Textile performance: Difference between revisions

RAJIVVASUDEV (talk | contribs) →High performance fibers: Copy and paste edits. Attribution Polybenzimidazole fiber |

RAJIVVASUDEV (talk | contribs) →High performance fibers: Copy and paste edits. Attribution Polybenzimidazole fiber |

||

| Line 121: | Line 121: | ||

* [[Carbon fibers]] have several advantages including high stiffness, high tensile strength, low weight to strength ratio, high chemical resistance, high temperature tolerance and low thermal expansion.<ref>{{Cite web|date=2018-07-02|title=Carbon woven fabrics |publisher=Compositesplaza|url=https://web.archive.org/web/20180702122309/https://compositesplaza.com/products/carbon/carbon-woven-fabrics|url-status=live|access-date=2021-06-17|website=web.archive.org|quote=Carbon woven fabrics from Compositesplaza are used in the following applications:Model building, Yachts- and Boats construction, Automotive (car parts), Sporting goods, Orthopedic parts, Aviation parts, industrial Construction, Luxury items and jewelery, Motorsport parts.}}</ref><ref>{{Cite journal|date=2011-02-07|title=Compressibility of carbon woven fabrics with carbon nanotubes/nanofibres grown on the fibres|url=https://www.sciencedirect.com/science/article/abs/pii/S026635381000463X|journal=[[Composites Science and Technology]]|language=en|volume=71|issue=3|pages=315–325|doi=10.1016/j.compscitech.2010.11.024|issn=0266-3538}}</ref> |

* [[Carbon fibers]] have several advantages including high stiffness, high tensile strength, low weight to strength ratio, high chemical resistance, high temperature tolerance and low thermal expansion.<ref>{{Cite web|date=2018-07-02|title=Carbon woven fabrics |publisher=Compositesplaza|url=https://web.archive.org/web/20180702122309/https://compositesplaza.com/products/carbon/carbon-woven-fabrics|url-status=live|access-date=2021-06-17|website=web.archive.org|quote=Carbon woven fabrics from Compositesplaza are used in the following applications:Model building, Yachts- and Boats construction, Automotive (car parts), Sporting goods, Orthopedic parts, Aviation parts, industrial Construction, Luxury items and jewelery, Motorsport parts.}}</ref><ref>{{Cite journal|date=2011-02-07|title=Compressibility of carbon woven fabrics with carbon nanotubes/nanofibres grown on the fibres|url=https://www.sciencedirect.com/science/article/abs/pii/S026635381000463X|journal=[[Composites Science and Technology]]|language=en|volume=71|issue=3|pages=315–325|doi=10.1016/j.compscitech.2010.11.024|issn=0266-3538}}</ref> |

||

* UHMWPE ([[Ultra-high-molecular-weight polyethylene]]) is a high abrasion and wear resistance material suitable for durability, low friction, and chemical resistance.<ref name=":6">{{Cite book|last=Paul|first=Roshan|url=https://books.google.com/books?id=1sOKDwAAQBAJ&newbks=0&printsec=frontcover&pg=PA354&dq=mobiltech&hl=en|title=High Performance Technical Textiles|date=2019-02-19|publisher=[[John Wiley & Sons]]|isbn=978-1-119-32505-5|pages=110, 121|language=en}}</ref> |

* UHMWPE ([[Ultra-high-molecular-weight polyethylene]]) is a high abrasion and wear resistance material suitable for durability, low friction, and chemical resistance.<ref name=":6">{{Cite book|last=Paul|first=Roshan|url=https://books.google.com/books?id=1sOKDwAAQBAJ&newbks=0&printsec=frontcover&pg=PA354&dq=mobiltech&hl=en|title=High Performance Technical Textiles|date=2019-02-19|publisher=[[John Wiley & Sons]]|isbn=978-1-119-32505-5|pages=110, 121|language=en}}</ref> |

||

* [[Polybenzimidazole fiber]], also known as PBI, has high thermal stability, flame resistance, and moisture recovery, making it suitable for use in protective clothing. PBI is also used in [[Space suit|Space suits.]] In 1969, the United States Air Force selected polybenzimidazole (PBI) for its superior thermal protective performance after a 1967 fire aboard the [[Apollo 1]] spacecraft killed three astronauts.<ref name="Haertsch">{{cite journal|last1=Haertsch|first1=Emilie|last2=Meyer|first2=Michal|date=2016|title=Tough Stuff|url=https://www.sciencehistory.org/distillations/magazine/tough-stuff|journal=Distillations|volume=2|issue=2|pages=12–13|accessdate=26 March 2018}}</ref>. In the early 1970s USAF laboratories experimented with polybenzimidazole fibers for [[protective clothing]] to reduce aircrew deaths from fires.<ref>[https://babel.hathitrust.org/cgi/pt?id=uc1.31210017813369;view=1up;seq=618 Statement of Hon. Grant L. Hansen, Assistant Secretary of the Air Force (Research and Development)], Department of Defense Appropriations for Fiscal Year 1972, p. 612.</ref> |

* [[Polybenzimidazole fiber]], also known as PBI, has high thermal stability, flame resistance, and moisture recovery, making it suitable for use in protective clothing. PBI are usually yellow to brown solid infusible up to 400 °C or higher.<ref>{{cite book|title=Some problems encountered with degradation mechanisms of addition polymers (in Synthesis and degradation, rheology and extrusion)|vauthors=Bhuiyan AL|publisher=Springer|year=1982|isbn=978-3-540-11774-2|location=Berlin u.a.}}</ref>PBI is also used in [[Space suit|Space suits.]] In 1969, the United States Air Force selected polybenzimidazole (PBI) for its superior thermal protective performance after a 1967 fire aboard the [[Apollo 1]] spacecraft killed three astronauts.<ref name="Haertsch">{{cite journal|last1=Haertsch|first1=Emilie|last2=Meyer|first2=Michal|date=2016|title=Tough Stuff|url=https://www.sciencehistory.org/distillations/magazine/tough-stuff|journal=Distillations|volume=2|issue=2|pages=12–13|accessdate=26 March 2018}}</ref>. In the early 1970s USAF laboratories experimented with polybenzimidazole fibers for [[protective clothing]] to reduce aircrew deaths from fires.<ref>[https://babel.hathitrust.org/cgi/pt?id=uc1.31210017813369;view=1up;seq=618 Statement of Hon. Grant L. Hansen, Assistant Secretary of the Air Force (Research and Development)], Department of Defense Appropriations for Fiscal Year 1972, p. 612.</ref> |

||

Revision as of 05:55, 20 June 2021

An editor has nominated this article for deletion. You are welcome to participate in the deletion discussion, which will decide whether or not to retain it. |

Performance is the capacity of textiles to withstand various conditions, environments, and hazards. The performance of textile products influences their appearance, comfort, durability, and protection. Different areas of textile applications (clothing, sleepwear, workwear, sportswear, upholstery, and PPE) require a unique set of performance parameters. As a result, the specifications determine the level of performance for a textile product concerning the specific application’s needs. Textile testing certifies the product's suitability for use.

The performance of textile products is desired by both producers and buyers, as are the expectations of the target market.[1][2][3][4][5]

Expectations

Performance is the ability of textiles to withstand various conditions, environments, and hazards.[1] Users have five basic criteria for performance, including appearance, comfort, durability, maintenance, and cost.[6] These performance expectations are not the same as those of specialist textiles. Due to the often highly technical and legal requirements of these products, these textiles are typically tested in order to ensure they meet stringent performance requirements. Here are a few examples of different areas:

- Sportswear must have these characteristics: strength, moisture management, stretch, and thermal comfort.

- Military textiles demand protection from hostile weather. A bulletproof vest necessitates low impact.[7]

- Firefighting clothing needs flame retardance and thermal resistance and light materials.

- Occupational hazards demand a specific degree of protection.[7]

- Medical textiles need clothing with barriers and antimicrobial surfaces. Such as cleanroom suits and hazmat suits.

- Wearable electronics in E-textiles require flexibility as well as washability.

- Body armor (protective clothing designed to absorb or deflect physical attacks) demands specific performance standards.

- Wetsuits are made with neoprene that is typically used where the water temperature is between 10 and 25 °C (50 and 77 °F). The foamed neoprene of the suit thermally insulates the wearer.

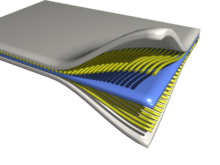

- Automotive textiles have specific performance requirements in various sections of the car. The different types of fibers used for separate areas of the car's interior are shown below:

Car section/part Fabric consumption in square meters[8] Material[9] Properties of fibers Performance expectations from the material used[9] Airbags 3.5 Nylon coated with silicone or neoprene from inside. Strong, elastic, tough and stable in terms of shrinkage Capability of holding air when inflated and should be strong enough to withstand the impact without rupturing Upholstery 10.0 Nylon & Polyester Abrasion resistance Strong abrasion resistance to withstand the friction when sliding of objects and the passengers. To retain the shape and smoothness of the seats. Colors should be fast to the sunlight and rubbing to sustain the exposure. Carpet 4.0 Nylon Strong, tough and abrasion resistant Strong enough to stand with the friction, the material must be tough and resilient. Trunk 4.0-5.0 Nylon Strong, tough and abrasion resistant Strong enough to stand friction, antimicrobial Seat belts 0.5 Polyester Headliner 4.0-6.0 Composite/ Blended/Laminated fabric adheres to melted polyurethane foam. Strong, insulating Aesthetics, feel, stiffness, and sound reduction

Tensile strength, bursting, sensorial comfort, thermal comfort, heat transfer, water repellency MVTR, air permeablity, pilling, shrinkage, fading, lightfastness, drape and hand feel are a few performance parameters.[2][10][11]

Factors and methods

Performance of textile products is primarily based on fiber and fabric structure.Fiber properties are fundamentally determined by their physical and chemical properties.[6] Specific finishing methods, functional finishes, fit, and product design could improve the overall performance of the textile product to attain higher degrees of performance.[12][13]

Performance has an array of characteristics that affect appearance, durability, and comfort. Performance characteristics are in-built or incorporated into the textile materials. For example, technical textiles are classified into twelve separate categories. In which the performance is predetermined, and textiles are manufactured and structured as per the application and end-use.[14]

Fiber properties

Natural and synthetic fibers have various properties that influence the final textile performance. Natural fibers are suitable for comfort, where synthetics are better for aesthetics and durability.

A stain repellent is a product added to fabric in order to prevent stains.[15]

There is a whole panoply of properties that relate to material functionality and their use in peformance fabric applications.[15] These include, inter alia:

- Abrasion resistance

- Antimicrobial

- Antistatic

- Breathability

- Biodegradable

- Bioresorbable

- Conductive

- Crease and wrinkle resistance

- Enhanced coloration

- Flame and heat resistance

- Fluorescence

- Hydrophilicity

- Hydrophobicity

- Light responsive

- Luminescence

- Oleophobicity

- Pill resistance

- Reinforcement

- Stain resistance

- Thermal insulation

- Thermal responsive

- Ultrafiltration

- Ultraviolet resistance[15]

In-built (natural) properties

- Cotton, wool and linen are absorbent fibers.

- Linen has lustre.[16]

- Wool has insulating properties.

- Most synthetic fibers such as polyester, nylon, polypropylene, and spandex are hydrophobic and thermoplastic.

- Spandex is a polyether-polyurea copolymer that is exceptionally elastic.

High performance fibers

High performance fibers are specifically synthesized to achieve unique properties (exceptional strength, with a very high strength-to-weight ratio, stiffness, tensile strength, heat resistance, operating temperature, limiting oxygen index, fire retardancy or chemical resistance.)[17] These high-performance fibers are used in protective clothing (PPE) with exceptional characteristics like chemical resistance and fire resistance.[18]

- Aramid fiber, namely Kevlar, a strong, abrasion-resistant, durable material with high performance. Fiber and fabric engineering can optimize the functionality of the materials.[19]

- Carbon fibers have several advantages including high stiffness, high tensile strength, low weight to strength ratio, high chemical resistance, high temperature tolerance and low thermal expansion.[20][21]

- UHMWPE (Ultra-high-molecular-weight polyethylene) is a high abrasion and wear resistance material suitable for durability, low friction, and chemical resistance.[18]

- Polybenzimidazole fiber, also known as PBI, has high thermal stability, flame resistance, and moisture recovery, making it suitable for use in protective clothing. PBI are usually yellow to brown solid infusible up to 400 °C or higher.[22]PBI is also used in Space suits. In 1969, the United States Air Force selected polybenzimidazole (PBI) for its superior thermal protective performance after a 1967 fire aboard the Apollo 1 spacecraft killed three astronauts.[23]. In the early 1970s USAF laboratories experimented with polybenzimidazole fibers for protective clothing to reduce aircrew deaths from fires.[24]

Finishing methods

Finishing improves appearance and performance.[25] Finishing processes like heat-setting makes cloths stable. Mercerization, treatments with enzymes (bio polishing) and napping, can alter the surface and the performance of the treated textiles. Mercerized cotton material will be lustrous, absorb more dye, and have a smoother surface than conventional cotton. A napped cloth feels softer. Singeing improves pilling.

Functional finishes

Functional finishes enable treated textiles with different characteristics, which may be opposite to their natural or inherent nature. Functional finishes add value other than handfeel and aesthetics.[1] Moisture wicking is an example of functional finish that enhance the wearer's comfort.[1] Certain finishes can alter the performance suiting for thermal comfort (thermal regulation), antimicrobial, UV protection, easy care (crease resistant cotton fabrics), and insect repellant etc.[26]

Surface treatments

Certain technologies can alter the surface characterizations of textiles.

Plasma

Plasma is a highly reactive state that activates the substrate, and the oxidized surface of the plasma-treated textile improves dyeing while reducing environmental impacts. Plasma can also be used to treat textiles to obtain waterproofing and oil repellency properties. Different gases in the same fiber may have other effects, and various gases are chosen for different results.[27]

| Plasma process with | By using chemical element | Result on treated textile[27] |

|---|---|---|

| Noble gas | Helium, argon | Etching |

| Oxidizing | Oxygen, carbon dioxide, water | Cleaning, functionalisation and etching |

| Hydrocarbon | Nitrogen or Oxygen containing Hydrocarbons | Plasma polymerization |

Laser

Light amplification by stimulated emission of radition (Laser) irradiation is used to modify the structural and surface properties of textiles, as well as to texturize them.[27]

Testing standards

Standards vary with the use and application areas. Military textiles, industrial textiles have separate tests to analyze performance in extreme conditions.[28] Different countries have their own performance standards for various textile products.[29] American National Standards Institute approves the textile performance standards set by ASTM International.[30] Other testing agencies/ bodies which are recognized/accepted as international standards depending on the contracts:[7]

| Standards Organisation | |

|---|---|

| ASTM | ASTM International |

| AATCC | American Association of Textile Chemists and Colorists |

| BS | British Standards |

| ISO | International Organization for Standardization |

| IWTO | International Wool Textile Organisation |

| EN | European Standard |

| Oekotex | Oeko-Tex |

| AS/NZS |

Special test methods

Manikin tests

- A thermal manikin is a device for analysing the thermal interface of the human body and its environment. It assesses the thermal comfort and insulation properties of clothing, such as protective gear for the military.[31][32]

Care labelling

Care labelling for textile products takes into account the performance of each component as well as the manufacturing methods.[33]

Function of textiles

The performance of textiles extends to functionality through comfort and protection.

Comfort

Comfort is related to various perceptions, physiological, social, and psychological needs, and after food, clothing is one of the significant objects that suffices for comfort requirements. Clothes provide aesthetic comfort, thermal comfort, moisture comfort, tactile comfort, and pressure comfort.[34]

- Aesthetic comfort: Color, style, garment fitting, fashion compatibility, fabric construction, and finish of clothing material satisfies visual perception. Aesthetic comfort is necessary for psychological and social comfort.[35][36][37]

- Thermal comfort: The heat dissipation efficiency of clothes transfers a "neither too hot nor too cold" feeling to the wearer. The human body remains in comfort around 30 °C.[38] Secondly clothing acts as a buffer against environmental changes and maintain a thermal balance between the heat generated by the body and the heat lost to the environment while allowing the skin to remain free of liquids released from the body such as perspiration. Thermal comfort is one major criterion of physiological needs.[39]

- Moisture comfort: The preservation from the sensation of dampness. A study Hollies infers, when more than 50–65% of the body surface is wet, it feels uncomfortable.[40][41]

- Tactile comfort: The tactile comfort is related to the friction between the clothes and the body. It is associated with smoothness, roughness, softness, and stiffness of clothing material. The degree of tactile discomfort may vary with individuals, and it may be caused by an allergy, clinging to the skin, tickling, prickling, abrasion of the skin and coolness: the fabric weight, structure, thickness. There are certain surface finishes (mechanical and chemical) which can enhance tactile comfort. For example, napped fleece sweatshirt and velvet clothes. Some of the terms that describe the tactile sensations are clingy, sticky, scratchy, prickly, soft, stiff, heavy, light and hard.[42][43]

- Pressure comfort: It is the comfort of the human body's pressure receptors' (present in skin) sensory response towards clothing. Fabric with lycra feels more comfortable because of this response and superior pressure comfort. The sensation response effected by the snug, loose, heavy, lightweight, soft, and stiff structure of the material.[44][45]

Protection

Protection in textiles refers to a large application area where the performance (of functionality) is more central than aesthetic values.

- UV protection performance in textiles,[46] There are tests to quantify the protection values from harmful Ultraviolet rays.[47]

- Flame retardant textiles.[48]

- Warer repellant performance of textiles.[49]

- Water proofness.[50]

- Cold and wind protective textiles.[50]

- Bacteria and virus protection in textiles.[51] Antiviral textiles are a further exploitation of using antimicrobial surfaces that are applicable to both natural and synthetic textiles. Exhibiting antiviral properties, these surfaces may inactivate the lipid coated viruses.[51] There are particular test methods for assessing the performance of antiviral textiles.[52]

- Bulletproof vest

See also

- Automotive textile, used in a variety of applications in the automotive industry

- Clothing insulation

- Clothtech, technical textiles for clothing and footwear applications.

- Composite materials

- Technical textile, where performance requirements can be extreme and specialized

References

- ^ a b c d Kadolph, Sara J. (1998). Textiles. Upper Saddle River, New Jersey: Bobbs-Merrill Company. pp. 9, 11, 22, 23, 25, 392, 408, 407. ISBN 978-0-13-494592-7 – via Internet Archive.

- ^ a b Collier, Billie J. (2000). Understanding textiles. Internet Archive. Upper Saddle River, New Jersey: Prentice Hall. pp. 529, 530, 531, 532, 533, 534. ISBN 978-0-13-021951-0.

- ^ Fulton, Robert E. (1988). Managing Engineering Data: Emerging Issues : Presented at the 1988 ASME International Computers in Engineering Conference and Exhibition, July 31-August 4, 1988, San Francisco, California. American Society of Mechanical Engineers. p. 120.

- ^ Kawabata, S.; Niwa, Masako (1989-01-01). "Fabric Performance in Clothing and Clothing Manufacture". The Journal of the Textile Institute. 80 (1). The Textile Institute: 19–50. doi:10.1080/00405008908659184. ISSN 0040-5000.

- ^ Sieben, Wanda Kay Alphin (1985). Economic Analysis of the Impact of Imperfect Consumer Information Regarding Performance of Textile Products. University of Minnesota. pp. 14, 21, 51.

- ^ a b Smith, Betty F. (1982). Textiles in perspective. Internet Archive. Englewood Cliffs, New Jersey: Prentice-Hall. pp. vii, 65. ISBN 978-0-13-912808-0.

- ^ a b c Wang, Lijing (2016-06-17). Performance Testing of Textiles: Methods, Technology and Applications. Woodhead Publishing. pp. 25, 19. ISBN 978-0-08-100578-1.

- ^ Shishoo, Roshan (2008-10-20). Textile Advances in the Automotive Industry. Elsevier. p. 15. ISBN 978-1-84569-504-0.

- ^ a b Collier, Billie J. (2000). Understanding textiles. Internet Archive. Upper Saddle River, New Jersey: Prentice Hall. pp. 544, 545. ISBN 978-0-13-021951-0.

- ^ Tobler-Rohr, Marion I. (2011-06-27). Handbook of Sustainable Textile Production. Elsevier. p. 224. ISBN 978-0-85709-286-1.

- ^ "Performance Textile - an overview". ScienceDirect. www.sciencedirect.com. Retrieved 2021-06-15.

- ^ Kadolph, Sara J. (1998). Textiles. Upper Saddle River, New Jersey: Bobbs-Merrill Company. pp. 9, 11. ISBN 978-0-13-494592-7 – via Internet Archive.

- ^ "Performance Textile - an overview". ScienceDirect. www.sciencedirect.com. Retrieved 2021-06-13.

- ^ Rasheed, Abher (2020), Ahmad, Sheraz; Rasheed, Abher; Nawab, Yasir (eds.), "Classification of Technical Textiles", Fibers for Technical Textiles, Topics in Mining, Metallurgy and Materials Engineering, Cham: Springer International Publishing, pp. 49–64, doi:10.1007/978-3-030-49224-3_3, ISBN 978-3-030-49224-3, retrieved 2021-06-17

- ^ a b c "Stain Resistance". Textile Information Knowlwedge Platform. Textile Centre of Excellence. 2020. Retrieved June 19, 2021.

- ^ Kadolph, Sara J. (2007). Textiles. Internet Archive. Upper Saddle River, New Jersey: Pearson Prentice Hall. p. 53. ISBN 978-0-13-118769-6.

- ^ "High Performance Fiber - an overview". www.sciencedirect.com. Retrieved 2021-06-18.

- ^ a b Paul, Roshan (2019-02-19). High Performance Technical Textiles. John Wiley & Sons. pp. 110, 121. ISBN 978-1-119-32505-5.

- ^ O'Mahony, Marie (2002). Sportstech : revolutionary fabrics, fashion and design. Internet Archive. New York, NY : Thames & Hudson. ISBN 978-0-500-51086-5.

- ^ "Carbon woven fabrics". web.archive.org. Compositesplaza. 2018-07-02. Retrieved 2021-06-17.

Carbon woven fabrics from Compositesplaza are used in the following applications:Model building, Yachts- and Boats construction, Automotive (car parts), Sporting goods, Orthopedic parts, Aviation parts, industrial Construction, Luxury items and jewelery, Motorsport parts.

{{cite web}}: CS1 maint: url-status (link) - ^ "Compressibility of carbon woven fabrics with carbon nanotubes/nanofibres grown on the fibres". Composites Science and Technology. 71 (3): 315–325. 2011-02-07. doi:10.1016/j.compscitech.2010.11.024. ISSN 0266-3538.

- ^ Bhuiyan AL (1982). Some problems encountered with degradation mechanisms of addition polymers (in Synthesis and degradation, rheology and extrusion). Berlin u.a.: Springer. ISBN 978-3-540-11774-2.

- ^ Haertsch, Emilie; Meyer, Michal (2016). "Tough Stuff". Distillations. 2 (2): 12–13. Retrieved 26 March 2018.

- ^ Statement of Hon. Grant L. Hansen, Assistant Secretary of the Air Force (Research and Development), Department of Defense Appropriations for Fiscal Year 1972, p. 612.

- ^ Kadolph, Sara J. (2007). Textiles. Internet Archive. Upper Saddle River, New Jersey: Pearson Prentice Hall. pp. 330, 331. ISBN 978-0-13-118769-6.

- ^ Bonaldi, R.R. (2018-01-01). "Functional finishes for high-performance apparel". High-Performance Apparel. Woodhead Publishing Series in Textiles. Woodhead Publishing: 129–156. doi:10.1016/B978-0-08-100904-8.00006-7. ISBN 978-0-08-100904-8.

- ^ a b c Lawrence, Carl, Editor (July 5, 2014). High Performance Textiles and Their Applications (Hardcover, eBook). Woodhead Publishing Series in Textiles (1st ed.). Woodhead Publishing. pp. 70–75, 80–82. ISBN 978-1-84569-180-6. ISBN 978-0-85709-907-5 – via Elsevier.

{{cite book}}:|first1=has generic name (help)CS1 maint: multiple names: authors list (link) - ^ Wang, Lijing (2016-06-17). Performance Testing of Textiles: Methods, Technology and Applications. Woodhead Publishing. ISBN 978-0-08-100578-1.

- ^ Institute, United States of America Standards (1968). USA Standard Performance Requirements for Textile Fabrics. The Institute.

- ^ Tortora, Phyllis G.; Collier, Billie J. (1997). Understanding textiles. Internet Archive. Upper Saddle River, New Jersey: Bobbs-Merrill Company. pp. 20, 21. ISBN 978-0-13-439225-7.

- ^ Parsons, Ken (2002-12-26). Human Thermal Environments: The Effects of Hot, Moderate, and Cold Environments on Human Health, Comfort and Performance, Second Edition. CRC Press. p. 182. ISBN 978-0-415-23792-5.

- ^ Yarborough, Portia Dalecene; Nelson, Cherilyn N. (2005). Performance of Protective Clothing: Global Needs and Emerging Markets : 8th Symposium. ASTM International. p. 27. ISBN 978-0-8031-3488-1.

- ^ Corbman, Bernard P. (1983). Textiles : fiber to fabric. Internet Archive. New York, New York: Gregg Division, McGraw-Hill. p. 542. ISBN 978-0-07-013137-8.

- ^ Song, Guowen (2011). Improving Comfort in Clothing. Woodhead Publishing. p. 22. ISBN 978-0-85709-064-5.

- ^ Song, Guowen (2011). Improving Comfort in Clothing. Woodhead Publishing. p. 440. ISBN 978-0-85709-064-5.

- ^ "Aesthetic Comfort - an overview | ScienceDirect Topics". www.sciencedirect.com. Retrieved 2021-05-30.

- ^ Lyle, Dorothy Siegert (1982). Modern textiles. Internet Archive. New York : Wiley. p. 29. ISBN 978-0-471-07805-0.

- ^ Gagge, A. P.; Stolwijk, J. A. J.; Hardy, J. D. (1967-06-01). "Comfort and thermal sensations and associated physiological responses at various ambient temperatures". Environmental Research. 1 (1): 1–20. Bibcode:1967ER......1....1G. doi:10.1016/0013-9351(67)90002-3. PMID 5614624.

- ^ Song, Guowen (2011). Improving Comfort in Clothing. Woodhead Publishing. pp. 149, 166. ISBN 978-0-85709-064-5.

- ^ Au, K.F. (2011). Advances in Knitting Technology. Woodhead Publishing. ISBN 978-1-84569-372-5.

- ^ Song, Guowen (2011). Improving Comfort in Clothing. Woodhead Publishing. pp. 167, 192, 208. ISBN 978-0-85709-064-5.

- ^ Song, Guowen (2011). Improving Comfort in Clothing. Woodhead Publishing. pp. 223, 235, 237, 427. ISBN 978-0-85709-064-5.

- ^ Das, A.; Alagirusamy, R. (2011-01-01). "Improving tactile comfort in fabrics and clothing". Improving Comfort in Clothing: 216–244. doi:10.1533/9780857090645.2.216. ISBN 978-1-84569-539-2.

- ^ Song, Guowen (2011). Improving Comfort in Clothing. Woodhead Publishing. pp. 25, 235, 432. ISBN 978-0-85709-064-5.

- ^ "Pressure Comfort - an overview | ScienceDirect Topics". www.sciencedirect.com. Retrieved 2021-05-30.

- ^ Ray, Amal; Singha, Kunal; Pandit, Pintu; Maity, Subhankar (2020-01-01). "Advanced ultraviolet protective agents for textiles and clothing". Advances in Functional and Protective Textiles: 243–260. doi:10.1016/B978-0-12-820257-9.00011-4. ISBN 978-0-12-820257-9.

- ^ Paul, Roshan (2014-10-20). Functional Finishes for Textiles: Improving Comfort, Performance and Protection. Elsevier. p. 481. ISBN 978-0-85709-845-0.

- ^ Pan, N.; Sun, G. (2011-06-21). Functional Textiles for Improved Performance, Protection and Health. Elsevier. pp. 99–125. ISBN 978-0-85709-287-8.

- ^ Mansdorf, Seymour Zack; Sager, Richard (1988). Performance of Protective Clothing: Second Symposium. ASTM International. ISBN 978-0-8031-1167-7.

- ^ a b Williams, J. T. (2009-09-29). Textiles for Cold Weather Apparel. Elsevier. p. 222. ISBN 978-1-84569-717-4.

- ^ a b Iyigundogdu, Zeynep Ustaoglu; Demir, Okan; Asutay, Ayla Burcin; Sahin, Fikrettin (2017). "Developing Novel Antimicrobial and Antiviral Textile Products". Applied Biochemistry and Biotechnology. 181 (3): 1155–1166. doi:10.1007/s12010-016-2275-5. PMC 7091037. PMID 27734286.

- ^ "A quantitative test method to assess the antiviral performance". www.iso.org. Retrieved 2021-06-14.

{{cite web}}: CS1 maint: url-status (link)