Nitric acid

| |||

| |||

| |||

| Names | |||

|---|---|---|---|

| IUPAC name

Nitric acid

| |||

| Identifiers | |||

3D model (JSmol)

|

|||

| 3DMet | |||

| ChEBI | |||

| ChemSpider | |||

| ECHA InfoCard | 100.028.832 | ||

| EC Number |

| ||

| 1576 | |||

| KEGG | |||

| MeSH | Nitric+acid | ||

PubChem CID

|

|||

| RTECS number |

| ||

| UNII | |||

| UN number | 2031 | ||

CompTox Dashboard (EPA)

|

|||

| |||

| |||

| Properties | |||

| HNO3 | |||

| Molar mass | 63.012 g·mol−1 | ||

| Appearance | Colourless liquid | ||

| Density | 1.5129 g cm-3 | ||

| Melting point | −42 °C (−44 °F; 231 K) | ||

| Boiling point | 83 °C (181 °F; 356 K) | ||

| Completely miscible | |||

| Acidity (pKa) | -1.4 | ||

Refractive index (nD)

|

1.397 (16.5 °C) | ||

| 2.17 ± 0.02 D | |||

| Hazards | |||

| NFPA 704 (fire diamond) | |||

| Flash point | Non-flammable | ||

| Related compounds | |||

Other anions

|

Nitrous acid | ||

Other cations

|

Sodium nitrate Potassium nitrate Ammonium nitrate | ||

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |||

Nitric acid (HNO3), also known as aqua fortis and spirit of nitre, is a highly corrosive and toxic strong acid.

Colorless when pure, older samples tend to acquire a yellow cast due to the accumulation of oxides of nitrogen. If the solution contains more than 86% nitric acid, it is referred to as fuming nitric acid. Fuming nitric acid is further characterized as white fuming nitric acid and red fuming nitric acid, depending on the amount of nitrogen dioxide present. At concentrations above 95% at room temperature, nitric acid tends to rapidly develop a yellow color due to decomposition. Nitric acid is also commonly used as a strong oxidizing agent.

Properties

Pure anhydrous nitric acid (100%) is a colorless mobile liquid with a density of 1.522 g/cm3 which solidifies at −42 °C to form white crystals and boils at 83 °C. When boiling in light, and slowly even at room temperature, there is a partial decomposition with the formation of nitrogen dioxide following the reaction:

- 4 HNO3 → 2 H2O + 4 NO2 + O2

Thus, anhydrous nitric acid should be stored below 0 °C to avoid decomposition. The nitrogen dioxide (NO2) remains dissolved in the nitric acid coloring it yellow, or red at higher temperatures. While the pure acid tends to give off white fumes when exposed to air, acid with dissolved nitrogen dioxide gives off reddish-brown vapors, leading to the common name "red fuming acid" or "fuming nitric acid". Fuming nitric acid is also referred to as 16 molar nitric acid. It is the most concentrated form of nitric acid at Standard Temperature and Pressure (STP).

Nitric acid is miscible with water and distillation gives a maximum-boiling azeotrope with a concentration of 68% HNO3 and a boiling temperature of 120.5 °C at 1 atm, which is the ordinary concentrated nitric acid of commerce. Two solid hydrates are known; the monohydrate (HNO3·H2O) and the trihydrate (HNO3·3H2O).

Nitrogen oxides (NOx) are soluble in nitric acid and this property influences more or less all the physical characteristics depending on the concentration of the oxides. These mainly include the vapor pressure above the liquid and the boiling temperature, as well as the color mentioned above.

Nitric acid is subject to thermal or light decomposition with increasing concentration and this may give rise to some non-negligible variations in the vapor pressure above the liquid because the nitrogen oxides produced dissolve partly or completely in the acid.

Acidic properties

Being a typical strong acid, nitric acid reacts with alkalis, basic oxides, and carbonates to form salts, such as ammonium nitrate. Due to its oxidizing nature, nitric acid generally does not donate its proton (that is, it does not liberate hydrogen) on reaction with metals and the resulting salts are usually in the higher oxidized states. For this reason, heavy corrosion can be expected and should be guarded against by the appropriate use of corrosion resistant metals or alloys.

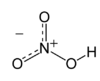

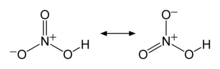

Nitric acid has an acid dissociation constant (pKa) of −1.4. In aqueous solution, it almost completely (93% at 0.1 mol/L) ionizes into the nitrate ion NO−

3 and a hydrated proton, known as a hydronium ion, H

3O+

.

- HNO

3 + H

2O ⇌ H

3O+

+ NO−

3

Oxidizing properties

Reactions with metals

Being a powerful oxidizing acid, nitric acid reacts violently with many organic materials and the reactions may be explosive. Depending on the acid concentration, temperature and the reducing agent involved, the end products can be variable. Reaction takes place with all metals except a few of the precious metal series and certain alloys. This characteristic has made it a common agent to be used in acid tests. As a general rule, oxidizing reactions occur primarily with the concentrated acid, favoring the formation of nitrogen dioxide (NO2).

- Cu + 4 H+ + 2 NO3− → Cu2+ + 2 NO2 + 2 H2O

The acidic properties tend to dominate with dilute acid, coupled with the preferential formation of nitric oxide (NO). However, when the reaction is carried out in the presence of atmospheric oxygen, the nitric oxide rapidly reacts to form brown nitrogen dioxide (NO2):

- 3 Cu + 8 HNO3 → 3 Cu(NO3)2 + 2 NO + 4 H2O

- 2 NO + O2 → 2 NO2

Since nitric acid is an oxidizing agent, hydrogen (H2) is rarely formed. Only magnesium (Mg), manganese (Mn) and calcium (Ca) react with cold, dilute nitric acid to give hydrogen:

- Mg(s) + 2 HNO3(aq) → Mg(NO3)2(aq) + H2(g)

Passivation

Although chromium (Cr), iron (Fe) and aluminium (Al) readily dissolve in dilute nitric acid, the concentrated acid forms a metal oxide layer that protects the metal from further oxidation, which is called passivation. Typical passivation concentrations range from 18% to 22% by weight.

Reactions with non-metals

Reaction with non-metallic elements, with the exceptions of nitrogen, oxygen, noble gases, silicon and halogens, usually oxidizes them to their highest oxidation states as acids with the formation of nitrogen dioxide for concentrated acid and nitric oxide for dilute acid.

- C + 4 HNO3 → CO2 + 4 NO2 + 2 H2O

or

- 3 C + 4 HNO3 → 3 CO2 + 4 NO + 2 H2O

Xanthoproteic test

Nitric acid reacts with proteins to form yellow nitrated products. This reaction is known as the xanthoproteic reaction. This test is carried out by adding concentrated nitric acid to the substance being tested, and then heating the mixture. If proteins are present that contains amino acids with aromatic rings, the mixture turns yellow. Upon adding a strong base such as liquid ammonia, the color turns orange. These color changes are caused by nitrated aromatic rings in the protein.[1][2] Xanthoproteins are formed when the acid contacts epithelial cells and are indicative of inadequate safety precautions when handling nitric acid.

Grades

The concentrated nitric acid of commerce consists of the maximum boiling azeotrope of nitric acid and water. Technical grades are normally 68% HNO3, (approx 15 molar), while reagent grades are specified at 70% HNO3. The density of concentrated nitric acid is 1.42 g/mL. An older density scale is occasionally seen, with concentrated nitric acid specified as 42° Baumé.[3]

White fuming nitric acid, also called 100% nitric acid or WFNA, is very close to anhydrous nitric acid. One specification for white fuming nitric acid is that it has a maximum of 2% water and a maximum of 0.5% dissolved NO2. Anhydrous nitric acid has a density of 1.513 g/mL and has the approximate concentration of 24 molar.

A commercial grade of fuming nitric acid, referred to in the trade as "strong nitric acid" contains 90% HNO3 and has a density of 1.50 g/mL. This grade is much used in the explosives industry. It is not as volatile nor as corrosive as the anhydrous acid and has the approximate concentration of 21.4 molar.

Red fuming nitric acid, or RFNA, contains substantial quantities of dissolved nitrogen dioxide (NO2) leaving the solution with a reddish-brown color. One formulation of RFNA specifies a minimum of 17% NO2, another specifies 13% NO2. Because of the dissolved nitrogen dioxide, the density of red fuming nitric acid is lower at 1.490 g/mL.

An inhibited fuming nitric acid (either IWFNA, or IRFNA) can be made by the addition of 0.6 to 0.7% hydrogen fluoride (HF). This fluoride is added for corrosion resistance in metal tanks. The fluoride creates a metal fluoride layer that protects the metal.

Industrial production

Nitric acid is made by reacting nitrogen dioxide (NO2) with water.

- 3 NO2 + H2O → 2 HNO3 + NO

Normally, the nitric oxide produced by the reaction is reoxidized by the oxygen in air to produce additional nitrogen dioxide.

Bubbling nitrogen dioxide through hydrogen peroxide can help to improve acid yield.

- 2 NO2 + H2O2 → 2 HNO3

Almost pure nitric acid can be made by adding sulfuric acid to a nitrate salt, and heating the mixture with an oil bath. A condenser is used to condense the nitric acid fumes that bubble out of the solution.

- 2 NaNO3 + H2SO4 → 2 HNO3 + Na2SO4

Dilute nitric acid may be concentrated by distillation up to 68% acid, which is a maximum boiling azeotrope containing 32% water. In the laboratory, further concentration involves distillation with either sulfuric acid or magnesium nitrate which act as dehydrating agents. Such distillations must be done with all-glass apparatus at reduced pressure, to prevent decomposition of the acid. Industrially, strong nitric acid is produced by dissolving additional nitrogen dioxide in 68% nitric acid in an absorption tower.[4] Dissolved nitrogen oxides are either stripped in the case of white fuming nitric acid, or remain in solution to form red fuming nitric acid. More recently, electrochemical means have been developed to produce anhydrous acid from concentrated nitric acid feedstock.[5]

Commercial grade nitric acid solutions are usually between 52% and 68% nitric acid. Production of nitric acid is via the Ostwald process, named after German chemist Wilhelm Ostwald. In this process, anhydrous ammonia is oxidized to nitric oxide, which is then reacted with oxygen in air to form nitrogen dioxide. This is subsequently absorbed in water to form nitric acid and nitric oxide. The nitric oxide is cycled back for reoxidation. By using ammonia derived from the Haber process, the final product can be produced from nitrogen, hydrogen, and oxygen which are derived from air and natural gas as the sole feedstocks.[6]

Prior to the introduction of the Haber process for the production of ammonia in 1913, nitric acid was produced using the Birkeland–Eyde process, also known as the arc process. This process is based upon the oxidation of atmospheric nitrogen by atmospheric oxygen to nitric oxide at very high temperatures. An electric arc was used to provide the high temperatures, and yields of up to 4% nitric oxide were obtained. The nitric oxide was cooled and oxidized by the remaining atmospheric oxygen to nitrogen dioxide, and this was subsequently absorbed in dilute nitric acid. The process was very energy intensive and was rapidly displaced by the Ostwald process once cheap ammonia became available.

Laboratory synthesis

In laboratory, nitric acid can be made from copper(II) nitrate or by reacting approximately equal masses of a nitrate salt with 96% sulfuric acid (H2SO4), and distilling this mixture at nitric acid's boiling point of 83 °C until only a white crystalline mass, a metal sulfate, remains in the reaction vessel. The red fuming nitric acid obtained may be converted to the white nitric acid.

- H

2SO

4 + NO−

3 → HSO−

4(s) + HNO

3(g)

The dissolved NOx are readily removed using reduced pressure at room temperature (10-30 min at 200 mmHg or 27 kPa) to give white fuming nitric acid. This procedure can also be performed under reduced pressure and temperature in one step in order to produce less nitrogen dioxide gas.[citation needed]

Uses

The main use of nitric acid is for the production of fertilizers; other important uses include the production of explosives, etching and dissolution of metals, especially as a component of aqua regia for the purification and extraction of gold, and in chemical synthesis.

Rocket fuel

Nitric acid has been used in various forms as the oxidizer in liquid-fueled rockets. These forms include red fuming nitric acid, white fuming nitric acid, mixtures with sulfuric acid, and these forms with HF inhibitor.[7] IRFNA (inhibited red fuming nitric acid) was one of 3 liquid fuel components for the BOMARC missile.[8]

Chemical reagent

In elemental analysis by ICP-MS, ICP-AES, GFAA, and Flame AA, dilute nitric acid (0.5 to 5.0 %) is used as a matrix compound for determining metal traces in solutions.[9] Ultrapure trace metal grade acid is required for such determination, because small amounts of metal ions could affect the result of the analysis.

It is also typically used in the digestion process of turbid water samples, sludge samples, solid samples as well as other types of unique samples which require elemental analysis via ICP-MS, ICP-OES, ICP-AES, GFAA and FAA. Typically these digestions use a 50% solution of the purchased HNO

3 mixed with Type 1 DI Water.[10]

In organic synthesis, nitric acid may be used to introduce the nitro group. When used with sulfuric acid, it generates the nitronium ion, which electrophilically reacts with aromatic compounds such as benzene.

Woodworking

In a low concentration (approximately 10%), nitric acid is often used to artificially age pine and maple. The color produced is a grey-gold very much like very old wax or oil finished wood (wood finishing).[11]

Other uses

A solution of nitric acid and alcohol, Nital, is used for etching of metals to reveal the microstructure.[citation needed]

Commercially available aqueous blends of 5-30% nitric acid and 15-40% phosphoric acid are commonly used for cleaning food and dairy equipment primarily to remove precipitated calcium and magnesium compounds (either deposited from the process stream or resulting from the use of hard water during production and cleaning).

Safety

Nitric acid is a powerful oxidizing agent, and the reactions of nitric acid with compounds such as cyanides, carbides, and metallic powders can be explosive. Reactions of nitric acid with many organic compounds, such as turpentine, are violent and hypergolic (i.e., self-igniting). Due to its properties it is stored away from bases and organics.

Concentrated nitric acid dyes human skin yellow due to a reaction with the keratin. These yellow stains turn orange when neutralized.[12] (See #Xanthoproteic test)

History

The first mention of nitric acid is in Pseudo-Geber´s De Inventione Veritatis, wherein it is obtained by calcining a mixture of niter, alum and blue vitriol. It was again described by Albert the Great in the 13th century and by Ramon Lull, who prepared it by heating niter and clay and called it "eau forte" (aqua fortis).[13]

Glauber devised the process still used today to obtain it, namely by heating niter with strong sulfuric acid. Its true nature was determined by Lavoisier in (1776), when he showed that it contained oxygen, whilst in 1785 Henry Cavendish determined its constitution and showed that it could be synthesized by passing a stream of electric sparks through moist air.[13]

References

- ^ Sherman, Henry Clapp (2007). Methods of Organic Analysis. READ BOOKS. p. 315. ISBN 1408628023.

- ^ Knowles, Frank (2007). A Practical Course in Agricultural Chemistry. READ BOOKS. p. 76. ISBN 1406745839.

- ^ Dean, John (1992). Lange's Handbook of Chemistry (14 ed.). McGraw-Hill. pp. 2.79–2.80. ISBN 0070161941.

- ^ Urbanski, Tadeusz (1965). Chemistry and technology of explosives. Oxford: Pergamon Press. pp. 85–86. ISBN 978-0-08-010239-9.

{{cite book}}:|access-date=requires|url=(help) - ^ US 6200456

- ^ Considine, Douglas M., ed. (1974). Chemical and process technology encyclopedia. New York: McGraw-Hill. pp. 769–72. ISBN 978-0-07-012423-3.

{{cite book}}:|access-date=requires|url=(help) - ^ Clark, John D. Ignition!. ISBN 0-8135-0725-1.

- ^ "BOMARC Summary". BILLONY.COM. Retrieved 2009-05-28.

- ^ Franson, Mary A. H., Clesceri Lenore S., Greenberg Arnold E., Eaton Andrew D., ed. (1998). Standard methods for the examination of water and wastewater (20th ed.). American Public Health Association, American Water Works Association, Water Environment Federation. ISBN 978-0-87553-235-6.

{{cite book}}:|access-date=requires|url=(help)CS1 maint: multiple names: editors list (link) - ^ EPA Method 200.8

- ^ Jewitt, Jeff (1997). Hand-applied finishes (illustrated ed.). Taunton Press. ISBN 978-1-56158-154-2. Retrieved 2009-05-28.

- ^ Paul, May (2007). "Nitric Acid". Retrieved 2009-05-28.

{{cite web}}: Unknown parameter|month=ignored (help) - ^ a b Encyclopedia Britannica 1911 edition, Nitric Acid