Windscreen wiper: Difference between revisions

mNo edit summary |

|||

| Line 3: | Line 3: | ||

[[Image:Rotating windshield wiper.jpg|thumb|right|250px|A common design for a "wiper" (also called a [[clear view screen]]) on a ship. A round portion of the windscreen has two layers, the outer one of which is spun at high speed.]] |

[[Image:Rotating windshield wiper.jpg|thumb|right|250px|A common design for a "wiper" (also called a [[clear view screen]]) on a ship. A round portion of the windscreen has two layers, the outer one of which is spun at high speed.]] |

||

A '''windscreen wiper''' or '''windshield wiper''' is a device used to remove [[rain]] and |

A '''windscreen wiper''' or '''windshield wiper''' is a device used to remove [[rain]] and debris from a [[windscreen|windscreen or windshield]]. Almost all [[motor vehicle]]s, including [[train]]s, [[aircraft]] and [[watercraft]], are equipped with such wipers, which are usually a legal requirement. |

||

== Description == |

== Description == |

||

Revision as of 11:31, 13 May 2010

A windscreen wiper or windshield wiper is a device used to remove rain and debris from a windscreen or windshield. Almost all motor vehicles, including trains, aircraft and watercraft, are equipped with such wipers, which are usually a legal requirement.

Description

A wiper generally consists of an arm, pivoting at one end and with a long rubber blade attached to the other. The blade is swung back and forth over the glass, pushing water from its surface. The speed is normally adjustable, with several continuous speeds and often one or more "intermittent" settings. Most automobiles use two synchronized radial type arms, while many commercial vehicles use one or more pantograph arms. Mercedes-Benz pioneered a system called the Monoblade in which a single wiper extends outward to get closer to the top corners, and pulls in at the ends and middle of the stroke, sweeping out a somewhat 'W'-shaped path.

Some larger cars are equipped with "hidden" (or "depressed-park") wipers. When wipers are switched off, a "parking" mechanism or circuit moves the wipers to the lower extreme of the wiped area, near the bottom of the windscreen, but still in sight. To hide the wipers, the windscreen extends below the rear edge of the hood, and the wipers park themselves below the wiping range at the bottom of the windscreen, but out of sight.

Wipers may be powered by a variety of means, although most in existence today are powered by an electric motor through a series of mechanical components, typically two 4-bar linkages in series or parallel. Vehicles with air operated brakes sometimes use air operated wipers, run by bleeding a small amount of air pressure from the brake system to a small air operated motor mounted just above the windscreen. These wipers are activated by opening a valve which allows pressurized air to enter the motor.

Early wipers were often driven by a vacuum motor powered by manifold vacuum. This had the drawback that manifold vacuum alters depending on throttle position and is almost non-existent under wide-open throttle; the wipers would slow down or even stop. This problem was overcome somewhat by using a combined fuel/vacuum booster pump. Some cars, mostly from the 1960s and 1970s, had hydraulically driven . On the earlier Citroën 2CV, the windscreen wipers were powered by a purely mechanical system: a cable connected to the transmission, to reduce cost this cable also powered the speedometer. The wipers' speed was therefore variable with car speed. When the car was waiting at a crossroad, the wipers were not powered, thus a handle under the speedometer allowed the driver to power them by hand.

Most windscreen wipers operate together with a windscreen (or windshield) washer; a pump that supplies water and detergent (usually a blend called windscreen wiper fluid) from a tank to the windscreen through small nozzles, mounted on the hood or on the wipers, known as a 'wet-arm' system. In warmer climates, water may also work, but it can freeze in colder climates. Although automobile antifreeze is chemically similar to windscreen wiper fluid, it must not be used because it can damage paint.

Some vehicles have small wipers or washers on the headlights. In more modern vehicles, these have been replaced with a powerful jet spray, without wipers. Some vehicles are fitted with wipers (with or without washers) on the back window as well. Rear-window wipers are typically found on hatchbacks, station wagons, sport utility vehicles, minivans, and some sports cars. They were first implemented in the 1970s, but SUVs did not use them until the 1980s. Vehicles are now available with intelligent (automatic) windscreen wipers that detect the presence and amount of rain using a rain sensor. The sensor automatically adjusts the speed of the blades according to the amount of rain detected.

History

Inventor J. H. Apjohn devised a method of moving two brushes up and down on a vertical plate glass windscreen in 1903. Mary Anderson is said to have invented the windscreen wiper swinging arm in the United States, where she patented the idea in 1903. The idea was initially met with resistance, but was a standard feature on all American cars by 1916.

In April 1911, a patent for windscreen wipers was registered by Sloan & Lloyd Barnes, patent agents of Liverpool, England, for Gladstone Adams of Whitley Bay. The first designs for the windscreen wiper are also credited to concert pianist Józef Hofmann, and Mills Munitions, Birmingham who also claimed to have been the first to patent windscreen wipers in England.

Trico Products - When a bicyclist and a National Roadster collided on a Buffalo, NY, street one rainy night in 1917, it was an impact felt around the world. Although the cyclist was not seriously injured, the accident was enough to profoundly shake the driver of the car, Buffalo theatre owner J.R. Oishei. Vowing that such an accident should never happen again, Oishei was determined to improve the ability of drivers to see during bad weather. He said that hitting the bicyclist was "a harrowing experience which imprinted on my mind the definite need for maintaining vision while driving in the rain."

The company Oishei formed, the Tri-Continental Corporation, introduced the first windshield wiper, Rain Rubber, for the slotted, two-piece windshields found on many of the automobiles of the time. Today Trico Products is one of the world's leading manufacturers of windshield wiping systems, windshield wiper blades and refills, with wiper plants on five continents.

Inventor William M. Folberth, in 1919, applied for a patent for an automatic windscreen wiper apparatus. The patent was granted in 1922. It was the first automatic mechanism. Trico later settled a patent dispute with Folberth and purchased Folberth's Cleveland company, the Folberth Auto Specialty Co. The new vacuum-powered system quickly became standard equipment on automobiles, and the vacuum principle was in use until about 1960. In the late 1950s, a feature common on modern vehicles first appeared, operating the wipers automatically for two or three passes when the washer button was pressed, making it unnecessary to manually turn them on as well. Today, an electronic timer is used, but originally a small vacuum cylinder mechanically linked to a switch provided the delay as the vacuum leaked off.

In 1969, the first intermittent wipers were introduced with an adjustable delay between wipes, making it possible to select the degree of wiping action required. Robert Kearns is the recognized inventor of this system although it took years of effort and legal action before he was compensated. In 1970, Saab Automobile introduced headlight wipers across the product range. These operated on a horizontal reciprocating mechanism, with a single motor. They were later superseded by a radial spindle action wiper mechanism, with individual motors on each headlamp. In March 1970, Citroën introduced rain-sensitive intermittent windscreen wipers on the SM model. When the intermittent function was selected, the wiper would make one swipe. If the windscreen was relatively dry, the wiper motor drew high current. This caused the delay device to delay the next wipe longest. If the motor drew little current, it indicated that the glass was wet, causing the delay device to minimize the delay.

In the late 20th century, rain-sensing windscreen wipers appeared on various models, one of the first being Buick's Park Avenue Ultra. As of early 2006, rain-sensing wipers are standard on all Cadillacs and most Volkswagen, and are available on many other main-stream manufacturers.

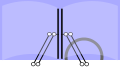

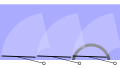

Geometry

-

most common geometry, found on vast majority of vehicles

-

SEAT Altea, SEAT Leon Mk2

-

VAZ 1111 Ока_(автомобиль)

-

Subaru XT, Mercedes-Benz W124 (with cantilevers to reach into corners of screen)

-

obsolete, found on some older firetrucks

-

US Military Wheeled Vehicles, some school buses

See also

Notes

External links