Nylon 66

This article needs additional citations for verification. (March 2015) |

| |

| Names | |

|---|---|

| IUPAC name

Poly[imino(1,6-dioxohexamethylene) iminohexamethylene]

| |

| Other names

Poly(hexamethylene adipamide),Poly(N,N′-hexamethyleneadipinediamide), Maranyl, Ultramid, Zytel, Akromid, Durethan, Frianyl, Vydyne

| |

| Identifiers | |

| ChemSpider |

|

| ECHA InfoCard | 100.130.739 |

PubChem CID

|

|

CompTox Dashboard (EPA)

|

|

| Properties | |

| (C12H22N2O2)n | |

| Density | 1.14 g/mL (Zytel) |

| Melting point | 515.9 °F (268.6 °C) |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

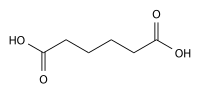

Nylon 66 (aka nylon 6-6, nylon 6/6 or nylon 6,6) is a type of polyamide or nylon. Nylons come in many types, and the two most common for textile and plastics industries are nylon 6 and nylon 66. Nylon 66 is made of two monomers each containing 6 carbon atoms, hexamethylenediamine and adipic acid, which give nylon 66 its name.[1]

Synthesis and manufacturing of Nylon 66

Nylon 66 is synthesised by polycondensation of hexamethylenediamine and adipic acid. Equivalent amounts of hexamethylenediamine and adipic acid are combined with water in a reactor. This is crystallized to make nylon salt, which has precisely stoichiometric equivalents. The nylon salt goes into a reaction vessel where polymerization process takes place either in batches or continuously. Removing water drives the reaction

n HOOC-(CH2)4-COOH + n H2N-(CH2)6-NH2 → [-OC-( CH2)4-CO-NH-(CH2)6-NH-]n + 2n H2O

toward polymerization through the formation of amide bonds from the acid and amine functions. Thus molten nylon 66 is formed. It can either be extruded and granulated at this point or directly spun into fibres by extrusion through a spinneret (a small metal plate with fine holes) and cooling to form filaments.

Applications

In 2010 worldwide production was 2 million tons. At that time fibres consumed just over half of production and engineering resins the rest. It is not used in films due to its inability to be oriented. Fibre markets represented 55% of the 2010 demand with engineering thermoplastics being the remainder.[2]

Nylon 66 is frequently used when high mechanical strength, rigidity, good stability under heat and/or chemical resistance are required [3] It is used in fibers for textiles and carpets and molded parts. For textiles, fibers are sold under various brands, for example Nilit brands or the Cordura brand for luggage, but it is also used in airbags, apparel for carpet fibres under the Ultron brand. Nylon 66 lends itself well to make 3D structural objects, mostly by injection molding finding broad use in auto application under the hood such as radiator end tanks, rocker covers, air intake manifolds, oil pans [4] and numerous other structural parts [5] such as ball bearing cages, electro-insulating elements, pipes, profiles and various machine parts.zip ties, conveyor belts, hoses, polymer framed weapons, and the outer layer of turnout blankets.[clarification needed] Nylon 66 is also a popular guitar nut material.[6]

References

- ^ Palmer, R. J. 2001. Polyamides, Plastics. Encyclopedia Of Polymer Science and Technology. doi:10.1002/0471440264.pst251

- ^ http://pcinylon.com/index.php/markets-covered/polyamide-66 PCI extract for PA66

- ^ Viers, Brendt D. (1999). Polymer Data Handbook. Oxford University Press, Inc. p. 189. ISBN 978-0195107890.

- ^ http://www.materialdatacenter.com/mb/main/pdf/application/16449 Oil Pan, 35% glass reinforced 66

- ^ http://www.materialdatacenter.com/mb/main/pdf/application/13531 Tailgate hinge 50% glass reinforced 66

- ^ "Nylon Guitar Nut Blank". www.mojotone.com. mojotone. Retrieved 18 April 2015.