SCADA: Difference between revisions

m Reverted edits by 89.138.164.58 (talk) to last version by 213.6.193.238 |

|||

| Line 35: | Line 35: | ||

== Hardware solutions == |

== Hardware solutions == |

||

SCADA solutions often have [[Distributed Control System]] (DCS) components. Use of "smart" [[RTU]]s or PLCs, which are capable of autonomously executing simple logic processes without involving the master computer, is increasing. A functional block programming language, [[IEC 61131-3]], is frequently used to create programs which run on these RTUs and PLCs. Unlike a procedural language such as the [[C (programming language)|C programming language]] or [[FORTRAN]], IEC 61131-3 has minimal training requirements by virtue of resembling historic physical control arrays. This allows SCADA system engineers to perform both the design and implementation of a program to be executed on a RTU or PLC. |

SCADA solutions often have [[Distributed Control System]] (DCS) components. Use of "smart" [[RTU]]s or PLCs, which are capable of autonomously executing simple logic processes without involving the master computer, is increasing. A functional block programming language, [[IEC 61131-3]], is frequently used to create programs which run on these RTUs and PLCs. Unlike a procedural language such as the [[C (programming language)|C programming language]] or [[FORTRAN]], IEC 61131-3 has minimal training requirements by virtue of resembling historic physical control arrays. This allows SCADA system engineers to perform both the design and implementation of a program to be executed on a RTU or PLC. WS500 is a software which are using in Ha Noi's Scada system. |

||

== System components == |

== System components == |

||

Revision as of 07:04, 19 September 2007

SCADA is the acronym for Supervisory Control And Data Acquisition. The term is used differently in North America than in the rest of the world:

- In North America; SCADA refers to a large-scale, distributed measurement and control system.

- In the rest of the world; SCADA is any system that performs Supervisory Control And Data Acquisition, independent of its size or geographical distribution.

SCADA systems are typically used to perform data collection and control at the supervisory level. Some SCADA systems only monitor without doing control, these systems are still referred to as SCADA systems.

The supervisory control system is a system that is placed on top of a real-time control system to control a process that is external to the SCADA system (i.e. a computer, by itself, is not a SCADA system even though it controls its own power consumption and cooling). This implies that the system is not critical to control the process in real-time, as there is a separate or integrated real-time automated control system that can respond quickly enough to compensate for process changes within the time-constants of the process. The process can be industrial, infrastructure or facility based as described below:

- Industrial processes include: manufacturing/production/power generation/fabrication/refining - continuous, batch, repetitive or discrete.

- Infrastructure processes may be public or private and include: water treatment and distribution, wastewater collection and wastewater treatment, oil & gas pipelines, electrical power transmission and distribution and large communication systems.

- Facility processes in private or public facilities including: buildings, airports, ships or space stations in order to monitor and control: HVAC, access control, energy consumption management

The SCADA systems for these applications all perform Supervisory Control And Data Acquisition, even though the use of the systems are very different.

Systems concepts

A SCADA system includes input/output signal hardware, controllers, HMI, networks, communication, database and software. It mainly comes in the branch of Instrumentation Engineering.

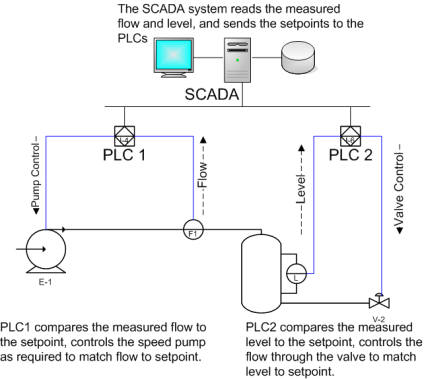

The term SCADA usually refers to a central system that monitors and controls a complete site or a system spread out over a long distance (kilometres/miles). The bulk of the site control is actually performed automatically by a Remote Terminal Unit (RTU) or by a Programmable Logic Controller (PLC). Host control functions are almost always restricted to basic site over-ride or supervisory level capability. For example, a PLC may control the flow of cooling water through part of an industrial process, but the SCADA system may allow an operator to change the control set point for the flow, and will allow any alarm conditions such as loss of flow or high temperature to be recorded and displayed. The feedback control loop is closed through the RTU or PLC; the SCADA system monitors the overall performance of that loop.

Data acquisition begins at the RTU or PLC level and includes meter readings and equipment statuses that are communicated to SCADA as required. Data is then compiled and formatted in such a way that a control room operator using the HMI can make appropriate supervisory decisions that may be required to adjust or over-ride normal RTU (PLC) controls. Data may also be collected in to a Historian, often built on a commodity Database Management System, to allow trending and other analytical work.

SCADA systems typically implement a distributed database, commonly referred to as a tag database, which contains data elements called tags or points. A point represents a single input or output value monitored or controlled by the system. Points can be either "hard" or "soft". A hard point is representative of an actual input or output connected to the system, while a soft point represents the result of logic and math operations applied to other hard and soft points. Most implementations conceptually remove this distinction by making every property a "soft" point (expression) that can equal a single "hard" point in the simplest case. Point values are normally stored as value-timestamp combinations; the value and the timestamp when the value was recorded or calculated. A series of value-timestamp combinations is the history of that point. It's also common to store additional metadata with tags such as: path to field device and PLC register, design time comments, and even alarm information.

It is possible to purchase a SCADA system or Distributed Control System (DCS) from a single supplier. It is more common to assemble a SCADA system from hardware and software components like ABB, Allen-Bradley, DirectLOGIC, GE Fanuc, Schneider Electric, or Siemens PLCs, along with related HMI packages from Adroit, Citect, GE Fanuc,Honeywell, ICONICS, Inductive Automation, Rockwell Automation, Schneider Electric, SUPCON, Telvent, or Wonderware.

Human Machine Interface

A Human-Machine Interface or HMI is the apparatus which presents process data to a human operator, and through which the human operator controls the process.

The HMI industry was essentially born out of a need for a standardized way to monitor and to control multiple remote controllers, PLCs and other control devices. While a PLC does provide automated, pre-programmed control over a process, they are usually distributed across a plant, making it difficult to gather data from them manually. Historically PLCs had no standardized way to present information to an operator. The SCADA system gathers information from the PLCs and other controllers via some form of network, and combines and formats the information. An HMI may also be linked to a database, to provide trending, diagnostic data, and management information such as scheduled maintenance procedures, logistic information, detailed schematics for a particular sensor or machine, and expert-system troubleshooting guides. Since about 1998, virtually all major PLC manufacturers have offered integrated HMI/SCADA systems, many of them using open and non-proprietary communications protocols. Numerous specialized third-party HMI/SCADA packages, offering built-in compatibility with most major PLCs, have also entered the market, allowing mechanical engineers, electrical engineers and technicians to configure HMIs themselves, without the need for a custom-made program written by a software developer.

SCADA is popular, due to its compatibility and reliability. It is used in small applications, like controlling the temperature of a room, to large applications, such as the control of nuclear power plants.

Hardware solutions

SCADA solutions often have Distributed Control System (DCS) components. Use of "smart" RTUs or PLCs, which are capable of autonomously executing simple logic processes without involving the master computer, is increasing. A functional block programming language, IEC 61131-3, is frequently used to create programs which run on these RTUs and PLCs. Unlike a procedural language such as the C programming language or FORTRAN, IEC 61131-3 has minimal training requirements by virtue of resembling historic physical control arrays. This allows SCADA system engineers to perform both the design and implementation of a program to be executed on a RTU or PLC. WS500 is a software which are using in Ha Noi's Scada system.

System components

The three components of a SCADA system are:

- Multiple Remote Terminal Units (also known as RTUs or Outstations).

- Master Station and HMI Computer(s).

- Communication infrastructure

Remote Terminal Unit (RTU)

The RTU connects to physical equipment, and reads status data such as the open/closed status from a switch or a valve, reads measurements such as pressure, flow, voltage or current. By sending signals to equipment the RTU can control equipment, such as opening or closing a switch or a valve, or setting the speed of a pump.

The RTU can read digital status data or analog measurement data, and send out digital commands or analog setpoints.

An important part of most SCADA implementations are alarms. An alarm is a digital status point that has either the value NORMAL or ALARM. Alarms can be created in such a way that when their requirements are met, they are activated. An example of an alarm is the "fuel tank empty" light in a car. The SCADA operator's attention is drawn to the part of the system requiring attention by the alarm. Emails and text messages are often sent along with an alarm activation alerting managers along with the SCADA operator.

Master Station

The term "Master Station" refers to the servers and software responsible for communicating with the field equipment (RTUs, PLCs, etc), and then to the HMI software running on workstations in the control room, or elsewhere. In smaller SCADA systems, the master station may be composed of a single PC. In larger SCADA systems, the master station may include multiple servers, distributed software applications, and disaster recovery sites

The SCADA system usually presents the information to the operating personnel graphically, in the form of a mimic diagram. This means that the operator can see a schematic representation of the plant being controlled. For example, a picture of a pump connected to a pipe can show the operator that the pump is running and how much fluid it is pumping through the pipe at the moment. The operator can then switch the pump off. The HMI software will show the flow rate of the fluid in the pipe decrease in real time. Mimic diagrams may consist of line graphics and schematic symbols to represent process elements, or may consist of digital photographs of the process equipment overlain with animated symbols.

The HMI package for the SCADA system typically includes a drawing program that the operators or system maintenance personnel use to change the way these points are represented in the interface. These representations can be as simple as an on-screen traffic light, which represents the state of an actual traffic light in the field, or as complex as a multi-projector display representing the position of all of the elevators in a skyscraper or all of the trains on a railway. Initially, more "open" platforms such as Linux were not as widely used due to the highly dynamic development environment and because a SCADA customer that was able to afford the field hardware and devices to be controlled could usually also purchase UNIX or OpenVMS licenses. Today, all major operating systems are used for both master station servers and HMI workstations.

Operational philosophy

Instead of relying on operator intervention, or master station automation, RTUs may now be required to operate on their own to control tunnel fires or perform other safety-related tasks. The master station software is required to do more analysis of data before presenting it to operators including historical analysis and analysis associated with particular industry requirements. Safety requirements are now being applied to the system as a whole and even master station software must meet stringent safety standards for some markets.

For some installations, the costs that would result from the control system failing is extremely high. Possibly even lives could be lost. Hardware for SCADA systems is generally ruggedized to withstand temperature, vibration, and voltage extremes, but in these installations reliability is enhanced by having redundant hardware and communications channels. A failing part can be quickly identified and its functionality automatically taken over by backup hardware. A failed part can often be replaced without interrupting the process. The reliability of such systems can be calculated statistically and is stated as the mean time to failure, which is a variant of mean time between failures. The calculated mean time to failure of such high reliability systems can be in the centuries.

Communication infrastructure and methods

SCADA systems have traditionally used combinations of radio and direct serial or modem connections to meet communication requirements, although Ethernet and IP over SONET is also frequently used at large sites such as railways and power stations.

This has also come under threat with some customers wanting SCADA data to travel over their pre-established corporate networks or to share the network with other applications. The legacy of the early low-bandwidth protocols remains, though. SCADA protocols are designed to be very compact and many are designed to send information to the master station only when the master station polls the RTU. Typical legacy SCADA protocols include Modbus, RP-570 and Conitel. These communication protocols are all SCADA-vendor specific. Standard protocols are IEC 60870-5-101 or 104, Profibus and DNP3. These communication protocols are standardized and recognized by all major SCADA vendors. Many of these protocols now contain extensions to operate over TCP/IP, although it is good security engineering practice to avoid connecting SCADA systems to the Internet so the attack surface is reduced.

RTUs and other automatic controller devices were being developed before the advent of industry wide standards for interoperability. The result is that developers and their management created a multitude of control protocols. Among the larger vendors, there was also the incentive to create their own protocol to "lock in" their customer base. A list of automation protocols is being compiled here.

In latest days, the OPC or "OLE for Process Control" has become a wide an accepted solution for intercomunicating differente hardware and software, allowing communication even between devices originally not intended to be part of an industrial network.

There are also other protocols like Modbus TCP/IP that became widely accepted and are now the standard for many hardware manufacturers.

Future trends in SCADA

The trend is for PLC and HMI/SCADA software to be more "mix-and-match". In the mid 1990s, the typical DAQ I/O manufacturer offered their own proprietary communications protocols over a suitable-distance carrier like RS-485. Towards the late 1990s, the shift towards open communications continued with I/O manufacturers offering support of open message structures like Modicon MODBUS over RS-485, and by 2000 most I/O makers offered completely open interfacing such as Modicon MODBUS over TCP/IP. The primary barriers of Ethernet TCP/IP's entrance into industrial automation (determinism, synchronization, protocol selection, environment suitability) are still a concern to a few extremely specialized applications, but for the vast majority of HMI/SCADA markets these barriers have been broken.

Security issues

Recently, the security of SCADA-based systems has come into question as they are increasingly seen as extremely vulnerable to cyberwarfare/cyberterrorism attacks on several fronts.[1] [2]

In particular, security researchers are concerned about:

- the lack of concern about security and authentication in the design, deployment and operation of existing SCADA networks

- the mistaken belief that SCADA systems have the benefit of security by obscurity through the use of specialized protocols and proprietary interfaces

- the mistaken belief that SCADA networks are secure because they are supposedly physically secured

- the mistaken belief that SCADA networks are secure because they are supposedly disconnected from the Internet

Due to the mission-critical nature of a large number of SCADA systems, such attacks could, in a worst case scenario, cause massive financial losses through loss of data or actual physical destruction, misuse or theft, even loss of life, either directly or indirectly. Whether such concerns will cause a move away from the use of existing SCADA systems for mission-critical applications towards more secure architectures and configurations remains to be seen, given that at least some influential people in corporate and governmental circles believe that the benefits and lower initial costs of SCADA based systems still outweigh potential costs and risks.[citation needed] Recently, multiple security vendors, such as Check Point and Innominate, have begun to address these risks by developing lines of specialized industrial firewall and VPN solutions for TCP/IP-based SCADA networks.

References

- ^ D. Maynor and R. Graham. "SCADA Security and Terrorism: We're Not Crying Wolf" (PDF).

- ^ Robert Lemos (2006-07-26). "SCADA system makers pushed toward security". SecurityFocus. Retrieved 2007-05-09.