Adipic acid

| |

| |

| Names | |

|---|---|

| Preferred IUPAC name

Hexanedioic acid | |

| Other names

Adipic acid

Hexane-1,6-dicarboxylic acid Hexane-1,6-dioic acid | |

| Identifiers | |

3D model (JSmol)

|

|

| ChEBI | |

| ChEMBL | |

| ChemSpider | |

| ECHA InfoCard | 100.004.250 |

| EC Number |

|

| E number | E355 (antioxidants, ...) |

| KEGG | |

PubChem CID

|

|

| RTECS number |

|

| UNII | |

CompTox Dashboard (EPA)

|

|

| |

| |

| Properties | |

| C6H10O4 | |

| Molar mass | 146.142 g·mol−1 |

| Appearance | White crystals[1] |

| Odor | Odorless |

| Density | 1.360 g/cm3 |

| Melting point | 152.1 °C (305.8 °F; 425.2 K) |

| Boiling point | 337.5 °C (639.5 °F; 610.6 K) |

| 14 g/L (10 °C) 24 g/L (25 °C) 1600 g/L (100 °C) | |

| Solubility | Very soluble in methanol, ethanol soluble in acetone slightly soluble in cyclohexane negligible in benzene, petroleum ether insoluble in acetic acid |

| log P | 0.08 |

| Vapor pressure | 0.0728 Pa (18.5 °C) |

| Acidity (pKa) | 4.43, 5.41 |

| Viscosity | 4.54 cP (160 °C) |

| Structure | |

| Monoclinic | |

| Thermochemistry | |

Std enthalpy of

formation (ΔfH⦵298) |

−994.3 kJ/mol[2] |

| Hazards | |

| NFPA 704 (fire diamond) | |

| Flash point | 196 °C (385 °F; 469 K) |

| 422 °C (792 °F; 695 K) | |

| Lethal dose or concentration (LD, LC): | |

LD50 (median dose)

|

3600 mg/kg (rat) |

| Safety data sheet (SDS) | External MSDS |

| Related compounds | |

Related dicarboxylic acids

|

glutaric acid pimelic acid |

Related compounds

|

hexanoic acid adipic acid dihydrazide hexanedioyl dichloride hexanedinitrile hexanediamide |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

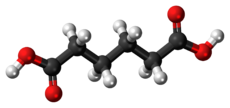

Adipic acid is the organic compound with the formula (CH2)4(COOH)2. From an industrial perspective, it is the most important dicarboxylic acid: About 2.5 billion kilograms of this white crystalline powder are produced annually, mainly as a precursor for the production of nylon. Adipic acid otherwise rarely occurs in nature.[3]

Preparation and reactivity

Adipic acid is produced from a mixture of cyclohexanol and cyclohexanone called "KA oil", the abbreviation of ketone-alcohol oil. The KA oil is oxidized with nitric acid to give adipic acid, via a multistep pathway. Early in the reaction the cyclohexanol is converted to the ketone, releasing nitrous acid:

- HOC6H11 + HNO3 → OC(CH2)5 + HNO2 + H2O

Among its many reactions, the cyclohexanone is nitrosated, setting the stage for the scission of the C-C bond:

- HNO2 + HNO3 → NO+NO3− + H2O

- OC6H10 + NO+ → OC6H9-2-NO + H+

Side products of the method include glutaric and succinic acids. Nitrous oxide is produced as well, via the intermediacy of a nitrolic acid.[3]

Related processes start from cyclohexanol, which is obtained from the hydrogenation of phenol.[3][4]

Alternative methods of production

Several methods have been developed by carbonylation of butadiene. For example, the hydrocarboxylation proceeds as follows:[3]

- CH2=CH−CH=CH2 + 2 CO + 2 H2O → HO2C(CH2)4CO2H

Another method is oxidative cleavage of cyclohexene using hydrogen peroxide.[5] The waste product is water.

Historically, adipic acid was prepared by oxidation of various fats,[6] thus the name (ultimately from Latin adeps, adipis – "animal fat"; cf. adipose tissue).

Reactions

Adipic acid is a dibasic acid (it has two acidic groups). The pKa values for their successive deprotonations are 4.41 and 5.41.[7]

With the carboxylate groups separated by four methylene groups, adipic acid is suited for intramolecular condensation reactions. Upon treatment with barium hydroxide at elevated temperatures, it undergoes ketonization to give cyclopentanone.[8]

Uses

About 60% of the 2.5 billion kg of adipic acid produced annually is used as monomer for the production of nylon [9] by a polycondensation reaction with hexamethylene diamine forming nylon 66. Other major applications also involve polymers: it is a monomer for production of Polyurethane and its esters are plasticizers, especially in PVC.

In medicine

Adipic acid has been incorporated into controlled-release formulation matrix tablets to obtain pH-independent release for both weakly basic and weakly acidic drugs. It has also been incorporated into the polymeric coating of hydrophilic monolithic systems to modulate the intragel pH, resulting in zero-order release of a hydrophilic drug. The disintegration at intestinal pH of the enteric polymer shellac has been reported to improve when adipic acid was used as a pore-forming agent without affecting release in the acidic media. Other controlled-release formulations have included adipic acid with the intention of obtaining a late-burst release profile.[10] Adipic acid is used to make bisobrin an antifibrinolytic.

In foods

Small but significant amounts of adipic acid are used as a food ingredient as a flavorant and gelling aid.[11] It is used in some calcium carbonate antacids to make them tart.

Safety

Adipic acid, like most carboxylic acids, is a mild skin irritant. It is mildly toxic, with an LD50 of 3600 mg/kg for oral ingestion by rats.[3]

Environmental

The production of adipic acid is linked to emissions of N

2O,[12] a potent greenhouse gas and cause of stratospheric ozone depletion. At adipic acid producers DuPont and Rhodia (now Invista and Solvay, respectively), processes have been implemented to catalytically convert the nitrous oxide to innocuous products:[13]

- 2 N2O → 2 N2 + O2

References

- ^ Mac Gillavry, C. H. (2010). "The crystal structure of adipic acid". Recueil des Travaux Chimiques des Pays-Bas. 60 (8): 605. doi:10.1002/recl.19410600805.

- ^ Haynes, W. M., ed. (2013). CRC Handbook of Chemistry and Physics (94th ed.). Boca Raton, Florida: CRC Press. ISBN 978-1-4665-7114-3.

- ^ a b c d e Musser, M. T. (2005). "Adipic Acid". Ullmann's Encyclopedia of Industrial Chemistry. Weinheim: Wiley-VCH. doi:10.1002/14356007.a01_269.

- ^ Ellis, B. A. (1925). "Adipic Acid". Organic Syntheses. 5: 9; Collected Volumes, vol. 1, p. 560.

- ^ Sato, K.; Aoki, M.; Noyori, R. (1998). "A "Green" route to adipic acid: direct oxidation of cyclohexenes with 30 percent hydrogen peroxide". Science. 281 (5383): 1646–47. Bibcode:1998Sci...281.1646S. doi:10.1126/science.281.5383.1646.

- ^ Ince, Walter (1895). "Preparation of adipic acid and some of its derivatives". Journal Chemical Society, London. 67: 155. doi:10.1039/CT8956700155.

- ^ Cornils, Boy and Lappe, Peter (2006) "Dicarboxylic Acids, Aliphatic" in Ullmann's Encyclopedia of Industrial Chemistry, Wiley-VCH, Weinheim. doi:10.1002/14356007.a08_523

- ^ Thorpe, J. F.; Kon, G. A. R. (1925). "Cyclopentanone". Organic Syntheses. 5: 37; Collected Volumes, vol. 1, p. 192.

- ^ http://pcinylon.com/index.php/markets-covered/adipic-acid PCI abstract for adipic acid

- ^ Roew, Raymond (2009), "Adipic Acid", Handbook of Pharmaceutical Excipients, pp. 11–12

- ^ "Cherry Jell-O Nutrition Facts". Kraft Foods. Retrieved 21 Mar 2012.

- ^ US EPA. "U.S. Greenhouse Gas Inventory Report, Chapter 4. Industrial Processes" (PDF). Retrieved 2013-11-29.

- ^ Reimer, R. A.; Slaten, C. S.; Seapan, M.; Koch, T. A.; Triner, V. G. (2000). "Adipic Acid Industry — N2O Abatement". Non-CO2 Greenhouse Gases: Scientific Understanding, Control and Implementation. Netherlands: Springer. pp. 347–358. doi:10.1007/978-94-015-9343-4_56. ISBN 978-94-015-9343-4.

Appendix

- E-number E355.

- U.S. FDA citations – GRAS (21 CFR 184.1009), Indirect additive (21 CFR 175.300, 21 CFR 175.320, 21 CFR 176.170, 21 CFR 176.180, 21 CFR 177.1200, 21 CFR 177.1390, 21 CFR 177.1500, 21 CFR 177.1630, 21 CFR 177.1680, 21 CFR 177.2420, 21 CFR 177.2600)

- European Union Citations – Decision 1999/217/EC – Flavoing Substance; Directive 95/2/EC, Annex IV – Permitted Food Additive; 2002/72/EC, Annex A – Authorized monomer for Food Contact Plastics

External links

- International Chemical Safety Card 0369

- SIDS Initial Assessment Report for Adipic acid from the Organisation for Economic Co-operation and Development (OECD)

- adipic acid on chemicalland[permanent dead link]