Fluorinated ethylene propylene

| FEP | |

|---|---|

| |

| Density[1] | 2150 kg/m3 |

| Flexural modulus(E) | 586 MPa |

| Tensile strength(t) | 23 MPa |

| Elongation @ break | 325% |

| Folding endurance | Varies |

| Notch test | |

| Melting point | 260 °C |

| Maximum operating | |

| temperature | 204 °C |

| Water absorption (ASTM) | <0.01 % after 24 hours |

| Dielectric constant (Dk) | |

| at 1MHz | 2.1 |

| Dissipation factor | |

| at 1MHz | 0.0007 |

| Arc resistance | < 300 seconds |

| Resistivity at 50% R.H. | > 1016 Ω m |

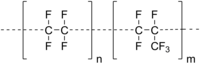

Fluorinated ethylene propylene or FEP is a copolymer of hexafluoropropylene and tetrafluoroethylene. It differs from the PTFE (polytetrafluoroethylene) resins in that it is melt-processable using conventional injection molding and screw extrusion techniques.[2] Fluorinated ethylene propylene was invented by DuPont and is sold under the brandname Teflon FEP. Other brandnames are Neoflon FEP from Daikin or Dyneon FEP from Dyneon/3M.

FEP is very similar in composition to the fluoropolymers PTFE (polytetrafluoroethylene) and PFA (perfluoroalkoxy polymer resin). FEP and PFA both share PTFE's useful properties of low friction and non-reactivity, but are more easily formable. FEP is softer than PTFE and melts at 260 °C; it is highly transparent and resistant to sunlight.[3][4]

Production

FEP is produced by free-radical polymerization of mixtures of tetrafluoroethylene and hexafluoropropylene. The mixture is biased to compensate for the relatively low reactivity of the propylene component. The process is typically initiated with peroxydisulfate, which homolyzes to generate sulfate radicals. Because FEP is poorly soluble in almost all solvents, the polymerization is conducted as an emulsion in water, often using a surfactant such as PFOS. The polymer contains about 5% of the propylene component.[2]

Properties

Useful comparison tables of PTFE against FEP, PFA and ETFE can be found on DuPont's website, listing the mechanical, thermal, chemical, electrical and vapour properties of each, side by side.[5]

In terms of corrosion resistance, FEP is the only other readily available fluoropolymer that can match PTFE's own resistance to caustic agents, as it is a pure carbon-fluorine structure and fully fluorinated.[5]

Thermally, FEP stands out from PTFE and PFA by having a melting point of 260 °C (500 °F), around forty degrees lower than PFA and lower again than PTFE.[5]

Electrically, PTFE, FEP and PFA have identical dielectric constants, but FEP's dielectric strength is only surpassed by PFA. However, while PFA has a similar dissipation factor to PTFE, FEP's dissipation is around six times that of PFA and EFTE (making it a more non-linear conductor of electrostatic fields).[5]

Mechanically, FEP is slightly more flexible than PTFE. Perhaps surprisingly, it does not withstand repetitive folding as well as PTFE. It also features a poorer coefficient of dynamic friction, is softer and has a slightly lower tensile strength than PTFE and PFA.[5]

A noteworthy property of FEP is that it is vastly superior to PTFE in some coating applications involving exposure to detergents.[5]

Ethylene tetrafluoroethylene (ETFE), in many ways, can be thought of as belonging to a different group, as it is essentially a high strength engineering version of the others featuring what are likely to be considered slightly diminished properties in the other fields when compared with PTFE, FEP and PFA.[5]

Applications

Like PTFE, FEP is mainly used for wiring, e.g.,hookup wire, coaxial cable, wiring for computer wires and technical gear.[2] An illustrative end product is for coaxial cables like RG-316.

In manufacturing high-quality composite parts, such as in the aerospace industry, FEP film can be used to protect molds during the curing process. In such applications, the film is called "release film" and is intended to prevent the curing adhesive polymer (e.g. the epoxy in a carbon fibre/epoxy composite laminate) from bonding to the metal tooling. One example is the A-5000 FEP release film by Richmond Aircraft Products (see link). Being able to maintain chemical composure in extreme temperatures and resist damage from chemical fuels further makes FEP a suitable choice in the industry.[6]

Due to its flexibility, extreme resistance to chemical attack and optical transparency, this material, along with PFA is routinely used for plastic labware and tubing that involves critical or highly corrosive processes. Brand GmbH, Finemech, Savillex and Nalgene are well known laboratory suppliers that makes extensive use of the two materials.

References

- ^ "PTFE, FEP, and PFA Specifications". Boedeker Corp. 2007. Retrieved 2007-12-22.

- ^ a b c D. Peter Carlson and Walter Schmiegel "Fluoropolymers, Organic" in Ullmann's Encyclopedia of Industrial Chemistry 2000, Wiley-VCH, Weinheim. doi:10.1002/14356007.a11_393

- ^ "Teflon FEP". DuPont. Retrieved 2007-10-17.

- ^ "FEP Detailed Properties". Parker-TexLoc. 2006-04-13. Retrieved 2013-10-17.

- ^ a b c d e f g Fluoropolymer Comparison - Typical Properties DuPont

- ^ "Uses for FEP Tubing | Fluorotherm". Fluorotherm. 22 June 2015.