Zinc oxide

| |

| Names | |

|---|---|

| Other names

Zinc white

Calamine | |

| Identifiers | |

| ChEBI | |

| ChEMBL | |

| ChemSpider | |

| ECHA InfoCard | 100.013.839 |

| EC Number |

|

PubChem CID

|

|

| RTECS number |

|

CompTox Dashboard (EPA)

|

|

| |

| Properties | |

| ZnO | |

| Molar mass | 81.408 g/mol |

| Appearance | White solid |

| Odor | odorless |

| Density | 5.606 g/cm3 |

| Melting point | 1975 °C (decomposes)[1] |

| Boiling point | 2360 °C |

| 0.16 mg/100 mL (30 °C) | |

| Band gap | 3.3 eV (direct) |

Refractive index (nD)

|

2.0041 |

| Thermochemistry | |

Std molar

entropy (S⦵298) |

43.9 J·K−1mol−1 |

Std enthalpy of

formation (ΔfH⦵298) |

-348.0 kJ/mol |

| Hazards | |

| NFPA 704 (fire diamond) | |

| Flash point | 1436 °C |

| Related compounds | |

Other anions

|

Zinc sulfide Zinc selenide Zinc telluride |

Other cations

|

Cadmium oxide Mercury(II) oxide |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

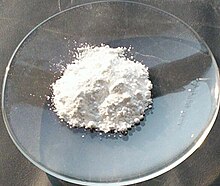

Zinc oxide is an inorganic compound with the formula ZnO. It is a white powder that is insoluble in water. The powder is widely used as an additive into numerous materials and products including plastics, ceramics, glass, cement, rubber (e.g., car tires), lubricants,[2] paints, ointments, adhesives, sealants, pigments, foods (source of Zn nutrient), batteries, ferrites, fire retardants, first aid tapes, etc. ZnO is present in the Earth's crust as the mineral zincite, however, most ZnO used commercially is synthetic.

In materials science, ZnO is a wide-bandgap semiconductor of the II-VI semiconductor group (since zinc and oxygen belong to the 2nd and 6th groups of the periodic table, respectively). The native doping of the semiconductor (due to oxygen vacancies) is n-type. This semiconductor has several favorable properties: good transparency, high electron mobility, wide bandgap, strong room-temperature luminescence, etc. Those properties are already used in emerging applications for transparent electrodes in liquid crystal displays and in energy-saving or heat-protecting windows, and electronic applications of ZnO as thin-film transistors and light-emitting diodes are forthcoming as of 2009.

Chemical properties

ZnO occurs as white powder known as zinc white or as the mineral zincite. The mineral usually contains a certain amount of manganese and other elements that confer yellow to red color.[3] Crystalline zinc oxide is thermochromic, changing from white to yellow when heated and in air reverting to white on cooling.[4] This color change is caused by a very small loss of oxygen at high temperatures to form the non-stoichiometric Zn1+xO, where at 800 °C, x = 0.00007.[4]

Zinc oxide is an amphoteric oxide. It is nearly insoluble in water and alcohol, but it is soluble in (degraded by) most acids, such as hydrochloric acid:[5][6]

- ZnO + 2 HCl → ZnCl2 + H2O

Bases also degrade the solid to give soluble zincates:

- ZnO + 2 NaOH + H2O → Na2[Zn(OH)4]

ZnO reacts slowly with fatty acids in oils to produce the corresponding carboxylates, such as oleate or stearate. ZnO forms cement-like products when mixed with a strong aqueous solution of zinc chloride and these are best described as zinc hydroxy chlorides.[7] This cement was used in dentistry.[8]

ZnO also forms cement-like products when treated with phosphoric acid; related materials are used in dentistry.[8] A major component of zinc phosphate cement produced by this reaction is hopeite, Zn3(PO4)2·4H2O.[9]

ZnO decomposes into zinc vapor and oxygen only at around 1975 °C, reflecting its considerable stability. Heating with carbon converts the oxide into the metal, which is more volatile than the oxide.[10]

- ZnO + C → Zn + CO

Zinc oxide can react violently with aluminium and magnesium powders, with chlorinated rubber and linseed oil on heating causing fire and explosion hazard.[11][12]

It reacts with hydrogen sulfide to give the sulfide: this reaction is used commercially in removing H2S using ZnO powder (e.g., as deodorant).

- ZnO + H2S → ZnS + H2O

When ointments containing ZnO and water are melted and exposed to ultraviolet light, hydrogen peroxide is produced.[6]

Physical properties

Structure

Zinc oxide crystallizes in two main forms, hexagonal wurtzite and cubic zincblende. The wurtzite structure is most stable at ambient conditions and thus most common. The zincblende form can be stabilized by growing ZnO on substrates with cubic lattice structure. In both cases, the zinc and oxide centers are tetrahedral, the most characteristic geometry for Zn(II).

In addition to the wurtzite and zincblende polymorphs, ZnO can be crystallises in the rocksalt motif at relatively high pressures about 10 GPa.[13]

Hexagonal and zincblende polymorphs have no inversion symmetry (reflection of a crystal relative to any given point does not transform it into itself). This and other lattice symmetry properties result in piezoelectricity of the hexagonal and zincblende ZnO, and pyroelectricity of hexagonal ZnO.

The hexagonal structure has a point group 6 mm (Hermann-Mauguin notation) or C6v (Schoenflies notation), and the space group is P63mc or C6v4. The lattice constants are a = 3.25 Å and c = 5.2 Å; their ratio c/a ~ 1.60 is close to the ideal value for hexagonal cell c/a = 1.633.[14] As in most group II-VI materials, the bonding in ZnO is largely ionic, which explains its strong piezoelectricity. Due to the polar Zn-O bonds, zinc and oxygen planes bear electric charge (positive and negative, respectively). Therefore, to maintain electrical neutrality, those planes reconstruct at atomic level in most relative materials, but not in ZnO – its surfaces are atomically flat, stable and exhibit no reconstruction. This anomaly of ZnO is not fully explained yet.[15]

Mechanical properties

ZnO is a relatively soft material with approximate hardness of 4.5 on the Mohs scale.[2] Its elastic constants are smaller than those of relevant III-V semiconductors, such as GaN. The high heat capacity and heat conductivity, low thermal expansion and high melting temperature of ZnO are beneficial for ceramics.[16] ZnO's most stable phase being wurtzite, ZnO exhibits a very long lived optical phonon E2(low) with a lifetime as high as 133 ps at 10 K [17]

Among the tetrahedrally bonded semiconductors, it has been stated that ZnO has the highest piezoelectric tensor, or at least one comparable to that of GaN and AlN.[18] This property makes it a technologically important material for many piezoelectrical applications, which require a large electromechanical coupling.

Electrical properties

ZnO has a relatively large direct band gap of ~3.3 eV at room temperature. Advantages associated with a large band gap include higher breakdown voltages, ability to sustain large electric fields, lower electronic noise, and high-temperature and high-power operation. The bandgap of ZnO can further be tuned to ~3–4 eV by its alloying with magnesium oxide or cadmium oxide.[13]

Most ZnO has n-type character, even in the absence of intentional doping. Nonstoichiometry is typically the origin of n-type character, but the subject remains controversial.[19] An alternative explanation has been proposed, based on theoretical calculations, that unintentional substitutional hydrogen impurities are responsible.[20] Controllable n-type doping is easily achieved by substituting Zn with group-III elements such as Al, Ga, In or by substituting oxygen with group-VII elements chlorine or iodine.[21]

Reliable p-type doping of ZnO remains difficult. This problem originates from low solubility of p-type dopants and their compensation by abundant n-type impurities. This problem is observed with GaN and ZnSe. Measurement of p-type in "intrinsically" n-type material is complicated by the inhomogeneity of samples.[22]

Current limitations to p-doping does not limit electronic and optoelectronic applications of ZnO, which usually require junctions of n-type and p-type material. Known p-type dopants include group-I elements Li, Na, K; group-V elements N, P and As; as well as copper and silver. However, many of these form deep acceptors and do not produce significant p-type conduction at room temperature.[13]

Electron mobility of ZnO strongly varies with temperature and has a maximum of ~2000 cm2/(V·s) at 80 K.[23] Data on hole mobility are scarce with values in the range 5–30 cm2/(V·s).[24]

Production

For industrial use, ZnO is produced at levels of 105 tons per year[3] by three main processes:[16]

Indirect (French) process

Metallic zinc is melted in a graphite crucible and vaporized at temperatures above 907 °C (typically around 1000 °C). Zinc vapor reacts with the oxygen in the air to give ZnO, accompanied by a drop in its temperature and bright luminescence. Zinc oxide particles are transported into a cooling duct and collected in a bag house. This indirect method was popularized by LeClaire (France) in 1844 and therefore is commonly known as the French process. Its product normally consists of agglomerated zinc oxide particles with an average size of 0.1 to a few micrometers. By weight, most of the world's zinc oxide is manufactured via French process.

Direct (American) process

The direct process starts with diverse contaminated zinc composites, such as zinc ores or smelter by-products. The zinc precursors are reduced (carbothermal reduction) by heating with a source of carbon such as anthracite to produce zinc vapor, which is then oxidized as in the indirect process. Because of the lower purity of the source material, the final product is also of lower quality in the direct process as compared to the indirect one.

Wet chemical process

A small amount of industrial production involves wet chemical processes, which start with aqueous solutions of purified zinc salts, from which zinc carbonate or zinc hydroxide is precipitated. The precipitate is then filtered, washed, dried and calcined at temperatures around 800 °C.

Laboratory synthesis

A large number of specialised methods exist for producing ZnO for scientific studies and niche applications. These methods can be classified by the resulting ZnO form (bulk, thin film, nanowire), temperature ("low", that is close to room temperature or "high", that is T ~ 1000 °C), process type (vapor deposition or growth from solution) and other parameters.

Large single crystals (many cubic centimeters) are usually grown by the gas transport (vapor-phase deposition), hydrothermal synthesis,[15][25][26] or melt growth.[1] However, because of high vapor pressure of ZnO, growth from the melt is problematic. Growth by gas transport is difficult to control, leaving the hydrothermal method as a preference.[1] Thin films can be produced by chemical vapor deposition, metalorganic vapour phase epitaxy, electrodeposition, pulsed laser deposition, sputtering, sol-gel synthesis, atomic layer deposition, spray pyrolysis, etc.

Ordinary white powdered zinc oxide can be produced in the laboratory by electrolyzing a solution of sodium bicarbonate with a zinc anode. Zinc hydroxide and hydrogen gas are produced. The zinc hydroxide upon heating decomposes to zinc oxide.

- Zn + 2 H2O → Zn(OH)2 + H2

- Zn(OH)2 → ZnO + H2O

Nanophase ZnO

Nanophase ZnO can be synthesized into a variety of morphologies including nanowires, nanorods, tetrapods, nanobelts, nanoflowers, nanoparticles etc. Nanostructures can be obtained with most above-mentioned techniques, at certain conditions, and also with the vapor-liquid-solid method.[15][27]

Rodlike nanostructures of ZnO can be produced via aqueous methods. They are attractive because of relatively low synthesis temperatures (<300 °C) and absence of complex vacuum setup. The synthesis is typically carried out at temperatures of about 90 °C, in an equimolar aqueous solution of zinc nitrate and hexamine, the latter providing the basic environment. Certain additives, such as polyethylene glycol or polyethylenimine, can improve the aspect ratio of the ZnO nanowires.[28] Doping of the ZnO nanowires has been achieved by adding other metal nitrates to the growth solution.[29] The morphology of the resulting nanostructures can be tuned by changing the parameters relating to the precursor composition (such as the zinc concentration and pH) or to the thermal treatment (such as the temperature and heating rate).[30]

Aligned ZnO nanowires on pre-seeded silicon, glass and gallium nitride substrates have been grown in aqueous solutions using aqueous zinc salts such as Zinc nitrate and Zinc acetate in basic environments.[31] Pre-seeding substrates with ZnO creates sites for homogeneous nucleation of ZnO crystal during the synthesis. Common pre-seeding methods include in-situ thermal decomposition of zinc acetate crystallites, spincoating of ZnO nanoparticles and the use of various physical vapor deposition methods to deposit ZnO thin films.[32][33] Pre-seeding can be performed in conjunction with top down patterning methods such as electron beam lithography and nanosphere lithography to designate nucleation sites prior to growth. Aligned ZnO nanowires can be used in dye-sensitized solar cells and field emission devices.[34][35]

Applications

The applications of zinc oxide powder are numerous, and the principal ones are summarized below. Most applications exploit the reactivity of the oxide as a precursor to other zinc compounds. For material science applications, zinc oxide has high refractive index, high thermal conductivity, binding, antibacterial and UV-protection properties. Consequently, it is added into various materials and products, including plastics, ceramics, glass, cement, rubber, lubricants,[2] paints, ointments, adhesive, sealants, pigments, foods, batteries, ferrites, fire retardants, etc.[36]

Rubber manufacture

About 50% of ZnO use is in the rubber industry. Zinc oxide along with stearic acid is used in the vulcanization of rubber[16][37][38] ZnO additive also protect rubber from fungi (see medical applications) and UV light.

Concrete industry

Zinc oxide is widely used for concrete manufacturing. Addition of ZnO improves the processing time and the resistance of concrete against water.[37]

Medical

Zinc oxide as a mixture with about 0.5% iron(III) oxide (Fe2O3) is called calamine and is used in calamine lotion. There are also two minerals, zincite and hemimorphite, which have been historically called calamine. When mixed with eugenol, a ligand, zinc oxide eugenol is formed, which has applications as restorative and prosthodontic in dentistry.[8][39]

Reflecting the basic properties of ZnO, fine particles of the oxide have deodorizing and antibacterial[40] action and for that reason are added into various materials including cotton fabric, rubber, food packaging, etc.[41][42] Enhanced antibacterial action of fine particles compared to bulk material is not intrinsic to ZnO and is observed for other materials, such as silver.[43]

Zinc oxide is widely used to treat a variety of other skin conditions, in products such as baby powder and barrier creams to treat diaper rashes, calamine cream, anti-dandruff shampoos, and antiseptic ointments.[44][45] It is also a component in tape (called "zinc oxide tape") used by athletes as a bandage to prevent soft tissue damage during workouts.[46]

Zinc oxide can be used in ointments, creams, and lotions to protect against sunburn and other damage to the skin caused by ultraviolet light (see sunscreen). It is the broadest spectrum UVA and UVB reflector that is approved for use as a sunscreen by the FDA,[47] and is completely photostable.[48] When used as an ingredient in sunscreen, zinc oxide sits on the skin’s surface i.e. is not absorbed into the skin, and blocks both UVA (320–400 nm) and UVB (280–320 nm) rays of ultraviolet light. Because zinc oxide (and the other most common physical sunscreen, titanium dioxide) are not absorbed into the skin, they are nonirritating and nonallergenic.[49]

Many sunscreens use nano-sized zinc oxide (along with nano titanium dioxide) because such small particles do not scatter light and therefore do not appear white. Although there has been concern that they might be absorbed into the skin,[50][51] comprehensive reviews of the medical literature have not uncovered any risk.[52]

Cigarette filters

Zinc oxide is a constituent of cigarette filters for removal of selected components from tobacco smoke. A filter consisting of charcoal impregnated with zinc oxide and iron oxide removes significant amounts of HCN and H2S from tobacco smoke without affecting its flavor.[36]

Food additive

Zinc oxide is added to many food products, e.g., breakfast cereals, as a source of zinc,[53] a necessary nutrient. (Other cereals may contain zinc sulfate for the same purpose.) Some prepackaged foods also include trace amounts of ZnO even if it is not intended as a nutrient.

Pigment

Zinc white is used as a pigment[54] in paints and is more opaque than lithopone, but less opaque than titanium dioxide. It is also used in coatings for paper. Chinese white is a special grade of zinc white used in artists' pigments. It is also a main ingredient of mineral makeup.[55]

Coatings

Paints containing zinc oxide powder have long been utilized as anticorrosive coatings for various metals. They are especially effective for galvanised Iron. The latter is difficult to protect because its reactivity with organic coatings leads to brittleness and lack of adhesion. Zinc oxide paints however, retain their flexibility and adherence on such surfaces for many years.[36]

ZnO highly n-type doped with Al, Ga or In is transparent and conductive (transparency ~90%, lowest resistivity ~10−4 Ω·cm[56]). ZnO:Al coatings are being used for energy-saving or heat-protecting windows. The coating lets the visible part of the spectrum in but either reflects the infrared (IR) radiation back into the room (energy saving) or does not let the IR radiation into the room (heat protection), depending on which side of the window has the coating.[3]

Various plastics, such as polyethylene naphthalate (PEN), can be protected by applying zinc oxide coating. The coating reduces the diffusion of oxygen with PEN.[57] Zinc oxide layers can also be used on polycarbonate (PC) in outdoor applications. The coating protects PC form solar radiation and decreases the oxidation rate and photo-yellowing of PC.[58]

Corrosion prevention in nuclear reactors

Zinc oxide depleted in the zinc isotope with the atomic mass 64 is used in corrosion prevention in nuclear pressurized water reactors. The depletion is necessary, because 64Zn is transformed into radioactive 65Zn under irradiation by the reactor neutrons.[59]

Potential applications

Electronics

ZnO has wide direct band gap (3.37 eV or 375 nm at room temperature). Therefore, its most common potential applications are in laser diodes and light emitting diodes (LEDs).[60] Some optoelectronic applications of ZnO overlap with that of GaN, which has a similar bandgap (~3.4 eV at room temperature). Compared to GaN, ZnO has a larger exciton binding energy (~60 meV, 2.4 times of the room-temperature thermal energy), which results in bright room-temperature emission from ZnO. ZnO can be combined with GaN for LED-applications. For instance as TCO layer and ZnO nanostructures provide better light outcoupling.[61] Other properties of ZnO favorable for electronic applications include its stability to high-energy radiation and to wet chemical etching.[62] Radiation resistance[63] makes ZnO a suitable candidate for space applications. ZnO is currently the most promising candidate in the field of random lasers to produce an electronically pumped UV laser source.

The pointed tips of ZnO nanorods result in a strong enhancement of an electric field. Therefore, they can be used as field emitters.[64]

Aluminium-doped ZnO layers are used as a transparent electrodes. The constituents Zn and Al are much cheaper and less poisonous compared to the generally used indium tin oxide (ITO). One application which has begun to be commercially available is the use of ZnO as the front contact for solar cells or of liquid crystal displays.[65]

Transparent thin-film transistors (TTFT) can be produced with ZnO. As field-effect transistors, they even may not need a p–n junction,[66] thus avoiding the p-type doping problem of ZnO. Some of the field-effect transistors even use ZnO nanorods as conducting channels.[67]

Zinc oxide nanorod sensor

Zinc oxide nanorod sensors are devices detecting changes in electrical current passing through zinc oxide nanowires due to adsorption of gas molecules. Selectivity to hydrogen gas was achieved by sputtering Pd clusters on the nanorod surface. The addition of Pd appears to be effective in the catalytic dissociation of hydrogen molecules into atomic hydrogen, increasing the sensitivity of the sensor device. The sensor detects hydrogen concentrations down to 10 parts per million at room temperature, whereas there is no response to oxygen.[68][69]

Spintronics

ZnO has also been considered for spintronics applications: if doped with 1–10% of magnetic ions (Mn, Fe, Co, V, etc.), ZnO could become ferromagnetic, even at room temperature. Such room temperature ferromagnetism in ZnO:Mn has been observed,[70] but it is not clear yet whether it originates from the matrix itself or from secondary oxide phases.

Piezoelectricity

The piezoelectricity in textile fibers coated in ZnO have been shown capable of fabricating "self-powered nanosystems" with everyday mechanical stress from wind or body movements.[71][72]

In 2008 the Center for Nanostructure Characterization at the Georgia Institute of Technology reported producing an electricity generating device (called flexible charge pump generator) delivering alternating current by stretching and releasing zinc oxide nanowires. This mini-generator creates an oscillating voltage up to 45 millivolts, converting close to seven percent of the applied mechanical energy into electricity. Researchers used wires with lengths of 0.2–0.3 mm and diameters of three to five micrometers, but the device could be scaled down to smaller size.[73]

History

It is hardly possible to trace the first usage of zinc oxide – various zinc compounds were widely used by early humans, in various processed and unprocessed forms, as a paint or medicinal ointment, but their exact composition is uncertain.

The use of pushpanjan, probably zinc oxide, as a salve for eyes and open wounds, is mentioned in the Indian medical text the Charaka Samhita, thought to date from 500 BC or before.[74] Zinc oxide ointment is also mentioned by the Greek physician Dioscorides (1st century AD.)[75] Avicenna mentions zinc oxide in The Canon of Medicine (1025 AD), which mentioned it as a preferred treatment for a variety of skin conditions, including skin cancer. Though it is no longer used for treating skin cancer, it is still widely used to treat a variety of other skin conditions, in products such as baby powder and creams against diaper rashes, calamine cream, anti-dandruff shampoos, and antiseptic ointments.[44]

The Romans produced considerable quantities of brass (an alloy of zinc and copper) as early as 200 BC by a cementation process where copper was reacted with zinc oxide.[76] The zinc oxide is thought to have been produced by heating zinc ore in a shaft furnace. This liberated metallic zinc as a vapor, which then ascended the flue and condensed as the oxide. This process was described by Dioscorides in the 1st century AD.[77] Zinc oxide has also been recovered from zinc mines at Zawar in India, dating from the second half of the first millennium BC. This was presumably also made in the same way and used to produce brass.[75]

From the 12th to the 16th century zinc and zinc oxide were recognized and produced in India using a primitive form of the direct synthesis process. From India, zinc manufacture moved to China in the 17th century. In 1743, the first European zinc smelter was established in Bristol, United Kingdom.[78]

The main usage of zinc oxide (zinc white) was again paints and additive to ointments. Zinc white was accepted as a watercolor by 1834 but it did not mix well with oil. This problem was quickly solved by optimizing the synthesis of ZnO. In 1845, LeClaire in Paris was producing the oil paint on a large scale, and by 1850, zinc white was being manufactured throughout Europe. The success of zinc white paint was due to its advantages over the traditional white lead: zinc white is essentially permanent in sunlight, it is not blackened by sulfur-bearing air, it is non-toxic and more economical. Because zinc white is so "clean" it is very valuable for making tints with other colors; however, it makes a rather brittle dry film when unmixed with other colors. For example, during the late 1890s and early 1900s, some artists used zinc white as a ground for their oil paintings. All those paintings developed cracks over the years.[79]

In the recent times, most zinc oxide was used in the rubber industry (see applications above). In the 1970s, the second largest application of ZnO was photocopying. High-quality ZnO produced by the "French process" was added into the photocopying paper as a filler. This application was however soon displaced.[16]

Safety

As a food additive, zinc oxide is on the U.S. FDA's generally recognized as safe, or GRAS, substances.[80]

Zinc oxide itself is non-toxic; however it is hazardous to inhale zinc oxide fumes, as generated when zinc or zinc alloys are melted and oxidized at high temperature. This problem occurs while melting brass because the melting point of brass is close to the boiling point of zinc.[81] Exposure to zinc oxide in the air, which also occurs while welding galvanized (zinc plated) steel, can result in a nervous malady called metal fume fever. For this reason, typically galvanized steel is not welded, or the zinc is removed first.[82]

In popular culture

Reflecting its many varied but relatively unobtrusive and unglamorous uses, zinc oxide was the theme of a spoof in The Kentucky Fried Movie as a short educational film Zinc Oxide and You.

See also

References

- ^ a b c Takahashi, Kiyoshi; Yoshikawa, Akihiko; Sandhu, Adarsh (2007). Wide bandgap semiconductors: fundamental properties and modern photonic and electronic devices. Springer. p. 357. ISBN 3540472347.

{{cite book}}: CS1 maint: multiple names: authors list (link) - ^ a b c Hernandezbattez, A; Gonzalez, R; Viesca, J; Fernandez, J; Diazfernandez, J; MacHado, A; Chou, R; Riba, J (2008). "CuO, ZrO2 and ZnO nanoparticles as antiwear additive in oil lubricants". Wear. 265 (3–4): 422. doi:10.1016/j.wear.2007.11.013.

- ^ a b c Klingshirn, C (2007). "ZnO: Material, Physics and Applications". ChemPhysChem. 8 (6): 782–803. doi:10.1002/cphc.200700002. PMID 17429819.

{{cite journal}}: More than one of|author=and|last1=specified (help) - ^ a b Wiberg, E. and Holleman, A. F. (2001). Inorganic Chemistry. Elsevier. ISBN 0123526515.

{{cite book}}: CS1 maint: multiple names: authors list (link) - ^ Greenwood, Norman N.; Earnshaw, Alan (1997). Chemistry of the Elements (2nd ed.). Butterworth-Heinemann. ISBN 978-0-08-037941-8.

- ^ a b Spero, J. M.; Devito, B.; Theodore, L. (2000). Regulatory chemical handbook. CRC Press. ISBN 0824703901.

{{cite book}}: CS1 maint: multiple names: authors list (link) - ^ Nicholson, J. W; Nicholson, J. W (1998). "The chemistry of cements formed between zinc oxide and aqueous zinc chloride". Journal of Materials Science. 33 (9): 2251. doi:10.1023/A:1004327018497.

- ^ a b c Ferracane, Jack L. (2001). Materials in Dentistry: Principles and Applications. Lippincott Williams & Wilkins. pp. 70, 143. ISBN 0781727332.

- ^ Park C.-K., Silsbee M. R., Roy D. M. (1998). "Setting reaction and resultant structure of zinc phosphate cement in various orthophosphoric acid cement-forming liquids". Cement and concrete research. 28 (1): 141–150. doi:10.1016/S0008-8846(97)00223-8.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - ^ Greenwood, N. N.; & Earnshaw, A. (1997). Chemistry of the Elements. Oxford:Butterworth-Heinemann. ISBN 0-7506-3365-4.

{{cite book}}: CS1 maint: multiple names: authors list (link) - ^ International Occupational Safety and Health Information Centre (CIS) Access date January 25, 2009.

- ^ Zinc oxide MSDS. Access date January 25, 2009.

- ^ a b c Özgür, Ü.; Alivov, Ya. I.; Liu, C.; Teke, A.; Reshchikov, M. A.; Doğan, S.; Avrutin, V.; Cho, S.-J.; Morkoç, H. (2005). "A comprehensive review of ZnO materials and devices". Journal of Applied Physics. 98 (4): 041301. doi:10.1063/1.1992666.

- ^ Rossler, U., ed. (1999). Landolt-Bornstein, New Series, Group III. Vol. Vol. 17B, 22, 41B. Springer, Heidelberg.

{{cite book}}:|volume=has extra text (help) - ^ a b c Baruah, S. and Dutta, J. (2009). "Hydrothermal growth of ZnO nanostructures". Sci. Technol. Adv. Mater. 10: 013001. doi:10.1088/1468-6996/10/1/013001.

{{cite journal}}:|format=requires|url=(help)CS1 maint: multiple names: authors list (link) - ^ a b c d Porter, F. (1991). Zinc Handbook: Properties, Processing, and Use in Design. CRC Press. ISBN 0824783409.

- ^ Millot, Marius; Munoz-Sanjose, Vicente; Broto, Jean-Marc; Gonzalez, Jesus; et al. (2010). "Anharmonic effects in ZnO optical phonons probed by Raman spectroscopy". Applied Physics letters. 96 (15): 152103. doi:10.1063/1.3387843.

{{cite journal}}: Explicit use of et al. in:|last2=(help)CS1 maint: extra punctuation (link) - ^ Dal Corso, Andrea; Posternak, Michel; Resta, Raffaele; Baldereschi, Alfonso (1994). "Ab initio study of piezoelectricity and spontaneous polarization in ZnO". Physical Review B. 50 (15): 10715. doi:10.1103/PhysRevB.50.10715.

- ^ Look, D.C. (1999). "Residual Native Shallow Donor in ZnO". Physical Review Letters. 82 (12): 2552. Bibcode:1999PhRvL..82.2552L. doi:10.1103/PhysRevLett.82.2552.

{{cite journal}}: Unknown parameter|coauthors=ignored (|author=suggested) (help) - ^ Janotti, A; Van De Walle, CG (2007). "Hydrogen multicentre bonds". Nature Materials. 6 (1): 44–7. doi:10.1038/nmat1795. PMID 17143265.

{{cite journal}}: More than one of|author=and|last1=specified (help); Unknown parameter|coauthors=ignored (|author=suggested) (help) - ^ Kato, H (2002). "Growth and characterization of Ga-doped ZnO layers on a-plane sapphire substrates grown by molecular beam epitaxy". Journal of Crystal Growth. 237–239: 538. Bibcode:2002JCrGr.237..538K. doi:10.1016/S0022-0248(01)01972-8.

- ^ Ohgaki, Takeshi; Ohashi, Naoki; Sugimura, Shigeaki; Ryoken, Haruki; Sakaguchi, Isao; Adachi, Yutaka; Haneda, Hajime (2008). "Positive Hall coefficients obtained from contact misplacement on evident n-type ZnO films and crystals". Journal of Materials Research. 23 (9): 2293. doi:10.1557/JMR.2008.0300.

- ^ Wagner, P; Helbig, R (1974). "Halleffekt und anisotropie der beweglichkeit der elektronen in ZnO". Journal of Physics and Chemistry of Solids. 35 (3): 327. Bibcode:1974JPCS...35..327W. doi:10.1016/S0022-3697(74)80026-0.

- ^ Ryu, Y. R.; Lee, T. S.; White, H. W. (2003). "Properties of arsenic-doped p-type ZnO grown by hybrid beam deposition". Applied Physics Letters. 83: 87. doi:10.1063/1.1590423.

- ^ a b Schulz, D.; et al. (2008). "Inductively heated Bridgman method for the growth of zinc oxide single crystals". Journal of Crystal Growth. 310 (7–9): 1832. doi:10.1016/j.jcrysgro.2007.11.050.

{{cite journal}}: Explicit use of et al. in:|author=(help) - ^ Baruah, Sunandan; Thanachayanont, Chanchana; Dutta, Joydeep (2008). "Growth of ZnO nanowires on nonwoven polyethylene fibers". Science and Technology of Advanced Materials. 9 (2): 025009. doi:10.1088/1468-6996/9/2/025009.

{{cite journal}}:|format=requires|url=(help) - ^ Miao, L.; Ieda, Y.; Tanemura, S.; Cao, Y.G.; Tanemura, M.; Hayashi, Y.; Toh, S.; Kaneko, K. (2007). "Synthesis, microstructure and photoluminescence of well-aligned ZnO nanorods on Si substrate". Science and Technology of Advanced Materials. 8 (6): 443. doi:10.1016/j.stam.2007.02.012.

{{cite journal}}:|format=requires|url=(help) - ^ Ying Zhou; et al. (2008). "Hydrothermal synthesis of ZnO nanorod arrays with the addition of polyethyleneimine". Materials Research Bulletin. 43 (8–9): 2113–2118. doi:10.1016/j.materresbull.2007.09.024.

{{cite journal}}: Explicit use of et al. in:|author=(help) - ^ Cui, Jingbiao; et al. (2006). "Synthesis and magnetic properties of Co-doped ZnO nanowires". Journal of Applied Physics. 99 (8): 08M113. doi:10.1063/1.2169411.

{{cite journal}}: Explicit use of et al. in:|author=(help) - ^ Elen, K.; et al. (2009). "Hydrothermal synthesis of ZnO nanorods: a statistical determination of the significant parameters in view of reducing the diameter". Nanotechnology. 20 (5): 055608. doi:10.1088/0957-4484/20/5/055608. PMID 19417355.

{{cite journal}}: Explicit use of et al. in:|author=(help) - ^ Greene, L. E.; et al. (2003). "Low-Temperature Wafer-Scale Production of ZnO Nanowire Arrays". Angew. Chem. Int. Ed. 42 (26): 3031–3032. doi:10.1002/anie.200351461. PMID 12851963.

{{cite journal}}: Explicit use of et al. in:|author=(help) - ^ Wu, Wan-Yu; et al. (2009). "Effects of Seed Layer Characteristics on the Synthesis of ZnO Nanowires". Journal of the American Ceramic Society. 92 (11): 2718–2723. doi:10.1111/j.1551-2916.2009.03022.x.

{{cite journal}}: Explicit use of et al. in:|author=(help) - ^ Greene, L. E.; Law, M; Tan, DH; Montano, M; Goldberger, J; Somorjai, G; Yang, P (2005). "General Route to Vertical ZnO Nanowire Arrays Using Textured ZnO Seeds". Nano Letters. 5 (7): 1231–1236. doi:10.1021/nl050788p. PMID 16178216.

- ^ Hua, Guomin; et al. (2008). "Fabrication of ZnO nanowire arrays by cycle growth in surfactantless aqueous solution and their applications on dye-sensitized solar cells". Materials Letters. 62 (25): 4109–4111. doi:10.1016/j.matlet.2008.06.018.

{{cite journal}}: Explicit use of et al. in:|author=(help) - ^ Lee, J.-H.; et al. (2009). "Density-controlled growth and field emission property of aligned ZnO nanorod arrays". Appl Phys A. 97 (2): 403–408. doi:10.1007/s00339-009-5226-y.

{{cite journal}}: Explicit use of et al. in:|author=(help) - ^ a b c Nav Bharat Metallic Oxide Industries Pvt. Limited. Applications of ZnO. Access date January 25, 2009.

- ^ a b Brown, H. E. (1957). Zinc Oxide Rediscovered. New York: The New Jersey Zinc Company.

- ^ Brown, H. E. (1976). Zinc Oxide Properties and Applications. New York: International Lead Zinc Research Organization.

- ^ van Noort, Richard (2002). Introduction to Dental Materials, 2d Edition. Elsevier Health Sciences. ISBN 0723432155.

- ^ Padmavathy, Nagarajan; Vijayaraghavan, Rajagopalan (2008). "Enhanced bioactivity of ZnO nanoparticles—an antimicrobial study". Science and Technology of Advanced Materials. 9 (3): 035004. doi:10.1088/1468-6996/9/3/035004.

{{cite journal}}:|format=requires|url=(help) - ^ Li, Qun; Chen, Shui-Lin; Jiang, Wan-Chao (2007). "Durability of nano ZnO antibacterial cotton fabric to sweat". Journal of Applied Polymer Science. 103: 412. doi:10.1002/app.24866.

- ^ Saito, M. (1993). "Antibacterial, Deodorizing, and UV Absorbing Materials Obtained with Zinc Oxide (ZnO) Coated Fabrics". Journal of Industrial Textiles. 23 (2): 150. doi:10.1177/152808379302300205.

- ^ Akhavan, Omid; Ghaderi, Elham (2009). "Enhancement of antibacterial properties of Ag nanorods by electric field". Science and Technology of Advanced Materials. 10: 015003. doi:10.1088/1468-6996/10/1/015003.

{{cite journal}}:|format=requires|url=(help) - ^ a b Harding, Fred John (2007). Breast Cancer: Cause – Prevention – Cure. Tekline Publishing. p. 83. ISBN 0955422108.

- ^ British National Formulary 2008. "Section 13.2.2 Barrier Preparations"

- ^ Hughes, G.; McLean, N. R. (1988). "Zinc oxide tape: a useful dressing for the recalcitrant finger-tip and soft-tissue injury" (Free full text). Arch Emerg Med. 5 (4): 223. PMC 1285538. PMID 3233136.

{{cite journal}}: More than one of|pages=and|page=specified (help)CS1 maint: multiple names: authors list (link) - ^ "Sunscreen". U.S. Food and Drug Administration.

- ^ Mitchnick, MA; Fairhurst, D; Pinnell, SR (1999). "Microfine zinc oxide (Z-cote) as a photostable UVA/UVB sunblock agent". Journal of the American Academy of Dermatology. 40 (1): 85–90. doi:10.1016/S0190-9622(99)70532-3. PMID 9922017.

- ^ "What to Look for in a Sunscreen". New York Times. June 10, 2009.

- ^ "Manufactured Nanomaterials and Sunscreens: Top Reasons for Precaution" (PDF). August 19, 2009. Retrieved April 12, 2010.

- ^ "Nano-tech sunscreen presents potential health risk". ABC News. December 18, 2008. Retrieved April 12, 2010.

- ^ M E. Burnett and S Q Wang,Current sunscreen controversies: a critical review,Photodermatology, Photoimmunology & Photomedicine 27, 58–67

- ^ Quaker cereals content Access date January 25, 2009.

- ^ Zinc Oxide as a pigment Access date January 25, 2009.

- ^ Bouchez, Colette. "The Lowdown on Mineral Makeup". WebMD. Retrieved January 25, 2009.

- ^ Schmidtmende, L; MacManusdriscoll, J (2007). "ZnO – nanostructures, defects, and devices". Materials Today. 10 (5): 40. doi:10.1016/S1369-7021(07)70078-0.

- ^ Guedri-Knani, L.; et al. (2004). "Photoprotection of poly(ethylene-naphthalate) by zinc oxide coating". Surface and Coatings Technology. 180–181: 71–75. doi:10.1016/j.surfcoat.2003.10.039.

{{cite journal}}: Explicit use of et al. in:|author=(help) - ^ Moustaghfir, A.; et al. (2004). "Sputtered zinc oxide coatings: structural study and application to the photoprotection of the polycarbonate". Surface and Coatings Technology. 180–181: 642. doi:10.1016/j.surfcoat.2003.10.109.

{{cite journal}}: Explicit use of et al. in:|author=(help) - ^ Cowan, R. L. (2001). "BWR water chemistry?a delicate balance". Nuclear Energy. 40 (4): 245. doi:10.1680/nuen.40.4.245.39338.

- ^ Bakin, A.; et al. (2007). "ZnMgO-ZnO Quantum Wells Embedded in ZnO Nanopillars: Towards Realisation of Nano-LEDs". Phys. Stat. Solidi (c). 4: 158–161. doi:10.1002/pssc.200673557.

{{cite journal}}: Explicit use of et al. in:|author=(help) - ^ Bakin, A.; et al. (2010). "ZnO – GaN Hybrid Heterostructures as Potential Cost Efficient LED Technology". IEEE (Invited Paper for a special volume), Proceedings of the IEEE. 98 (7): 1281–1287. doi:10.1109/JPROC.2009.2037444.

{{cite journal}}: Explicit use of et al. in:|author=(help) - ^ Look, D (2001). "Recent advances in ZnO materials and devices". Materials Science and Engineering B. 80: 383. doi:10.1016/S0921-5107(00)00604-8.

- ^ Kucheyev, S. O.; et al. (2003). "Ion-beam-produced structural defects in ZnO". Phys. Rev. B. 67 (9): 094115. doi:10.1103/PhysRevB.67.094115.

{{cite journal}}: Explicit use of et al. in:|author=(help) - ^ Li, Y. B.; Bando, Y.; Golberg, D. (2004). "ZnO nanoneedles with tip surface perturbations: Excellent field emitters". Applied Physics Letters. 84 (18): 3603. doi:10.1063/1.1738174.

- ^ Oh, Byeong-Yun; Jeong, Min-Chang; Moon, Tae-Hyoung; Lee, Woong; Myoung, Jae-Min; Hwang, Jeoung-Yeon; Seo, Dae-Shik (2006). "Transparent conductive Al-doped ZnO films for liquid crystal displays". Journal of Applied Physics. 99 (12): 124505. doi:10.1063/1.2206417.

- ^ Nomura, K; Ohta, H; Ueda, K; Kamiya, T; Hirano, M; Hosono, H (2003). "Thin-Film Transistor Fabricated in Single-Crystalline Transparent Oxide Semiconductor". Science. 300 (5623): 1269–72. doi:10.1126/science.1083212. PMID 12764192.

{{cite journal}}: More than one of|author=and|last1=specified (help) - ^ Heo, Y. W.; Tien, L. C.; Kwon, Y.; Norton, D. P.; Pearton, S. J.; Kang, B. S.; Ren, F. (2004). "Depletion-mode ZnO nanowire field-effect transistor". Applied Physics Letters. 85 (12): 2274. doi:10.1063/1.1794351.

- ^ Wang, H. T.; Kang, B. S.; Ren, F.; Tien, L. C.; Sadik, P. W.; Norton, D. P.; Pearton, S. J.; Lin, Jenshan (2005). "Hydrogen-selective sensing at room temperature with ZnO nanorods". Applied Physics Letters. 86 (24): 243503. doi:10.1063/1.1949707.

- ^ Tien, L. C.; Sadik, P. W.; Norton, D. P.; Voss, L. F.; Pearton, S. J.; Wang, H. T.; Kang, B. S.; Ren, F.; Jun, J. (2005). "Hydrogen sensing at room temperature with Pt-coated ZnO thin films and nanorods". Applied Physics Letters. 87 (22): 222106. doi:10.1063/1.2136070.

- ^ Mofor, A. Che; El-Shaer, A.; Bakin, A.; Waag, A.; Ahlers, H.; Siegner, U.; Sievers, S.; Albrecht, M.; Schoch, W. (2005). "Magnetic property investigations on Mn-doped ZnO Layers on sapphire". Applied Physics Letters. 87 (6): 062501. doi:10.1063/1.2007864.

- ^ Keim, Brandon (February 13, 2008). "Piezoelectric Nanowires Turn Fabric Into Power Source". Wired News. CondéNet.

- ^ Qin, Y; Wang, X; Wang, ZL (2008). "Editor's summary: Nanomaterial: power dresser". Nature. 451 (7180): 809–813. doi:10.1038/nature06601. PMID 18273015.

{{cite journal}}: More than one of|author=and|last1=specified (help) - ^ "New Small-scale Generator Produces Alternating Current By Stretching Zinc Oxide Wires". Science Daily. November 10, 2008.

- ^ Craddock, P. T.; et al. (1998). "Zinc in India". 2000 years of zinc and brass. British Museum. p. 27. ISBN 0861591240.

{{cite book}}: Explicit use of et al. in:|author=(help) - ^ a b Craddock, P. T. (2008). "Mining and Metallurgy, chapter 4". In Oleson, John Peter (ed.). The Oxford Handbook of Engineering and Technology in the Classical World. Oxford University Press. pp. 111–112. ISBN 0195187318.

- ^ "zinc." Encyclopædia Britannica. 2009 Encyclopædia Britannica Online. 10 March 2009

- ^ Craddock, Paul Terence (2009). "The origins and inspirations of zinc smelting". Journal of Materials Science. 44 (9): 2181. doi:10.1007/s10853-008-2942-1.

- ^ General Information of Zinc from the National Institute of Health, WHO, and International Zinc Association accessed 10 March 2009

- ^ Zinc zhite accessed 10 March 2009

- ^ "Database of Select Committee on GRAS Substances (SCOGS) Reviews". Retrieved 2009-08-03.

- ^ Theodore Gray. The Safety of Zinc Casting Access date January 25, 2009.

- ^ Calvert, J. B. Zinc and Cadmium Last modified August 20, 2007. Access date January 25, 2009.

Reviews

- U. Ozgur et al. "A comprehensive review of ZnO materials and devices" (103 pages) J. Appl. Phys. 98 (2005) 041301

- A. Bakin and A. Waag "ZnO Epitaxial Growth" (28 pages) Chapter in “Comprehensive Semiconductor Science and Technology“ 6 Volume Encyclopaedia, ELSEVIER, edited by Pallab Bhattacharya, Roberto Fornari and Hiroshi Kamimura, ISBN 978-0-444-53143-8

- S. Baruah and J. Dutta "Hydrothermal growth of ZnO nanostructures" (18 pages) Sci. Technol. Adv. Mater. 10 (2009) 013001 free download

- R. Janisch et al. "Transition metal-doped TiO2 and ZnO—present status of the field" (32 pages) J. Phys.: Condens. Matter 17 (2005) R657

- Y.W. Heo et al. "ZnO nanowire growth and devices" (47 pages) Mater. Sci. Eng. R 47 (2004) 1

- C. Klingshirn "ZnO: From basics towards applications" (46 pages) Phys. Stat. Solidi (b) 244 (2007) 3027

- C. Klingshirn "ZnO: Material, Physics and Applications" (21 pages) ChemPhysChem 8 (2007) 782

- J. G. Lu et al. "Quasi-one-dimensional metal oxide materials—Synthesis, properties and applications" (42 pages) Mater. Sci. Eng. R 52 (2006) 49

External links

- Zincite properties

- International Chemical Safety Card 0208.

- NIOSH Pocket Guide to Chemical Hazards.

- Nav Bharat Metallic Oxide Industries. (describes industrial uses of zinc oxide)

- External MSDS (Material Safety Data Sheet) on zinc oxide