Byssus

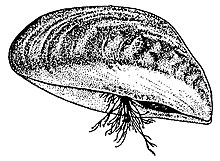

A byssus (/ˈbɪsəs/) is a bundle of filaments secreted by many species of bivalve mollusc that function to attach the mollusc to a solid surface. Species from several families of clams have a byssus, including pen shells (Pinnidae), true mussels (Mytilidae), and Dreissenidae.

Filaments

Byssus filaments are created by certain kinds of marine and freshwater bivalve mollusks, which use the byssus to attach themselves to rocks, substrates, or seabeds. In edible mussels, the inedible byssus is commonly known as the "beard", and is removed before cooking.

Many species of mussels secrete byssus threads to anchor themselves to surfaces, with families including the Arcidae, Mytilidae, Anomiidae, Pinnidae, Pectinidae, Dreissenidae, and Unionidae.[1][2]

Mechanics

The byssus, or byssal complex, is composed of multiple extracellular collagenous threads that are placed radially by the mussel from a central stem. Each thread is composed of three regions: a corrugated proximal region close to the mussel body, a longer, smooth distal region connecting the proximal region to the ending plaque, and the adhesive plaque itself, which anchors the mussel to the surface.[3] The proximal region consists of a corrugated sheath enveloping loosely-arranged coiled fibers; these coils can unravel to extend the fiber under an applied force. The distal region is more ordered, consisting of aligned collagenous fiber bundles that give the fiber stiffness. The plaque consists of collagen-like fibers over a spongy matrix, in which the adhesive protein is deposited and hardens.[4]

The purpose of the byssus is to keep the mussel attached to the desired surface, and to this end byssal threads must be able to withstand strong cyclic motion due to tidal action near the shorelines mussels inhabit. Mechanical testing of live mussels has shown that byssal threads can extend 39% before yield and 64% before breaking, at a nominal strain rate of 10 mm/min.[3] Tensile testing shows that threads exhibit three distinct phases: initial stiffness from both the distal and proximal regions, softening due to yield in the distal region, and finally stiffening directly preceding tensile failure.[4] The ability of the distal region to yield before breaking gives the mussels their characteristic hardiness even under strong tidal forces.[4] Many variables that influence the performance of byssal threads have been studied, including species variations,[5] seasonal variations,[3] temperature effects,[6] and ageing effects.[6] Temperature effects in particular have revealed a glass transition temperature of 6°C.[6]

The number of threads used by a mussel to attach is typically between 20-60; this can vary by the species, season, or age of the mussel. Under cyclic tidal conditions, the radial spread of fiber placement allows the mussel to dynamically align most of its fibers in the direction of applied force. This lowers the stress on any one thread, reducing the chances of failure and detachment.[4] Mussels are also capable of ejecting the entire byssal complex, including the central stem, without damaging themselves. The complex can simply be regenerated and with fibers placement resuming within 24 hours.[7]

When a mussel's foot encounters a crevice, it creates a vacuum chamber by forcing out the air and arching up, similar to a plumber's plunger unclogging a drain. The byssus, which is made of keratin, quinone-tanned proteins (polyphenolic proteins), and other proteins, is spewed into this chamber in liquid form similar to injection moulding in polymer processing, and bubbles into a sticky foam. By curling its foot into a tube and pumping the foam, the mussel produces sticky threads about the size of a human hair. The mussel then varnishes the threads with another protein, resulting in an adhesive.[2] The attachment dynamics of the plaque are studied both to imitate the strong adhesive and to create coatings to which the plaque cannot adhere. Foul release strategies such as fluoropolymer paints and lubricant-infused coatings are an active research area important to preventing the fouling of marine structures by invasive mussel species such as the zebra and quagga mussel.[8]

Biomimetics

Byssus is a remarkable adhesive, one that is neither degraded nor deformed by water as many synthetic adhesives are.[9] The remarkable properties of this adhesive, specifically the mussel foot proteins (Mfps), has spurred many attempts to imitate the excellent adhesive capacity that mussels show, either by producing Mfps via other organisms or by creating synthetic polymers with similar properties. For instance, genetic engineers have inserted mussel DNA into yeast cells to translate the genes into the appropriate proteins.[10] Synthetic approaches generally utilize catechol as a cross-linking agent to produce wear-resistant polymer networks. Imitation of Mfp-3 to induce coacervation is another key property, as this protects the material from partial dissolution in saltwater.[9]

Applications of biomimetic byssus adhesive include biomedical adhesives,[11] therapeutic applications,[12] and anti-fouling coatings.[13]

Historical uses

Byssus often refers to the long, fine, silky threads secreted by the large Mediterranean pen shell, Pinna nobilis. The byssus threads from this Pinna species can be up to 6 cm (2.4 in) in length and have historically been made into cloth.[14]

Byssus cloth is a rare fabric, also known as sea silk, that is made using the byssus of pen shells as the fiber source.[15][16]

References

- ^ Turner, Ruth; Rosewater, Joseph (June 1958). "The Family Pinnidae in the Western Atlantic". Johnsonia. 3 (38): 285–326.

- ^ a b Starr, Cecie; Taggart, Ralph (2004). Biology: The Unity and Diversity of Life. Belmont, CA: Thomson Learning.

- ^ a b c Moeser, Gretchen M.; Carrington, Emily (15 May 2006). "Seasonal variation in mussel byssal thread mechanics". Journal of Experimental Biology. 209 (10): 1996–2003. doi:10.1242/jeb.02234. PMID 16651564. Retrieved 8 May 2021.

- ^ a b c d Bell, Emily; Gosline, John (1 April 1996). "Mechanical design of mussel byssus: material yield enhances attachment strength". Journal of Experimental Biology. 199 (4): 1005–1017. doi:10.1242/jeb.199.4.1005. PMID 9318809. Retrieved 9 May 2021.

- ^ Brazee, Shanna; Carrington, Emily (December 2006). "Interspecific Comparison of the Mechanical Properties of Mussel Byssus". The Biological Bulletin. 211 (3): 263–274. doi:10.2307/4134548. JSTOR 4134548. PMID 17179385. S2CID 24797335. Retrieved 9 May 2021.

- ^ a b c Aldred, Nick (22 December 2007). "Tensile and dynamic mechanical analysis of the distal portion of mussel (Mytilus edulis) byssal threads". Journal of the Royal Society Interface. 4 (17): 1159–1167. doi:10.1098/rsif.2007.1026. PMC 2396211. PMID 17439859.

- ^ Peyer, Suzanne (23 December 2008). "Zebra mussels anchor byssal threads faster and tighter than quagga mussels in flow" (PDF). Journal of Experimental Biology. 212 (13): 2027–2036. doi:10.1242/jeb.028688. PMID 19525429. Retrieved 9 May 2021.

- ^ Verma, Shatakshi (20 February 2019). "A review on protective polymeric coatings for marine applications". Journal of Coatings Technology and Research. 16 (2): 307–338. doi:10.1007/s11998-018-00174-2. S2CID 139442176. Retrieved 9 May 2021.

- ^ a b Forooshani, Pegah; Lee, Bruce (11 October 2016). "Recent approaches in designing bioadhesive materials inspired by mussel adhesive protein". Journal of Polymer Science Part A: Polymer Chemistry. 55 (1): 9–33. doi:10.1002/pola.28368. PMC 5132118. PMID 27917020.

- ^ Robert L. Strausberg; et al. (31 December 1989). "Development of a Microbial System for Production of Mussel Adhesive Protein". Adhesives from Renewable Resources. ACS Symposium Series. Vol. 385. pp. 453–464. doi:10.1021/bk-1989-0385.ch032. ISBN 978-0-8412-1562-7.

- ^ Allen, Mark (May 2004). "Prospective randomized study evaluating a biodegradable polymeric sealant for sealing intraoperative air leaks that occur during pulmonary resection". The Annals of Thoracic Surgery. 77 (5): 1792–1801. doi:10.1016/j.athoracsur.2003.10.049. PMID 15111188. Retrieved 9 May 2021.

- ^ Black, Kvar (14 August 2012). "Polydopamine-enabled surface functionalization of gold nanorods for cancer cell-targeted imaging and photothermal therapy". Nanomedicine. 8 (1): 17–28. doi:10.2217/nnm.12.82. PMC 3544340. PMID 22891865.

- ^ Dalsin, Jeffrey (9 December 2004). "Protein Resistance of Titanium Oxide Surfaces Modified by Biologically Inspired mPEG−DOPA". Langmuir. 21 (2): 640–646. doi:10.1021/la048626g. PMID 15641834. Retrieved 9 May 2021.

- ^ McKinley, Daniel (June 1998). "Pinna and Her Silken Beard: A Foray Into Historical Misappropriations". Ars Textrina: A Journal of Textiles and Costumes. 29: 9–223.

- ^ Maeder, Felicitas (2002). "The project Sea-silk: Rediscovering an Ancient Textile Material". Archaeological Textiles Newsletter. 35: 8–11.

- ^ Hill, John (2009). Through the Jade Gate to Rome: A Study of the Silk Routes during the Later Han Dynasty, 1st to 2nd centuries CE (2nd ed.). Charleston, SC: Book Surge. ISBN 978-1439221341.

External links

The dictionary definition of byssus at Wiktionary

The dictionary definition of byssus at Wiktionary