Supply chain: Difference between revisions

rv vandalism |

|||

| Line 94: | Line 94: | ||

*[http://www.gs1us.org/Glossary/tabid/58/Default.aspx Glossary of supply chain standards] |

*[http://www.gs1us.org/Glossary/tabid/58/Default.aspx Glossary of supply chain standards] |

||

*[http://cscmp.org/digital/glossary/glossary.asp Supply Chain and Logistics Terms and Glossary] |

*[http://cscmp.org/digital/glossary/glossary.asp Supply Chain and Logistics Terms and Glossary] |

||

*[http://scmresearch.org/ Supply Chain Management Research] |

|||

{{DEFAULTSORT:Supply Chain}} |

{{DEFAULTSORT:Supply Chain}} |

||

Revision as of 18:13, 4 November 2012

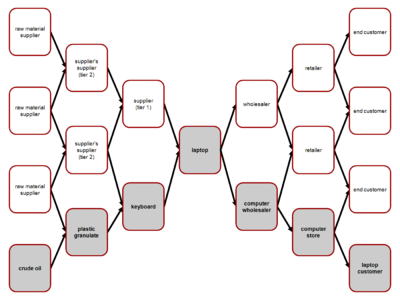

A supply chain is a system of organizations, people, technology, activities, information and resources involved in moving a product or service from supplier to customer. Supply chain activities transform natural resources, raw materials and components into a finished product that is delivered to the end customer. In sophisticated supply chain systems, used products may re-enter the supply chain at any point where residual value is recyclable. Supply chains link value chains.[2]

Overview

The Council of Supply Chain Management Professionals (CSCMP) defines supply chain management as follows: “Supply Chain Management encompasses the planning and management of all activities involved in sourcing and procurement, conversion, and all logistics management activities. Importantly, it also includes coordination and collaboration with channel partners, which can be suppliers, intermediaries, third-party service providers, and customers. In essence, supply chain management integrates supply and demand management within and across companies. Supply Chain Management is an integrating function with primary responsibility for linking major business functions and business processes within and across companies into a cohesive and high-performing business model. It includes all of the logistics management activities noted above, as well as manufacturing operations, and it drives coordination of processes and activities with and across marketing, sales, product design, finance and information technology.”

A typical supply chain begins with ecological and biological and political regulation of natural resources, followed by the human extraction of raw material, and includes several production links (e.g., component construction, assembly, and merging) before moving on to several layers of storage facilities of ever-decreasing size and ever more remote geographical locations, and finally reaching the consumer.

Many of the exchanges encountered in the supply chain will therefore be between different companies that will seek to maximize their revenue within their sphere of interest, but may have little or no knowledge or interest in the remaining players in the supply chain. More recently, the loosely coupled, self-organizing network of businesses that cooperates to provide product and service offerings has been called the Extended Enterprise.[citation needed]

Supply chain modeling

There are a variety of supply chain models, which address both the upstream and downstream sides. However the SCOR model is most common.

The SCOR Supply-Chain Operations Reference model, developed by the Supply Chain Council, measures total supply chain performance. It is a process reference model for supply-chain management, spanning from the supplier's supplier to the customer's customer.[3] It includes delivery and order fulfillment performance, production flexibility, warranty and returns processing costs, inventory and asset turns, and other factors in evaluating the overall effective performance of a supply chain.

The Global Supply Chain Forum (GSCF) introduced another Supply Chain Model. This framework[4] is built on eight key business processes that are both cross-functional and cross-firm in nature. Each process is managed by a cross-functional team, including representatives from logistics, production, purchasing, finance, marketing and research and development. While each process will interface with key customers and suppliers, the customer relationship management and supplier relationship management processes form the critical linkages in the supply chain.

The American Productivity & Quality Center (APQC) Process Classification Framework (PCF) SM is a high-level, industry-neutral enterprise process model that allows organizations to see their business processes from a cross-industry viewpoint. The PCF was developed by APQC and its member companies as an open standard to facilitate improvement through process management and benchmarking, regardless of industry, size, or geography. The PCF organizes operating and management processes into 12 enterprise level categories, including process groups, and over 1,000 processes and associated activities.

Supply chain management

In the 1980s, the term Supply Chain Management (SCM) was developed[5] to express the need to integrate the key business processes, from end user through original suppliers. Original suppliers being those that provide products, services and information that add value for customers and other stakeholders. The basic idea behind the SCM is that companies and corporations involve themselves in a supply chain by exchanging information regarding market fluctuations and production capabilities. Keith Oliver, a consultant at Booz Allen Hamilton, is credited with the term invention when he used it in an interview for the Financial Times in 1982.[6][7][8]

If all relevant information is accessible to any relevant company, every company in the supply chain has the ability to help optimize the entire supply chain rather than sub optimize based on a local interest. This will lead to better planned overall production and distribution which can cut costs and give a more attractive final product leading to better sales and better overall results for the companies involved.

Incorporating SCM successfully leads to a new kind of competition on the global market where competition is no longer of the company versus company form but rather takes on a supply chain versus supply chain form.

The primary objective of supply chain management is to fulfill customer demands through the most efficient use of resources, including distribution capacity, inventory and labor. In theory, a supply chain seeks to match demand with supply and do so with the minimal inventory. Various aspects of optimizing the supply chain include liaising with suppliers to eliminate bottlenecks; sourcing strategically to strike a balance between lowest material cost and transportation, implementing JIT (Just In Time) techniques to optimize manufacturing flow; maintaining the right mix and location of factories and warehouses to serve customer markets, and using location/allocation, vehicle routing analysis, dynamic programming and, of course, traditional logistics optimization to maximize the efficiency of the distribution side.

There is often confusion over the terms supply chain and logistics. It is now generally accepted that the term Logistics applies to activities within one company/organization involving distribution of product whereas the term supply chain also encompasses manufacturing and procurement and therefore has a much broader focus as it involves multiple enterprises, including suppliers, manufacturers and retailers, working together to meet a customer need for a product or service.[citation needed]

Starting in the 1990s several companies chose to outsource the logistics aspect of supply chain management by partnering with a 3PL, Third-party logistics provider. Companies also outsource production to contract manufacturers.[9] Technology companies have risen to meet the demand to help manage these complex systems.

There are actually four common Supply Chain Models. Besides the two mentioned above, there are the American Productivity & Quality Center's (APQC) Process Classification Framework and the Supply Chain Best Practices Framework

An unusual food supply chain operated by Dabbawalas in Mumbai is noted for being extremely reliable without using any computers or modern technology. It has been verified to be a six sigma supply chain.[10]

Regulations

Supply chain security has become particularly important in recent years. As a result, supply chains are often subject to global and local regulations. Several major regulations emerged in 2010 alone that have had a lasting impact on how global supply chains operate. These new regulations include: The Importer Security Filing (ISF)[11] additional provisions of the Certified Cargo Screening Program (CCSP).[12]

Development and design

With increasing globalization and easier access to alternative products in today’s markets, the importance of product design in demand generation is more significant than ever. In addition, as supply, and therefore competition, among companies for the limited market demand increases and pricing and other marketing elements become less distinguishing factors, product design also plays a different role by providing attractive features to generate demand. In this context, demand generation is used to define how attractive a product design is in terms of creating demand.

In other words, it is the ability of a product design to generate demand by satisfying customer expectations. However, product design impacts not only demand generation, but also manufacturing processes, cost, quality, and lead time. The product design affects the associated supply chain and its requirements directly including, but not limited to: manufacturing, transportation, quality, quantity, production schedule, material selection, production technologies, production policies, regulations, and laws. From a broad perspective, the success of the supply chain depends on the product design and the capabilities of the supply chain, but the reverse is also true—the success of the product depends on the supply chain that produces it.

Since the product design dictates multiple requirements on the supply chain, as mentioned previously, it is clear that once a product design is completed, it drives the structure of the supply chain, limiting the flexibility of the engineers to generate and evaluate different (potentially more cost effective) supply chain alternatives.[13]

See also

- American Production and Inventory Control Society

- Chemicals, Tire, and Process Industries (CTP)

- Cold chain

- Council of Supply Chain Management Professionals

- DIFOT

- Demand chain

- Demand chain management

- Demand optimization

- Document automation in supply chain management & logistics

- Distribution

- Distribution resource planning

- Factory Physics

- Extended Enterprise

- Industrial engineering

- Inventory control

- Last mile (transportation)

- Liquid logistics

- Logistics

- Management accounting in supply chains

- Military supply chain management

- Nomenclature

- Reverse logistics

- Supply network

- Supply chain management

- Supply chain network

- Supply-chain operations reference Model

- Supply chain optimization

- Supply chain risk management

- Supply chain security

- Value chain

- Value network

- Vertical integration

References

- ^ cf. Andreas Wieland, Carl Marcus Wallenburg (2011): Supply-Chain-Management in stürmischen Zeiten. Berlin.

- ^ Anna Nagurney: Supply Chain Network Economics: Dynamics of Prices, Flows, and Profits, Edward Elgar Publishing, 2006, ISBN 1-84542-916-8

- ^ SCC Supply Chain Council, SCOR Model

- ^ the Supply Chain Management Institute - framework

- ^ Oliver, R.K., Webber, M.D., 1982, “Supply-chain management: logistics catches up with strategy”, Outlook, Booz, Allen and Hamilton Inc. Reprinted 1992, in Logistics: The Strategic Issues, ed. M Christopher, Chapman Hall, London, pp. 63-75.

- ^ David Jacoby (2009), Guide to Supply Chain Management: How Getting it Right Boosts Corporate Performance (The Economist Books), Bloomberg Press; 1st edition, ISBN 978-1576603451

- ^ Andrew Feller, Dan Shunk, & Tom Callarman (2006). BPTrends, March 2006 - Value Chains Vs. Supply Chains

- ^ David Blanchard (2010), Supply Chain Management Best Practices, 2nd. Edition, John Wiley & Sons, ISBN 9780470531884

- ^ Selecting a Third Party Logistics (3PL) Provider Martin Murray, about.com

- ^ [1]

- ^ http://www.cbp.gov/linkhandler/cgov/newsroom/publications/trade/import_sf_carry.ctt/import_sf_carry.pdf

- ^ http://www.tsa.gov/what_we_do/layers/aircargo/certified_screening.shtm

- ^ Gokhan, Nuri Mehmet (2010). "Development of a Simultaneous Design for Supply Chain Process for the Optimization of the Product Design and Supply Chain Configuration Problem". Engineering Management Journal. 22 (4): 20–30.

{{cite journal}}: Unknown parameter|coauthors=ignored (|author=suggested) (help); Unknown parameter|month=ignored (help)