Cathode-ray tube: Difference between revisions

Citation bot (talk | contribs) Alter: url, template type, title, pages. URLs might have been internationalized/anonymized. Add: hdl, page, pages, issue, volume, journal, s2cid, doi, year, title, url, archive-date, archive-url, bibcode, pmid, isbn, date, author pars. 1-7. Converted bare reference to cite template. Removed parameters. Formatted dashes. Upgrade ISBN10 to ISBN13. | You can use this bot yourself. Report bugs here. | Suggested by Chris Capoccia | via #UCB_toolbar |

|||

| Line 15: | Line 15: | ||

[[File:Egun.jpg|thumb|Color computer monitor Electron gun]] |

[[File:Egun.jpg|thumb|Color computer monitor Electron gun]] |

||

A CRT is constructed from a glass envelope which is large, deep (i.e., long from front screen face to rear end), fairly heavy, and relatively fragile. The interior of a CRT is [[hard vacuum|evacuated]] to approximately {{Convert|0.01|Pa|atm}}<ref>[http://wps.aw.com/wps/media/objects/877/898586/topics/topic07.pdf Topic 7 |The Cathode-Ray Tube] {{Webarchive|url=https://web.archive.org/web/20171215132600/http://wps.aw.com/wps/media/objects/877/898586/topics/topic07.pdf |date=15 December 2017 }}. aw.com. 2003-08-01<!--The interior of the tube is a very good vacuum, with a pressure of around 0.01 Pa (10^−7 atm) or less. At any greater pressure, collisions of electrons with air molecules would scatter the electron beam excessively.--></ref> to {{Convert|133|nPa|atm}},<ref>[http://www.repairfaq.org/sam/lasercva.htm repairfaq.org – Sam's Laser FAQ – Vacuum Technology for Home-Built Gas Lasers] {{Webarchive|url=https://web.archive.org/web/20121009185307/http://repairfaq.org/sam/lasercva.htm|date=9 October 2012}}. repairfaq.org. 2012-08-02<!--The actual vacuum inside the CRT of a computer monitor or TV is probably at 10^-9 Torr or better.--></ref> evacuation being necessary to facilitate the free flight of electrons from the gun(s) to the tube's face. The fact that it is evacuated makes handling an intact CRT potentially dangerous due to the risk of breaking the tube and causing a violent [[implosion (mechanical process)|implosion]] that can hurl shards of glass at great velocity. As a matter of safety, the face is typically made of thick [[lead glass]] so as to be highly shatter-resistant and to block most [[X-ray]] emissions, particularly if the CRT is used in a consumer product. CRTs made up the majority of the weight of CRT TVs and computer monitors.<ref name="auto76">{{cite book |last1=Dhir |first1=Ravindra K. |last2=Limbachiya |first2=Mukesh C. |last3=Dyer |first3=Thomas D. |title=Recycling and Reuse of Glass Cullet: Proceedings of the International Symposium Organised by the Concrete Technology Unit and Held at the University of Dundee, Scotland, UK on 19-20 March 2001 |date=2001 |publisher=Thomas Telford |isbn=978-0-7277-2994-1 }}{{pn}}</ref><ref name="auto50">{{cite book |chapter=Cathod Ray-Tube Design |last1=Musgraves |first1=J. David |last2=Hu |first2=Juejun |last3=Calvez |first3=Laurent |title=Springer Handbook of Glass |publisher=Springer Nature |isbn=978-3-319-93728-1 |page=1367 |chapterurl=https://books.google.com/books?id=-ka9DwAAQBAJ&pg=PA1367 }}</ref> |

A CRT is constructed from a glass envelope which is large, deep (i.e., long from front screen face to rear end), fairly heavy, and relatively fragile. The interior of a CRT is [[hard vacuum|evacuated]] to approximately {{Convert|0.01|Pa|atm}}<ref>[http://wps.aw.com/wps/media/objects/877/898586/topics/topic07.pdf Topic 7 |The Cathode-Ray Tube] {{Webarchive|url=https://web.archive.org/web/20171215132600/http://wps.aw.com/wps/media/objects/877/898586/topics/topic07.pdf |date=15 December 2017 }}. aw.com. 2003-08-01<!--The interior of the tube is a very good vacuum, with a pressure of around 0.01 Pa (10^−7 atm) or less. At any greater pressure, collisions of electrons with air molecules would scatter the electron beam excessively.--></ref> to {{Convert|133|nPa|atm}},<ref>[http://www.repairfaq.org/sam/lasercva.htm repairfaq.org – Sam's Laser FAQ – Vacuum Technology for Home-Built Gas Lasers] {{Webarchive|url=https://web.archive.org/web/20121009185307/http://repairfaq.org/sam/lasercva.htm|date=9 October 2012}}. repairfaq.org. 2012-08-02<!--The actual vacuum inside the CRT of a computer monitor or TV is probably at 10^-9 Torr or better.--></ref> evacuation being necessary to facilitate the free flight of electrons from the gun(s) to the tube's face. The fact that it is evacuated makes handling an intact CRT potentially dangerous due to the risk of breaking the tube and causing a violent [[implosion (mechanical process)|implosion]] that can hurl shards of glass at great velocity. As a matter of safety, the face is typically made of thick [[lead glass]] so as to be highly shatter-resistant and to block most [[X-ray]] emissions, particularly if the CRT is used in a consumer product. CRTs made up the majority of the weight of CRT TVs and computer monitors.<ref name="auto76">{{cite book |last1=Dhir |first1=Ravindra K. |last2=Limbachiya |first2=Mukesh C. |last3=Dyer |first3=Thomas D. |title=Recycling and Reuse of Glass Cullet: Proceedings of the International Symposium Organised by the Concrete Technology Unit and Held at the University of Dundee, Scotland, UK on 19-20 March 2001 |date=2001 |publisher=Thomas Telford |isbn=978-0-7277-2994-1 }}{{pn}}</ref><ref name="auto50">{{cite book |chapter=Cathod Ray-Tube Design |last1=Musgraves |first1=J. David |last2=Hu |first2=Juejun |last3=Calvez |first3=Laurent |title=Springer Handbook of Glass |date=8 November 2019 |publisher=Springer Nature |isbn=978-3-319-93728-1 |page=1367 |chapterurl=https://books.google.com/books?id=-ka9DwAAQBAJ&pg=PA1367 }}</ref> |

||

Since the late 2000s, CRTs have been largely superseded by newer "[[flat panel]]" display technologies such as [[liquid-crystal display|LCD]], [[plasma display]], and [[OLED]] displays, which have lower manufacturing costs and power consumption, as well as significantly less weight and bulk. Flat-panel displays can also be made in very large sizes; whereas {{Convert|40|in|cm|abbr=on}}<ref>{{Cite web|url=https://www.cnet.com/news/remember-when-tvs-weighed-200-pounds-a-look-back-at-tv-trends-over-the-years/|title=Remember when TVs weighed 200 pounds? A look back at TV trends over the years|first=David|last=Katzmaier|website=CNET}}</ref> to {{Convert|43|in|cm|abbr=on}} (visible, total size was {{Convert|45|in|cm|abbr=on}}) was about the largest size of a CRT television or monitor,<ref>https://docs.sony.com/release/PVM4300.pdf</ref> flat panels are available in {{Convert|85|in|cm|abbr=on}} and even larger sizes. |

Since the late 2000s, CRTs have been largely superseded by newer "[[flat panel]]" display technologies such as [[liquid-crystal display|LCD]], [[plasma display]], and [[OLED]] displays, which have lower manufacturing costs and power consumption, as well as significantly less weight and bulk. Flat-panel displays can also be made in very large sizes; whereas {{Convert|40|in|cm|abbr=on}}<ref>{{Cite web|url=https://www.cnet.com/news/remember-when-tvs-weighed-200-pounds-a-look-back-at-tv-trends-over-the-years/|title=Remember when TVs weighed 200 pounds? A look back at TV trends over the years|first=David|last=Katzmaier|website=CNET}}</ref> to {{Convert|43|in|cm|abbr=on}} (visible, total size was {{Convert|45|in|cm|abbr=on}}) was about the largest size of a CRT television or monitor,<ref>https://docs.sony.com/release/PVM4300.pdf</ref> flat panels are available in {{Convert|85|in|cm|abbr=on}} and even larger sizes. |

||

| Line 58: | Line 58: | ||

In 1960 the [[Aiken tube]] was invented. It was a CRT in a flat panel display format with a single electron gun.<ref>{{Cite web|url=https://www.earlytelevision.org/geer_color_crt.html|title=Geer Experimental Color CRT|website=www.earlytelevision.org}}</ref><ref>{{Cite web|url=https://www.theatlantic.com/photo/2011/10/50-years-ago-the-world-in-1961/100172/|title=50 Years Ago: The World in 1961 - The Atlantic|first=Alan|last=Taylor|website=www.theatlantic.com}}</ref> Deflection was electrostatic and magnetic but due to patent problems it was never put into production. It was also envisioned for use as a [[Head-up display]] in aircraft.<ref>{{Cite web|url=http://www.earlytelevision.org/fairchild_crt.html|title=Fairchild Flat Screen CRT|website=www.earlytelevision.org}}</ref> By the time patent issues were solved RCA had already invested heavily in conventional CRTs.<ref>{{Cite web|url=http://blog.modernmechanix.com/flat-screen-tv-in-1958/|title=Flat Screen TV in 1958 - Popular Mechanics (Jan, 1958)}}</ref> |

In 1960 the [[Aiken tube]] was invented. It was a CRT in a flat panel display format with a single electron gun.<ref>{{Cite web|url=https://www.earlytelevision.org/geer_color_crt.html|title=Geer Experimental Color CRT|website=www.earlytelevision.org}}</ref><ref>{{Cite web|url=https://www.theatlantic.com/photo/2011/10/50-years-ago-the-world-in-1961/100172/|title=50 Years Ago: The World in 1961 - The Atlantic|first=Alan|last=Taylor|website=www.theatlantic.com}}</ref> Deflection was electrostatic and magnetic but due to patent problems it was never put into production. It was also envisioned for use as a [[Head-up display]] in aircraft.<ref>{{Cite web|url=http://www.earlytelevision.org/fairchild_crt.html|title=Fairchild Flat Screen CRT|website=www.earlytelevision.org}}</ref> By the time patent issues were solved RCA had already invested heavily in conventional CRTs.<ref>{{Cite web|url=http://blog.modernmechanix.com/flat-screen-tv-in-1958/|title=Flat Screen TV in 1958 - Popular Mechanics (Jan, 1958)}}</ref> |

||

In 1987, flat screen CRTs were developed by Zenith for computer monitors, reducing reflections and helping increase image contrast and brightness.<ref name="auto106">{{Cite web|url=https://books.google.com |

In 1987, flat screen CRTs were developed by Zenith for computer monitors, reducing reflections and helping increase image contrast and brightness.<ref name="auto106">{{Cite web|url=https://books.google.com/books?id=Frbtc4mssNQC&q=crt+shadow+mask+metal&pg=PA24|title=Popular Science|first=Bonnier|last=Corporation|date=5 August 1986|publisher=Bonnier Corporation|via=Google Books}}</ref><ref name="auto84">{{Cite web|url=https://books.google.com/books?id=kwEAAAAAMBAJ&q=shadow+mask+heat+warping&pg=PA45|title=Popular Science|first=Bonnier|last=Corporation|date=5 April 1992|publisher=Bonnier Corporation|via=Google Books}}</ref> Such CRTs were expensive which limited their use to computer monitors.<ref name="auto94">{{Cite web|url=https://www.chicagotribune.com/news/ct-xpm-1991-09-30-9103140692-story.html|title=TV MAKERS TUNING IN TO FLAT SCREENS TO HELP ROUND OUT SALES|first=Rich|last=Warren|website=chicagotribune.com}}</ref> Attempts were made to produce flat screen CRTs using inexpensive and widely available [[float glass]].<ref name="auto37">{{Cite web|url=https://www.crtsite.com/page3-3.html|title=Prototype CRT's|website=www.crtsite.com}}</ref> |

||

In 1990, the first CRTs with HD resolution were released to the market by Sony.<ref>{{Cite web|url=http://home.bt.com/tech-gadgets/television/retro-tech-the-crt-tv-11363858003032|title=History of the CRT TV|website=BT.com}}</ref> |

In 1990, the first CRTs with HD resolution were released to the market by Sony.<ref>{{Cite web|url=http://home.bt.com/tech-gadgets/television/retro-tech-the-crt-tv-11363858003032|title=History of the CRT TV|website=BT.com}}</ref> |

||

| Line 75: | Line 75: | ||

Worldwide sales of CRT computer monitors peaked in 2000, at 90 million units, while those of CRT TVs peaked in 2005 at 130 million units.<ref name="auto20">{{Cite web|url=https://news.mit.edu/2010/crt-recycle|title=CRTs going down the tubes? Hardly|website=MIT News | Massachusetts Institute of Technology}}</ref> |

Worldwide sales of CRT computer monitors peaked in 2000, at 90 million units, while those of CRT TVs peaked in 2005 at 130 million units.<ref name="auto20">{{Cite web|url=https://news.mit.edu/2010/crt-recycle|title=CRTs going down the tubes? Hardly|website=MIT News | Massachusetts Institute of Technology}}</ref> |

||

Beggining in the late 90s to the early 2000s CRTs began to be replaced with LCDs, starting first with computer monitors smaller than 15 inches in size<ref>{{Cite web|url=http://edition.cnn.com/2002/TECH/ptech/02/15/crt.monitors.idg/|title=CNN.com - Are you looking at your last CRT? - February 15, 2002|website=edition.cnn.com}}</ref> largely because of their lower bulk.<ref>{{Cite web|url=https://fcw.com/articles/1999/07/25/flexscan-l66-a-sound-choice-in-flatpanel-displays.aspx|title=FlexScan L66: A sound choice in flat-panel displays -|first1=By Pat|last1=McClung|first2=1999|last2=Jul 25|website=FCW}}</ref> Among the first<ref>{{Cite web|url=https://apnews.com/article/e8298d721b0631753c8a451d73591073|title=GE Announces Tube Plant Closing; 790 Jobs Cut|website=AP NEWS}}</ref> manufacturers to stop CRT production was [[Hitachi]], in 2001,<ref>{{Cite web|url=https://www.extremetech.com/extreme/50240-hitachi-will-still-manufacture-crt-monitors|title=Hitachi Will Still Manufacture CRT Monitors - ExtremeTech|website=www.extremetech.com}}</ref><ref>{{Cite web|url=https://www.theregister.com/2001/07/26/hitachi_to_ditch_crt_monitors/|title=Hitachi to ditch CRT monitors|first=Robert|last=Blincoe|website=www.theregister.com}}</ref> followed by Sony in Japan in 2004,<ref name="auto62">{{Cite web|url=https://www.marketwatch.com/story/sony-to-stop-making-old-style-cathode-ray-tube-tvs|title=Sony to stop making old-style cathode ray tube TVs|website=MarketWatch}}</ref> [[Technicolor SA|Thomson]] in the US in 2004,<ref>{{Cite web|url=https://www.tvtechnology.com/amp/news/thomson-shuts-down-american-picture-tube-production|title=Thomson shuts down American picture tube production | TV Technology|website=www.tvtechnology.com}}</ref><ref>{{Cite |

Beggining in the late 90s to the early 2000s CRTs began to be replaced with LCDs, starting first with computer monitors smaller than 15 inches in size<ref>{{Cite web|url=http://edition.cnn.com/2002/TECH/ptech/02/15/crt.monitors.idg/|title=CNN.com - Are you looking at your last CRT? - February 15, 2002|website=edition.cnn.com}}</ref> largely because of their lower bulk.<ref>{{Cite web|url=https://fcw.com/articles/1999/07/25/flexscan-l66-a-sound-choice-in-flatpanel-displays.aspx|title=FlexScan L66: A sound choice in flat-panel displays -|first1=By Pat|last1=McClung|first2=1999|last2=Jul 25|website=FCW}}</ref> Among the first<ref>{{Cite web|url=https://apnews.com/article/e8298d721b0631753c8a451d73591073|title=GE Announces Tube Plant Closing; 790 Jobs Cut|website=AP NEWS}}</ref> manufacturers to stop CRT production was [[Hitachi]], in 2001,<ref>{{Cite web|url=https://www.extremetech.com/extreme/50240-hitachi-will-still-manufacture-crt-monitors|title=Hitachi Will Still Manufacture CRT Monitors - ExtremeTech|website=www.extremetech.com}}</ref><ref>{{Cite web|url=https://www.theregister.com/2001/07/26/hitachi_to_ditch_crt_monitors/|title=Hitachi to ditch CRT monitors|first=Robert|last=Blincoe|website=www.theregister.com}}</ref> followed by Sony in Japan in 2004,<ref name="auto62">{{Cite web|url=https://www.marketwatch.com/story/sony-to-stop-making-old-style-cathode-ray-tube-tvs|title=Sony to stop making old-style cathode ray tube TVs|website=MarketWatch}}</ref> [[Technicolor SA|Thomson]] in the US in 2004,<ref>{{Cite web|url=https://www.tvtechnology.com/amp/news/thomson-shuts-down-american-picture-tube-production|title=Thomson shuts down American picture tube production | TV Technology|website=www.tvtechnology.com}}</ref><ref>{{Cite book|url=https://books.google.com/books?id=wpatIq2M5FYC&q=asahi+closes+crt+plant&pg=SL8-PA23|title=Certain Color Television Receivers from China, Invs. 731-TA-1034 (Final)|publisher=DIANE Publishing|isbn=9781457820526|via=Google Books}}</ref> [[Matsushita]] [[Toshiba]] picture display in 2005 in the US,<ref>{{Cite web|url=https://www.computerworld.com/article/2811895/hitachi--matsushita--toshiba-cement-lcd-venture-plan.amp.html|title=Hitachi, Matsushita, Toshiba cement LCD venture plan | Computerworld|website=www.computerworld.com}}</ref> 2006 in Malaysia<ref name="auto51">{{Cite web|url=https://www.networkworld.com/article/2305303/panasonic-toshiba-venture-to-shut-malaysia-crt-plant.html|title=Panasonic-Toshiba venture to shut Malaysia CRT plant|first=Martyn|last=Williams|date=27 July 2006|website=Network World}}</ref> and 2007 in China,<ref>{{Cite web|url=http://www.digitimes.com/news/a20070906PB203.html|title=Panasonic China stops CRT TV production at Shandong plant|website=DIGITIMES}}</ref> Sony in the US in 2006,<ref>{{Cite web|url=https://hackaday.com/2018/11/30/retrotechtacular-some-of-the-last-crts-from-the-factory-floor/|title=Retrotechtacular: Some Of The Last CRTs From The Factory Floor|date=30 November 2018}}</ref> Sony in Singapore and Malaysia for the Latin American and Asian markets in 2008,<ref name="auto62"/><ref>{{Cite web|url=https://spectrum.ieee.org/tech-talk/semiconductors/devices/sony_pulls_plug_on_historic_tr|title=Full Page Reload|website=IEEE Spectrum: Technology, Engineering, and Science News}}</ref> Samsung SDI in 2007<ref>{{Cite web|url=https://m.koreatimes.co.kr/pages/article.asp?newsIdx=15271|title=Samsung SDI Struggles to Close CRT Lines|date=10 December 2007|website=m.koreatimes.co.kr}}</ref><ref>{{Cite web|url=http://world.kbs.co.kr/service/news_view.htm?lang=e&Seq_Code=49355|title=Samsung Hungary to Halt CRT Production|website=world.kbs.co.kr}}</ref> and 2012<ref>{{Cite web|url=https://m.pulsenews.co.kr/view.php?year=2012&no=206660|title=Samsung SDI halts CRT production in Malaysia plant - Pulse by Maeil Business News Korea|website=m.pulsenews.co.kr}}</ref><ref>{{Cite web|url=https://www.mk.co.kr/news/english/view/2012/04/206660/|title=Samsung SDI halts CRT production in Malaysia plant|date=3 April 2012|website=www.mk.co.kr}}</ref> and Cathode Ray Technology(formerly Philips) in 2012<ref>{{Cite web|url=https://www.crtsite.com/page3-2.html|title=Cathode Ray Technology|website=www.crtsite.com}}</ref><ref>{{Cite web|url=http://lampes-et-tubes.info/cr/cr131.php?l=e|title=Cathode Ray Technology B.V. Engineering Model Type D10-XXX|website=lampes-et-tubes.info}}</ref> and [[Videocon]] in 2015-16.<ref>{{Cite web|url=https://resource-recycling.com/e-scrap/2015/10/22/videocon-shuts-down-furnaces-and-stokes-concerns/|title=Videocon shuts down furnaces - and stokes concerns|date=22 October 2015}}</ref><ref name="auto43">{{Cite web|url=https://resource-recycling.com/e-scrap/2018/02/01/demand-dwindling-questions-swirl-around-videocon/|title=With demand dwindling, questions swirl around Videocon|date=1 February 2018}}</ref><ref name="auto72">{{Cite web|url=https://resource-recycling.com/e-scrap/2016/03/03/videocon-begins-accepting-crt-glass-again/|title=Videocon begins accepting CRT glass again|first=Bobby|last=Elliott|date=3 March 2016}}</ref><ref name="auto88"/> Ekranas in Lithuania<ref>{{Cite web|url=https://www.baltictimes.com/news/articles/15121/|title=Ekranas files for bankruptcy, Vilniaus Vingis braces for worst|website=www.baltictimes.com}}</ref> and LG.Philips Displays<ref>{{Cite web|url=https://www.electronicsweekly.com/news/products/led/lg-philips-seeks-bankruptcy-protection-in-europe-2006-01/|title=LG.Philips seeks bankruptcy protection in Europe|first=Steve|last=Bush|date=27 January 2006}}</ref> went bankrupt in 2005 and 2006 respectively. Matsushita Toshiba stopped in the US in 2004 due to losses of $109 million,<ref>{{Cite web|url=https://www.computerweekly.com/news/2240058540/LCD-plant-coming-soon-after-CRT-close-down|title=LCD plant coming soon after CRT close-down|website=ComputerWeekly.com}}</ref> and in Malaysia in 2006 due to losses that almost equaled their sales.<ref name="auto51"/> The last CRT TVs at CES were shown by Samsung in 2007<ref name="auto86">{{Cite web|url=https://www.engadget.com/2007-01-07-samsung-introduces-2007-lcd-plasma-dlp-and-crt-lineup.html|title=Samsung introduces 2007 LCD, plasma, DLP and CRT lineup|website=Engadget}}</ref><ref name="auto86"/> and the last mass produced model was introduced by LG in 2008 for developing markets due to its low price.<ref>https://www.techradar.com/news/television/tv/world-s-thinnest-crt-tv-bucks-all-trends-167665#:~:text=Specifically%2C%20Korean%20firm%20LG%20has,select%20markets%20later%20this%20year.</ref><ref name="auto101">{{Cite web|url=https://news.softpedia.com/news/LG-Presents-the-Slimmest-CRT-TV-Display-49012.shtml|title=LG Presents the Slimmest CRT TV Display|first=Bogdan|last=Solca|website=softpedia}}</ref> The last CRT TV by a major manufacturer was introduced by LG in 2010.<ref>{{Cite web|url=https://www.engadget.com/amp/2010-01-25-lgs-classic-tv-gives-old-crt-new-legs.html|title=LG's Classic TV gives old CRT new legs|website=Engadget}}</ref><ref>{{Cite web|url=https://www.techhive.com/article/187656/Retro_LG_Introduce_CRT_TV.amp.html|title=LG Goes Retro, Introduces New CRT TV | TechHive|website=www.techhive.com}}</ref> |

||

CRTs were first replaced by LCD in developed markets such as Japan and Europe in the 2000s and continued to be popular in developing markets such as Latin America,<ref>{{Cite web|url=https://amp.smh.com.au/technology/lg-samsung-try-to-save-the-crt-20050819-gdlwh2.html|title=LG, Samsung try to save the CRT|website=amp.smh.com.au}}</ref><ref name="auto20"/> China, Asia and the Middle East due to their low price compared to contemporary flat panel TVs,<ref>{{Cite web|url=https://www.techradar.com/news/television/what-s-happening-to-all-the-crt-tvs-525649|title=What's happening to all the CRT TVs?|first=Dean Evans 06|last=February 2009|website=TechRadar}}</ref> and later in markets like rural India, however in around 2014 even rural markets started favoring LCD over CRT, leading to the demise of the technology.<ref>{{Cite web|url=https://www.thehindubusinessline.com/info-tech/Rise-of-flat-screen-televisions-lowers-the-curtain-on-the-bulky-box/article20921397.ece|title=Rise of flat-screen televisions lowers the curtain on the bulky box|first=R.|last=Ravikumar|website=@businessline}}</ref> |

CRTs were first replaced by LCD in developed markets such as Japan and Europe in the 2000s and continued to be popular in developing markets such as Latin America,<ref>{{Cite web|url=https://amp.smh.com.au/technology/lg-samsung-try-to-save-the-crt-20050819-gdlwh2.html|title=LG, Samsung try to save the CRT|website=amp.smh.com.au}}</ref><ref name="auto20"/> China, Asia and the Middle East due to their low price compared to contemporary flat panel TVs,<ref>{{Cite web|url=https://www.techradar.com/news/television/what-s-happening-to-all-the-crt-tvs-525649|title=What's happening to all the CRT TVs?|first=Dean Evans 06|last=February 2009|website=TechRadar}}</ref> and later in markets like rural India, however in around 2014 even rural markets started favoring LCD over CRT, leading to the demise of the technology.<ref>{{Cite web|url=https://www.thehindubusinessline.com/info-tech/Rise-of-flat-screen-televisions-lowers-the-curtain-on-the-bulky-box/article20921397.ece|title=Rise of flat-screen televisions lowers the curtain on the bulky box|first=R.|last=Ravikumar|website=@businessline}}</ref> |

||

| Line 87: | Line 87: | ||

In the United Kingdom, [[DSG International (retailer)|DSG (Dixons)]], the largest retailer of domestic electronic equipment, reported that CRT models made up 80–90% of the volume of televisions sold at Christmas 2004 and 15–20% a year later, and that they were expected to be less than 5% at the end of 2006. Dixons ceased selling CRT televisions in 2006.<ref>{{cite news |title=The future is flat as Dixons withdraws sale of 'big box' televisions |newspaper=London Evening Standard |date=26 November 2006 |url=http://www.thisislondon.co.uk/news/article-23376023-details/The+future+is+flat+as+Dixons+withdraws+sale+of+'big+box'+televisions/article.do |archive-url=https://archive.today/20130505112036/http://www.thisislondon.co.uk/news/article-23376023-details/The+future+is+flat+as+Dixons+withdraws+sale+of+'big+box'+televisions/article.do |url-status=dead |archive-date=5 May 2013 |accessdate=3 December 2006 }}</ref> |

In the United Kingdom, [[DSG International (retailer)|DSG (Dixons)]], the largest retailer of domestic electronic equipment, reported that CRT models made up 80–90% of the volume of televisions sold at Christmas 2004 and 15–20% a year later, and that they were expected to be less than 5% at the end of 2006. Dixons ceased selling CRT televisions in 2006.<ref>{{cite news |title=The future is flat as Dixons withdraws sale of 'big box' televisions |newspaper=London Evening Standard |date=26 November 2006 |url=http://www.thisislondon.co.uk/news/article-23376023-details/The+future+is+flat+as+Dixons+withdraws+sale+of+'big+box'+televisions/article.do |archive-url=https://archive.today/20130505112036/http://www.thisislondon.co.uk/news/article-23376023-details/The+future+is+flat+as+Dixons+withdraws+sale+of+'big+box'+televisions/article.do |url-status=dead |archive-date=5 May 2013 |accessdate=3 December 2006 }}</ref> |

||

CRTs' demise has made maintaining arcade machines made before the wide adoption of flat panel displays difficult, due to a lack of spare replacement CRTs. (CRTs may need replacement due to wear as explained further below) Repairing CRTs, although possible, requires a high level of skill.<ref name="auto65">{{Cite web|url=https://venturebeat.com/2017/03/03/what-the-death-of-the-crt-display-technology-means-for-classic-arcade-machines/|title=Donkey |

CRTs' demise has made maintaining arcade machines made before the wide adoption of flat panel displays difficult, due to a lack of spare replacement CRTs. (CRTs may need replacement due to wear as explained further below) Repairing CRTs, although possible, requires a high level of skill.<ref name="auto65">{{Cite web|url=https://venturebeat.com/2017/03/03/what-the-death-of-the-crt-display-technology-means-for-classic-arcade-machines/|title=Donkey Kong's failing liver: What the death of the CRT display technology means for classic arcade machines|date=3 March 2017}}</ref> |

||

=== Current uses === |

=== Current uses === |

||

| Line 124: | Line 124: | ||

https://www.calrecycle.ca.gov/docs/cr/electronics/resources/publications/glassmff.pdf also calls it a panel </ref><ref>https://www.illinoisrecycles.org/wp-content/uploads/2014/10/150618_T_3.1_ChrisCahnovsky.pdf</ref><ref name="auto34">{{cite journal |last1=Ha |first1=Kuedong |last2=Shin |first2=Soon-Cheol |last3=Kim |first3=Do-Nyun |last4=Lee |first4=Kue-Hong |last5=Kim |first5=Jeong-Hoon |title=Development of a 32-in. slim CRT with 125° deflection |journal=Journal of the Society for Information Display |date=2006 |volume=14 |issue=1 |pages=65 |doi=10.1889/1.2166838 }}</ref><ref name="auto104">https://dnr.mo.gov/env/hwp/escrap/docs/crttcp99.pdf</ref><ref name="auto73">{{Cite web|url=https://www.vice.com/en/article/z4gv73/americas-television-graveyards|title=America's Television Graveyards|website=www.vice.com}}</ref> The joined screen, funnel and neck are known as the bulb or envelope.<ref name="auto42"/> |

https://www.calrecycle.ca.gov/docs/cr/electronics/resources/publications/glassmff.pdf also calls it a panel </ref><ref>https://www.illinoisrecycles.org/wp-content/uploads/2014/10/150618_T_3.1_ChrisCahnovsky.pdf</ref><ref name="auto34">{{cite journal |last1=Ha |first1=Kuedong |last2=Shin |first2=Soon-Cheol |last3=Kim |first3=Do-Nyun |last4=Lee |first4=Kue-Hong |last5=Kim |first5=Jeong-Hoon |title=Development of a 32-in. slim CRT with 125° deflection |journal=Journal of the Society for Information Display |date=2006 |volume=14 |issue=1 |pages=65 |doi=10.1889/1.2166838 }}</ref><ref name="auto104">https://dnr.mo.gov/env/hwp/escrap/docs/crttcp99.pdf</ref><ref name="auto73">{{Cite web|url=https://www.vice.com/en/article/z4gv73/americas-television-graveyards|title=America's Television Graveyards|website=www.vice.com}}</ref> The joined screen, funnel and neck are known as the bulb or envelope.<ref name="auto42"/> |

||

The neck is made from a glass tube<ref>{{Cite web|url=https://patents.google.com/patent/CN1545118A/en|title=Processing technique for straight tube necking glass cone for CRT}}</ref> while the funnel and screen are made by pouring and then pressing glass into a mold.<ref>{{Cite web|url=https://patents.google.com/patent/US3484225A/en|title=Method of reforming glass face plates on a shaping mold}}</ref><ref>{{Cite web|url=https://patents.google.com/patent/US7093732B1/en|title=CRT funnel with positioning reference portions}}</ref><ref>{{Cite web|url=https://patents.google.com/patent/US20060001351A1/en|title=Glass panel and a cathode ray tube including the same}}</ref><ref>{{Cite web|url=https://patents.google.com/patent/US3264080A/en|title=Method for forming rectangular face plate}}</ref><ref>{{Cite web|url=https://patents.google.com/patent/JP3539635B2/en|title=Funnel for cathode ray tube}}</ref> The glass, known as CRT glass<ref>{{Cite web|url=https://ric.werecycle.eu/c/CRT_tubes_and_glass|title=6. CRT Glass|website=ric}}</ref><ref>{{Cite web|url=https://www.epa.gov/hw/frequent-questions-about-regulation-used-cathode-ray-tubes-crts-and-crt-glass|title=Frequent Questions About the Regulation of Used Cathode Ray Tubes (CRTs) and CRT Glass|first=OLEM|last=US EPA|date=22 February 2016|website=US EPA}}</ref> or TV glass,<ref>{{Cite |

The neck is made from a glass tube<ref>{{Cite web|url=https://patents.google.com/patent/CN1545118A/en|title=Processing technique for straight tube necking glass cone for CRT}}</ref> while the funnel and screen are made by pouring and then pressing glass into a mold.<ref>{{Cite web|url=https://patents.google.com/patent/US3484225A/en|title=Method of reforming glass face plates on a shaping mold}}</ref><ref>{{Cite web|url=https://patents.google.com/patent/US7093732B1/en|title=CRT funnel with positioning reference portions}}</ref><ref>{{Cite web|url=https://patents.google.com/patent/US20060001351A1/en|title=Glass panel and a cathode ray tube including the same}}</ref><ref>{{Cite web|url=https://patents.google.com/patent/US3264080A/en|title=Method for forming rectangular face plate}}</ref><ref>{{Cite web|url=https://patents.google.com/patent/JP3539635B2/en|title=Funnel for cathode ray tube}}</ref> The glass, known as CRT glass<ref>{{Cite web|url=https://ric.werecycle.eu/c/CRT_tubes_and_glass|title=6. CRT Glass|website=ric}}</ref><ref>{{Cite web|url=https://www.epa.gov/hw/frequent-questions-about-regulation-used-cathode-ray-tubes-crts-and-crt-glass|title=Frequent Questions About the Regulation of Used Cathode Ray Tubes (CRTs) and CRT Glass|first=OLEM|last=US EPA|date=22 February 2016|website=US EPA}}</ref> or TV glass,<ref>{{Cite book|url=https://books.google.com/books?id=MpQR01fTv7YC&q=tv+glass&pg=PA11|title=Quality Wars: The Triumphs and Defeats of American Business|first=Jeremy|last=Main|date=11 May 2010|publisher=Simon and Schuster|isbn=9781439138458|via=Google Books}}</ref> needs special properties to shield against x-rays while providing adequate light transmission in the screen or being very electrically insulating in the funnel and neck. The formulation that gives the glass its properties is also known as the melt. The glass is of very high quality, being almost contaminant and defect free. Most of the costs associated with glass production come from the energy used to melt the raw materials into glass. Glass furnaces for CRT glass production have several taps to allow molds to be replaced without stopping the furnace, to allow production of CRTs of several sizes. Only the glass used on the screen needs to have precise optical properties. The optical properties of the glass used on the screen affects color reproduction and purity in Color CRTs. Transmittance, or how transparent the glass is, may be adjusted to be more transparent to certain colors (wavelengths) of light. Transmittance is measured at the center of the screen with a 546nm wavelength light, and a 10.16mm thick screen. Transmittance goes down with increasing thickness. Standard transmittances for Color CRT screens are 86%, 73%, 57%, 46%, 42% and 30%. Lower transmittances are used to improve image contrast but they put more stress on the electron gun, requiring more power on the electron gun for a higher electron beam power to light the phosphors more brightly to compensate for the reduced transmittance.<ref name="auto94"/><ref name="auto4">http://gradllc.com/images/Def.pdf</ref> The transmittance must be uniform across the screen to ensure color purity. The radius (curvature) of screens has increased (grown less curved) over time, from 30 to 68 inches, ultimately evolving into completely flat screens, reducing reflections. The thickness of both curved<ref name="auto22">{{Cite web|url=https://www.yumpu.com/en/document/read/3266017/flatron|title=FLATRON|website=yumpu.com}}</ref> and flat screens graudally increases from the center outwards, and with it, transmittance is gradually reduced. This means that flat screen CRTs may not be completely flat on the inside. <ref name="auto22"/><ref>{{Cite web|url=https://patents.google.com/patent/US6806636B2/en|title=Flat CRT with improved coating}}</ref> The glass used in CRTs arrives from the glass factory to the CRT factory as either separate screens and funnels with fused necks, for Color CRTs, or as bulbs made up of a fused screen, funnel and neck. There were several glass formulations for different types of CRTs, that were classified using codes specific to each glass manufacturer. The compositions of the melts were also specific to each manufacturer.<ref name="glassts">https://www.glass-ts.com/userfiles/files/2003-08%20New%20Approach%20to%20Cathode%20Ray%20Tube%20(CRT)%20Recycling.pdf</ref> Those optimized for high color purity and contrast were doped with Neodymium, while those for monochrome CRTs were tinted to differing levels, depending on the formulation used and had transmittances of 42% or 30%.<ref name="auto38">https://spie.org/samples/TT54.pdf</ref> Purity is ensuring that the correct colors are activated (for example, ensuring that red is displayed uniformly across the screen) while convergence ensures that images are not distorted. Convergence may be modified using a cross hatch pattern.<ref name="auto85">{{Cite web|url=https://www.repairfaq.org/samnew/tvfaq/tvccrtssa.htm|title=SER FAQ: TVFAQ: Color CRTs - shadow masks and aperture grills|website=www.repairfaq.org}}</ref><ref name="auto48">{{Cite web|url=https://www.repairfaq.org/samnew/tvfaq/tvcrtcona.htm|title=SER FAQ: TVFAQ: CRT convergence adjustment|website=www.repairfaq.org}}</ref><ref>{{Cite web|url=https://www.mediacollege.com/video/test-patterns/convergence/|title=Convergence Test Patterns|website=www.mediacollege.com}}</ref> |

||

CRT glass used to be made by dedicated companies<ref>{{Cite web|url=https://www.eetimes.com/corning-asahi-video-to-sell-plant-assets-to-chinese-supplier/|title=Corning Asahi Video to sell plant assets to Chinese supplier | EE Times}}</ref> such as [[AGC Inc.]],<ref>{{Cite web|url=http://www.digitimes.com/news/a20060725A6027.html|title=CPT expects limited impact from Asahi Glass CRT plant closure in Taiwan|website=DIGITIMES}}</ref><ref>{{Cite web|url=https://www.glassonline.com/asahi-techno-vision-to-close-singapore-plant/|title=Asahi Techno Vision to close Singapore plant|date=12 June 2007}}</ref><ref>{{Cite web|url=https://www.glassonline.com/asahi-glass-restructures-crt-funnel-manufacturing/|title=Asahi Glass restructures CRT funnel manufacturing|date=13 January 2005}}</ref> [[O-I Glass]],<ref>{{Cite web|url=https://www.neg.co.jp/en/company/history/|title=History|website=Nippon Electric Glass Co., Ltd.}}</ref> Samsung Corning Precision Materials,<ref>{{Cite web|url=http://www.koreatimes.co.kr/www/tech/2020/12/693_100541.html|title=4 CRT glass makers fined for price fixing|date=11 December 2011|website=koreatimes}}</ref> [[Corning Inc.]],<ref>{{Cite web|url=https://www.photonics.com/Articles/Corning_to_Close_Plant_and_Cut_1000_Jobs/a15760|title=Corning to Close Plant and Cut 1000 Jobs|website=www.photonics.com}}</ref><ref>{{Cite web|url=https://www.zdnet.com/article/corning-to-close-tv-glass-plant/|title=Corning to close TV glass plant|first=Richard|last=Shim|website=ZDNet}}</ref> and [[Nippon Electric Glass]];<ref>{{Cite web|url=https://www.bcnretail.com/news/detail/050901_2045.html|title=日本電気硝子、CRT用ガラスの国内生産を9月末で停止、国内需要の消滅に対応|website=BCN+R}}</ref> others such as Videocon, Sony for the US market and Thomson made their own glass.<ref name="auto72"/><ref>{{Cite |

CRT glass used to be made by dedicated companies<ref>{{Cite web|url=https://www.eetimes.com/corning-asahi-video-to-sell-plant-assets-to-chinese-supplier/|title=Corning Asahi Video to sell plant assets to Chinese supplier | EE Times}}</ref> such as [[AGC Inc.]],<ref>{{Cite web|url=http://www.digitimes.com/news/a20060725A6027.html|title=CPT expects limited impact from Asahi Glass CRT plant closure in Taiwan|website=DIGITIMES}}</ref><ref>{{Cite web|url=https://www.glassonline.com/asahi-techno-vision-to-close-singapore-plant/|title=Asahi Techno Vision to close Singapore plant|date=12 June 2007}}</ref><ref>{{Cite web|url=https://www.glassonline.com/asahi-glass-restructures-crt-funnel-manufacturing/|title=Asahi Glass restructures CRT funnel manufacturing|date=13 January 2005}}</ref> [[O-I Glass]],<ref>{{Cite web|url=https://www.neg.co.jp/en/company/history/|title=History|website=Nippon Electric Glass Co., Ltd.}}</ref> Samsung Corning Precision Materials,<ref>{{Cite web|url=http://www.koreatimes.co.kr/www/tech/2020/12/693_100541.html|title=4 CRT glass makers fined for price fixing|date=11 December 2011|website=koreatimes}}</ref> [[Corning Inc.]],<ref>{{Cite web|url=https://www.photonics.com/Articles/Corning_to_Close_Plant_and_Cut_1000_Jobs/a15760|title=Corning to Close Plant and Cut 1000 Jobs|website=www.photonics.com}}</ref><ref>{{Cite web|url=https://www.zdnet.com/article/corning-to-close-tv-glass-plant/|title=Corning to close TV glass plant|first=Richard|last=Shim|website=ZDNet}}</ref> and [[Nippon Electric Glass]];<ref>{{Cite web|url=https://www.bcnretail.com/news/detail/050901_2045.html|title=日本電気硝子、CRT用ガラスの国内生産を9月末で停止、国内需要の消滅に対応|website=BCN+R}}</ref> others such as Videocon, Sony for the US market and Thomson made their own glass.<ref name="auto72"/><ref>{{Cite book|url=https://books.google.com/books?id=BAmBhJta85wC&q=thomson+picture+tube&pg=PA4|title=Industry and Trade Summary: Television Picture Tubes and other Cathode-Ray Tubes|publisher=DIANE Publishing|isbn=9781457825903|via=Google Books}}</ref><ref>{{Cite web|url=http://archive.glassonline.com/site/news/topic/Sector-trends/id/4797/American-Video-Glass-Company-TV-glass-plant-officially-dedicated|title=American Video Glass Company: TV glass plant officially dedicated|website=archive.glassonline.com}}</ref><ref>https://www.bizjournals.com/pittsburgh/stories/2006/12/04/daily32.html</ref><ref name="auto95">{{Cite web|url=http://www.gic.jp/museum/tv_tale/tv_tale02.html|title=テレビ今昔物語|website=www.gic.jp}}</ref> |

||

The funnel and the neck are made of leaded potash-soda glass or lead silicate glass<ref name="auto50"/> formulation to shield against x-rays generated by high voltage electrons as they decelerate after striking a target, such as the phosphor screen or shadow mask of a color CRT. The velocity of the electrons depends on the anode voltage of the CRT; the higher the voltage, the higher the speed.<ref name="auto2">{{Cite web|url=https://www2.physics.ox.ac.uk/accelerate/resources/demonstrations/cathode-ray-tube|title=Cathode ray tube | University of Oxford Department of Physics|website=www2.physics.ox.ac.uk}}</ref> The amount of x-rays emitted by a CRT can also lowered by reducing the brightness of the image.<ref>{{Cite web|url=http://repairfaq.cis.upenn.edu/Misc/samnew/tvfaq/tvsibwaxray.htm|title=SER FAQ: TVFAQ: Should I be worried about X-ray exposure while servicing a TV or monitor?|website=repairfaq.cis.upenn.edu}}</ref><ref>{{Cite web|url=http://repairfaq.cis.upenn.edu/Misc/samnew/tvfaq/tvxrayoem.htm|title=SER FAQ: TVFAQ: X-ray and other EM emission from my TV or monitor?|website=repairfaq.cis.upenn.edu}}</ref><ref name="auto35">{{Cite magazine|title=X-Rays from TV Sets - Are They Harmful? <!--https://www.rfcafe.com/references/radio-news/tv-set-x-rays-radio-tv-news-november-1958.htm-->|date=November 1958|magazine=Radio News}}</ref><ref name="auto104"/> Leaded glass is used because it is inexpensive, while also shielding heavily against x-rays, although some funnels may also contain barium.<ref name="Lee & Hsi 2002">{{cite journal |last1=Lee |first1=Ching-Hwa |last2=Hsi |first2=Chi-Shiung |title=Recycling of Scrap Cathode Ray Tubes |journal=Environmental Science & Technology |date=1 January 2002 |volume=36 |issue=1 |pages=69–75 |doi=10.1021/es010517q }}</ref><ref>{{Cite |

The funnel and the neck are made of leaded potash-soda glass or lead silicate glass<ref name="auto50"/> formulation to shield against x-rays generated by high voltage electrons as they decelerate after striking a target, such as the phosphor screen or shadow mask of a color CRT. The velocity of the electrons depends on the anode voltage of the CRT; the higher the voltage, the higher the speed.<ref name="auto2">{{Cite web|url=https://www2.physics.ox.ac.uk/accelerate/resources/demonstrations/cathode-ray-tube|title=Cathode ray tube | University of Oxford Department of Physics|website=www2.physics.ox.ac.uk}}</ref> The amount of x-rays emitted by a CRT can also lowered by reducing the brightness of the image.<ref>{{Cite web|url=http://repairfaq.cis.upenn.edu/Misc/samnew/tvfaq/tvsibwaxray.htm|title=SER FAQ: TVFAQ: Should I be worried about X-ray exposure while servicing a TV or monitor?|website=repairfaq.cis.upenn.edu}}</ref><ref>{{Cite web|url=http://repairfaq.cis.upenn.edu/Misc/samnew/tvfaq/tvxrayoem.htm|title=SER FAQ: TVFAQ: X-ray and other EM emission from my TV or monitor?|website=repairfaq.cis.upenn.edu}}</ref><ref name="auto35">{{Cite magazine|title=X-Rays from TV Sets - Are They Harmful? <!--https://www.rfcafe.com/references/radio-news/tv-set-x-rays-radio-tv-news-november-1958.htm-->|date=November 1958|magazine=Radio News}}</ref><ref name="auto104"/> Leaded glass is used because it is inexpensive, while also shielding heavily against x-rays, although some funnels may also contain barium.<ref name="Lee & Hsi 2002">{{cite journal |last1=Lee |first1=Ching-Hwa |last2=Hsi |first2=Chi-Shiung |title=Recycling of Scrap Cathode Ray Tubes |journal=Environmental Science & Technology |date=1 January 2002 |volume=36 |issue=1 |pages=69–75 |doi=10.1021/es010517q |pmid=11811492 |bibcode=2002EnST...36...69L }}</ref><ref>{{Cite book|url=https://books.google.com/books?id=z4Ha0AYdon4C&q=cathode+ray+tube+funnel+lead+glass+inexpensive&pg=PA57|title=Lead-free Electronics|first1=Sanka|last1=Ganesan|first2=Michael G.|last2=Pecht|date=31 March 2006|publisher=John Wiley & Sons|isbn=9780470007792|via=Google Books}}</ref><ref>{{Cite book|url=https://books.google.com/books?id=FvkqeL4IDMwC&q=cathode+ray+tube+funnel+lead+glass+inexpensive&pg=PA5|title=Image Performance in CRT Displays|first=Kenneth|last=Compton|date=5 December 2003|publisher=SPIE Press|isbn=9780819441447|via=Google Books}}</ref><ref name="auto38"/> The screen is usually instead made out of a special lead-free silicate<ref name="auto50"/> glass formulation with barium and strontium to shield against x-rays. Another glass formulation uses 2-3% of lead on the screen.<ref name="auto104"/> Monochrome CRTs may have a tinted barium-lead glass formulation in both the screen and funnel, with a potash-soda lead glass in the neck; the potash-soda and barium-lead formulations have different thermal expansion coefficients. The glass used in the neck must be an excellent electical insulator to contain the voltages used in the electron optics of the electron gun, such as focusing lenses. The lead in the glass causes it to brown (darken) with use due to x-rays, usually the CRT cathode wears out due to cathode poisoning before browning becomes apparent. The glass formulation determines the highest possible anode voltage and hence the maximum possible CRT screen size. For color, maximum voltages are often 24 to 32kV, while for monochrome it is usually 21 or 24.5kV,<ref name="auto63">{{Cite book|url=https://books.google.com/books?id=FvkqeL4IDMwC&q=crt+venting&pg=PA9|title=Image Performance in CRT Displays|first=Kenneth|last=Compton|date=5 December 2003|publisher=SPIE Press|isbn=9780819441447|via=Google Books}}</ref> limiting the size of monochrome CRTs to 21 inches, or approx. 1kV per inch. The voltage needed depends on the size and type of CRT.<ref name="auto3">{{Cite web|url=patents.google.com/patent/US5096445A/en|title=Anode connector assembly for a cathode ray tube}}</ref> Since the formulations are different, they must be compatible with one another, having similar thermal expansion coefficients.<ref name="auto38"/> The screen may also have an anti-glare or anti-reflective coating, <ref>{{Cite web|url=https://patents.google.com/patent/US5404073A/no|title=Antiglare/antistatic coating for CRT}}</ref><ref name="auto4"/><ref>{{Cite web|url=https://www.tomshardware.com/reviews/comparison,440.html|title=Comparison: Twelve 19" CRT Monitors|first=Philippe Ramelet 19|last=March 2002|website=Tom's Hardware}}</ref> or be ground to prevent reflections.<ref>{{Cite web|url=https://patents.google.com/patent/US4884006A/en|title=Inner surface specular reflection suppression in flat CRT faceplate}}</ref> CRTs may also have an anti-static coating.<ref name="auto4"/><ref>{{Cite web|url=https://patents.google.com/patent/US6590352B1/en|title=Electrical grounding of CRT antistatic/antireflective coating}}</ref><ref name="auto94"/> |

||

The leaded glass in the funnels of CRTs may contain 21 to 25% of lead oxide,<ref name="auto81">{{Cite web|url=https://patents.google.com/patent/US6163106A/en|title=Color cathode ray tube and water resistant glass frit}}</ref><ref>https://ipen.org/sites/default/files/documents/Looking-through-glass-CRT-recycling-in-India.pdf</ref><ref name="glassts"/> The neck may contain 30 to 40% of lead oxide,<ref>{{cite journal |last1=Xu |first1=Qingbo |last2=Li |first2=Guangming |last3=He |first3=Wenzhi |last4=Huang |first4=Juwen |last5=Shi |first5=Xiang |title=Cathode ray tube (CRT) recycling: Current capabilities in China and research progress |journal=Waste Management |date=August 2012 |volume=32 |issue=8 |pages=1566–1574 |doi=10.1016/j.wasman.2012.03.009 }}</ref> and the screen may contain 12% of barium oxide, and 12% of strontium oxide.<ref name="auto50"/> A typical CRT contains several kilograms of lead as lead oxide in the glass<ref name="auto73"/> depending on its size; 12 inch CRTs contain 0.5 kg of lead in total while 32 inch CRTs contain up to 3 kg.<ref name="auto50"/> |

The leaded glass in the funnels of CRTs may contain 21 to 25% of lead oxide,<ref name="auto81">{{Cite web|url=https://patents.google.com/patent/US6163106A/en|title=Color cathode ray tube and water resistant glass frit}}</ref><ref>https://ipen.org/sites/default/files/documents/Looking-through-glass-CRT-recycling-in-India.pdf</ref><ref name="glassts"/> The neck may contain 30 to 40% of lead oxide,<ref>{{cite journal |last1=Xu |first1=Qingbo |last2=Li |first2=Guangming |last3=He |first3=Wenzhi |last4=Huang |first4=Juwen |last5=Shi |first5=Xiang |title=Cathode ray tube (CRT) recycling: Current capabilities in China and research progress |journal=Waste Management |date=August 2012 |volume=32 |issue=8 |pages=1566–1574 |doi=10.1016/j.wasman.2012.03.009 |pmid=22542858 }}</ref> and the screen may contain 12% of barium oxide, and 12% of strontium oxide.<ref name="auto50"/> A typical CRT contains several kilograms of lead as lead oxide in the glass<ref name="auto73"/> depending on its size; 12 inch CRTs contain 0.5 kg of lead in total while 32 inch CRTs contain up to 3 kg.<ref name="auto50"/> |

||

Some early CRTs used a metal funnel insulated with polyethylene instead of glass with conductive material.<ref name="auto59"/> Others had ceramic or blown pyrex instead of pressed glass funnels.<ref>{{Cite web|url=https://www.earlytelevision.org/racs_pyrex_rebuild.html|title=RACS - Pyrex CRT Rebuilding|website=www.earlytelevision.org}}</ref><ref>http://www.nostalgiatech.co.uk/GB470885A.pdf</ref><ref name="auto30"/><ref>https://vintagetek.org/ceramic-strips/</ref><ref name="auto69">{{Cite web|url=https://www.crtsite.com/oscilloscope-crt.html|title=The Cathode Ray Tube site. oscilloscope crt's|website=www.crtsite.com}}</ref> Early CRTs did not have a dedicated anode cap connection; the funnel was the anode connection, so it was live during operation.<ref name="auto53">{{Cite web|url=https://www.oldtellys.co.uk/otmonotube.html|title=The Monochrome Tube|website=www.oldtellys.co.uk}}</ref> |

Some early CRTs used a metal funnel insulated with polyethylene instead of glass with conductive material.<ref name="auto59"/> Others had ceramic or blown pyrex instead of pressed glass funnels.<ref>{{Cite web|url=https://www.earlytelevision.org/racs_pyrex_rebuild.html|title=RACS - Pyrex CRT Rebuilding|website=www.earlytelevision.org}}</ref><ref>http://www.nostalgiatech.co.uk/GB470885A.pdf</ref><ref name="auto30"/><ref>https://vintagetek.org/ceramic-strips/</ref><ref name="auto69">{{Cite web|url=https://www.crtsite.com/oscilloscope-crt.html|title=The Cathode Ray Tube site. oscilloscope crt's|website=www.crtsite.com}}</ref> Early CRTs did not have a dedicated anode cap connection; the funnel was the anode connection, so it was live during operation.<ref name="auto53">{{Cite web|url=https://www.oldtellys.co.uk/otmonotube.html|title=The Monochrome Tube|website=www.oldtellys.co.uk}}</ref> |

||

| Line 149: | Line 149: | ||

===Size and weight=== |

===Size and weight=== |

||

The size of the screen of a CRT is measured in two ways: the size of the screen or the face diagonal, and the viewable image size/area or viewable screen diagonal, which is the part of the screen with phosphor. The size of the screen is the viewable image size plus its edges which are not coated with phosphor.<ref>{{Cite web|url=https://www.anandtech.com/show/1370|title=Buyer's Guide: High End System - July 2004|first=Wesley|last=Fink|website=www.anandtech.com}}</ref><ref name="auto7"/><ref>https://wiki.arcadeotaku.com/images/c/c6/Crt.jpg</ref> The viewable image may be perfectly square or rectangular while the edges of the CRT are black and have a curvature or are flat (black stripe CRT),<ref name="auto22"/><ref name="auto95"/><ref>https://web.archive.org/web/20071013164327/http://www.lgphilips-displays.com/english/download/LGPD%20BROCH%20APR07_3.pdf {{Cite web|url=https://web.archive.org/web/20030317014636/http://www.lgphilips-displays.com/download/ezFlat_HB.pdf| |

The size of the screen of a CRT is measured in two ways: the size of the screen or the face diagonal, and the viewable image size/area or viewable screen diagonal, which is the part of the screen with phosphor. The size of the screen is the viewable image size plus its edges which are not coated with phosphor.<ref>{{Cite web|url=https://www.anandtech.com/show/1370|title=Buyer's Guide: High End System - July 2004|first=Wesley|last=Fink|website=www.anandtech.com}}</ref><ref name="auto7"/><ref>https://wiki.arcadeotaku.com/images/c/c6/Crt.jpg</ref> The viewable image may be perfectly square or rectangular while the edges of the CRT are black and have a curvature or are flat (black stripe CRT),<ref name="auto22"/><ref name="auto95"/><ref>https://web.archive.org/web/20071013164327/http://www.lgphilips-displays.com/english/download/LGPD%20BROCH%20APR07_3.pdf {{Cite web|url=http://www.lgphilips-displays.com/download/ezFlat_HB.pdf|date=17 March 2003|archive-url=https://web.archive.org/web/20030317014636/http://www.lgphilips-displays.com/download/ezFlat_HB.pdf|archive-date=17 March 2003}} |

||

https://hardforum.b-cdn.net/data/attachment-files/2020/08/368434_LRG_DSC04662.jpg</ref> or the edges of the image may follow the curvature of the edges of the CRT. <ref>http://www.earlytelevision.org/pdf/rca_lancaster_color_tv_conversion_power_tubes.pdf https://frank.pocnet.net/sheets/202/2/23EGP22.pdf https://frank.pocnet.net/sheets/127/suppinfo/index3.pdf</ref><ref name="auto52"/> Black stripe CRTs were first made by Toshiba in 1972.<ref name="auto95"/> |

https://hardforum.b-cdn.net/data/attachment-files/2020/08/368434_LRG_DSC04662.jpg</ref> or the edges of the image may follow the curvature of the edges of the CRT. <ref>http://www.earlytelevision.org/pdf/rca_lancaster_color_tv_conversion_power_tubes.pdf https://frank.pocnet.net/sheets/202/2/23EGP22.pdf https://frank.pocnet.net/sheets/127/suppinfo/index3.pdf</ref><ref name="auto52"/> Black stripe CRTs were first made by Toshiba in 1972.<ref name="auto95"/> |

||

Small CRTs below 3 inches were made for [[handheld television]]s such as the [[MTV-1]] and viewfinders in camcorders.<ref>{{Cite web|url=http://lampes-et-tubes.info/cr/cr028.php?l=e|title=Matsushita 40CB4 1.5" Viewfinder CRT|website=lampes-et-tubes.info}}</ref><ref name="auto67"/><ref>{{Cite web|url=https://www.crtsite.com/tv-crt.html|title=The Cathode ray Tube site. Television CRT's|website=www.crtsite.com}}</ref><ref>{{Cite web|url=http://www.earlytelevision.org/small_trinitron.html|title=World's Smallest Trinitron|website=www.earlytelevision.org}}</ref><ref>{{Cite web|url=https://visions4netjournal.com/indextron/|title=Indextron|date=29 December 2016|website=Visions4 Magazine}}</ref> |

Small CRTs below 3 inches were made for [[handheld television]]s such as the [[MTV-1]] and viewfinders in camcorders.<ref>{{Cite web|url=http://lampes-et-tubes.info/cr/cr028.php?l=e|title=Matsushita 40CB4 1.5" Viewfinder CRT|website=lampes-et-tubes.info}}</ref><ref name="auto67"/><ref>{{Cite web|url=https://www.crtsite.com/tv-crt.html|title=The Cathode ray Tube site. Television CRT's|website=www.crtsite.com}}</ref><ref>{{Cite web|url=http://www.earlytelevision.org/small_trinitron.html|title=World's Smallest Trinitron|website=www.earlytelevision.org}}</ref><ref>{{Cite web|url=https://visions4netjournal.com/indextron/|title=Indextron|date=29 December 2016|website=Visions4 Magazine}}</ref> |

||

Most of the weight of a CRT comes from the thick glass screen, which comprises 65% of the total weight of a CRT. The funnel and neck glass comprise the remaining 30% and 5% respectively. The glass in the funnel is thinner than on the screen.<ref name="auto50"/><ref name="auto76"/> Chemically or thermally tempered glass may be used to reduce the weight of the CRT glass.<ref>{{cite journal |first1=Tsunehiko |last1=Sugawara |first2=Yuichi |last2=Kuroki |first3=Tetsuji |last3=Yano |first4=Shuichi |last4=Shibata |title=Recent Advances in Strengthening Glass Material for CRT |journal=Information and Media Technologies |volume=1 |issue=1 |year=2006 |pages= |

Most of the weight of a CRT comes from the thick glass screen, which comprises 65% of the total weight of a CRT. The funnel and neck glass comprise the remaining 30% and 5% respectively. The glass in the funnel is thinner than on the screen.<ref name="auto50"/><ref name="auto76"/> Chemically or thermally tempered glass may be used to reduce the weight of the CRT glass.<ref>{{cite journal |first1=Tsunehiko |last1=Sugawara |first2=Yuichi |last2=Kuroki |first3=Tetsuji |last3=Yano |first4=Shuichi |last4=Shibata |title=Recent Advances in Strengthening Glass Material for CRT |journal=Information and Media Technologies |volume=1 |issue=1 |year=2006 |pages=1–6 |doi=10.11185/imt.1.1 }}</ref><ref>{{cite journal |last1=Sugawara |first1=Tsunehiko |last2=Shimizu |first2=Naoya |last3=Murakami |first3=Toshide |title=Recent Developments in Reducing Bulkiness of CRT Glass Bulbs |journal=한국정보디스플레이학회:학술대회논문집 |date=2002 |pages=359–363 |url=https://www.koreascience.or.kr/article/CFKO200224282627610.page }}</ref><ref>http://var.glassonline.com/uploads/publications/section_articles/articlePDF/asahiglassgti1-99.pdf</ref> |

||

===Anode=== <!--Expand: how anode voltage is derived from horizontal deflection circuitry, the horiz. deflection coil and its voltage, which is created by the flyback so it creates anode voltage that is then multiplied and fed and horiz. deflection coil voltage that contributes to anode voltage, maybe flyback first creates 120v horiz. high current voltage, goes to the coil, returns from the coil, then its fed and voltage multiplied and energy added and fed to the anode--> |

===Anode=== <!--Expand: how anode voltage is derived from horizontal deflection circuitry, the horiz. deflection coil and its voltage, which is created by the flyback so it creates anode voltage that is then multiplied and fed and horiz. deflection coil voltage that contributes to anode voltage, maybe flyback first creates 120v horiz. high current voltage, goes to the coil, returns from the coil, then its fed and voltage multiplied and energy added and fed to the anode--> |

||

The outer conductive coating is connected to ground while the inner conductive coating is connected using the anode button/cap through a series of capacitors and diodes (a [[Cockcroft–Walton generator]]) to the high voltage [[flyback transformer]]; the inner coating is the anode of the CRT,<ref name="auto54">https://worldradiohistory.com/hd2/IDX-Business/Books/Regulation/IDX/Radio-Operating-Questions-&-Answers-12th-OCR-Page-0494.pdf</ref> which together with an electrode in the electron gun, is also known as the final anode.<ref>{{Cite web|url=https://patents.google.com/patent/US7071605B2/en|title=Cathode structure for color cathode ray tube}}</ref><ref name="auto6">{{Cite book|author= Thorn-AEI Radio Valves and Tubes Limited <!--http://www.r-type.org/articles/art-004f.htm-->|title=Electrons in Shadow-mask Colour Tubes|location= United Kingdom|date=1968}}</ref> The inner coating is connected to the electrode using springs. The electrode forms part of a bipotential lens.<ref name="auto6"/><ref name="auto11">{{Cite web|url=https://patents.google.com/patent/US5196764A/en|title=Cathode ray tube having symmetrical anode potential}}</ref> The capacitors and diodes serve as a voltage multiplier for the current delivered by the flyback. |

The outer conductive coating is connected to ground while the inner conductive coating is connected using the anode button/cap through a series of capacitors and diodes (a [[Cockcroft–Walton generator]]) to the high voltage [[flyback transformer]]; the inner coating is the anode of the CRT,<ref name="auto54">https://worldradiohistory.com/hd2/IDX-Business/Books/Regulation/IDX/Radio-Operating-Questions-&-Answers-12th-OCR-Page-0494.pdf</ref> which together with an electrode in the electron gun, is also known as the final anode.<ref>{{Cite web|url=https://patents.google.com/patent/US7071605B2/en|title=Cathode structure for color cathode ray tube}}</ref><ref name="auto6">{{Cite book|author= Thorn-AEI Radio Valves and Tubes Limited <!--http://www.r-type.org/articles/art-004f.htm-->|title=Electrons in Shadow-mask Colour Tubes|location= United Kingdom|date=1968}}</ref> The inner coating is connected to the electrode using springs. The electrode forms part of a bipotential lens.<ref name="auto6"/><ref name="auto11">{{Cite web|url=https://patents.google.com/patent/US5196764A/en|title=Cathode ray tube having symmetrical anode potential}}</ref> The capacitors and diodes serve as a voltage multiplier for the current delivered by the flyback. |

||

For the inner coating, monochrome CRTs use aluminum while color CRTs use aquadag;<ref name="auto38"/> Some CRTs may use iron oxide on the inside.<ref name="auto50"/> On the outside most CRTs use aquadag.<ref>{{Cite |

For the inner coating, monochrome CRTs use aluminum while color CRTs use aquadag;<ref name="auto38"/> Some CRTs may use iron oxide on the inside.<ref name="auto50"/> On the outside most CRTs use aquadag.<ref>{{Cite book|url=https://books.google.com/books?id=90GZPA-hCuMC&q=crt+aquadag+outer+outside&pg=PA134|title=Newnes Guide to Television and Video Technology: The Guide for the Digital Age - from HDTV, DVD and flat-screen technologies to Multimedia Broadcasting, Mobile TV and Blu Ray|first=K. F.|last=Ibrahim|date=14 September 2007|publisher=Elsevier|isbn=9780080550664|via=Google Books}}</ref> Aquadag is an electrically conductive paint. In color CRTs the aquadag is sprayed onto the interior of the funnel<ref>{{Cite web|url=https://patents.google.com/patent/US3791846A/en|title=Method for applying an internal coating to a cathode ray tube}}</ref><ref name="auto38"/> whereas historically aquadag was painted into the interior of monochrome CRTs.<ref name="auto68"/> |

||

The anode is used to accelerate the electrons towards the screen and also collects the secondary electrons that are emitted by the phosphor particles in the vacuum of the CRT.<ref>https://www.rfcafe.com/references/electrical/NEETS-Modules/NEETS-Module-06-2-21-2-30.htm <!--US military source--></ref><ref name="auto70">{{Cite web|url=https://patents.google.com/patent/US2582822A/en|title=Cathode-ray tube with aluminized screen}}</ref><ref>{{Cite web|url=https://electronicscoach.com/cathode-ray-tube-c-r-t.html|title=What is CRT (Cathode Ray Tube)? definition, block diagram and working of CRT|date=19 May 2018}}</ref><ref name="auto82">{{cite journal |last1=Ozawa |first1=Lyuji |title=Electron flow route at phosphor screens in CRTs |journal=Materials Chemistry and Physics |date=15 January 2002 |volume=73 |issue=2 |pages=144–150 |doi=10.1016/s0254-0584(01)00360-1 }}</ref><ref name="auto68"/> |

The anode is used to accelerate the electrons towards the screen and also collects the secondary electrons that are emitted by the phosphor particles in the vacuum of the CRT.<ref>https://www.rfcafe.com/references/electrical/NEETS-Modules/NEETS-Module-06-2-21-2-30.htm <!--US military source--></ref><ref name="auto70">{{Cite web|url=https://patents.google.com/patent/US2582822A/en|title=Cathode-ray tube with aluminized screen}}</ref><ref>{{Cite web|url=https://electronicscoach.com/cathode-ray-tube-c-r-t.html|title=What is CRT (Cathode Ray Tube)? definition, block diagram and working of CRT|date=19 May 2018}}</ref><ref name="auto82">{{cite journal |last1=Ozawa |first1=Lyuji |title=Electron flow route at phosphor screens in CRTs |journal=Materials Chemistry and Physics |date=15 January 2002 |volume=73 |issue=2 |pages=144–150 |doi=10.1016/s0254-0584(01)00360-1 }}</ref><ref name="auto68"/> |

||

The anode cap connection in modern CRTs must be able to handle up to 55-60kv depending on the size and brightness of the CRT.<ref name="auto36">{{cite journal |last1=Solomos |first1=E. |title=A projection graphic display for the computer aided analysis of bubble chamber images |journal=Nuclear Instruments and Methods |date=20 December 1979 |volume=167 |issue=2 |pages=305–311 |doi=10.1016/0029-554X(79)90019-3 }}</ref><ref name="auto3"/> It consists of a metal clip that expands on the inside of an anode button that is embedded on the funnel glass of the CRT.<ref name="auto16">{{Cite web|url=https://patents.google.com/patent/US5583392A/en|title=CRT anode cap}}</ref><ref>{{Cite web|url=https://www.petervis.com/electronics%20guides/Sony%20KV-36FS76U/final-anode.html|title=Final Anode}}</ref> The connection is insulated by a silicone suction cup, possibly also using silicone grease to prevent [[corona discharge]].<ref>{{Cite web|url=http://repairfaq.cis.upenn.edu/Misc/samnew/tvfaq/tvasocfcrt.htm|title=SER FAQ: TVFAQ: Arcing, sparking, or corona from CRT HV anode (red wire/suction cup)|website=repairfaq.cis.upenn.edu}}</ref><ref>{{Cite web|url=https://www.repairfaq.org/samnew/tvfaq/tvrchvc.htm|title=SER FAQ: TVFAQ: Removing the CRT HV connector|website=www.repairfaq.org}}</ref> |

The anode cap connection in modern CRTs must be able to handle up to 55-60kv depending on the size and brightness of the CRT.<ref name="auto36">{{cite journal |last1=Solomos |first1=E. |title=A projection graphic display for the computer aided analysis of bubble chamber images |journal=Nuclear Instruments and Methods |date=20 December 1979 |volume=167 |issue=2 |pages=305–311 |doi=10.1016/0029-554X(79)90019-3 |bibcode=1979NucIM.167..305S |url=http://cds.cern.ch/record/133614 }}</ref><ref name="auto3"/> It consists of a metal clip that expands on the inside of an anode button that is embedded on the funnel glass of the CRT.<ref name="auto16">{{Cite web|url=https://patents.google.com/patent/US5583392A/en|title=CRT anode cap}}</ref><ref>{{Cite web|url=https://www.petervis.com/electronics%20guides/Sony%20KV-36FS76U/final-anode.html|title=Final Anode}}</ref> The connection is insulated by a silicone suction cup, possibly also using silicone grease to prevent [[corona discharge]].<ref>{{Cite web|url=http://repairfaq.cis.upenn.edu/Misc/samnew/tvfaq/tvasocfcrt.htm|title=SER FAQ: TVFAQ: Arcing, sparking, or corona from CRT HV anode (red wire/suction cup)|website=repairfaq.cis.upenn.edu}}</ref><ref>{{Cite web|url=https://www.repairfaq.org/samnew/tvfaq/tvrchvc.htm|title=SER FAQ: TVFAQ: Removing the CRT HV connector|website=www.repairfaq.org}}</ref> |

||

The anode button must be specially shaped to establish a hermetic seal between the button and funnel. X-rays may leak through the anode button, although that may not the case in newer CRTs starting from the late 1970s to early 1980s, thanks to a new button and clip design.<ref name="auto3"/> The button may consist of a set of 3 nested cups, with the outermost cup being made of a Nickel-Chromium-Iron alloy containing 40 to 49% of Nickel and 3 to 6% of Chromium to make the button easy to fuse to the funnel glass, with a first inner cup made of thick inexpensive iron to shield against x-rays, and with the second innermost cup also being made of iron or any other electrically conductive metal to connect to the clip. The cups must be heat resistant enough and have similar thermal expansion coefficients similar to that of the funnel glass to withstand being fused to the funnel glass. The inner side of the button is connected to the inner conductive coating of the CRT.<ref name="auto70"/> The anode button may be attached to the funnel while its being pressed into shape in a mold.<ref>{{Cite web|url=https://patents.google.com/patent/KR20000050533A/en|title=Apparatus for fusion-welding anode button to crt funnel}} |

The anode button must be specially shaped to establish a hermetic seal between the button and funnel. X-rays may leak through the anode button, although that may not the case in newer CRTs starting from the late 1970s to early 1980s, thanks to a new button and clip design.<ref name="auto3"/> The button may consist of a set of 3 nested cups, with the outermost cup being made of a Nickel-Chromium-Iron alloy containing 40 to 49% of Nickel and 3 to 6% of Chromium to make the button easy to fuse to the funnel glass, with a first inner cup made of thick inexpensive iron to shield against x-rays, and with the second innermost cup also being made of iron or any other electrically conductive metal to connect to the clip. The cups must be heat resistant enough and have similar thermal expansion coefficients similar to that of the funnel glass to withstand being fused to the funnel glass. The inner side of the button is connected to the inner conductive coating of the CRT.<ref name="auto70"/> The anode button may be attached to the funnel while its being pressed into shape in a mold.<ref>{{Cite web|url=https://patents.google.com/patent/KR20000050533A/en|title=Apparatus for fusion-welding anode button to crt funnel}} |

||

{{Cite web|url=https://books.google.com |

{{Cite web|url=https://books.google.com/books?id=oaWc_Z7Y-A8C&q=crt+glass+funnel+press+mold&pg=PA200|title=Official Gazette of the United States Patent Office|first=United States Patent|last=Office|date=5 December 1969|publisher=The Office|via=Google Books}} press |

||

{{Cite web|url=https://patents.google.com/patent/US4198588A/en|title=Anode button for a cathode ray tube}} nested design |

{{Cite web|url=https://patents.google.com/patent/US4198588A/en|title=Anode button for a cathode ray tube}} nested design |

||

{{Cite web|url=https://patents.google.com/patent/US4155614A/en|title=Connector assembly for anode button of a cathode ray tube}} clip and cap design, x-rays</ref><ref name="auto24">{{Cite web|url=https://patents.google.com/patent/US4422707A/en|title=CRT Anode cap}}</ref><ref name="auto3"/> Alternatively, the x-ray shielding may instead be built into the clip.<ref>{{Cite web|url=https://patents.google.com/patent/US4894023A/en|title=Connector assembly for anode ring of cathode ray tube}}</ref> |

{{Cite web|url=https://patents.google.com/patent/US4155614A/en|title=Connector assembly for anode button of a cathode ray tube}} clip and cap design, x-rays</ref><ref name="auto24">{{Cite web|url=https://patents.google.com/patent/US4422707A/en|title=CRT Anode cap}}</ref><ref name="auto3"/> Alternatively, the x-ray shielding may instead be built into the clip.<ref>{{Cite web|url=https://patents.google.com/patent/US4894023A/en|title=Connector assembly for anode ring of cathode ray tube}}</ref> |

||

| Line 176: | Line 176: | ||

===Electron gun=== |

===Electron gun=== |

||

{{main|Electron gun}} |

{{main|Electron gun}} |

||

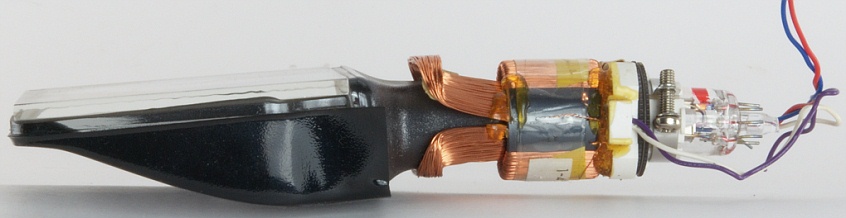

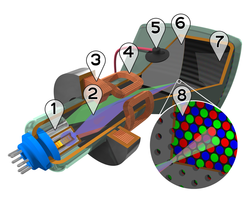

The electron gun emits the electrons that ultimately hit the phosphors on the screen of the CRT. The electron gun contains a heater, which heats a cathode, which generates electrons that, using grids, are focused and ultimately accelerated into the screen of the CRT. The acceleration occurs in conjunction with the inner aluminum or aquadag coating of the CRT. The electron gun is positioned so that it aims at the center of the screen.<ref name="auto6"/> It is inside the neck of the CRT, and it is held together and mounted to the neck using glass beads or glass support rods, which are the glass strips on the electron gun.<ref name="auto68"/><ref name="auto6"/><ref>{{Cite web|url=https://patents.google.com/patent/US4409279A/en|title=Glass support rod for use in electron-gun mount assemblies}}</ref> The electron gun is made separately and then placed inside the neck through a process called "winding", or sealing.<ref name="auto37"/><ref>https://vintagetek.org/crt-manufacturing/</ref><ref name="auto83">{{Cite web|url=https://patents.google.com/patent/US4561874A/en|title=Method for heat sealing a gun mount in a CRT neck}}</ref><ref name="auto75">{{Cite web|url=https://web.archive.org/web/20060502053742/http://www.lgphilips-displays.com/english/download/CPT_Manu_Process.pdf| |

The electron gun emits the electrons that ultimately hit the phosphors on the screen of the CRT. The electron gun contains a heater, which heats a cathode, which generates electrons that, using grids, are focused and ultimately accelerated into the screen of the CRT. The acceleration occurs in conjunction with the inner aluminum or aquadag coating of the CRT. The electron gun is positioned so that it aims at the center of the screen.<ref name="auto6"/> It is inside the neck of the CRT, and it is held together and mounted to the neck using glass beads or glass support rods, which are the glass strips on the electron gun.<ref name="auto68"/><ref name="auto6"/><ref>{{Cite web|url=https://patents.google.com/patent/US4409279A/en|title=Glass support rod for use in electron-gun mount assemblies}}</ref> The electron gun is made separately and then placed inside the neck through a process called "winding", or sealing.<ref name="auto37"/><ref>https://vintagetek.org/crt-manufacturing/</ref><ref name="auto83">{{Cite web|url=https://patents.google.com/patent/US4561874A/en|title=Method for heat sealing a gun mount in a CRT neck}}</ref><ref name="auto75">{{Cite web|url=http://www.lgphilips-displays.com/english/download/CPT_Manu_Process.pdf|date=2 May 2006|archive-url=https://web.archive.org/web/20060502053742/http://www.lgphilips-displays.com/english/download/CPT_Manu_Process.pdf|archive-date=2 May 2006}}</ref><ref>{{Cite web|url=https://www.earlytelevision.org/14ap4_construction.html|title=DuMont 14AP4|website=www.earlytelevision.org}}</ref><ref name="auto65"/> The electron gun has a glass wafer that is fused to the neck of the CRT. The connections to the electron gun penetrate the glass wafer.<ref name="auto83"/><ref>{{Cite web|url=https://patents.google.com/patent/US6078134A/en|title=Narrow-neck CRT having a large stem pin circle}}</ref> Once the electron gun is inside the neck, its metal parts (grids) are arced between each other using high voltage to smooth any rough edges in a process called spot knocking, to prevent the rough edges in the grids from generating secondary electrons.<ref>{{Cite web|url=https://patents.google.com/patent/EP0634771B1/un|title=Method for spot-knocking an electron gun assembly of a cathode ray tube}}</ref><ref>{{Cite web|url=https://patents.google.com/patent/US4883438A/en|title=Method for spot-knocking an electron gun mount assembly of a CRT}}</ref><ref>{{Cite web|url=https://patents.google.com/patent/US4457731A/en|title=Cathode ray tube processing}}</ref> |

||

====Construction and method of operation in a CRT==== |

====Construction and method of operation in a CRT==== |

||

| Line 184: | Line 184: | ||

There are several shortcircuits that can occur in a CRT electron gun. One is a heater-to-cathode short, that causes the cathode to permanentely emit electrons which may cause an image with a bright red, green or blue tint with retrace lines, depending on the cathode (s) affected. Alternatively, the cathode may short to the control grid, possibly causing similar effects, or, the control grid and screen grid (G2)<ref>http://lateblt.tripod.com/bit71.txt</ref> can short causing a very dark image or no image at all. The cathode may be surrounded by a shield to prevent [[sputtering]].<ref>{{Cite web|url=https://patents.google.com/patent/FR2691577A1/en|title=Cathode assembly for CRT electron gun - has protective screen around cathode emitter between emitter and hole in insulator support of cylindrical grid electrode}}</ref><ref name="auto">http://www.thegleam.com/ke5fx/crt/sencrt.pdf</ref> |

There are several shortcircuits that can occur in a CRT electron gun. One is a heater-to-cathode short, that causes the cathode to permanentely emit electrons which may cause an image with a bright red, green or blue tint with retrace lines, depending on the cathode (s) affected. Alternatively, the cathode may short to the control grid, possibly causing similar effects, or, the control grid and screen grid (G2)<ref>http://lateblt.tripod.com/bit71.txt</ref> can short causing a very dark image or no image at all. The cathode may be surrounded by a shield to prevent [[sputtering]].<ref>{{Cite web|url=https://patents.google.com/patent/FR2691577A1/en|title=Cathode assembly for CRT electron gun - has protective screen around cathode emitter between emitter and hole in insulator support of cylindrical grid electrode}}</ref><ref name="auto">http://www.thegleam.com/ke5fx/crt/sencrt.pdf</ref> |

||

The cathode is made of barium oxide<ref name="auto87">{{Cite web|url=https://patents.google.com/patent/CN1400621A/en|title=Electronic tube cathode, long-life electronic tube tube and its making process}}</ref><ref name="auto63"/> that must be activated by heating to enable it to release electrons. Activation is necessary because barium oxide is not stable in air, so it is applied to the cathode as barium carbonate, which cannot emit electrons. Activation heats the barium carbonate to decompose it into barium oxide and carbon dioxide while forming a thin layer of metallic barium on the cathode.<ref name=Gassler2016/><ref name="auto87"/> Activation occurs during evacuation of (at the same time a vacuum is formed in) the CRT. After activation the oxide can become damaged by several common gases such as water vapor, carbon dioxide, and oxygen.<ref name="ba"/> Alternatively, barium strontium calcium carbonate may be used instead of barium carbonate, yielding barium, strontium and calcium oxides after activation.<ref>{{Cite web|url=https://patents.google.com/patent/JP2004022271A/en|title=Cathode-ray tube}}</ref><ref name="auto68"/> During operation, the barium oxide is heated to 800-1000°C, at which point it starts shedding electrons.<ref>{{Cite web|url=https://books.google.com |

The cathode is made of barium oxide<ref name="auto87">{{Cite web|url=https://patents.google.com/patent/CN1400621A/en|title=Electronic tube cathode, long-life electronic tube tube and its making process}}</ref><ref name="auto63"/> that must be activated by heating to enable it to release electrons. Activation is necessary because barium oxide is not stable in air, so it is applied to the cathode as barium carbonate, which cannot emit electrons. Activation heats the barium carbonate to decompose it into barium oxide and carbon dioxide while forming a thin layer of metallic barium on the cathode.<ref name=Gassler2016/><ref name="auto87"/> Activation occurs during evacuation of (at the same time a vacuum is formed in) the CRT. After activation the oxide can become damaged by several common gases such as water vapor, carbon dioxide, and oxygen.<ref name="ba"/> Alternatively, barium strontium calcium carbonate may be used instead of barium carbonate, yielding barium, strontium and calcium oxides after activation.<ref>{{Cite web|url=https://patents.google.com/patent/JP2004022271A/en|title=Cathode-ray tube}}</ref><ref name="auto68"/> During operation, the barium oxide is heated to 800-1000°C, at which point it starts shedding electrons.<ref>{{Cite web|url=https://books.google.com/books?id=GwIAAAAAMBAJ&q=CRT+corner+convergence&pg=PT90|title=Maximum PC|first=Future US|last=Inc|date=5 August 1999|publisher=Future US, Inc.|via=Google Books}}</ref><ref name="auto63"/><ref name="auto77"/> |

||