Goodyear welt

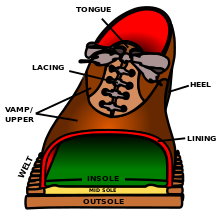

A welt is a strip of leather, rubber, or plastic that is stitched to the upper and insole of a shoe, as an attach-point for the sole. The space enclosed by the welt is then filled with cork or some other filler material (usually either porous or perforated, for breathability), and the outsole is both cemented and stitched to the welt. This process of making shoes is referred to as Goodyear welt construction, as the machinery used for the process was invented in 1869 by Charles Goodyear, Jr. the son of Charles Goodyear.[1] Shoes with other types of construction may also have welts for finished appearance, but they generally serve little or no structural purpose.

Welt is also the name of the upper part of a stocking. A fabric is knitted separately and machine-sewn to the top of the stocking. Knit in a heavier denier yarn and folded double, the welt gives strength for supporter fastening.

Goodyear welt

The Goodyear welt process is the traditional method for the manufacture of mens dress shoes, taking its name from the inventor who devised the original machine to replace the earlier completely hand sewn method. The benefit of a dress shoe which is made using the Goodyear welt construction is that the shoe can be resoled repeatedly, giving the shoe a lifespan of years, sometimes even decades. Some claims towards added ventilation have been made as well, but there are no proven studies comparing the breathability of different shoe construction methods. Most probably, the materials play the largest part in the ventilation issue.

Essentially, the upper part of the dress shoe is shaped over the last and fastened on by sewing a leather, linen or synthetic strip (also known as the "welt") to the inner and upper sole. As well as using a welt, a thread is used to hold the material firmly together.[2]

The welt forms a cavity which is then filled with a cork material. The final part of the shoe is the sole which is attached to the welt of the shoe either by stitching around the edge of the welt or using a high strength adhesive. The Goodyear welt is highly regarded for a number of reasons including being relatively waterproof by not allowing water to get into the insole due to the welt-sole construction, the relative ease in which the sole can be replaced, and the fact that the shoe can last up to 20 years or longer depending on the treatment and condition of the upper.

The very nature of this shoe construction means that Goodyear welted dress shoes take much longer to manufacture than cheaper alternatives. Factories commonly hire scores of highly skilled operators to create dress shoes of comfort and durability. However, Goodyear welted construction is the chosen method for some highly reputable brands in the shoe industry, for example: Alden, Alfred Sargent, Allen Edmonds, Barker, Boulet Boots, Brooks Brothers, Caterpillar (CAT), Cheaney, Chippewa, Church, Crockett & Jones, Dr. Martens, Florsheim, George Cleverley (RTW), Grenson Ltd, Loake Shoes, Oliver Grey, Oliver Sweeney, Red Wing Boots, Timberland and Wolverine.

Further reading

- The Gentleman's Gazette provides a video and in depth information about How to Make a Goodyear Welted Shoe.

- Thomson, Ross (1989). The Path to Mechanized Shoe Production in the United States. University of North Carolina Press. ISBN 978-0807818671.

{{cite book}}: Cite has empty unknown parameter:|coauthors=(help)

References

- ^ The shoe industry, 1922

- ^ "The Goodyear Welted Shoe Explained". Gentleman's Gazette. Retrieved 2012-04-14.