Electrical ballast

An electrical ballast (sometimes called control gear) is a device intended to control the amount of current flowing in an electric circuit.

Ballasts vary greatly in complexity. They can be as simple as a series resistor as commonly used with small neon lamps. For higher-power installations, too much energy would be wasted in a resistive ballast, so alternatives are used that depend upon the reactance of inductors, capacitors, or both. Finally, ballasts can be as complex as the computerized, remote-controlled electronic ballasts used with fluorescent lamps.

Necessity for current limiting

Ballasts are most commonly needed when an electrical circuit or device presents a negative resistance to the supply. If such a device were connected to a constant-voltage power supply, it would draw an ever-increasing amount of current until it was destroyed or caused the power supply to fail. To prevent this, a ballast provides a positive resistance or reactance that limits the ultimate flow of current to an appropriate level. In this way, the 'ballast' provides for the proper operation of the negative resistance device. Examples of such negative-resistance devices are gas discharge tubes and lamps.

Ballasts can also be used simply to deliberately reduce the current flow in an ordinary, positive-resistance circuit. Prior to the advent of solid-state ignition, automobile ignition systems commonly included a ballast resistor to regulate the voltage applied to the ignition system.

Resistors

The term ballast resistor primarily refers to a resistor which compensates for normal or incidental changes in the physical state of a system. It may be a fixed or variable resistor.

Fixed resistors

For simple, low-powered loads such as a neon lamp, a fixed resistor is commonly used. Because the resistance of the ballast resistor is large it dominates the flow of current in the circuit even in the face of negative resistance introduced by the lamp.

The term also refers to an automobile engine component that lowers the supply voltage to the ignition system after the engine has been started. Because cranking the engine causes a very heavy load on the battery, the system voltage can drop quite low during cranking. To allow the engine to start, the ignition system must be designed to operate on this lower voltage. But once cranking is completed, the normal operating voltage is regained; this voltage would overload the ignition system. To avoid this problem, a ballast resistor is inserted in series with the supply voltage feeding the ignition system. Occasionally, this ballast resistor will fail and the classic symptom of this failure is that the engine runs while being cranked (while the resistor is bypassed) but stalls immediately when cranking ceases (and the resistor is reinserted in the circuit).

Modern electronic ignition systems do not require a ballast resistor as they are flexible enough to operate on the low cranking voltage or the ordinary operating voltage.

In old AC/DC receivers, the vacuum tube filaments are connected in series. Since the voltage drop across all the filaments in series may be less than the full 117 volts from house's line voltage, it was necessary to get rid of the excess voltage. The resistive component use for this purpose was often referred to as a ballast resistor.

Self-variable resistors

Some ballast resistors have the property of increasing in resistance as current flowing through them increases, and decreasing in resistance as current decreases. Physically, some such devices are often built quite like incandescent lamps. Like the tungsten filament of an ordinary incandescent lamp, if current increases, the ballast resistor gets hotter, its resistance goes up, and its voltage drop increases. If voltage decreases, the ballast resistor gets colder, its resistance drops, and the voltage drop decreases. Therefore the ballast resistor tends to maintain a constant current flowing through it, despite variations in applied voltage or changes in the rest of an electric circuit. These devices are sometimes termed barretters.

This property can lead to more-precise current control than merely choosing an appropriate fixed resistor. The power lost in the resistive ballast is also minimized because a smaller portion of the overall power is dropped in the ballast compared to what might be required with a fixed resistor.

In times past, household clothes dryers sometimes incorporated a germicidal lamp in series with an ordinary incandescent lamp; the incandescent lamp operated as the ballast for the germicidal lamp. For the same reason, certain older designs of mercury-vapor lamps also incorporated ordinary tungsten filaments within the overall envelope of the lamp.

Reactive ballasts

Because of the power that would be lost, resistors are not used as ballasts for lamps of more than a watt or two. Instead, a reactance is used. In an ideal or theoretically perfect reactance, no power would be lost while limiting the current flow; realistically, losses due to resistance can only be minimized, not eliminated entirely.

An inductor is very common in line-frequency ballasts to provide the proper starting and operating electrical condition to power a fluorescent lamp, neon lamp, or high intensity discharge (HID) lamp. (Because of the use of the inductor, such ballasts are usually called magnetic ballasts.) The inductor has two benefits:

- Its reactance limits the power available to the lamp with only minimal power losses in the inductor

- The voltage spike produced when current through the inductor is rapidly interrupted is used in some circuits to first strike the arc in the lamp.

A disadvantage of the inductor is that current is shifted out of phase with the voltage, producing a poor power factor. In more expensive ballasts, a capacitor is often teamed up with the inductor to correct the power factor. In ballasts that control two or more lamps, line-frequency ballasts commonly use different phase relationships between the multiple lamps. This not only mitigates the flicker of the individual lamps, it also helps maintain a high power factor. These ballasts are often called lead-lag ballasts because the current in one lamp leads the mains phase and the current in the other lamp lags the mains phase.

In most parts of the world, the mains voltage is sufficient to strike and maintain an arc in the lamp. In the USA, the mains voltage is not sufficient for the larger lamps so an autotransformer is used to step-up the voltage. The autotransformer is designed with enough leakage inductance so that the flow of current is appropriately limited.

Because of the large inductors and capacitors that must be used, reactive ballasts operated at line frequency tend to be large and heavy. They commonly also produce acoustic noise (line-frequency hum).

Prior to 1980 in the United States, PCB-based oils were used as dielectric in capacitors contained in many ballasts. (see transformer oil).

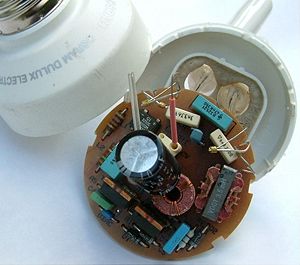

Electronic 'ballasts'

An electronic lamp ballast uses solid state electronic circuitry to provide the proper starting and operating electrical condition to power one or more fluorescent lamps and more recently HID lamps. Electronic ballasts usually change the frequency of the power from the standard mains frequency to 20,000 Hz or higher, substantially eliminating the stroboscopic effect of flicker (100 or 120 Hz, twice the line frequency) associated with fluorescent lighting (see photosensitive epilepsy). In addition, because more gas remains ionized in the arc stream, the lamps actually operate at about 9% higher efficiency above approximately 10KHz. Lamp efficacy increases sharply to about 10KHz and continues to improve until approximately 20KHz*(IES Lighting Handbook 1984). Because of the high frequency of operation, electronic ballasts are generally smaller, lighter, and more efficient (and thus run cooler) than line frequency magnetic ballasts.

In addition, the higher operating frequency means that it is often practical to use a capacitor as the current-limiting reactance rather than the inductor required at line frequencies. Capacitors tend to be much lower-loss devices than inductors, allowing them to more-closely approach an "ideal reactance".

Electronic ballasts are often based on inverter/converter style switched-mode power supplies, first rectifying the input power and then chopping it at a high frequency. Advanced electronic ballasts may allow dimming via pulse-width modulation and remote control and monitoring via networks such as LonWorks, DALI, DSI or simple analog control using a 0-10V DC brightness control signal.

There are three starting methods available for electronic ballasts:

Instant Start

Starts lamps without heating the cathodes at all by using a high voltage (around 600V). It is the most energy efficient type, but gives the least number of starts from a lamp as emissive oxides are blasted from the cold cathode surfaces each time the lamp is started. This is the best type for installations where lamps are not turned on and off very often.

Rapid Start

Applies voltage and heats the cathodes simultaneously. Provides superior lamp life and more cycle life, but uses slightly more energy as the cathodes in each end of the lamp continue to consume heating power as the lamp operates.

Programmed Start

More advanced version of rapid start. Applies cathode power first, then after a short delay to allow the cathodes to preheat, applies voltage to the lamps to strike an arc. Gives the best life and most starts from lamps. This is the preferred type of ballast for applications with very frequent power cycling such as vision examination rooms and restrooms with a motion detector switch.