Epoxy: Difference between revisions

Reverted 3 edits by NormLambert (talk); Advert. using TW |

No edit summary |

||

| Line 45: | Line 45: | ||

Epoxy materials tend to harden somewhat more gradually, while polyester materials tend to harden quickly, particularly if a lot of catalyst is used. The chemical reactions in both cases are exothermic. Large quantities of mix will generate their own heat and greatly speed the reaction, so it usual to mix small amounts which can be used quickly. |

Epoxy materials tend to harden somewhat more gradually, while polyester materials tend to harden quickly, particularly if a lot of catalyst is used. The chemical reactions in both cases are exothermic. Large quantities of mix will generate their own heat and greatly speed the reaction, so it usual to mix small amounts which can be used quickly. |

||

While it is common to associate polyester resins and epoxy resins, their properties are sufficiently different that they are properly treated as separatedifferent materials. |

While it is common to associate polyester resins and epoxy resins, their properties are sufficiently different that they are properly treated as separatedifferent materials. Polyester resins are typically low strength unless used with a reinforcing material like glass fibre, relatively brittle unless reinforced, and have low adhesion. Epoxies, by contrast, are inherently strong, somewhat flexible and have excellent adhesion. However, polyester resins are much cheaper. |

||

Epoxy resins typically require a precise mix of two components which form a third chemical. Depending on the properties required, the ratio may be anything from 1:1 or over 10:1, but in every case they must be mixed exactly. The final product is then a precise thermo-setting plastic. Until they are mixed the two elements are relatively inert, although the 'hardeners' tend to be more chemically active and should be protected from the atmosphere and moisture. The rate of the reaction can be changed by using different hardeners, which may change the nature of the final product, or by controlling the temperature. |

Epoxy resins typically require a precise mix of two components which form a third chemical. Depending on the properties required, the ratio may be anything from 1:1 or over 10:1, but in every case they must be mixed exactly. The final product is then a precise thermo-setting plastic. Until they are mixed the two elements are relatively inert, although the 'hardeners' tend to be more chemically active and should be protected from the atmosphere and moisture. The rate of the reaction can be changed by using different hardeners, which may change the nature of the final product, or by controlling the temperature. |

||

Revision as of 14:40, 13 December 2010

Epoxy or polyepoxide is a thermosetting polymer formed from reaction of an epoxide "resin" with polyamine "hardener". Epoxy has a wide range of applications, including fiber-reinforced plastic materials and general purpose adhesives.

Chemistry

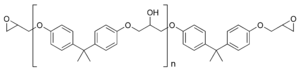

Epoxy is a copolymer; that is, it is formed from two different chemicals. These are referred to as the "resin" and the "hardener". The resin consists of monomers or short chain polymers with an epoxide group at either end. Most common epoxy resins are produced from a reaction between epichlorohydrin and bisphenol-A, though the latter may be replaced by similar chemicals. The hardener consists of polyamine monomers, for example Triethylenetetramine (TETA). When these compounds are mixed together, the amine groups react with the epoxide groups to form a covalent bond. Each NH group can react with an epoxide group, so that the resulting polymer is heavily crosslinked, and is thus rigid and strong.[1][2]

The process of polymerization is called "curing", and can be controlled through temperature and choice of resin and hardener compounds; the process can take minutes to hours. Some formulations benefit from heating during the cure period, whereas others simply require time, and ambient temperatures.

History

The first commercial attempts to prepare resins from epichlorohydrin were made in 1927 in the United States. Credit for the first synthesis of bisphenol-A-based epoxy resins is shared by Dr. Pierre Castan of Switzerland and Dr. S.O. Greenlee of the United States in 1936. Dr. Castan's work was licensed by Ciba, Ltd. of Switzerland, which went on to become one of the three major epoxy resin producers worldwide. Ciba's epoxy business was spun off and later sold in the late 1990s and is now the advanced materials business unit of Huntsman Corporation of the United States. Dr. Greenlee's work was for the firm of Devoe-Reynolds of the United States. Devoe-Reynolds, which was active in the early days of the epoxy resin industry, was sold to Shell Chemical (now Hexion, formerly Resolution Polymers and others).

Applications

The applications for epoxy-based materials are extensive and include coatings, adhesives and composite materials such as those using carbon fiber and fiberglass reinforcements (although polyester, vinyl ester, and other thermosetting resins are also used for glass-reinforced plastic). The chemistry of epoxies and the range of commercially available variations allows cure polymers to be produced with a very broad range of properties. In general, epoxies are known for their excellent adhesion, chemical and heat resistance, good-to-excellent mechanical properties and very good electrical insulating properties. Many properties of epoxies can be modified (for example silver-filled epoxies with good electrical conductivity are available, although epoxies are typically electrically insulating). Variations offering high thermal insulation, or thermal conductivity combined with high electrical resistance for electronics applications, are available.[3]

Paints and coatings

Two part epoxy coatings were developed for heavy duty service on metal substrates and use less energy than heat-cured powder coatings. These systems use a 4:1 by volume mixing ratio, and dry quickly providing a tough, UV resistant [citation needed], protective coating with excellent hardness. Their low volatility and water clean up makes them useful for factory cast iron, cast steel, cast aluminum applications and reduces exposure and flammability issues associated with solvent-borne coatings. They are usually used in industrial and automotive applications since they are more heat resistant than latex-based and alkyd-based paints. Epoxy paints tend to chaulk out due to UV exposure.

Polyester epoxies are used as powder coatings for washers, driers and other "white goods". Fusion Bonded Epoxy Powder Coatings (FBE) are extensively used for corrosion protection of steel pipes and fittings used in the oil and gas industry, potable water transmission pipelines (steel), concrete reinforcing rebar, et cetera. Epoxy coatings are also widely used as primers to improve the adhesion of automotive and marine paints especially on metal surfaces where corrosion (rusting) resistance is important. Metal cans and containers are often coated with epoxy to prevent rusting, especially for foods like tomatoes that are acidic. Epoxy resins are also used for high performance and decorative flooring applications especially terrazzo flooring, chip flooring[4] and colored aggregate flooring.[5]

Adhesives

Epoxy adhesives are a major part of the class of adhesives called "structural adhesives" or "engineering adhesives" (that includes polyurethane, acrylic, cyanoacrylate, and other chemistries.) These high-performance adhesives are used in the construction of aircraft, automobiles, bicycles, boats, golf clubs, skis, snowboards, and other applications where high strength bonds are required. Epoxy adhesives can be developed to suit almost any application. They can be used as adhesives for wood, metal, glass, stone, and some plastics. They can be made flexible or rigid, transparent or opaque/colored, fast setting or slow setting. Epoxy adhesives are better in heat and chemical resistance than other common adhesives. In general, epoxy adhesives cured with heat will be more heat- and chemical-resistant than those cured at room temperature. The strength of epoxy adhesives is degraded at temperatures above 350 °F (177 °C).[6]

Some epoxies are cured by exposure to ultraviolet light. Such epoxies are commonly used in optics, fiber optics, optoelectronics, and dentistry.[citation needed]

Industrial tooling and composites

Epoxy systems are used in industrial tooling applications to produce molds, master models, laminates, castings, fixtures, and other industrial production aids. This "plastic tooling" replaces metal, wood and other traditional materials, and generally improves the efficiency and either lowers the overall cost or shortens the lead-time for many industrial processes. Epoxies are also used in producing fiber-reinforced or composite parts. They are more expensive than polyester resins and vinyl ester resins, but usually produce stronger and more temperature-resistant composite parts.

Electrical systems and electronics

Epoxy resin formulations are important in the electronics industry, and are employed in motors, generators, transformers, switchgear, bushings, and insulators. Epoxy resins are excellent electrical insulators and protect electrical components from short circuiting, dust and moisture. In the electronics industry epoxy resins are the primary resin used in overmolding integrated circuits, transistors and hybrid circuits, and making printed circuit boards. The largest volume type of circuit board—an "FR-4 board"—is a sandwich of layers of glass cloth bonded into a composite by an epoxy resin. Epoxy resins are used to bond copper foil to circuit board substrates, and are a component of the solder mask on many circuit boards.

Flexible epoxy resins are used for potting transformers and inductors. By using vacuum impregnation on uncured epoxy, winding-to-winding, winding-to-core, and winding-to-insulator air voids are eliminated. The cured epoxy is an electrical insulator and a much better conductor of heat than air. Transformer and inductor hot spots are greatly reduced, giving the component a stable and longer life than unpotted product.

Epoxy resins are applied using the technology of resin dispensing.

Consumer and marine applications

Epoxies are sold in hardware stores, typically as a pack containing separate resin and hardener, which must be mixed immediately before use. They are also sold in boat shops as repair resins for marine applications. Epoxies typically are not used in the outer layer of a boat because they deteriorate by exposure to UV light. They are often used during boat repair and assembly, and then over-coated with conventional or two-part polyurethane paint or marine-varnishes that provide UV protection.

There are two main areas of marine use. Because of the better mechanical properties relative to the more common polyester resins, epoxies are used for commercial manufacture of components where a high strength/weight ratio is required. The second area is that their strength, gap filling properties and excellent adhesion to many materials including timber have created a boom in amateur building projects including aircraft and boats.

Normal gelcoat formulated for use with polyester resins and vinylester resins does not adhere to epoxy surfaces, though epoxy adheres very well if applied to polyester resin surfaces. "Flocoat" that is normally used to coat the interior of polyester fibreglass yachts is also compatible with epoxies.

Epoxy materials tend to harden somewhat more gradually, while polyester materials tend to harden quickly, particularly if a lot of catalyst is used. The chemical reactions in both cases are exothermic. Large quantities of mix will generate their own heat and greatly speed the reaction, so it usual to mix small amounts which can be used quickly.

While it is common to associate polyester resins and epoxy resins, their properties are sufficiently different that they are properly treated as separatedifferent materials. Polyester resins are typically low strength unless used with a reinforcing material like glass fibre, relatively brittle unless reinforced, and have low adhesion. Epoxies, by contrast, are inherently strong, somewhat flexible and have excellent adhesion. However, polyester resins are much cheaper.

Epoxy resins typically require a precise mix of two components which form a third chemical. Depending on the properties required, the ratio may be anything from 1:1 or over 10:1, but in every case they must be mixed exactly. The final product is then a precise thermo-setting plastic. Until they are mixed the two elements are relatively inert, although the 'hardeners' tend to be more chemically active and should be protected from the atmosphere and moisture. The rate of the reaction can be changed by using different hardeners, which may change the nature of the final product, or by controlling the temperature.

By contrast, polyester resins are usually made available in a 'promoted' form, such that the progress of previously-mixed resins from liquid to solid is already underway, albeit very slowly. The only variable available to the user is to change the rate of this process using a catalyst, often Methyl-Ethyl-Ketone-Peroxide (MEKP), which is very toxic. The presence of the catalyst in the final product actually detracts from the desirable properties, so that small amounts of catalyst are preferable, so long as the hardening proceeds at an acceptable pace. The rate of cure of polyesters can therefore be controlled both by the amount of catalyst and by the temperature.

As adhesives, epoxies bond in three ways: a) Mechanically, because the bonding surfaces are roughened; b) By proximity, because the cured resins are physically so close to the bonding surfaces that they are hard to separate; c) Ionically, because the epoxy resins form ionic bonds at an atomic level with the bonding surfaces. This is substantially the strongest of the three. By contrast, polyester resins can only bond using the first two of these, which greatly reduces their utility as adhesives and in marine repair.

Aerospace applications

In the aerospace industry, epoxy is used as a structural matrix material which is then reinforced by fiber. Typical fiber reinforcements include glass, carbon, Kevlar, and boron. Epoxies are also used as a structural glue. Materials like wood, and others that are 'low-tech' are glued with epoxy resin. One example would be the RJ.03 IBIS homebuilt canard aircraft. This design is based on a classic wooden lattice structured fuselage and a classic wooden spar, internally stiffened with foam and completely covered with plywood. Except for the plywood covering the wings, everything is glued with epoxy resin.

Art

Epoxy resin, mixed with pigment, is used as a painting medium, by pouring layers on top of each other to form a complete picture.[7]

Wind Energy applications

Epoxy resin is used in manufacturing the rotor blades of wind turbines. The resin is infused in the core materials, such as balsa wood or foam, and the reinforcing media, such as fabric, glass fibre or carbon fibre. The process is called VARTM, i.e. Vacuum Assisted Resin Transfer Moulding. Due to excellent properties and good finish, epoxy is the most favoured resin for composites.

Industry

As of 2006, the epoxy industry amounts to more than US$5 billion in North America and about US$15 billion worldwide. The Chinese market has been growing rapidly, and accounts for more than 30% of the total worldwide market. It is made up of approximately 50–100 manufacturers of basic or commodity epoxy resins and hardeners of which the three largest are Hexion (formerly Resolution Performance Products, formerly Shell Development Company; whose epoxy tradename is "Epon"), the Dow Chemical Company (tradename "D.E.R."), and Huntsman Corporation's Advanced Materials business unit (formerly Vantico, formerly Ciba Specialty Chemical; tradename "Araldite"). In 2007 Huntsman Corporation agreed to merge with Hexion (owned by the Apollo Group).[8][9] KUKDO Chemical is one of the largest epoxy manufacturers in Asia, and recently their capacity has been increased up to 210,000 MT/Y (Korea 150,000 MT/Y, China 60,000 MT/Y and will be increased totally 300,000 MT/Y by 2009). Nanya Plastic also has the capacity of over 250,000 MT/Y (Taiwan and China), which is mostly for captive use. There are over 50 smaller epoxy manufacturers primarily producing epoxies only regionally, epoxy hardeners only, specialty epoxies, or epoxy modifiers.

These commodity epoxy manufacturers mentioned above typically do not sell epoxy resins in a form usable to smaller end users, so there is another group of companies that purchase epoxy raw materials from the major producers and then compounds (blends, modifies, or otherwise customizes) epoxy systems from these raw materials. These companies are known as "formulators". The majority of the epoxy systems sold are produced by these formulators and they comprise over 60% of the dollar value of the epoxy market. There are hundreds of ways that these formulators can modify epoxies—by adding mineral fillers (talc, silica, alumina, etc.), by adding flexibilizers, viscosity reducers, colorants, thickeners, accelerators, adhesion promoters, etc.. These modifications are made to reduce costs, to improve performance, and to improve processing convenience. As a result a typical formulator sells dozens or even thousands of formulations—each tailored to the requirements of a particular application or market.

Impacted by the global economic slump, the epoxy market size declined to $15.8 billion in 2009, almost to the level of 2005. In some regional markets it even decreased nearly 20%. The current epoxy market is experiencing positive growth as the global economy revives. With an annual growth rate of 3.5 - 4% the epoxy market is expected to reach $17.7 billion by 2012 and $21.35 by 2015. Higher growth rate is foreseen thereafter due to stronger demands from epoxy composite market and epoxy adhesive market.[10]

Health risks

The primary risk associated with epoxy use is sensitization to the hardener, which, over time, can induce an allergic reaction. It is a main source of occupational asthma among users of plastics.[11] Bisphenol A, which is used in epoxy resin, is a known endocrine disruptor.

See also

References

- ^ "Epoxy Chemistry".

- ^ "Epoxy Polymers".

- ^ May, Clayton A. (1987-12-23). Epoxy Resins: Chemistry and Technology (Second ed.). New York: Marcel Dekker Inc. p. 794. ISBN 0824776909.

- ^ Norm Lambert. "Chips Flooring". Epoxy.com. Retrieved 2010-07-24.

- ^ Norman L. Lambert. "Quartz Flooring". Epoxy.com. Retrieved 2010-07-24.

- ^ Morena, John J (1988). Advanced Composite Mold Making. New York: Van Nostrand Reinhold Co. Inc. pp. 124–125. ISBN 9780442264147.

- ^ McCreight, Tim. Color on Metal: 50 Artists Share Insights and Techniques. Madison, WI: Guild. p. 74. ISBN 1893164063.

{{cite book}}: Unknown parameter|coauthors=ignored (|author=suggested) (help) - ^ Steve Gelsi, "Huntsman OK's $10.6 bln takeover offer from Apollo's Hexion", Market Watch, July 12, 2007.

- ^ Market Participant, "Hexion IPO Creates Way Too Much Debt", June 22, 2006.

- ^ "Market Report: World Epoxy Resin Market". Acmite Market Intelligence.

{{cite web}}: External link in|publisher= - ^ MayoClinic --> Occupational asthma May 23, 2009

External links

- Epoxy Resin health hazards (California Department of Health Services)

- The chemistry of epoxide, simple to understand