Skylon (spacecraft)

| Skylon | |

|---|---|

| |

| The Skylon vehicle is an aircraft designed to reach orbit. | |

| Role | Re-usable spaceplane |

| National origin | |

| Designer | Reaction Engines Limited |

| Status | Research and development |

| Developed from | HOTOL (Horizontal Take-Off and Landing) project |

Skylon is a design for an unpiloted spaceplane by the British company, Reaction Engines Limited (REL). It uses a combined-cycle, air-breathing rocket engine to reach orbit in a single stage. A fleet of vehicles is envisaged; the design is aiming for re-usability up to 200 times. In paper studies, the costs per kilogram of payload are hoped to be lowered from the current £15,000/kg to £650/kg (as of 2011[update]),[1] including the costs of research and development (R&D), with costs expected to fall much more over time after the initial expenditures have amortised.[2] The cost of the programme has been estimated by the developer to be about $12 billion.

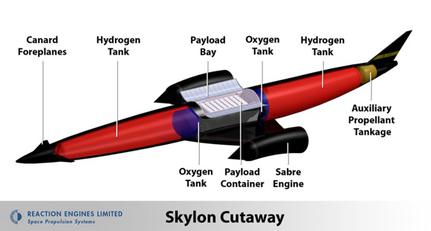

The vehicle design is for a hydrogen-powered aircraft that would take off from a conventional runway, and accelerate to Mach 5.4 at 26 km using atmospheric air before switching the engines to use the internal liquid oxygen (LOX) supply to take it to orbit.[3] It would then release its payload, which can weigh up to 15-tonnes, and re-enter the atmosphere. The payload would be carried in a standardised payload container or passenger compartment.

During re-entry the relatively light vehicle would fly back through the atmosphere and land back at the runway, with its skin protected by a ceramic composite. It would then undergo inspection and any necessary maintenance and, if the design goal is achieved, be able to fly again within two days. As of 2010, only a small portion of the funding required to develop and build Skylon has been secured. The research and development work on the SABRE engine design is proceeding under a small European Space Agency (ESA) grant. In January 2011, REL submitted a proposal to the British Government to request additional funding for the Skylon project. In April 2011, REL announced that they had secured $350 million of further funding contingent on a test of the engine's precooler technology being successful in June.

Research and development programme

Skylon is based upon a previous project of Alan Bond, which was known as HOTOL.[4] The development programme of HOTOL began in 1982, a time when space technology was moving towards reusable launch systems such as the American Space Shuttle.[4] In conjunction with British Aerospace and Rolls Royce, a design emerged that proved highly promising, so much so that the British Government donated £2 million to further their work.[4] However, in 1988, the Conservative government withdrew funding, and the development programme was terminated.[4] Following this major setback, Alan Bond decided to set up his own company, Reaction Engines Limited, with the hope of continuing development with private funding.[4]

After having secured funding, the design of the craft was revisited, undergoing a rigorous redesign throughout much of the 1990s.[4] In the last decade, Reaction Engines has been working with the University of Bristol to develop the engines vital to the success of Skylon. The STRICT/STERN engines produced by this programme were deemed a great success.[5] The next stage of development is to construct a full-sized working prototype of the SABRE Engine.[6]

The differences between Skylon and its predecessor are numerous. For example, HOTOL was to have been launched from a rocket sled (to save weight), whereas Skylon uses a conventional retractable undercarriage.[4] Skylon also uses a different engine design; the SABRE engine is expected to offer higher performance.[7] Another issue that the Skylon design aims to circumvent was the intrinsically poor stability of HOTOL.[4] The weight of the rear-mounted engine would have tended to make the HOTOL vehicle flip over mid-flight due to the centre of mass lying behind the centre of drag.[4] Attempts to fix this problem ended up sacrificing much of the potential payload that the HOTOL vehicle could carry, and contributed to the failure of the project.[4] Skylon would solve this by placing the engines at the end of the wings closer to the centre of the vehicle and thus moving the centre of mass forward, ahead of the centre of drag.[4][8]

Request for funding from the British government was undertaken in 2000, with a proposal that could have offered a large potential return on investment.[9] The request was not taken up at that time. Subsequent discussions with the British National Space Centre led to agreement in 2009 on a co-funding agreement between BNSC, ESA and REL to continue technology development for the SABRE engine.[10][11]

In February 2009, the British National Space Centre (now the UK Space Agency) and ESA announced that they were partially funding work with €1 million Euros ($1.28 million dollars) on Skylon's engine to produce a demonstration engine by 2011.[12][13][14]

The Technology Demonstration Programme will last approximately 2.5 years and will benefit from another €1 million from the ESA.[15] This programme will take Reaction Engines Ltd from a Technology Readiness Level (TRL) of 2/3 up to 4/5.[16] The former UK Minister for Science and Innovation in 2009, Lord Drayson, commented on Skylon in a speech: "This is an example of a British company developing world-beating technology with exciting consequences for the future of space."[1]

As of 2010, the funding required to develop and build the entire craft has not yet been secured, and so current research and development work is focused on the engines, under an ESA grant of €1 million.[17] In January 2011, REL submitted a proposal to the British Government requesting additional funding for the Skylon project.[1]

On April 13, 2011, REL announced that the Skylon design had passed several rigorous independent reviews. On May 24, the ESA publicly declared the design to be feasible, having found "no impediments or critical items" in the proposal.[18]

The next milestone will be a static test of the engine precooler in June, 2011. Testing of the SABRE engine will commence in June 2011 with the start of Phase 3 in the Skylon development programme.[1] An REL spokesperson announced that they had secured $350 million of further funding, contingent on successful completion of the full-sized precooled jet engine test in June 2011.[19]

Pre-orders are expected in the 2011–2013 time frame coinciding with the formation of the manufacturing consortium.[1]

Technology and innovations

Structure of the fuselage

The fuselage of Skylon is expected to be carbon fibre space frame; a light and strong structure that supports the weight of the aluminium fuel tanks and to which the ceramic skin is attached.[8] Multiple layers of reflective foil thermal insulation fill the spaces of the frame.[20]

The currently proposed Skylon model C2 will be a physically large vehicle, with a length of 82 metres (269 ft) and a diameter of 6.3 metres (21 ft).[21] Because it will use a low-density liquid hydrogen fuel, a great volume is needed to contain enough energy to reach orbit. The propellant is intended to be kept at low pressure to minimise stress; a vehicle that is both large and light has an advantage during atmospheric reentry compared to other vehicles due to a low ballistic coefficient.[22] Because of the low ballistic coefficient, Skylon would be slowed at higher altitudes where the air is thinner. As a result, the skin of the vehicle would only reach 1100 Kelvin (K).[23] In contrast, the smaller Space Shuttle is heated to 2000 K on its leading edge, and so employs an extremely heat-resistant but extremely fragile silica thermal protection system. The Skylon design need not use such a system, instead opting for using a far thinner yet durable reinforced ceramic skin.[2] However, due to turbulent flow around the wings during re-entry, some parts of Skylon would need to be actively cooled.[20]

Skylon would employ a highly-loaded tightly spaced wheel assembly, to save weight and also interior space when the wheels are retracted into the fuselage.[24] Because this wheel design distributes the weight of the aircraft and the force of its landing over a smaller area of the runway, it would require a specially strengthened runway.[25] It will possess a retractable undercarriage with high pressure tires and water cooled brakes.[26] If problems were to occur just before a take-off the brakes would be applied to stop the vehicle, the water boiling away to dissipate the heat.[26] Upon a successful take-off, the water would be jettisoned, thus reducing the weight of the undercarriage by many tons. During landing, the empty vehicle would be far lighter, and hence the water would be unneeded.[26] The payload fraction would be significantly greater than normal rockets and the vehicle should be fully reusable (200 times or more).[27]

SABRE Engines

One of the significant features of the Skylon design is the engine, called SABRE.[7][28] The engines are designed to operate much like a conventional jet engine[citation needed] at up to around Mach 5.5 (1700 m/s),[28] 26 kilometres (16 mi) altitude, beyond which the air inlet closes and the engine operates as a highly efficient rocket to orbital speed.[28]

The proposed engine for the vehicle is not a scramjet, but a jet engine running combined cycles of a precooled jet engine, rocket engine and ramjet.[2] Originally the key technology for this type of precooled jet engine did not exist as it required a heat exchanger that was ten times lighter than the state of the art.[5] Research conducted since then has achieved the necessary performance.[7]

Operating an air-breathing jet engine at up to Mach 5.5 is difficult.[28] Several previous engines proposed by other designers have been good as jet engines but performed poorly as rockets.[28] This engine design aims to be a good jet engine within the atmosphere, as well as being an excellent rocket engine outside.[28] The problem with operating at Mach 5.5 has been that the air coming into the engine heats up as it is compressed into the engine, which can cause the engine to overheat.[28] Attempts to avoid these issues typically make the engine much heavier (scramjets/ramjets) or greatly reduce the thrust (conventional turbojets/ramjets).[28] In either case the end result is an engine that has a poor thrust to weight ratio at high speeds, resulting in an engine that is too heavy to assist much in reaching orbit.[28]

The SABRE engine design aims to avoid this by using some of the liquid hydrogen fuel to cool the air at the inlet.[28] The air is then used for combustion much like in a conventional jet.[28] Because the air is cooled at all speeds, the jet can be built of light alloys and the weight is roughly halved.[28] Additionally, more fuel can be burnt at high speed.[28] Beyond Mach 5.5, the air would still be unusably hot despite the cooling, so the air inlet closes and the engine relies solely on on-board liquid oxygen and hydrogen fuel as in a normal rocket.[28]

Because the engine uses the atmosphere as reaction mass at low altitude, it will have a high specific impulse (around 2,800 seconds), and burn about one fifth of the propellant that would have been required by a conventional rocket.[28] Therefore, it would be able to take off with much less total propellant than conventional systems.[28] This, in turn, means that it does not need as much lift or thrust, which permits smaller engines, and allows conventional wings to be used.[28] While in the atmosphere, using wings to counteract gravity drag is more fuel-efficient than simply expelling propellant (as in a rocket), again reducing the total amount of propellant needed.[28]

"Single Stage to Orbit" capability

A vehicle that can fly to orbit without staging is known as single stage to orbit (SSTO).[29] Proponents of SSTO claim that staging causes a number of problems such as being difficult, expensive or even impossible to recover, reuse and reassemble the parts and therefore believe that SSTO designs hold the promise of reducing the cost of space-flight.[29]

The Skylon design aims to take off from its specially strengthened runway, fly into low earth orbit, re-enter the atmosphere, and land back on its runway like a conventional aeroplane, without staging, while being fully reusable.[3]

Payload bay

The payload bay of the Skylon C2 design is a cylinder 13 metres (42.7 ft) long and 4.8 metres (16 ft) in diameter.[24] It is designed to be comparable with current payload dimensions, and yet able to support the containerisation of payloads that Reaction Engines hopes for in the future.[24] To an equatorial orbit, Skylon could deliver 15 tonnes (33,069 lb) to a 300 kilometres (186 mi) height or 11 tonnes (24,251 lb) to a 800 kilometres (497 mi) altitude.[30] Using interchangeable payload containers, Skylon could be fitted to carry satellites or fluid cargo into orbit, or, in a specialised habitation module, up to 30 astronauts in a single launch.[31][32]

Economics and political will

The complete Skylon project has a projected R&D cost of over $10 billion and will continue for another 7–10 years.[2]

Once operative, Skylon could potentially lower satellite costs from the current £15,000/kg to £650/kg, according to evidence submitted to the UK parliament by Reaction Engines Ltd.[1] However, funding and support from the British government has not been easy to establish.[33]

According to David Willetts, the UK Minister of State for Universities and Science:

"The European Space Agency is funding proof of concept work for Skylon from UK contributions. This work is focusing on demonstrating the viability of the advanced British engine technology that would underpin the project. Initial work will be completed in mid 2011 and if the trial is successful, we will work with industry to consider next steps."[1]

REL intend Skylon to be a fully for-profit commercial venture, with the aircraft being manufactured and sold to operators. REL themselves (as a small company) intend to manufacture the precooler, with the other parts of the aircraft being designed and built by aerospace manufacturers.[34] According to Management Today, Skylon is sometimes discussed as a possible replacement for NASA's Space Shuttle.[35]

Specifications (Skylon C2)

Data from the Skylon User Manual[24]

General characteristics

- Crew: None, remote controlled from ground.

- Capacity: Potential for up to 24 passengers

Performance

- Thrust/weight: ~1.2 – 3 at burnout (~0.768 atmospheric)

- Fuselage diameter: 6.75 m (22.15 ft)

- Specific impulse: 3500 s (35 kN·s/kg) atmospheric, 450 s (4.5 kN·s/kg) exoatmospheric[24]

- SABRE engine thrust/weight ratio: up to 14 atmospheric

See also

- Reaction Engines A2 a design for an antipodal airliner by the same company, using similar engine technology

- Reusable launch system

- Spaceplane

References

- Citations

- ^ a b c d e f g Background "Skylon Test Date". UK Parliament. 2011. Retrieved 2011-01-27.

{{cite web}}: Check|url=value (help) - ^ a b c d Cite error: The named reference

sf20110125was invoked but never defined (see the help page). - ^ a b Hempsell and Longstaff (2009). Skylon User Manual. p. 5.

- ^ a b c d e f g h i j k "Reaction Engines Ltd : Company Background". Reaction Engines Limited. Retrieved 2010-09-25.

- ^ a b "Reaction Engines Ltd : Projects STERN and STRICT". Reaction Engines Limited. Retrieved 2010-09-25.

- ^ "Reaction Engines Limited :: Technology Demonstration Programme". Reaction Engines Limited. Retrieved 2010-09-25.

- ^ a b c Hempsell and Longstaff (2009). Skylon User Manual. p. 4.

- ^ a b Hempsell and Longstaff (2009). Skylon User Manual. p. 11.

- ^ "Memorandum submitted by the Association of Aerospace Universities". Parliament of the United Kingdom. 2000. Retrieved 2009-07-01.

- ^ Rob Coppinger (2009). "Skylon spaceplane engine technology gets European funding". Flight Global. Retrieved 2009-04-15.

- ^ Jonathan Amos (2009). "Skylon spaceplane gets cash boost". BBC News. Retrieved 2009-04-15.

- ^ Rob Coppinger (2009). "Skylon spaceplane engine technology gets European funding". Flight International. Retrieved 2009-07-01.

- ^ Jonathan Amos (2009). "Skylon spaceplane gets cash boost". BBC News. Retrieved 2009-07-01.

- ^ Jeremy Hsu (2009). "British Space Plane Concept Gets Boost". space.com. Retrieved 2009-07-01.

- ^ "Rockets and Skylon". 20 Years Since HOTOL: Reaction Engines Ltd and SKYLON. UK Rocketeers. 2009. Retrieved 2010-10-01.

- ^ "Reaction Engines Celebrates 20 Years, Looks Forward to Success with Skylon". Parabolic Arc. 2009. Retrieved 2010-09-25.

- ^ "The rocket that thinks it's a jet". UK Space Agency. 2009. Retrieved 2010-08-08.

- ^ Page, Lewis ESA: British Skylon spaceplane seems perfectly possible (whizzo robot runway rocketplane cleared to proceed) The Register, 24 May 2011

- ^ "Big Test Looms for British Space Plane Concept". space.com. 2011. Retrieved 2011-04-18.

- ^ a b Hempsell and Longstaff (2009). Skylon User Manual. p. 15.

- ^ "Reaction Engines Ltd : Current Projects : SKYLON – The Vehicle". Reaction Engines Limited. Retrieved 2010-09-25.

- ^ Hempsell and Longstaff (2009). Skylon User Manual. p. 7.

- ^ R.Varvill and A. Bond (2004). p. 25.

{{cite book}}: Missing or empty|title=(help) - ^ a b c d e Hempsell and Longstaff (2009). Skylon User Manual. p. 12. Cite error: The named reference "hl3" was defined multiple times with different content (see the help page).

- ^ "Skylon Construction". Skylon-Current Projects. Reaction Engines Limited. 2010. Retrieved 2011-01-25.

- ^ a b c Hempsell and Longstaff (2009). Skylon User Manual. p. 21.

- ^ R.Varvill and A. Bond (2004). p. 22.

{{cite book}}: Missing or empty|title=(help) - ^ a b c d e f g h i j k l m n o p q r "SABRE engine". The Sabre Engine. Reaction Engines Limited. 2010. Retrieved 2011-01-25.

- ^ a b Varvill and Bond (2003). p. 108.

{{cite book}}: Missing or empty|title=(help) - ^ Hempsell and Longstaff (2009). Skylon User Manual. p. 7.

- ^ "Reaction Engines Ltd : Current Projects : SKYLON – Passenger Capability". Reaction Engines Limited. Retrieved 2010-09-25.

- ^ J.L. Scott-Scott, M. Harrison and A.D. Woodrow (2003). "Considerations for Passenger Transport by Advanced Spaceplanes" (PDF). Journal of British Interplanetary Society. 56: 118–126. Retrieved 2009-07-01.

- ^ House of Commons: Science and Technology Committee (2007). p. 262.

{{cite book}}: Missing or empty|title=(help) - ^ http://www.thespaceshow.com/detail.asp?q=1203

- ^ Emma Haslett (2011-06-01). "Skylon to Replace Space Shuttle?". Brits blast off. Management Today. Retrieved 2011-06-11.

- Bibliography

- Richard Varvill and Alan Bond (2003). "A Comparison of Propulsions Concepts for SSTO Reusable launchers" (PDF). Journal of the British Interplanetary Society, Vol. 56. pp. 108–117.

{{cite web}}: Italic or bold markup not allowed in:|publisher=(help) - Mark Hempsell and Roger Longstaff (2009). "Skylon User Manual" (PDF). Reaction Engines Limited. pp. 1–21.

{{cite web}}: Italic or bold markup not allowed in:|publisher=(help) - Richard Varvill and Alan Bond (2004). "Skylon" (PDF). The SKYLON Spaceplane. Journal of the British Interplanetary Society, Vol. 57. pp. 22–32.

- House of Commons: Science and Technology Committee (2007). 2007: A Space Policy - Seventh Report of Session 2006-08, Volume II. Her Majesty's Stationery Office. ISBN 9780-215-03509-7.

External links

- Mark Hempsell from REL on The Space Show talking about Skylon

- World Tiles Skylon model

- Liquid Air Cycle Engine (LACE) rocket equation reasonably well predicts the performance of Skylon