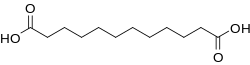

Dodecanedioic acid

| |

| Names | |

|---|---|

| IUPAC name

Dodecanedioic acid

| |

| Other names

DDDA

| |

| Identifiers | |

3D model (JSmol)

|

|

| ChEBI | |

| ChemSpider | |

| ECHA InfoCard | 100.010.680 |

| KEGG | |

PubChem CID

|

|

| UNII | |

CompTox Dashboard (EPA)

|

|

| |

| |

| Properties | |

| C12H22O4 | |

| Molar mass | 230.304 g·mol−1 |

| Appearance | White flakes |

| Density | 1.066 g/cm3 |

| Melting point | 127–129 °C (261–264 °F; 400–402 K) |

| Boiling point | 245 °C (473 °F; 518 K) |

| pH dependent | |

| Hazards | |

| Flash point | 220 °C (428 °F; 493 K) |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

Dodecanedioic acid (DDDA) is a dicarboxylic acid mainly used in antiseptics, top-grade coatings, painting materials, corrosion inhibitors, surfactants, and engineering plastics such as nylon 612 [1].

Experimental work with dodecanedioic acid in type 2 diabetic patients has demonstrated that IV infusion helps to maintain normal blood sugar and energy levels without increasing the blood glucose load in the process.[2]

Production

DDDA is currently produced by both chemical and biological routes.

Chemical process

It has traditionally been produced from butadiene using a multi-step chemical process.[3] Butadiene is first converted to cyclododecatriene through a cyclotrimerization process.[4]

Cyclododecatriene (1) is converted to dodecanedioic acid (4) by hydrogenation to cyclododecane (2) followed by air oxidation in the presence of boric acid at elevated temperatures to a mixture of the alcohol (3a) and the ketone (3b). In the final step, this mixture oxidized further by nitric acid.

Biological process

Paraffin wax can be converted into DDDA[5] with a special strain of Candida tropicalis yeast in a multi-step process[6]. Renewable plant-oil feedstocks sourced from switchgrass can also be used to produce DDDA.[3]

References

- ^ Nylon#Homopolymers

- ^ Greco, A. V.; Mingrone, G; Capristo, E; Benedetti, G; De Gaetano, A; Gasbarrini, G (1998). "The metabolic effect of dodecanedioic acid infusion in non-insulin-dependent diabetic patients". Nutrition. 14 (4): 351–7. doi:10.1016/s0899-9007(97)00502-9. PMID 9591306.

- ^ a b "BIOLON® DDDA". verdezyne.com. Archived from the original on 2016-09-24. Retrieved 2016-09-23.

- ^ Klaus Weissermel, Hans-Jurgen Arpe (1997). Industrial Organic Chemistry (3rd ed.). John Wiley & Sons. ISBN 3-527-28838-4.

- ^ "Dibasic acids". www.cathaybiotech.com. Retrieved 2019-03-15.

- ^ Kroha, Kyle. "Industrial biotechnology provides opportunities for commercial production of new long-chain dibasic acids" (PDF). Inform. 15(9) (Sep 2004). American Oil Chemists Society: 568. Archived from the original (PDF) on 6 October 2014. Retrieved 15 March 2019.