Separation process: Difference between revisions

ClueBot NG (talk | contribs) m Reverting possible vandalism by 204.154.122.42 to version by Mild Bill Hiccup. False positive? Report it. Thanks, ClueBot NG. (1788743) (Bot) |

awesome Tag: repeating characters |

||

| Line 1: | Line 1: | ||

{{non-free|date=July 2012}} |

{{non-free|date=July 2012}} YOU DUM DON'T READ!!!!!!!!! |

||

{{Chemical engineering}} |

{{Chemical engineering}} |

||

In [[chemistry]] and [[chemical engineering]], a '''separation process''', or simply a '''separation''', is any [[mass transfer]] process that converts a [[mixture]] of substances into two or more distinct product mixtures, at least one of which is enriched in one or more of the mixture's constituents. In some cases, a separation may fully divide the mixture into its pure constituents. Separations are carried out based on differences in chemical properties, or physical properties such as size, shape, mass, density, or chemical affinity, between the constituents of a mixture, and are often classified according to the particular differences they use to achieve separation. In the case that no single difference can be used to accomplish a desired separation, multiple processes will often be performed in combination to achieve the desired end. |

In [[chemistry]] and [[chemical engineering]], a '''separation process''', or simply a '''separation''', is any [[mass transfer]] process that converts a [[mixture]] of substances into two or more distinct product mixtures, at least one of which is enriched in one or more of the mixture's constituents. In some cases, a separation may fully divide the mixture into its pure constituents. Separations are carried out based on differences in chemical properties, or physical properties such as size, shape, mass, density, or chemical affinity, between the constituents of a mixture, and are often classified according to the particular differences they use to achieve separation. In the case that no single difference can be used to accomplish a desired separation, multiple processes will often be performed in combination to achieve the desired end. |

||

Revision as of 17:54, 10 April 2014

This article may contain improper use of non-free material. (July 2012) |

YOU DUM DON'T READ!!!!!!!!!

| Part of a series on |

| Chemical engineering |

|---|

| Fundamentals |

| Unit processes |

| Aspects |

| Glossaries |

|

|

|

In chemistry and chemical engineering, a separation process, or simply a separation, is any mass transfer process that converts a mixture of substances into two or more distinct product mixtures, at least one of which is enriched in one or more of the mixture's constituents. In some cases, a separation may fully divide the mixture into its pure constituents. Separations are carried out based on differences in chemical properties, or physical properties such as size, shape, mass, density, or chemical affinity, between the constituents of a mixture, and are often classified according to the particular differences they use to achieve separation. In the case that no single difference can be used to accomplish a desired separation, multiple processes will often be performed in combination to achieve the desired end.

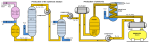

Barring a few exceptions, almost every element or compound is naturally found in an impure state. Often these impure raw materials must be separated into their purified components before they can be put to productive use, making separation processes essential for the modern industrial economy. In some cases, these separations require total purification, as in the electrolysis refining of bauxite ore for aluminum metal, but a good example of an incomplete separation process is oil refining. Crude oil occurs naturally as a mixture of various hydrocarbons and impurities. The refining process splits this mixture into other, more valuable mixtures such as natural gas, gasoline and chemical feedstocks, none of which are pure substances, but each of which must be separated from the raw crude. In both of these cases, a series of separations is necessary to obtain the desired end products. In the case of oil refining, crude is subjected to a long series of individual distillation steps, each of which produces a different product or intermediate.

This article discusses separation processes of any scale that completely or partially separate components of a mixture from each other (which may be referred to as fractions) usually without substantial chemical modification.[1] The purpose of such a separation may be analytical, i.e. to help analyze components in the original mixture without any attempt to save the fractions, or may be preparative, i.e. to "prepare" fractions or samples of the components that can be saved. The separation can be done on a small scale, effectively a laboratory scale for analytical or preparative purposes, or on a large scale, effectively an industrial scale for preparative purposes, or on some intermediate scale.

Chromatography

In paper chromatography, the movement of each substance in the mixture depends on two factors: solubility of the substance in the solvent and absorption of the substance on the filter paper. The substance moves with the solvent easily if the substance is very soluble in the solvent, and some solids can attract other substances and hold them on their surface. This is called adsorption, and such solids are called adsorbents. The substance does not move with the solvent easily if the substance in the mixture is strongly absorbed by the filter paper. Since neither substance has the same adsorption and solubility, each travels a different distance along the filter paper—and the two separate.

Substances separated by chromatography need not be colored. Colorless substances can be made visible by spraying the paper with a locating agent that reacts with the colorless substances to produce a color. Labs use chromatography to identify the substances in a mixture. Hospital labs, for example, use the technique to determine if a patient has diabetes by identifying sugar in urine. Chromatography also identifies dyes used in food.

List of separation processes

- Adsorption, adhesion of atoms, ions or molecules of gas, liquid, or dissolved solids to a surface

- Centrifugation and cyclonic separation, separates based on density differences

- Chromatography separates dissolved substances by different interaction with (i.e., travel through) a material

- Crystallization

- Decantation

- Demister (vapor), removes liquid droplets from gas streams

- Distillation, used for mixtures of liquids with different boiling points

- Drying, removes liquid from a solid by vaporisation

- Electrophoresis, separates organic molecules based on their different interaction with a gel under an electric potential (i.e., different travel)

- Elutriation

- Evaporation

- Extraction

- Flotation

- Dissolved air flotation, removes suspended solids non-selectively from slurry by bubbles that are generated by air coming out of solution

- Froth flotation, recovers valuable, hydrophobic solids by attachment to air bubbles generated by mechanical agitation of an air-slurry mixture, which float, and are recovered

- Deinking, separating hydrophobic ink particles from hydrophilic paper pulp in paper recycling

- Flocculation, separates a solid from a liquid in a colloid, by use of a flocculant, which promotes the solid clumping into flocs

- Filtration – Mesh, bag and paper filters are used to remove large particulates suspended in fluids (e.g., fly ash) while membrane processes including microfiltration, ultrafiltration, nanofiltration, reverse osmosis, dialysis (biochemistry) utilising synthetic membranes, separates micrometre-sized or smaller species

- Fractional distillation

- Fractional freezing

- Oil-water separation, gravimetrically separates suspended oil droplets from waste water in oil refineries, petrochemical and chemical plants, natural gas processing plants and similar industries

- Magnetic separation

- Precipitation

- Recrystallization

- Sedimentation, separates using vocal density pressure differences

- Sieving

- Stripping

- Sublimation

- Vapor-liquid separation, separates by gravity, based on the Souders-Brown equation

- Winnowing

- Zone refining

See also

References

- ^ Wilson, Ian D.; Adlard, Edward R.; Cooke, Michael; Poole, Colin F., eds. (2000). Encyclopedia of separation science. San Diego: Academic Press. ISBN 978-0-12-226770-3.

External links

- Separation of Mixtures Using Different Techniques, instructions for performing classroom experiments

- Separation of Components of a Mixture, instructions for performing classroom experiments