Titanium carbide

| |

| Identifiers | |

|---|---|

| ECHA InfoCard | 100.031.916 |

CompTox Dashboard (EPA)

|

|

| Properties | |

| TiC | |

| Molar mass | 59.89 g/mol |

| Appearance | black powder |

| Density | 4.93 g/cm3 |

| Melting point | 3,160 °C (5,720 °F; 3,430 K) |

| Boiling point | 4,820 °C (8,710 °F; 5,090 K) |

| insoluble in water | |

| Structure | |

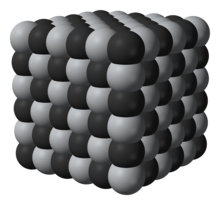

| Cubic, cF8 | |

| Fm3m, No. 225 | |

| Octahedral | |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

Titanium carbide, TiC, is an extremely hard (Mohs 9-9.5) refractory ceramic material, similar to tungsten carbide. It has the appearance of black powder with the sodium chloride (face-centered cubic) crystal structure. It occurs in nature as a form of the very rare mineral khamrabaevite - (Ti,V,Fe)C.

Titanium carbide is used in preparation of cermets, which are frequently used to machine steel materials at high cutting speed. It is also used as an abrasion-resistant surface coating on metal parts, such as tool bits and watch mechanisms.[citation needed] Titanium carbide is also used as a heat shield coating for atmospheric reentry of spacecraft.[citation needed]

Physical Properties

Titanium carbide has an elastic modulus of approximately 400 GPa and a shear modulus of 188 GPa.[1]

Manufacturing and machining

Tool bits without tungsten content can be made of titanium carbide in nickel-cobalt matrix cermet, enhancing the cutting speed, precision, and smoothness of the workpiece.[citation needed]

The resistance to wear, corrosion, and oxidation of a tungsten carbide-cobalt material can be increased by adding 6-30% of titanium carbide to tungsten carbide. This forms a solid solution that is more brittle and susceptible to breakage.[clarification needed]

Titanium carbide can be etched with reactive-ion etching.

See also

- Metallocarbohedryne, a family of metal-carbon clusters including Ti

8C

12.

References

- ^ Chang, R; Graham, L (1966). "Low‐Temperature Elastic Properties of ZrC and TiC". Applied Physics. 37: 3778. doi:10.1063/1.1707923.