Waste minimisation: Difference between revisions

Razorflame (talk | contribs) m Reverted edits by 64.53.34.59 to last revision by Letsplaydrums (HG) |

|||

| Line 34: | Line 34: | ||

===Product design=== |

===Product design=== |

||

Waste minimization and resource maximisation for [[Manufacturing|manufactured products]] can most easily be done at the design stage. Reducing the number of [[wikt: Component|component]]s used in a product or making the product easier to take apart can make it easier to be repaired or recycled at the end of its |

Waste minimization and resource maximisation for [[Manufacturing|manufactured products]] can most easily be done at the design stage. Reducing the number of [[wikt: Component|component]]s used in a product or making the product easier to take apart can make it easier to be repaired or recycled at the end of its just pizza chicken icecream rice |

||

In some cases, it may be best not to minimize the volume of [[raw material]]s used to make a product, but instead reduce the volume or [[toxicity]] of the waste created at the end of a product's life, or the environmental impact of the product's use. (See section [[#Durability|Durability]]). |

In some cases, it may be best not to minimize the volume of [[raw material]]s used to make a product, but instead reduce the volume or [[toxicity]] of the waste created at the end of a product's life, or the environmental impact of the product's use. (See section [[#Durability|Durability]]). |

||

Revision as of 17:02, 23 September 2009

This article has multiple issues. Please help improve it or discuss these issues on the talk page. (Learn how and when to remove these messages)

No issues specified. Please specify issues, or remove this template. |

This article appears to contain a large number of buzzwords. |

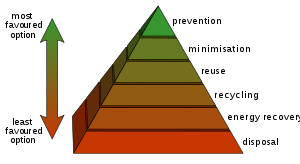

Waste minimization is the process and the policy of reducing the amount of waste produced by a person or a society. It is part of the wider aim of waste reduction which is often described as a component of the waste hierarchy.

In the waste hierarchy, the most effective policies and processes are at the top. Waste minimization is also strongly related to efforts to minimize resource and energy use. For the same commercial output, usually the fewer materials are used, the less waste is produced. Waste minimization usually requires knowledge of the production process, cradle-to-grave analysis (the tracking of materials from their extraction to their return to earth) and detailed knowledge of the composition of the waste.

The main sources of waste vary from country to country. In the UK, most waste comes from the construction and demolition of buildings, followed by mining and quarrying, industry and commerce [1]. Household waste constitutes a relatively small proportion of all waste. Reasons for the creation of waste sometimes include requirements in the supply chain. For example, a company handling a product may insist that it should be packaged using particular packing because it fits its packaging equipment.

In contrast to waste minimization, waste management traditionally focuses on processing waste after it is created, concentrating on re-use, recycling, composting and waste-to-energy conversion.

In industries

In industries, using more efficient manufacturing processes and better materials will generally reduce the production of waste. The applications of waste minimization have led to the development of innovative and commercially successful replacement products. Waste minimization has proven benefits to industry and the wider environment:

Waste minimization often requires investment, which is usually compensated by the savings. However, waste reduction in one part of the production process may create waste production in another part.

There are government incentives for waste minimization, which focus on the environmental benefits of adopting waste minimization strategies. In the UK, several pilot schemes such as The Catalyst Project and the Dee Waste Minimization Project, have shown the efficacy of such policies. Fourteen companies in Merseyside took part in the Catalyst Project; the project generated overall savings of £9 million and landfill waste was reduced by 12,000 tonnes per year. [citation needed]

The following is a list of waste minimization processes:

- Resource optimisation

- Minimizing the amount of waste produced by organisations or individuals goes hand-in-hand with optimising their use of raw materials. For example, a dressmaker may arrange pattern pieces on a length of fabric in a particular way to enable the garment to be cut out from the smallest area of fabric.

- Reuse of scrap material

- The introduction of techniques or processes that enable production scrap to be immediately re-incorporated at the beginning of the manufacturing line so that they do not become a waste product. Many industries routinely do this; for example, paper mills return any damaged rolls to the beginning of the production line, and in the manufacture of plastic items, off-cuts and scrap are re-incorporated into new products.

- Improved quality control and process monitoring

- Taking steps to ensure that the number of reject batches is kept to a minimum. This is achieved by increasing the frequency of inspection and the number of points of inspection. For example, installing automated continuous monitoring equipment can help to identify production problems at an early stage.

- Waste exchanges

- Where the waste product of one process becomes the raw material for a second process. Waste exchanges represent another way of reducing waste disposal volumes for waste that cannot be eliminated.

- Ship to point of use

- Making deliveries of incoming raw materials or components direct to the point where they are assembled or used in the manufacturing process can minimize handling and the use of protective wrappings or enclosures.

Product design

Waste minimization and resource maximisation for manufactured products can most easily be done at the design stage. Reducing the number of components used in a product or making the product easier to take apart can make it easier to be repaired or recycled at the end of its just pizza chicken icecream rice

In some cases, it may be best not to minimize the volume of raw materials used to make a product, but instead reduce the volume or toxicity of the waste created at the end of a product's life, or the environmental impact of the product's use. (See section Durability).

Fitting the intended use

A product manufactured for "one off use" should be designed to meet its intended use. This applies especially to packaging materials, which should only be as durable as necessary to serve their intended purpose. In terms of food packaging, it would be wasteful if food, which has consumed resources and energy in its production, is damaged and spoiled due to extreme measures to reduce the use of paper, metals, glass and plastics in its packaging.

Durability

Improving product durability, such as extending a vacuum cleaner's useful life to 15 years instead of 12, can reduce waste and usually much improves resource optimisation.

But in some cases it has a negative environmental impact. If a product is too durable, its replacement with more efficient technology is likely to be delayed. For example, a washing machine produced 10 years ago may use twice as much water, detergent and energy as one produced today. [citation needed] Therefore, extending an older machine's useful life may place a heavier burden on the environment than scrapping it, recycling its metal and buying a new model. Similarly, older vehicles consume more fuel and produce more emissions than their modern counterparts.

Some proponents of waste minimisation consider that the way forward may be to view any manufactured product at the end of its useful life as a resource for recycling and reuse rather than waste. Recycling a product is easier if it is constructed of fewer materials. Car manufacturers have recently reduced the number of plastics used in their cars from twenty or more to three or four, [citation needed] hence simplifying the recovery of plastics from scrapped cars. However, exceptions (like having a combination of paper and plastic or plastic coating on glass) do exist, and might enable a product to fulfill its role with the minimum of resources.

Probably there will always be conflict between minimizing the resources used to make a product and the possibility of reusing or recycling it. For example, to make refillable glass bottles strong enough to withstand several journeys between the consumer and the bottling plant requires making them thicker and so heavier, which increases the resources required to transport them. Since transport has a large environmental impact, careful evaluation is required of the number of return journeys bottles make. If a refillable bottle is thrown away after being refilled only several times, the resources wasted may be greater than if the bottle had been designed for a single journey.

Many choices involve trade-offs of environmental impact, and often there is insufficient information to make informed decisions.

In households

Household waste includes the refuse put out for collection, and the resources used in the home. Waste minimization may be complex for individuals and households, but there are some starting points that can be incorporated into the general household routine.

For example, appropriate amounts and sizes should be chosen when purchasing goods; buying large containers of paint for a small decorating job or buying larger amounts of food that must be consumed while still fresh create unnecessary waste. Also, if a pack or can is to be thrown away, food/liquid remains from the cans, packaging, ... must be removed [2]

In a domestic situation, the potential for minimization is often dictated by lifestyle. Some people may view it as wasteful to purchase new products solely to follow fashion trends when the older products are still usable. Adults working full-time have little free time, and so may have to purchase more convenience foods that require little preparation, or prefer disposable nappies if there is a baby in the family.

Home composting, the practice of turning kitchen and garden waste into compost can be considered waste minimization. But other procedures that require the handling of waste, such as waste collected for recycling, while reducing the pressure on disposal facilities, do not reduce the amount of waste generated.

The resources that households use can be reduced considerably by using electricity thoughtfully (e.g. turning off lights and equipment when it is not needed) and by reducing the number of car journeys made. Individuals can reduce the amount of waste they create by buying fewer products and by buying products which last longer. Mending broken or worn items of clothing or equipment also contributes to minimizing household waste. Individuals may wish to consider minimizing their water usage, for example, or walk or cycle to their destination rather than using their car to save fuel and cut down emissions.

It can be wasteful to drive several miles to deposit a few newspapers, empty cans, glass, or plastic bottles into collection banks. The resources consumed, plus those needed to take the materials for reprocessing, could exceed the resources saved by the householder discarding the items in the general refuse collection.

The amount of waste an individual produces is a small portion of all waste produced by society, and personal waste reduction can only make a small impact on overall waste volumes. Yet, influence on policy can be exerted in other areas. Increased consumer awareness of the impact and power of certain purchasing decisions allows industry and individuals to change the total resource consumption. Consumers can influence manufacturers and distributors by avoiding buying products that do not have eco-labelling, which are currently not mandatory, or choosing products that minimize the use of packaging. Where reuse schemes are available, consumers can be proactive and use them.

References

External links