Smelting

This article needs additional citations for verification. (February 2008) |

This article contains weasel words: vague phrasing that often accompanies biased or unverifiable information. (February 2008) |

Smelting is a form of extractive metallurgy; its main use is to produce a metal from its ore. This includes iron extraction (for the production of steel) from iron ore, and copper extraction and other base metals from their ores. Smelting uses heat and a chemical reducing agent, commonly a fuel that is a source of carbon such as coke, or in earlier times charcoal, to change the oxidation state of the metal ore. The carbon or carbon monoxide derived from it removes oxygen from the ore to leave the metal. The carbon is thus oxidized, producing carbon dioxide and carbon monoxide. As most ores are impure, it is often necessary to use flux, such as limestone, to remove the accompanying rock gangue as slag.

Plants for the electrolytic reduction of aluminium, while not using carbon, are also generally referred to as smelters.

Smelting basics

Template:Expert-subject-multiple

Smelting involves more than just "melting the metal out of its ore". In most ores, the metal is tightly combined with other elements, such as oxygen (as an oxide) or sulfur (as a sulfide). With the exception of mercury oxide, which decomposes at about 500 °C (932 °F), these compounds will resist temperatures much higher than those that can be attained in a wood- or coal-burning furnace. Smelting therefore requires providing suitable reducing substances that will combine with those oxidizing elements, freeing the metal.

Historically, the first smelting processes used carbon (in the form of charcoal) to reduce the oxides of tin (cassiterite, SnO2), copper (cuprite, CuO) and lead (Lead(II) oxide, PbO), and eventually iron (hematite, Fe2O3) according to the overall reactions

- 2 SnO2 + 2 C → 2 Sn + 2 CO2

- 2 PbO + C → 2 Pb + CO2

- 2 CuO + C → 2 Cu + CO2

- 2 Fe2O3 + 3 C → 4 Fe + 3 CO2

In all these reactions the reducing agent was actually carbon monoxide, as the charcoal and oxides remained solid and therefore could not react directly with each other. The list above is sorted in increasing order of the temperature required for the process. It is not surprising that humans mastered the production of copper, tin, and lead several millennia before they were able to smelt iron.

The reduction may even occur at a temperature below the metal's melting point. This procedure is used in iron bloomeries, and produces a spongy mass of metal that must be processed to become a compact metal.

For tin, the primary ore was indeed the oxide SnO2 (cassiterite). For copper and lead, the primary ores were actually the sulfides, chalcocite (CuS2) and galena (PbS); these first had to be converted to oxides by roasting with air, through the overall reactions

- 2 CuS2 + 5 O2 → 2 CuO + 4 SO2

- 2 PbS + 3 O2 → 2 PbO + 2 SO2

Silver was generally found in the form of sulfides mixed with galena; it was smelted together with lead and was afterwards separated from it by cupellation.

For mercury, the main sulfide ore (cinnabar, HgS) was roasted to produce the oxide HgO, which decomposed at about 500 °C (932 °F) into oxygen and mercury. Since the metal boils at 357 °C (675 °F), it left the furnace as a (highly toxic) vapor, that was condensed in appropriate containers.

History

Template:Expert-subject-multiple

In the Old World, humans learned to smelt metals still in the prehistory, more than 8000 years ago. The discovery of the "useful" metals — copper and bronze at first, then iron a few millennia later — had an enormous impact on human society. The impact was so pervasive that scholars traditionally divide ancient history into Stone Age, Bronze Age, and Iron Age.

In the Americas, the Incas and other civilizations of the Andes had mastered the smelting of copper and bronze when the first Europeans arrived in the 16th century.[citation needed]

Tin and lead

In the Old World, the first metals smelted were tin and lead. The earliest cast lead beads known today were found in the Çatal Höyük site in Anatolia (Turkey), and were dated about 6500 BC, but it cannot be assumed that the metal was not known before.

Since the discovery happened several millennia before the invention of writing, we have no evidence about how it was made. However, tin and lead can be smelted by placing the ores in a wood fire, so it is possible that the discovery may have occurred by accident.

Although lead is a relatively common metal, its discovery had relatively little impact in the ancient world. It is too soft to be used for weapons (except possibly as sling projectiles) or for structural elements. However, being easy to cast and shape, it came to be extensively used in the classical world of Ancient Greece and Ancient Rome for piping and storage of water. It was also used as like a mortar in stone buildings, and as a writing material for commemorative plaques and curses.

Tin was much less common than lead and was only marginally harder, and had even less impact by itself.

Copper and bronze

After tin and lead, the next metal to be smelted appears to have been copper. How the discovery came about is a matter of much debate. Campfires are about 200 °C short of the temperature needed for that,[citation needed] so it has been conjectured that the first smelting of copper may have been achieved in pottery kilns. The earliest known instances in Europe and the Near East were found in Persia, dated about 6000 BC.[citation needed] The first known cast copper artifact is a mace head found in Can Hasan, Turkey and dated from 6000 to 5000 BC. The development of copper smelting in the Andes, which is believed to have been an independent of the old world, may have occurred in the same way.[citation needed].

By combining copper with tin and/or arsenic in the right proportions one obtains bronze, an alloy which is significantly harder than copper.The first copper/arsenic bronzes date of 4200 BC from Asia Minor. The Inca bronze alloys were also of this type. Arsenic is often an impurity in copper ores, so the discovery could have been made by accident; but eventually arsenic-bearing minerals were intentionally added during smelting.[citation needed]

Copper/tin bronzes, harder and more durable, were developed around 1500 BC or 3200 BC,also in Asia Minor.[citation needed]

The discovery of copper smelting and bronze manufacture had a significant impact on the history of the Old World. The metal was hard enough to make weapons, which were heavier, stronger, and more resistant to impact-related damage than their wood, bone, or stone equivalents. For several millennia, bronze was the material of choice for weapons such as swords, daggers, battle axes, spear and arrow points, as well as protective gear such as shields, helmets, shin guards, and other body armor. Bronze also supplanted stone, wood and organic materials in all sorts of tools and household utensils, such as chisels, saws, adzes, nails, shears, knives, needles and pins, jugs, pots and cauldrons, mirrors, horse harnesses, and much more.[citation needed] In turn, bronze tools brought about an increase in the quantity, quality, and complexity of manufactured products, from buildings to leather goods.[citation needed] Tin and copper also contributed to the establishment of trade networks spanning large areas of Europe and Asia, and had a major effect on the distribution of wealth among individuals and nations.[citation needed]

The process through which the smiths learned to produce copper/tin bronzes is once again a mystery. The first such bronzes were probably a lucky accident from tin contamination of copper ores, but by 2000 BC we know that tin was being mined on purpose for the production of bronze. This is amazing, given that tin is a semi-rare metal, and even a rich cassiterite ore only has 5% tin. Also it takes special skills (or special instruments) to find it and locate the richer lodes. But, whatever steps were taken to learn about tin, these were fully understood by 2000 BC.

Iron smelting

Early iron smelting

The earliest evidence to date for the bloomery smelting of iron is found at Tell Hammeh, Jordan (see also external link), and dates to 930 BC (C14 dating). However, based on the archaeological record of iron artifacts, it is clear that intentional reduction of iron metal from terrestrial ores (in the case of Hammeh a Haematite ore), must have started near the end of the Late Bronze Age (ca. 1600–1150 BC). Where and how iron smelting was discovered is widely debated, and remains uncertain due to the significant lack of production finds. Nevertheless, there is some consensus[citation needed] that iron technology originated in the Near East, perhaps in Eastern Anatolia.

In Ancient Egypt, somewhere between the Third Intermediate Period and 23rd Dynasty (ca. 1100–750 BC), there are indications of iron working. Significantly though, no evidence for the smelting of iron from ore has been attested to Egypt in any period. There is a further possibility of iron smelting and working in West Africa by 1200 BC[1]. In addition, very early instances of carbon steel were found to be in production around 2000 years before the present in northwest Tanzania, based on complex preheating principles. These discoveries are significant for the history of metallurgy.[2]

Most early processes in Europe and Africa involved smelting iron ore in a bloomery, where the temperature is kept low enough so that the iron does not melt. This produces a spongy mass of iron called a bloom, which then has to be consolidated with a hammer.

Later iron smelting

From the medieval period, the process of direct reduction in bloomeries began to be replaced by an indirect process. In this, a blast furnace was used to make pig iron, which then had to undergo a further process to make forgeable bar iron. Processes for the second stage include fining in a finery forge and from the Industrial Revolution puddling. However both processes are now obsolete, and wrought iron is now hardly made. Instead, mild steel is produced from a bessemer converter or by other means.

Base metals

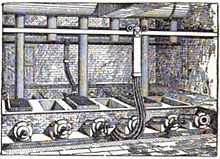

The ores of base metals are often sulfides. In recent centuries, reverberatory smelters (sometimes called cupolas) have been used. These keep the fuel and the charge being smelted separate. Traditionally these were used for carrying out the first step: formation of two liquids, one an oxide slag containing most of the impurity elements, and the other a sulfide matte containing the valuable metal sulfide and some impurities. Such "reverb" furnaces are today about 40 m long, 3 m high and 10 m wide. Fuel is burned at one end and the heat melts the dry sulfide concentrates (usually after partial roasting), which is fed through the openings in the roof of the furnace. The slag floats on top of the heavier matte, and is removed and discarded or recycled. The sulfide matte is then sent to the converter. However the precise details of the process will vary for one metal to another.

See also

- Blast furnace

- Bloomery

- Cast iron

- Clinker (waste)

- Copper extraction

- Furnace

- Iron Age

- Metallurgy

- Pyrometallurgy

- Slag

- Wrought iron

- Zinc smelting

References

- ^ How Old is the Iron Age in Sub-Saharan Africa? - by Roderick J. McIntosh, Archaeological Institute of America (1999)

- ^ Peter Schmidt, Donald H. Avery. Complex Iron Smelting and Prehistoric Culture in Tanzania, Science 22 September 1978: Vol. 201. no. 4361, pp. 1085 - 1089

- ^ Minet, Adolphe (1905). The Production of Aluminum and Its Industrial Use. Leonard

Waldo (translator, additions). New York, London: John Wiley and Sons, Chapman & Hall, via Google Books scan of University of Wisconsin - Madison copy. pp. 244 (Minet speaking) +116 (Héroult speaking). Retrieved 2007-10-28.

{{cite book}}: line feed character in|others=at position 8 (help)

Bibliography

- Pleiner, R. (2000) Iron in Archaeology. The European Bloomery Smelters, Praha, Archeologický Ústav Av Cr.

- Veldhuijzen, H.A. (2005) Technical Ceramics in Early Iron Smelting. The Role of Ceramics in the Early First Millennium Bc Iron Production at Tell Hammeh (Az-Zarqa), Jordan. In: Prudêncio, I.Dias, I. and Waerenborgh, J.C. (Eds.) Understanding People through Their Pottery; Proceedings of the 7th European Meeting on Ancient Ceramics (Emac '03). Lisboa, Instituto Português de Arqueologia (IPA).

- Veldhuijzen, H.A. and Rehren, Th. (2006) Iron Smelting Slag Formation at Tell Hammeh (Az-Zarqa), Jordan. In: Pérez-Arantegui, J. (Ed.) Proceedings of the 34th International Symposium on Archaeometry, Zaragoza, 3-7 May 2004. Zaragoza, Institución «Fernando el Católico» (C.S.I.C.) Excma. Diputación de Zaragoza.