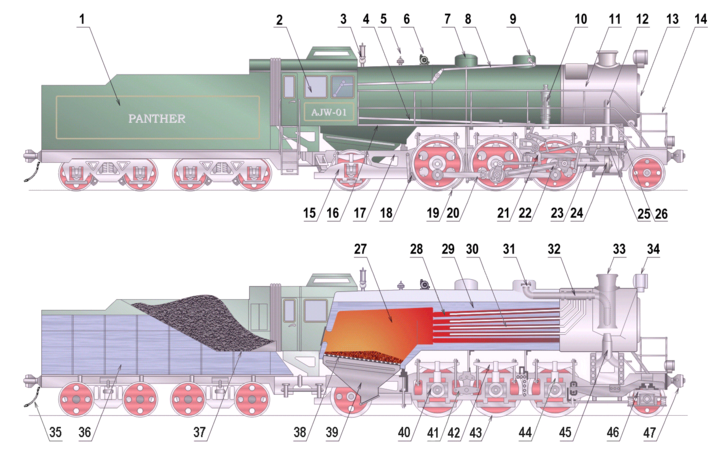

Steam locomotive components

Appearance

This is a glossary of the components found on typical steam locomotives.

Guide to steam locomotive components (The image is of a composite imaginary locomotive, not all components are present on all locomotives and not all possible components are present and/or labelled in the illustration above).

- 1 Tender – Container holding both water for the boiler and fuel such as wood, coal or oil for the fire box.[1][2]

- 2 Cab – Compartment where the engineer and fireman control the engine and tend the firebox.[1][2][3][4]

- 3 Whistle – Steam powered whistle, located on top of the boiler and used for signalling and warning.[2][3][5]

- 4 Reach rod – Rod linking the reversing lever in the cab (often a johnson bar) to the valve gear.[2][3]

- 5 Safety valve – Pressure relief valve to stop the boiler pressure exceeding the operating limit.[1][2][6][7]

- 6 Generator – electrical generator driven by small steam turbine, for locomotive lighting and headlight.

- 7 Sand dome – Holds sand that is dropped on the rail in front of the driving wheels to improve traction, especially in wet or icy conditions.[2][3][4]

- 8 Throttle Lever/Regulator – sets the opening of the regulator/throttle valve (#31) which controls the pressure of steam entering the cylinders.[1][8][9]

- 9 Steam dome – Collects the steam at the top of the boiler so that it can be fed to the engine via main steam pipe, or dry pipe, and the regulator/throttle valve.[2][3][10]

- 10 Air pump or compressor – compresses air for operating the brakes (train air brake system). This is sometimes called a Westinghouse pump or Knorr pump after George Westinghouse and Georg Knorr. Single stage steam-driven air compressor or higher capacity two-stage, cross-compound compressors were used.[11]

- 11 Smokebox – Collects the hot gases that have passed from the firebox and through the boiler tubes.[2][12][13] It may contain a cinder guard to prevent hot cinders being exhausted up the chimney. Usually has a blower to help draw the fire when the regulator is closed. Steam exhausting from the cylinders is also directed up the chimney to draw air through the firebed while the regulator is open.[1]

- Blower a circular pipe below the chimney petticoat pipe, with holes to blow steam upwards. Provides a draught to maintain adequate combustion when locomotive is stationary and the blastpipe is not effective.[2][12] This draught also prevents smoke and flames from entering the cab.

- Petticoat pipe is a pipe with a bellmouth-shaped end extending into the smokebox and the other end in the smoke stack. Its function is to enhance and equalize draft through the boiler tubes.[14]

- 12 Steam pipe – carries steam to the cylinders.[2][15]

- 13 Smoke box door – Hinged circular door to allow service access to the smoke box to fix air leaks and remove char.[2][16]

- 14 Hand rail – Support rail for crew when walking along the foot board.[3][17]

- 15 Trailing truck/Rear bogie – Wheels at the rear of the locomotive to help support the weight of the cab and fire box.

- 16 Foot board/Running board – Walkway along the locomotive to facilitate inspection and maintenance.[3][17] UK terminology is Footplate.

- 17 Frame – Carries boiler, cab and engines and is supported on driving wheels and leading and trailing trucks. The axles run in slots in the frames.[3][18] American locomotives usually have bar frames (made from steel bar) or cast steel frames (see Bury bar frame locomotive), while British locomotives usually have plate frames (made from steel plate).[2]

- 18 Brake shoe and brake block – rub on all the driving wheel treads for braking.[1][2]

- 19 Sand pipe – Deposits sand directly in front of the driving wheels to aid traction.[3]

- 20 Side rods/Coupling rods – Connects the driving wheels together.[2][3][19]

- 21 Valve gear/motion – System of rods and linkages synchronising the valves with the pistons and controls the running direction and power of the locomotive.[2][20]

- 22 Main rod/Connecting rod – Steel arm that converts the horizontal motion of the piston into a rotary motion of the driver wheels. The connection between piston and main rod is a cross-head which slides on a horizontal bar behind the cylinder.[2][3]

- 23 Piston rod – Connects the piston to the cross-head.[2]

- 24 Piston – Driven backward and forward within the cylinder by steam pressure, producing motion from steam expansion.[1]

- 25 Valve – Controls the supply of steam to the cylinders, valve position relative to piston determined by valve gear connected to driving wheel. Steam locomotives may have slide valves, piston valves or poppet valves.[2]

- 26 Valve chest/steam chest – Valve chamber adjacent to cylinder, contains passageways to distribute steam to the cylinders.[21]

- 27 Firebox – Furnace chamber that is built into the boiler and surrounded by water. Various combustible materials can be used as fuel but the most common were coal, coke, wood or oil.[1][2][12][13]

- 28 Boiler tubes – Carry hot gasses from the fire box through the boiler, heating the surrounding water.[2]

- 29 Boiler – container almost full of water with air space above. The water is heated by hot gases passing through tubes, producing steam in the space above the water.[1][2][3]

- 30 Superheater tubes – Pass steam back through the boiler to dry and superheat the steam for greater efficiency.[2]

- 31 Regulator/Throttle valve – Controls the amount of steam delivered to the cylinders (also see #8), one of two ways to vary power of the engine (throttle governing)[1][2][9]

- 32 Superheater – Feeds steam back through boiler tubes to superheat (heat beyond boiling temperature of water at boiler pressure) the steam to increase the engine efficiency and power.[2][12]

- 33 Chimney/Smokestack – Short chimney on top of the smokebox to carry the exhaust (smoke) away from the engine so that it doesn't obscure the footplate crew forward view.[1][2][3][22][13] Usually extended down inside the smokebox – the extension is called a petticoat. Some railways, e.g. the Great Western Railway, fitted a decorative copper cap to the top of the chimney.

- 34 Headlight – Light on front of the smoke box to illuminate track ahead and warn approach of locomotive to other track occupants.[3][4]

- 35 Brake hose – Air or vacuum hose for transmitting brake system pressure/vacuum to train brakes. See air brake and vacuum brake.[23]

- 36 Water compartment – Container for water used by the boiler to produce steam.

- 37 Coal bunker – Fuel supply for the furnace, may be wood, coal/coke or oil. Fed to the firebox either manually or, for bigger fire grates, by mechanical stoker.[2]

- 38 Grate – Holds the burning fuel and allows ash to drop through.[2]

- 39 Ashpan hopper – Collects the ash from the fire.[2][3]

- 40 Journal box – Housing for the plain bearing on a Driving wheel axle.[24]

- 41 Equalising beams/Equalising levers/Equalising bars – Part of the locomotive suspension system, connected to leaf springs, free to pivot about their centre which is fixed to the frame. Function is to even out weight carried on adjacent axles on uneven or poorly laid tracks.[3][25]

- 42 Leaf Springs – Main suspension springs for the locomotive. Each driver wheel supports its share of the locomotive weight using a leaf spring which connects the axle journal box to the frame.

- 43 Driving wheel/Driver – Wheel driven by the pistons to move the locomotive.[1][2][3] Drivers are balanced with weights to reduce unwanted motion of the locomotive. There are three sets of driving wheels in this example.

- 44 Pedestal or saddle – Connects a leaf spring to a driver wheel journal box.[26]

- 45 Blast pipe – Directs exhaust steam up the chimney, creating a draught that draws air through the fire and along the boiler tubes.[2]

- 46 Pilot truck/Leading bogie – Wheels at the front to support weight of boiler front end/smokebox and reduce flanging forces between front driving wheels and rail when rounding curves.

- 47 Coupling/Coupler – Device at the front and rear of the locomotive for connecting locomotives and rail cars together.[1][3]

- Snifting valve (not shown) – An anti-vacuum valve which permits air to be drawn through the superheater and cylinders which allows the engine to coast freely when the regulator is closed.

See also

- Cylinder (steam locomotive)

- Glossary of boiler terminology

- Horsepower#Drawbar horsepower

- Power classification

- Rail terminology

- Tractive effort

References

- ^ a b c d e f g h i j k l m "A Glossary of 19th Century Railroad Terms". The Transcontinental Railroad. Kansas City, MO: Linda Hall Library. Retrieved July 7, 2019.

- ^ a b c d e f g h i j k l m n o p q r s t u v w x y z aa ab ac ad "Steam Glossary". The Railway Technical Website. Retrieved July 7, 2019.

- ^ a b c d e f g h i j k l m n o p q r Kirkman 1917, p. 14.

- ^ a b c Forney 1891, p. 118.

- ^ Forney 1891, pp. 247–248.

- ^ Forney 1891, p. 240.

- ^ Kirkman 1917, p. 37.

- ^ Forney 1891, p. 255.

- ^ a b Kirkman 1917, p. 39.

- ^ Forney 1891, pp. 211–212.

- ^ Forney 1891, pp. 482–483.

- ^ a b c d Carlson, Neil (November 14, 2011). "Glossary of steam locomotive terms". Classic Trains. Waukesha, WI: Kalmbach Media. Retrieved July 7, 2019.

- ^ a b c Forney 1891, p. 117.

- ^ Forney 1891, pp. 602 and 632.

- ^ Forney 1891, p. 212.

- ^ Forney 1891, p. 602.

- ^ a b Forney 1891, p. 437.

- ^ Kirkman 1917, p. 18.

- ^ Forney 1891, p. 276.

- ^ Forney 1891, pp. 281–356.

- ^ Forney 1891, p. 41.

- ^ Kirkman 1917, p. 25.

- ^ Forney 1891, pp. 483–486.

- ^ Forney 1891, p. 412.

- ^ Forney 1891, p. 425.

- ^ Forney 1891, p. 416.

- Forney, Matthias N. (1891). Catechism of the Locomotive (second ed.). New York: The Railroad Gazette – via Internet Archive.

locomotive glossary.

- Kirkman, Marshall M. (1917). The Locomotive: Its Working Described and Illustrated. Chicago: Cropley Phillips Company – via Google Books.

Further reading

- John Daniel (2008) [2000]. "Steam locomotive introduction (The Great Western archive)". Retrieved 2008-05-14.

- Michael Quin Heavener (2008) [1997]. "Glossary of Steam Locomotive Terms". Retrieved 2008-05-14.

- Semmens, P.W.B.; Goldfinch, A.J. (2000). How Steam Locomotives Really Work. Oxford, New York: Oxford University Press. ISBN 978-0-19-860782-3.