Tobacco: Difference between revisions

m "It's" to "its". Minor. |

SoilMan2007 (talk | contribs) Section on no-till tobacco added - A student wrote this based on a class project in the Fall of 2007 |

||

| Line 100: | Line 100: | ||

After tobacco is cured, it is moved from the curing barn into a storage area for processing. If whole plants were cut, the leaves are removed from the tobacco stalks in a process called stripping. For both cut and pulled tobacco, the leaves are then sorted into different grades. In colonial times, the tobacco was then "prized" into hogsheads for transportation. In bright tobacco regions, prizing was replaced by stacking wrapped "hands" into loose piles to be sold at auction. Today, most cured tobacco is baled before sales are made under pre-sold contracts. |

After tobacco is cured, it is moved from the curing barn into a storage area for processing. If whole plants were cut, the leaves are removed from the tobacco stalks in a process called stripping. For both cut and pulled tobacco, the leaves are then sorted into different grades. In colonial times, the tobacco was then "prized" into hogsheads for transportation. In bright tobacco regions, prizing was replaced by stacking wrapped "hands" into loose piles to be sold at auction. Today, most cured tobacco is baled before sales are made under pre-sold contracts. |

||

==No-Tillage Tobacco Production Systems== |

|||

Tobacco production has been a high value enterprise historically in the southeastern US, but tillage methods often implemented in the production of this crop has also caused farmers to lose many millions of tons of soil because of erosion. Soil erosion in the United States costs the public billions of dollars each year. Tobacco is an intensively tilled crop when cultivated under the traditional conventional tillage system in place on the vast majority of tobacco farms in the USA. The viability of no-tillage production will be essential for the preservation of this crop, and the land suitable for its production. No-till along with other conservation practices can drastically decrease soil erosion rates especially on the gently to moderately sloping land often used for tobacco production. |

|||

===Background & Purposes:=== |

|||

The conventional tillage system implemented on most tobacco farms involves the use of heavy tillage machinery designed to intensively mix the soil and keep it essentially bare throughout the growing season, exposing it to the erosive forces of wind and water that detach soil particles and move them easily across the land surface and downslope to drainage areas. No-tillage systems now implemented on some tobacco farms show great promise for reducing soil erosion while maintaining comparable yields to those of conventional tillage systems. By leaving essentially all residues from the previous crop, often a small grain cover crop, on the soil surface, no-till discourages erosion by preventing water and wind from direct soil contact. Erosion in most tobacco fields is most noticeable between rows of plants where rills are often formed that channel excess water out of the field during rain events. Crop residues prevent this from occurring by slowing down the water and increasing its infiltration while decreasing runoff. A two year study at the North Carolina State University in the 1980’s showed that erosion in tobacco fields on a coastal plain soil with a 3.1% slope were reduced 90 fold(Journal of Soil and Water Conservation). Erosion rates in many conventionally tilled tobacco fields are not in the tolerable range, but the implementation of no-till and other conservation practices could certainly bring erosion rates into that range. |

|||

===History and Obstacles:=== |

|||

A historical marker in Christian county, Kentucky records that the first practice of no-tillage crop production occurred on the farm of Lawrence and Harry young in 1962. No-till production of grain crops became widespread over the next decade. No-Till agriculture got its start because of a broad interest in soil conservation and the need for a more suitable practice in certain management situations. From the outset, no-till systems for tobacco production were sought, but were not developed nearly as quickly as systems for other crops. Weed control and plant establishment have been the two primary obstacles to adoption of no-till tobacco production. In grain crops such as wheat, corn, and soybeans herbicides were developed that provided satisfactory weed control throughout the season, and the use of seeds rather than seedlings made crop establishment less complicated. |

|||

Tobacco is a broadleaf plant which is harvested for its leaves, thus any chemical damage to the foliage of the plant decreases its value tremendously. Over the top broadleaf herbicide treatments that would control weeds commonly found in tobacco are not currently an option as the plant would be severely damaged or killed by such action. Pre-plant herbicide options are limited in tobacco production because chemicals such as roundup or touchdown, traditionally used burn down chemicals, are not labeled for use in no-till tobacco within 30 days of transplanting(Bob Pearce). They can therefore be used early to decrease the number of weeds, but by the time the tobacco plants have firmly rooted many new weeds may have germinated and surpassed them in growth. Recently the Gramoxone label was changed to allow this product to be used in no-till tobacco |

|||

Herbicides such as Spartan and Command have been shown to work well in controlling weeds in no-till tobacco when properly applied (ID-160 University of Kentucky Cooperative Extension Service). However, escapes do occur and one of the most troublesome limitations for no-till tobacco is the lack of post-transplant weed control options. Tobacco is easily stunted by intense weed pressure during early developmental stages, and this could affect the plant throughout its life cycle. It is also undesirable to implement mechanical tillage weed removal in a no till operation for a couple of reasons. If the surface of the soil is disturbed, erosion accelerates, defeating the initial purpose of no till production. Also the residue barrier for further weed control will be removed, increasing the rate of weed proliferation. Ultimately, if intense weed pressure is observed in no-till tobacco production, producers have very few options. Limited herbicide treatments and the unavailability of mechanical removal create a tricky situation. Therefore manual weed removal is the common practice on most tobacco farms when weed pressure becomes intense. This is usually done by workers with a hoe, and in combination with cultivation equipment to remove weeds from the row middles in conventionally tilled operations. |

|||

Another obstacle for no-till production is consistent plant establishment. In the production of grain crops, seeds are planted into the ground, and with the presence of moisture and warmth, they germinate and begin their life cycle. Their propagation is usually relatively uniform, and stands are generally good. Tobacco cannot be seeded directly into the field. This is partially because of the small seed size (comparable to mustard seed) which usually results in a less than uniform stand. Also, the growing season in most areas suited for tobacco production would not allow for enough time to seed into a field and satisfactorily harvest the crop during preferable conditions. To overcome these difficulties tobacco seeds are sowed in greenhouses and grown to a size of 4 or 5 inches tall, then transplanted to the field. |

|||

As tobacco is transplanted in the seedling form, one requirement for a successful and uniform stand is satisfactory root to soil contact. Without good contact, the roots will whither and the plant will wilt and die without having taken up sufficient water or nutrients. A transplanter must open a small furrow in the soil about 2-4 inches deep and 1-2 inches wide so the root ball can be placed in the soil and it must then close the furrow completely around the roots. The soil must be packed snug against the root ball but not too tightly as this could cause the plant to be stunted or die. Conventional bare root plants were very susceptible to root dehydration. Container grown plants have improved plant establishment under no-till production. This task has been of major concern for those designing no-till tobacco transplanters. |

|||

Conventional transplanters are pulled through a thoroughly tilled seed bed that is soft and the soil is easy to repack around the root ball. No-till transplanters must cut into the undisturbed soil and then repack this soil that is not loose around the root ball without restricting the seedling. No-till transplanters often have a problem closing the furrow around the root ball and therefore the sunlight and air dry out the roots and the plant consequently dies of dehydration. Most conventional transplanters are not able to penetrate an unprepared seed bed in order to cut the furrow required for transplanting. These transplanters basically slide on top of the soil surface without placing plants into the soil. Modified transplanters have been developed to overcome some of these problems. |

|||

===No till Transplanters & Transplanting:=== |

|||

Most transplanters currently in use are not equipped for no-tillage systems. Conventional transplanters are equipped with a metal “shoe” that slices a groove into the prepared seedbed into which the seedlings are placed by mechanical “fingers” or dropped into “cups” by workers. A set of packing wheels is also installed behind the shoe to press the soil around the roots of the plants to ensure good root to soil contact. These transplanters are not suitable for no-tillage production because they are not able to penetrate undisturbed soil or use it as an effective seedbed. |

|||

Most no-tillage transplanters are equipped with rippled coulters and a sub-soiler shank placed in front of the shoe on the transplanter in order for a slit in the ground to be formed so that the shoe can clear a path and cut a groove in the soil so that the seedlings can be mechanically placed in the furrow and covered by the packing wheels so that a proper stand is reached(Bob Pearce). Many conventional transplanters are equipped with coulters in front of the shoe, in order to slice through residue in the seedbed and to prevent clogging of the shoe, but only no-till transplanters require the sub-soiler shank to be placed in front of the shoe. The coulters slice through the crop residue satisfactorily, but do not dig a deep enough furrow suitable for the transplanter to work efficiently. The shank may be adjusted up or down in order to accommodate different planting conditions and soil types. The packing wheels on a no-till transplanter are also heavier than those on a conventional transplanter in order to press the harder surface back down around the plant roots effectively. The packing wheels must be monitored though, in order to ensure compaction is not too great in the root zone for proper development(Pearce, Zeleznik). Compaction from the shoe may also be a problem, even more so than the packing wheels in some cases(Gray Palmer). In the early days of no-till transplanters for tobacco (10-30 years ago) compaction problems and the inability to get the transplanter to go into the soil deep enough for proper root to soil contact were major obstacles. Early transplanters were loaded with weights in order to press the transplanter into the soil, and packing wheels were so heavy that damage to the plant occurred during the transplanting process(Morrison et al. 1973). The implementation of coulters and the sub-soiler shank in front of the shoe largely alleviated these problems and the need for a heavy transplanter. |

|||

===Weed Control in No-Till Tobacco Production Systems=== |

|||

The options for weed control in no-till tobacco vary from those available for conventional operations. With the objective of no-till production being the decrease of erosion, using cultivation equipment would be the antithesis of the goal. Cultivation would in many cases harm a crop that is not accustomed to being tilled around regularly by releasing soil moisture and damaging roots. |

|||

Site selection is the first step in weed control along with planning and consideration of suppression of weeds by residue. No-till production should be implemented on a sight with some existing ground cover that will aid in weed suppression. When planning crop rotations, no-till tobacco producers would benefit from observing the tendency of certain crop residues to persist or dissipate throughout the growing season. Stubble from cereal grains such as wheat or rye harvested in the spring for hay persist consistently through the summer growing season, but corn and soybean stubble seem to dissipate more quickly. Most No-Till tobacco is transplanted directly into stubble of winter wheat or rye residue, or in some cases soybean or corn stubble. |

|||

About thirty days prior to transplanting, the producer should use a “Burn down” chemical such as Roundup or Touch Down to kill existing weeds to create a layer of residue for suppression of further weed growth. Prior to transplanting, but not more than a week before, producers should then spray the herbicide Spartan 4F(Active Ingredient Sulfentrazone) for preventative broadleaf protection and then spray Command 3ME (Active Ingredient Clomazone) over the top no more than one week after transplanting (ID-160). For success in any No-Till tobacco operation, these two pre treatment chemicals are necessary for the control of broadleaf plants such as pigweed and nightshade, and for grasses such as nutsedge and crabgrass. These are essentially the only herbicides available for use in tobacco which cover most broadleaf and grass species. Poast herbicide can be sprayed over the top of tobacco to control certain grasses. |

|||

In experimental plots at the University of Kentucky a shielded spray of Gramoxone was used in a tobacco field with severe weed pressure in which the alternative would have been to bushhog the crop down(Bob Pearce). The shielded spray substantially reduced weed populations and essentially saved the crop. However Gramoxone is not labeled for such use in tobacco at this stage. Manual weed removal is still an option, but only by hand. The use of cultivation equipment in a no-till operation could damage the root systems of the crop and release moisture from the soil and potentially decrease yields in the long run. |

|||

===Additional Benefits=== |

|||

There are other benefits realized through No-Till tobacco production. A more efficient harvest is possible because even during times of rainfall and stormy weather, time out of the field will be decreased in a no-till field because of the ground cover which will reduce the amount of mud and water ponding. Leaf buying companies should also be more pleased with the product they receive, which should be cleaner, especially in the case of an abnormally wet harvest season. Farmers should be able to spend less time operating heavy machinery, and could possibly eliminate the need for certain pieces of tillage equipment, not to mention the fuel savings associated with no-tillage versus intensive tillage. |

|||

===No Till Tobacco References === |

|||

* Morrison J. E., J. H. Smiley, W. O. Atkinson, and D. C. Milbocker. 1973. A no-tillage transplanter. Tobacco Science. Vol. 44: p.44-46. |

|||

*Journal of Soil and Water Conservation: Reducing Soil Erosion in Tobacco Fields with No-Till Transplanting. Vol. 41, No. 3, Pg 193-196, May-June 1986 |

|||

==Types== |

==Types== |

||

Revision as of 06:27, 26 May 2008

This article needs additional citations for verification. |

Tobacco is an agricultural product processed from the fresh leaves of plants in the genus Nicotiana. It is most commonly smoked in the form of cigarettes or cigars. Tobacco has been growing on both American continents since about 6000 BC and was used by native cultures by around 3000 BC. [citation needed] It has been smoked, in one form or another, since about 2000 BC.[citation needed] Tobacco has a long history of use in Native American culture, and played an important role in the political, economic, and cultural history of the United States of America.

Dried, cured, and unprocessed tobacco is commercially available all over the world. Smoke from burning, or otherwise heated, tobacco can be inhaled in the forms of cigarettes, cigars, stem pipes, water pipes, and hookahs. Tobacco can also be chewed, dipped (placed between the cheek and gum), or sniffed into the nose as finely powdered snuff. Many countries set minimum legal smoking ages, regulating the purchase and use of tobacco products. Bhutan is the only country in the world where tobacco sales are illegal.[1] According to the World Health Organization, tobacco smoke is the second biggest cause of death worldwide, and is reported to have been responsible for the deaths of 100 million people in the 20th century.[2]

All methods of tobacco consumption result in varying quantities of nicotine being absorbed into the user's bloodstream. Over time, tolerance and dependence develop. Absorption quantity, frequency, and speed of tobacco consumption are believed to be directly related to biological strength of nicotine dependence, addiction, and tolerance. [3] [4].

Etymology

The Spanish word "tabaco" is thought to have its origin in Arawakan language, particularly, in the Taino language of the Caribbean. In Taino, it was said to refer either to a roll of tobacco leaves (according to Bartolome de Las Casas, 1552), or to the tabago, a kind of Y-shaped pipe for sniffing tobacco smoke (according to Oviedo; with the leaves themselves being referred to as Cohiba)[5].

However, similar words in Spanish and Italian were commonly used from 1410 to define medicinal herbs, originating from the Arabic tabbaq, a word reportedly dating to the 9th century, as the name of various herbs[6].

History

This section needs expansion. You can help by adding to it. (May 2008) |

Tobacco had already long been used in the Americas by the time European settlers arrived and introduced the practice to Europe, where it became hugely popular. At high doses, tobacco can become hallucinogenic [citation needed]; accordingly, Native Americans did not always use the drug recreationally. Instead, it was often consumed as an entheogen; among some tribes, this was done only by experienced shamans or medicine men. [citation needed] Eastern North American tribes would carry large amounts of tobacco in pouches as a readily accepted trade item and would often smoke it in pipes, either in defined ceremonies that were considered sacred, or to seal a bargain[7], and they would smoke it at such occasions in all stages of life, even in childhood[8]. It was believed that tobacco was a gift from the Creator and that the exhaled tobacco smoke was capable of carrying one's thoughts and prayers to heaven[9].

In addition to being smoked, uncured tobacco was often eaten, used in enemas, or drunk as extracted juice. [citation needed] Early missionaries often reported on the ecstatic state caused by tobacco. [citation needed] As its use spread into Western cultures, however, it was no longer used primarily for entheogenic or religious purposes, although religious use of tobacco is still common among many indigenous peoples, particularly in the Americas. Among the Cree and Ojibway of Canada and the north-central United States, it is offered to the Creator, with prayers, and is used in sweat lodges, pipe ceremonies, smudging, and is presented as a gift. A gift of tobacco is tradition when asking an Ojibway elder a question of a spiritual nature. Because of its sacred nature, tobacco abuse (thoughtlessly and addictively chain smoking) is seriously frowned upon by the Algonquian tribes of Canada, as it is believed that if one so abuses the plant, it will abuse that person in return, causing sickness[10].

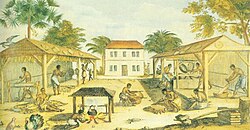

With the arrival of Europeans, tobacco became one of the primary products fueling the colonization of the future American South, long before the official formation of the United States. The initial colonial expansion, fueled by the desire to increase tobacco production, was one cause of early conflicts between Native Americans and European settlers, and was a driving factor in the encorporation of African slave labor.

In 1609, John Rolfe arrived at the Jamestown Settlement in Virginia, and is credited as the first settler to have successfully raised tobacco (commonly referred to at that time as "brown gold")[11] for commercial use. The tobacco raised in Virginia at that time, Nicotiana rustica, [citation needed] did not suit European tastes, but Rolfe raised a more popular variety, Nicotiana tabacum, from seeds brought with him from Bermuda.[citation needed] Tobacco was used as currency by the Virginia settlers for years, and Rolfe was able to make his fortune in farming it for export at Varina Farms Plantation. When he left for England with his wife, Pocahontas a daughter of Chief Powhatan, he had become wealthy. Returning to Jamestown, following Pocahontas' death in England, Rolfe continued in his efforts to improve the quality of commercial tobacco, and, by 1620, 40,000 pounds (18,000 kg) pounds of tobacco were shipped to England. By the time John Rolfe died in 1622, Jamestown was thriving as a producer of tobacco, and its population had topped 4,000. Tobacco led to the importation of the colony's first black slaves in 1619. In the year 1616, 2,500 pounds (1,100 kg) of tobacco were produced in Jamestown, Virginia, quickly rising up to 119,000 pounds (54,000 kg) in 1620.[citation needed]

The importation of tobacco into Europe was not without resistance and controversy even in the 17th century. Stuart king James I wrote a famous polemic titled A Counterblaste to Tobacco in 1604 (published in 1672), in which the king denounced tobacco use as "[a] custome lothsome to the eye, hatefull to the Nose, harmefull to the braine, dangerous to the Lungs, and in the blacke stinking fume thereof, neerest resembling the horrible Stigian smoke of the pit that is bottomelesse." In that same year, an English statute was enacted that placed a heavy protective tariff on every pound of tobacco brought into England. [citation needed]

Throughout the 17th and 18th centuries, tobacco continued to be the cash crop of the Virginia Colony, as well as The Carolinas. Large tobacco warehouses filled the areas near the wharves of new, thriving towns such as Dumfries on the Potomac, Richmond and Manchester at the fall line (head of navigation) on the James, and Petersburg on the Appomattox.

Until 1883, tobacco excise tax accounted for one third of internal revenue collected by the United States government.[citation needed]

A historian of the American South in the late 1860s reported on typical usage in the region where it was grown:[12]

The chewing of tobacco was well-nigh universal. This habit had been widespread among the agricultural population of America both North and South before the war. Soldiers had found the quid a solace in the field and continued to revolve it in their mouths upon returning to their homes. Out of doors where his life was principally led the chewer spat upon his lands without offence to other men, and his homes and public buildings were supplied with spittoons. Brown and yellow parabolas were projected to right and left toward these receivers, but very often without the careful aim which made for clean living. Even the pews of fashionable churches were likely to contain these familiar conveniences. The large numbers of Southern men, and these were of the better class (officers in the Confederate army and planters, worth $20,000 or more, and barred from general amnesty) who presented themselves for the pardon of President Johnson, while they sat awaiting his pleasure in the ante-room at the White House, covered its floor with pools and rivulets of their spittle. An observant traveller in the South in 1865 said that in his belief seven-tenths of all persons above the age of twelve years, both male and female, used tobacco in some form. Women could be seen at the doors of their cabins in their bare feet, in their dirty one-piece cotton garments, their chairs tipped back, smoking pipes made of corn cobs into which were fitted reed stems or goose quills. Boys of eight or nine years of age and half-grown girls smoked. Women and girls "dipped" in their houses, on their porches, in the public parlors of hotels and in the streets.

As a lucrative crop, tobacco has been the subject of a great deal of biological and genetic research. The economic impact of Tobacco Mosaic disease was the impetus that led to the isolation of Tobacco mosaic virus, the first virus to be identified[citation needed]; the fortunate coincidence that it is one of the simplest viruses and can self-assemble from purified nucleic acid and protein led, in turn, to the rapid advancement of the field of virology. The 1946 Nobel Prize in Chemistry was shared by Wendell Meredith Stanley for his 1935 work crystallizing the virus and showing that it remains active.

Tobacco in the Ottoman Empire

Tobacco as a commercial product first arrived in the Ottoman Empire in the late 16th century.[13] By 1700, it had reached Europe and Asia, and would soon arrive in the Middle East[14], where it was welcomed with the same enthusiasm with which coffee had been greeted, two centuries earlier.

When tobacco first arrived in the Ottoman Empire, it attracted the attention of doctors[15] and became a commonly prescribed medicine for many ailments. Although tobacco was initially prescribed as medicine, further study led to claims that smoking caused dizziness, fatigue, dulling of the senses, and a foul taste/odour in the mouth.[16]

In 1682, Damascene jurist Abd al-Ghani al-Nabulsi declared: “Tobacco has now become extremely famous in all the countries of Islam ... People of all kinds have used it and devoted themselves to it ... I have even seen young children of about five years applying themselves to it.”[17]

In 1750, a Damascene townsmen observed “a number of women greater than the men, sitting along the bank of the Barada River. They were eating and drinking, and drinking coffee and smoking tobacco just as the men were doing.”[18]

Further reading

- Murphey, Rhoads. Studies on Ottoman Society and Culture: 16th-18th Centuries. Burlington, VT: Ashgate: Variorum, 2007 ISBN 9780754659310 ISBN 0754659313

- Price, Jacob M. “Tobacco Use and Tobacco Taxation: A battle of Interests in Early Modern Europe”. Consuming Habits: Drugs in History and Anthropology. Jordan Goodman, et al. New York: Routledge, 1995 166-169 ISBN 0-415-09039-3

Cultivation

Sowing

Tobacco seeds are scattered onto the surface of the soil, as their germination is activated by light. In colonial Virginia, seedbeds were fertilized with wood ash or animal manure (frequently powdered horse manure). Seedbeds were then covered with branches to protect the young plants from frost damage, and the plants were left alone until around April.

In the 19th century, young plants came under increasing attack from certain types of flea beetles, Epitrix cucumeris or Epitrix pubescens, which caused destruction of half the tobacco crops in United States in 1876. In the years afterward, many experiments were attempted and discussed to control the flea beetle. By 1880 it was discovered that replacing the branches with a frame covered by thin fabric would effectively protect plants from the beetle. This practice spread until it became ubiquitous in the 1890s.

Today, in the United States, unlike other countries, tobacco is often fertilized with the mineral apatite in order to partially starve the plant for nitrogen, which changes the taste. This (together with the use of licorice and other additives) accounts for the different flavor of American cigarettes from those available in other countries. There is, however, some suggestion that this may have adverse health effects attributable to the content of apatite[citation needed].

Transplanting

After the plants have reached a certain height, they are transplanted into fields. This was originally done by making a relatively large hole in the tilled earth with a tobacco peg, then placing the small plant in the hole. Various mechanical tobacco planters were invented throughout the late 19th and early 20th century to automate this process, making a hole, fertilizing it, and guiding a plant into the hole with one motion.

Harvest

Tobacco can be harvested in several ways. In the oldest method, the entire plant is harvested at once by cutting off the stalk at the ground with a sickle. In the nineteenth century, bright tobacco began to be harvested by pulling individual leaves off the stalk as they ripened. The leaves ripen from the ground upwards, so a field of tobacco may go through several so-called "pullings," more commonly known as topping (topping always refers to the removal of the tobacco flower before the leaves are systematically removed and, eventually, entirely harvested. The stalks are left as compost to postpone over-farming and thus soil lacking essential nutrients for a strong crop the following year. "Cropping," "Topping," "Pulling", and "Priming" are terms for removing mature leaves from tobacco crops. Leaves are cropped as they ripen, from the bottom to the top of the stalk. The first crop of leaves, located near the base of the tobacco stalk, are called "sand lugs" in more rural southern tobacco states, where these leaves are often against the ground, coated with sand and clay, splashed upon them when it rains. Sand lugs weigh the most, and are most difficult to work with. Their weight is due to their large size and the added weight of caked-on soil; slaves would "lug" each stack to the stringer, a typically female slave who bundled each stack of leaves. Eventually workers carried the tobacco and placed it on sleds or trailers. As the industrial revolution approached America, the harvesting wagons used to transport leaves were equipped with man powered stringers, an apparatus which used twine to attach leaves onto a poll. In modern times, large fields are harvested by a single piece of farm equipment, although topping the flower and in some cases the plucking of immature leaves is still done by hand.

Some farmers still use "tobacco harvesters." They are not very efficient yet highly cost effective for harvesting premium and rare strains of tobacco. The harvester trailer for in-demand crops are now pulled by gasoline fueled tractors. The croppers pull the leaves off in handfuls, and pass these to the "stringer", which bundles the leaves to a four-sided pole with twine. These poles are hung until the harvester is full; the poles are then placed in much larger wagon to be pulled by modern farm tractors to their destination. For rare tobaccos, they are often cured on the farm. Traditionally, the slaves who cropped, pulled etc... had a very tough time with the first pull of the large, dirty, base leaves in particular. The leaves slapped their faces, dark tobacco sap which dries into a pitch black tar covered their bodies, and the soil stuck to the tar. There was one perk, however: nicotine, the addictive psychotropic stimulant in tobacco acts as a powerful insecticide. Slaves could enjoy a bug free day of forced labor when harvesting tobacco. The croppers were men, and the stringers, seated on the higher elevated seats were women or children. The harvesters had places for one team of ten workers: eight people cropping and stringing, plus a packer who moved the heavy strung poles of wet green tobacco from the stringers and packed them onto the pallet section of the harvester, plus a horseman, making the total crew of each harvester 10 people. Interestingly, the outer seats are suspended from the harvester - slung out over to fit into the aisles of tobacco. As these seats are suspended it is important to balance the weight of the two outside teams (similar to a playground see-saw). Having too heavy or light a person in an unbalanced combination often results in the harvester tipping over especially when turning around at the end of a lane. Water tanks are a common feature on the harvester due to heat, and danger of dehydration for the slaves.

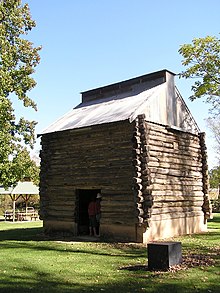

Curing

Cut plants or pulled leaves are immediately transferred to tobacco barns (kiln houses), where they will be cured. Curing methods vary with the type of tobacco grown, and tobacco barn design varies accordingly.

Air-cured tobacco is hung in well-ventilated barns and allowed to dry over a period of four to eight weeks.

Fire-cured tobacco is hung in large barns where fires of hardwoods are kept on continuous or intermittent low smoulder and takes between three days and ten weeks, depending on the process and the tobacco.

Flue-cured tobacco was originally strung onto tobacco sticks, which were hung from tier-poles in curing barns (Aus: kilns, also traditionally called Oasts). These barns have flues which run from externally fed fire boxes, heat-curing the tobacco without exposing it to smoke, slowly raising the temperature over the course of the curing. The process will generally take about a week.

Traditional curing barns in the U.S. are falling into disuse, as the trend toward using prefabricated metal curing machines within factories allows greater efficiency. These machines are also found on location at tobacco farms in 2nd world countries.

Curing and subsequent aging allows for the slow oxidation and degradation of carotenoids in tobacco leaf. This produces certain compounds in the tobacco leaves very similar and give a sweet hay, tea, rose oil, or fruity aromatic flavor that contribute to the "smoothness" of the smoke. Starch is converted to sugar which glycates protein and is oxidized into advanced glycation endproducts (AGEs), a caramelization process that also adds flavor. Inhalation of these AGEs in tobacco smoke contributes to atherosclerosis and cancer.[19]

Non-aged or low quality tobacco is often flavored with these naturally occurring compounds. Tobacco flavoring is a significant source of revenue for the international multi-million dollar flavor and fragrance industry.

The aging process continues for a period of months and often extends into the post-curing harvest process.

After tobacco is cured, it is moved from the curing barn into a storage area for processing. If whole plants were cut, the leaves are removed from the tobacco stalks in a process called stripping. For both cut and pulled tobacco, the leaves are then sorted into different grades. In colonial times, the tobacco was then "prized" into hogsheads for transportation. In bright tobacco regions, prizing was replaced by stacking wrapped "hands" into loose piles to be sold at auction. Today, most cured tobacco is baled before sales are made under pre-sold contracts.

No-Tillage Tobacco Production Systems

Tobacco production has been a high value enterprise historically in the southeastern US, but tillage methods often implemented in the production of this crop has also caused farmers to lose many millions of tons of soil because of erosion. Soil erosion in the United States costs the public billions of dollars each year. Tobacco is an intensively tilled crop when cultivated under the traditional conventional tillage system in place on the vast majority of tobacco farms in the USA. The viability of no-tillage production will be essential for the preservation of this crop, and the land suitable for its production. No-till along with other conservation practices can drastically decrease soil erosion rates especially on the gently to moderately sloping land often used for tobacco production.

Background & Purposes:

The conventional tillage system implemented on most tobacco farms involves the use of heavy tillage machinery designed to intensively mix the soil and keep it essentially bare throughout the growing season, exposing it to the erosive forces of wind and water that detach soil particles and move them easily across the land surface and downslope to drainage areas. No-tillage systems now implemented on some tobacco farms show great promise for reducing soil erosion while maintaining comparable yields to those of conventional tillage systems. By leaving essentially all residues from the previous crop, often a small grain cover crop, on the soil surface, no-till discourages erosion by preventing water and wind from direct soil contact. Erosion in most tobacco fields is most noticeable between rows of plants where rills are often formed that channel excess water out of the field during rain events. Crop residues prevent this from occurring by slowing down the water and increasing its infiltration while decreasing runoff. A two year study at the North Carolina State University in the 1980’s showed that erosion in tobacco fields on a coastal plain soil with a 3.1% slope were reduced 90 fold(Journal of Soil and Water Conservation). Erosion rates in many conventionally tilled tobacco fields are not in the tolerable range, but the implementation of no-till and other conservation practices could certainly bring erosion rates into that range.

History and Obstacles:

A historical marker in Christian county, Kentucky records that the first practice of no-tillage crop production occurred on the farm of Lawrence and Harry young in 1962. No-till production of grain crops became widespread over the next decade. No-Till agriculture got its start because of a broad interest in soil conservation and the need for a more suitable practice in certain management situations. From the outset, no-till systems for tobacco production were sought, but were not developed nearly as quickly as systems for other crops. Weed control and plant establishment have been the two primary obstacles to adoption of no-till tobacco production. In grain crops such as wheat, corn, and soybeans herbicides were developed that provided satisfactory weed control throughout the season, and the use of seeds rather than seedlings made crop establishment less complicated. Tobacco is a broadleaf plant which is harvested for its leaves, thus any chemical damage to the foliage of the plant decreases its value tremendously. Over the top broadleaf herbicide treatments that would control weeds commonly found in tobacco are not currently an option as the plant would be severely damaged or killed by such action. Pre-plant herbicide options are limited in tobacco production because chemicals such as roundup or touchdown, traditionally used burn down chemicals, are not labeled for use in no-till tobacco within 30 days of transplanting(Bob Pearce). They can therefore be used early to decrease the number of weeds, but by the time the tobacco plants have firmly rooted many new weeds may have germinated and surpassed them in growth. Recently the Gramoxone label was changed to allow this product to be used in no-till tobacco Herbicides such as Spartan and Command have been shown to work well in controlling weeds in no-till tobacco when properly applied (ID-160 University of Kentucky Cooperative Extension Service). However, escapes do occur and one of the most troublesome limitations for no-till tobacco is the lack of post-transplant weed control options. Tobacco is easily stunted by intense weed pressure during early developmental stages, and this could affect the plant throughout its life cycle. It is also undesirable to implement mechanical tillage weed removal in a no till operation for a couple of reasons. If the surface of the soil is disturbed, erosion accelerates, defeating the initial purpose of no till production. Also the residue barrier for further weed control will be removed, increasing the rate of weed proliferation. Ultimately, if intense weed pressure is observed in no-till tobacco production, producers have very few options. Limited herbicide treatments and the unavailability of mechanical removal create a tricky situation. Therefore manual weed removal is the common practice on most tobacco farms when weed pressure becomes intense. This is usually done by workers with a hoe, and in combination with cultivation equipment to remove weeds from the row middles in conventionally tilled operations. Another obstacle for no-till production is consistent plant establishment. In the production of grain crops, seeds are planted into the ground, and with the presence of moisture and warmth, they germinate and begin their life cycle. Their propagation is usually relatively uniform, and stands are generally good. Tobacco cannot be seeded directly into the field. This is partially because of the small seed size (comparable to mustard seed) which usually results in a less than uniform stand. Also, the growing season in most areas suited for tobacco production would not allow for enough time to seed into a field and satisfactorily harvest the crop during preferable conditions. To overcome these difficulties tobacco seeds are sowed in greenhouses and grown to a size of 4 or 5 inches tall, then transplanted to the field. As tobacco is transplanted in the seedling form, one requirement for a successful and uniform stand is satisfactory root to soil contact. Without good contact, the roots will whither and the plant will wilt and die without having taken up sufficient water or nutrients. A transplanter must open a small furrow in the soil about 2-4 inches deep and 1-2 inches wide so the root ball can be placed in the soil and it must then close the furrow completely around the roots. The soil must be packed snug against the root ball but not too tightly as this could cause the plant to be stunted or die. Conventional bare root plants were very susceptible to root dehydration. Container grown plants have improved plant establishment under no-till production. This task has been of major concern for those designing no-till tobacco transplanters. Conventional transplanters are pulled through a thoroughly tilled seed bed that is soft and the soil is easy to repack around the root ball. No-till transplanters must cut into the undisturbed soil and then repack this soil that is not loose around the root ball without restricting the seedling. No-till transplanters often have a problem closing the furrow around the root ball and therefore the sunlight and air dry out the roots and the plant consequently dies of dehydration. Most conventional transplanters are not able to penetrate an unprepared seed bed in order to cut the furrow required for transplanting. These transplanters basically slide on top of the soil surface without placing plants into the soil. Modified transplanters have been developed to overcome some of these problems.

No till Transplanters & Transplanting:

Most transplanters currently in use are not equipped for no-tillage systems. Conventional transplanters are equipped with a metal “shoe” that slices a groove into the prepared seedbed into which the seedlings are placed by mechanical “fingers” or dropped into “cups” by workers. A set of packing wheels is also installed behind the shoe to press the soil around the roots of the plants to ensure good root to soil contact. These transplanters are not suitable for no-tillage production because they are not able to penetrate undisturbed soil or use it as an effective seedbed. Most no-tillage transplanters are equipped with rippled coulters and a sub-soiler shank placed in front of the shoe on the transplanter in order for a slit in the ground to be formed so that the shoe can clear a path and cut a groove in the soil so that the seedlings can be mechanically placed in the furrow and covered by the packing wheels so that a proper stand is reached(Bob Pearce). Many conventional transplanters are equipped with coulters in front of the shoe, in order to slice through residue in the seedbed and to prevent clogging of the shoe, but only no-till transplanters require the sub-soiler shank to be placed in front of the shoe. The coulters slice through the crop residue satisfactorily, but do not dig a deep enough furrow suitable for the transplanter to work efficiently. The shank may be adjusted up or down in order to accommodate different planting conditions and soil types. The packing wheels on a no-till transplanter are also heavier than those on a conventional transplanter in order to press the harder surface back down around the plant roots effectively. The packing wheels must be monitored though, in order to ensure compaction is not too great in the root zone for proper development(Pearce, Zeleznik). Compaction from the shoe may also be a problem, even more so than the packing wheels in some cases(Gray Palmer). In the early days of no-till transplanters for tobacco (10-30 years ago) compaction problems and the inability to get the transplanter to go into the soil deep enough for proper root to soil contact were major obstacles. Early transplanters were loaded with weights in order to press the transplanter into the soil, and packing wheels were so heavy that damage to the plant occurred during the transplanting process(Morrison et al. 1973). The implementation of coulters and the sub-soiler shank in front of the shoe largely alleviated these problems and the need for a heavy transplanter.

Weed Control in No-Till Tobacco Production Systems

The options for weed control in no-till tobacco vary from those available for conventional operations. With the objective of no-till production being the decrease of erosion, using cultivation equipment would be the antithesis of the goal. Cultivation would in many cases harm a crop that is not accustomed to being tilled around regularly by releasing soil moisture and damaging roots. Site selection is the first step in weed control along with planning and consideration of suppression of weeds by residue. No-till production should be implemented on a sight with some existing ground cover that will aid in weed suppression. When planning crop rotations, no-till tobacco producers would benefit from observing the tendency of certain crop residues to persist or dissipate throughout the growing season. Stubble from cereal grains such as wheat or rye harvested in the spring for hay persist consistently through the summer growing season, but corn and soybean stubble seem to dissipate more quickly. Most No-Till tobacco is transplanted directly into stubble of winter wheat or rye residue, or in some cases soybean or corn stubble. About thirty days prior to transplanting, the producer should use a “Burn down” chemical such as Roundup or Touch Down to kill existing weeds to create a layer of residue for suppression of further weed growth. Prior to transplanting, but not more than a week before, producers should then spray the herbicide Spartan 4F(Active Ingredient Sulfentrazone) for preventative broadleaf protection and then spray Command 3ME (Active Ingredient Clomazone) over the top no more than one week after transplanting (ID-160). For success in any No-Till tobacco operation, these two pre treatment chemicals are necessary for the control of broadleaf plants such as pigweed and nightshade, and for grasses such as nutsedge and crabgrass. These are essentially the only herbicides available for use in tobacco which cover most broadleaf and grass species. Poast herbicide can be sprayed over the top of tobacco to control certain grasses. In experimental plots at the University of Kentucky a shielded spray of Gramoxone was used in a tobacco field with severe weed pressure in which the alternative would have been to bushhog the crop down(Bob Pearce). The shielded spray substantially reduced weed populations and essentially saved the crop. However Gramoxone is not labeled for such use in tobacco at this stage. Manual weed removal is still an option, but only by hand. The use of cultivation equipment in a no-till operation could damage the root systems of the crop and release moisture from the soil and potentially decrease yields in the long run.

Additional Benefits

There are other benefits realized through No-Till tobacco production. A more efficient harvest is possible because even during times of rainfall and stormy weather, time out of the field will be decreased in a no-till field because of the ground cover which will reduce the amount of mud and water ponding. Leaf buying companies should also be more pleased with the product they receive, which should be cleaner, especially in the case of an abnormally wet harvest season. Farmers should be able to spend less time operating heavy machinery, and could possibly eliminate the need for certain pieces of tillage equipment, not to mention the fuel savings associated with no-tillage versus intensive tillage.

No Till Tobacco References

- Morrison J. E., J. H. Smiley, W. O. Atkinson, and D. C. Milbocker. 1973. A no-tillage transplanter. Tobacco Science. Vol. 44: p.44-46.

- Journal of Soil and Water Conservation: Reducing Soil Erosion in Tobacco Fields with No-Till Transplanting. Vol. 41, No. 3, Pg 193-196, May-June 1986

Types

Aromatic Fire-cured

Aromatic Fire-cured smoking tobacco is a robust variety of tobacco used as a condimental for pipe blends. It is cured by smoking over gentle fires. In the United States, it is grown in the western part of Tennessee, Western Kentucky and in Virginia. Fire-cured tobacco grown in Kentucky and Tennessee is used in some chewing tobaccos, moist snuff, some cigarettes and as a condiment leaf in pipe tobacco blends. It has a rich, slightly floral taste, and adds body and aroma to the blend.

Another fire-cured tobacco is Latakia and is produced from oriental varieties of N. tabacum. The leaves are cured and smoked over smoldering fires of local hardwoods and aromatic shrubs in Cyprus and Syria. Latakia has a pronounced flavor and a very distinctive smoky aroma, and is used in Balkan and English-style pipe tobacco blends.

Brightleaf tobacco

Brightleaf is commonly known as "Virginia tobacco", often regardless of which state they are planted. Prior to the American Civil War, most tobacco grown in the US was fire-cured dark-leaf. This type of tobacco was planted in fertile lowlands, used a robust variety of leaf, and was either fire cured or air cured.

Sometime after the War of 1812, demand for a milder, lighter, more aromatic tobacco arose. Ohio, Pennsylvania and Maryland all innovated quite a bit with milder varieties of the tobacco plant. Farmers around the country experimented with different curing processes. But the breakthrough didn't come until around 1839.

It had been noticed for centuries that sandy, highland soil produced thinner, weaker plants. Captain Abisha Slade, of Caswell County, North Carolina had a good deal of infertile, sandy soil, and planted the new "gold-leaf" varieties on it. Slade owned a slave, Stephen, who around 1839 accidentally produced the first real bright tobacco. He used charcoal to restart a fire used to cure the crop. The surge of heat turned the leaves yellow. Using that discovery, Slade developed a system for producing bright tobacco, cultivating on poorer soils and using charcoal for heat-curing.

Slade made many public appearances to share the bright-leaf process with other farmers. Prosperous and outgoing, he built a brick house in Yanceyville, North Carolina, and at one time had many servants.

News spread through the area pretty quickly. The infertile sandy soil of the Appalachian piedmont was suddenly profitable, and people rapidly developed flue-curing techniques, a more efficient way of smoke-free curing. Farmers discovered that Bright leaf tobacco needs thin, starved soil, and those who could not grow other crops found that they could grow tobacco. Formerly unproductive farms reached 20–35 times their previous worth. By 1855, six Piedmont counties adjoining Virginia ruled the tobacco market.

By the outbreak of the Civil War, the town of Danville, Virginia actually had developed a bright-leaf market for the surrounding area in Caswell County, North Carolina and Pittsylvania County, Virginia.

Danville was also the main railway head for Confederate soldiers going to the front. These brought bright tobacco with them from Danville to the lines, traded it with each other and Union soldiers, and developed quite a taste for it. At the end of the war, the soldiers went home and suddenly there was a national market for the local crop. Caswell and Pittsylvania counties were the only two counties in the South that experienced an increase in total wealth after the war.

White burley

In 1865, George Webb of Brown County, Ohio planted Red Burley seeds he had purchased, and found that a few of the seedlings had a whitish, sickly look. He transplanted them to the fields anyway, where they grew into mature plants but retained their light color. The cured leaves had an exceedingly fine texture and were exhibited as a curiosity at the market in Cincinnati. The following year he planted ten acres (40,000 m²) from seeds from those plants, which brought a premium at auction. The air-cured leaf was found to be mild tasting and more absorbent than any other variety. White Burley, as it was later called, became the main component in chewing tobacco, American blend pipe tobacco, and American-style cigarettes. The white part of the name is seldom used today, since red burley, a dark air-cured variety of the mid-1800s, no longer exists.

Shade tobacco

It is not well known that the northern US states of Connecticut and Massachusetts are also one of the important tobacco-growing regions of the country. Long before Europeans arrived in the area, Native Americans harvested wild tobacco plants that grew along the banks of the Connecticut River. Today, the Connecticut River valley north of Hartford, Connecticut is known as "Tobacco Valley", and the fields and drying sheds are visible to travelers on the road to and from Bradley International Airport, the major Connecticut airport. The tobacco grown here is known as shade tobacco, and is used as outer wrappers for some of the world's cigars.

Early Connecticut colonists acquired from the Native Americans the habit of smoking tobacco in pipes and began cultivating the plant commercially, even though the Puritans referred to it as the "evil weed". The plant was outlawed in Connecticut in 1650, but in the 1800s as cigar smoking began to be popular, tobacco farming became a major industry, employing farmers, laborers, local youths, southern African Americans, and migrant workers.

Working conditions varied from backbreaking work for young local children, ages 13 and up, to backbreaking exploitation of migrants. Each tobacco plant yields only 18 leaves useful as cigar wrappers, and each leaf requires a great deal of individual manual attention during harvesting. Although the temperature in the curing sheds sometimes exceeds 38 C (100 F), no work is done inside the sheds while the tobacco is being fired.

In 1921, Connecticut tobacco production peaked, at 31,000 acres (125 km²) under cultivation. The rise of cigarette smoking and the decline of cigar smoking have caused a corresponding decline in the demand for shade tobacco, reaching a minimum in 1992 of 2,000 acres (8 km²) under cultivation. Since then, however, cigar smoking has become more popular again, and in 1997 tobacco farming had risen to 4,000 acres (16 km²). However, only 1,050 acres (4.2 km²) of shade tobacco were harvested in the Connecticut Valley in 2006. Connecticut seed is being grown in Ecuador, where labor is very cheap. The industry has weathered some major catastrophes, including a devastating hailstorm in 1929, and an epidemic of brown spot fungus in 2000, but is now in danger of disappearing altogether, given the value of the land to real estate speculators. The older and much less labor intensive Broadleaf plant, which produces an excellent maduro wrapper as well as binder and filler for cigars, is increasing in area in the Connecticut Valley.

Perique

Perhaps the most strongly flavored of all tobaccos is the Perique, from Saint James Parish, Louisiana. When the Acadians made their way into this region in 1755, the Choctaw and Chickasaw tribes were cultivating a variety of tobacco with a distinctive flavor. A farmer called Pierre Chenet is credited with first turning this local tobacco into the Perique in 1824 through the technique of pressure-fermentation.

Considered the truffle of pipe tobaccos, the Perique is used as a component of many blended pipe tobaccos, but is too strong to be smoked pure. At one time, the freshly moist Perique was also chewed, but none is now sold for this purpose. It is traditionally a pipe tobacco, and is still very popular with pipe-smokers, typically blended with pure Virginia to lend spice, strength, and coolness to the blend.

Oriental Tobacco

Oriental tobacco is a sun-cured, highly aromatic, small-leafed variety (Nicotiana tabacum) that is grown in Turkey, Greece, Bulgaria, and Macedonia. Oriental tobacco is frequently referred to as "Turkish tobacco", as these regions were all historically part of the Ottoman Empire. Many of the early brands of cigarettes were made mostly or entirely of Oriental tobacco; today, its main use is in blends of pipe and especially cigarette tobacco (a typical American cigarette is a blend of bright Virginia, burley and Oriental).

Dokha

Dokha is a tobacco of Iranian origin mixed with leaves, bark, and herbs for smoking in a midwakh.

Wild Tobacco

Wild tobacco is native to the soutwestern United States, Mexico, and parts of South America. Its botanical name is Nicotiana rustica.

Tobacco products

This article needs additional citations for verification. (March 2007) |

Snuff

Snuff is a generic term for fine-ground smokeless tobacco products. Originally the term referred only to dry snuff, a fine tan dust popular mainly in the eighteenth century. This is often called "Scotch Snuff", a folk-etymology derivation of the scorching process used to dry the cured tobacco by the factory. Snuff powder originated in the UK town of Great Harwood and was famously ground in the town's monument prior to local distribution and transport further up north to Scotland.

Types of Snuff

European (dry) snuff is intended to be sniffed up the nose. Snuff is not "snorted" because snuff shouldn't get past the nose, i.e.; into sinuses, throat or lungs. European snuff comes in several varieties: Plain, Toast (fine ground - very dry), "Medicated" (menthol, camphor, eucalyptus, etc.), Scented, and Schmalzler, a German variety. The major brand names of European snuffs are: Toque Tobacco (UK), Bernards (Germany), Fribourg & Treyer (UK), Gawith (UK), Gawith Hoggarth] (UK), Hedges (UK), Lotzbeck (Germany), McChrystal's (UK), Pöschl (Germany) and Wilsons of Sharrow (UK), TUTUN-CTC (Moldova).

American (moist) snuff is much stronger, and is intended to be dipped. It comes in two varieties—"sweet" and "salty." Until the early 20th century, snuff dipping was popular in the United States among rural people, who would often use sweet barkless twigs to apply it to their gums. Popular brands are Tube Rose and Navy.

Moist snuff is also referred to as dipping tobacco or smokeless tobacco, and its use is known as dipping. In the Southern states, taking a "dip" of moist snuff is called "putting a rub in," the moist snuff in the mouth is known as a "rub." This is occasionally referred to as "snoose" in New England and the Midwest and is derived from the Scandinavian word for snuff, "snus." Like the word, the origins of moist snuff are Scandinavian, and the oldest American brands indicate that by their names. However, snuff may also be called a "dinger" or a "lipper" in New England, and its user may "pack a dinger." American Moist snuff is made from dark fire-cured tobacco that is ground, sweetened, and aged by the factory. Prominent North American brands are Copenhagen, Skoal, Timber Wolf, Chisholm, Grizzly, and Kodiak.

Some modern smokeless tobacco brands, such as Kodiak, have an aggressive nicotine delivery. This is accomplished with a higher dose of nicotine than cigarettes, a high pH level (which helps nicotine enter the blood stream faster), and a high portion of unprotonated (free base) nicotine.

It has been suggested by The Economist magazine that the ban on smoking tobacco indoors in some areas, such as Britain and New York City, may lead to a resurgence in the popularity of snuff as an alternative to tobacco smoking. Although the large-scale closure of British mines in the 1980s deprived the snuff industry of its major market since snuff became unfashionable (miners took snuff underground instead of smoking to avoid lethal explosions and fires), sales at Britain's largest snuff retailer have reportedly been rising at about 5% per year.[20]

Chewing tobacco

Chewing is one of the oldest ways of consuming tobacco leaves. Native Americans in both North and South America chewed the leaves of the plant, frequently mixed with lime. Modern chewing tobacco is produced in three forms: twist, plug, and scrap. A few manufacturers in the United Kingdom produce particularly strong twist tobacco meant for use in smoking pipes rather than chewing. These twists are not mixed with lime although they may be flavored with whiskey, rum, cherry or other flavors common to pipe tobacco.

Twist is the oldest form. One to three high-quality leaves are braided and twisted into a rope while green, and then are cured in the same manner as other tobacco. This was originally devised by sailors due to fire hazards of smoking at sea, and until recently this was done by farmers for their personal consumption, in addition to other tobacco intended for sale. Modern twist is occasionally lightly sweetened. It is still sold commercially, but rarely seen outside of Appalachia. Popular brands are Mammoth Cave, Moore's Red Leaf, and Cumberland Gap. Users cut a piece off the twist and chew it, expectorating.

Plug chewing tobacco is made by pressing together cured tobacco leaves in a sweet (often molasses-based) syrup. Originally this was done by hand, but since the second half of the 19th century leaves were pressed between large tin sheets. The resulting sheet of tobacco is cut into plugs. Like twist, consumers sometimes cut, but more often bite off, a piece of the plug to chew. Major brands are Axton's, Days Work, and Cannonball.

Scrap, or looseleaf chewing tobacco, was originally the excess of plug manufacturing. It is sweetened like plug tobacco, but sold loose in bags rather than a plug. Looseleaf is one of the more popular forms of tobacco in modern times. Among those, popular brands are Red Man, Beechnut, Mail Pouch and Southern Pride. Looseleaf chewing tobacco can also be dipped.

Snus

Swedish snus is different in that it is made from steam-cured tobacco, made in other ways than fire-cured, and its health effects are markedly different, with epidemiological studies showing in lower rates of cancer and other tobacco-related health problems than cigarettes, American "Chewing Tobacco", Indian Gutka or African other. Prominent Swedish brands are Swedish Match, General, Ettan, and Tre Ankare. In the Scandinavian countries, moist tobacco comes either in loose powder form, to be pressed into a small ball or ovoid either by hand or with the use of a special tool. It is sometimes packaged in small bags, suitable for placing inside the upper lip, called "portion snus". These small bags keep the loose tobacco from becoming stuck between the users teeth; they also produce less spittle when in contact with mucous membranes inside the mouth which extends the usage time of the tobacco product.

Since it is not smoked, snuff in general generates less of the nitrosamines and other carcinogens in the tar that forms from the partially anaerobic reactions in the smoldering smoked tobacco. The steam curing of snus rather than fire-curing or flue-curing of other smokeless tobaccos has been demonstrated to generate even fewer of such compounds than other options of snuff; 2.8 parts per mil for Ettan brand compared to as high as 127.9 parts per mil in American brands, according to a study by the State of Massachusetts Health Department. It is hypothesized that the widespread use of snus by Swedish men (estimated at 30% of Swedish men, possibly because it is much cheaper than cigarettes), displacing tobacco smoking and other varieties of snuff, is responsible for the incidence of tobacco-related mortality in men being significantly lower in Sweden than any other European country. In contrast, since women are much less likely to use snus, their rate of tobacco-related deaths in Sweden is similar to that in other European countries. Snus is clearly less harmful than other tobacco products; according to Kenneth Warner, director of the University of Michigan Tobacco Research Network,

- "The Swedish government has studied this stuff to death, and to date, there is no compelling evidence that it has any adverse health consequences. ... Whatever they eventually find out, it is dramatically less dangerous than smoking."

Public health researchers maintain that, nevertheless, even the low nitrosamine levels in snus cannot be completely risk free, but snus proponents maintain that inasmuch as snus is used as a substitute for smoking or a means to quit smoking, the net overall effect is positive, similar to the effect of nicotine patches, for instance. Snus is banned in the European Union countries outside of Sweden (regular snus, not portion, is allowed in Denmark and snus is also becoming a regular among Norwegians, as cigarettes are seen by Norwegian popular culture as untrendy and much more unhealthy than snus[citation needed]). Although this is officially for health reasons, it is widely regarded, in fact, as being for economic reasons, since other smokeless tobacco products (mainly from India) associated with much greater risk to health are sold too.

Although it lacks the carcinogenicity of high levels of nitrosamines, however, any harmful effects of nicotine will still be seen with snus usage. Current research concentrates on nicotine's effect on the circulatory system and on the pancreas.[citation needed]

On June 11, 2006, Reynolds Tobacco announced that the new be nem marketing brand of Camel snus in Portland, Oregon and Austin, Texas by the end of the month. The product would be manufactured in Sweden, in conjunction with British American Tobacco, manufacturers of BAT snus.[21]

Creamy snuff

Creamy snuff is a tobacco paste, consisting of tobacco, clove oil, glycerin, spearmint, menthol, and camphor, and sold in a toothpaste tube. It is marketed mainly to women in India, and is known by the brand names Ipco (made by Asha Industries), Denobac, Tona, Ganesh. It is locally known as "mishri" in some parts of Maharashtra. According to the U.S. NIH-sponsored 2002 Smokeless Tobacco Fact Sheet, it is marketed as a dentifrice. The same factsheet also mentions that it is "often used to clean teeth". The manufacturer recommends letting the paste linger in the mouth before rinsing.

Gutka

Gutka (also spelled gutkha, guttkha, guthka) is a preparation of crushed betel nut, tobacco, and sweet or savory flavorings. It is manufactured in India and exported to a few other countries. A mild stimulant, it is sold across India in small, individual-size packets. It is consumed much like chewing tobacco, and like chewing tobacco it is considered responsible for oral cancer and other severe negative health effects.

Used by millions of adults, it is also marketed to children. Some packaging does not mention tobacco as an ingredient, and some brands are pitched as candies - featuring packaging with children's faces and are brightly colored. Some are chocolate-flavored, and some are marketed as breath fresheners.

Tobacco water

Tobacco water is a traditional organic insecticide used in domestic gardening. Tobacco dust can be used similarly.

It is produced by boiling strong tobacco in water, or by steeping the tobacco in water for a longer period. When cooled the mixture can be applied as a spray, or 'painted' on to the leaves of garden plants, where it will prove deadly to insects.

Basque angulero fishermen kill immature eels (elvers) in an infusion of tobacco leaves before parboiling them in salty water for transportation to market as angulas, a seasonal delicacy.[22]

Tobacco paste treatment for stinging insects

Topical tobacco paste is sometimes recommended as a treatment for wasp, hornet, fire ant, scorpion, and bee stings.[23] An amount equivalent to the contents of a cigarette is mashed in a cup with about a 0.5 to 1 teaspoon of water to make a paste that is then applied to the affected area. Paste has a diameter of 4 to 5 cm (1.5 to 2 inches) and may need to be moistened in dry weather. If made and applied immediately, complete remission is common within 20–30 minutes, at which point the paste can be removed. The next day there may be a some residual itching, but virtually no swelling or redness. There seems to be no scientific evidence, as yet, that this common home remedy works to relieve pain.[24] For about 2 percent of people, allergic reactions can be life-threatening and require emergency treatment. For more on this, see bee stings.

See also

- Chewing Tobacco

- Chop Chop

- Cigarette

- Cigar

- Dipping tobacco

- Health effects of tobacco smoking

- History of commercial tobacco in the United States

- Tobacco company

- Tobacco industry

- Tobacco plantations and slaves

- Tobacco mosaic virus

- Tobacco smoking

- Turkish tobacco

- Nicotine

- Passive smoking

- Shag (tobacco)

- Smoking

- Smoking ban

- Smoking cessation

- Smoking culture

Notes

- ^ The First Nonsmoking Nation,Slate.com

- ^ 2008 report on tobacco smoke, World Health Organization, 2008

- ^ Tobacco Facts - Why is Tobacco So Addictive?

- ^ Philip Morris Information Sheet

- ^ World Association of International Studies, Stanford University

- ^ Online Etymological Dictionary

- ^ eg. Heckewelder, History, Manners and Customs of the Indian Nations who Once Inhabited Pennsylvania, p. 149 ff.

- ^ "They smoke with excessive eagerness ... men, women, girls and boys, all find their keenest pleasure in this way." - Dièreville describing the Mi'kmaq, c. 1699 in Port Royal.

- ^ Tobacco: A Study of Its Consumption in the United States, Jack Jacob Gottsegen, 1940, p. 107.

- ^ Aboriginal Youth Network / Health Canada, "A Tribe called Quit"

- ^ http://curry.edschool.virginia.edu/socialstudies/projects/jvc/overview.html

- ^ A History of the United States since the Civil War Volume: 1. by Ellis Paxson Oberholtzer; 1917. P 93.

- ^ Grehan, p.1

- ^ Grehan, p.2

- ^ Grehan, p.2

- ^ Grehan, p.7

- ^ Grehan, p.3

- ^ Grehan, p.3

- ^ Cerami C, Founds H, Nicholl I, Mitsuhashi T, Giordano D, Vanpatten S, Lee A, Al-Abed Y, Vlassara H, Bucala R, Cerami A (1997). "Tobacco smoke is a source of toxic reactive glycation products". PROCEEDINGS OF THE NATIONAL ACADEMY OF SCIENCES OF THE UNITED STATES OF AMERICA (PNAS). 94 (25): 13915–20. doi:10.1073/pnas.94.25.13915. PMID 9391127.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - ^ The Economist: Thou shalt not inhale, Issue 8465, February 18th, pg 28

- ^ Reynolds Makes Big Move Into Smokeless Tobacco

- ^ Angulas

- ^ Beverly Sparks, "Stinging and Biting Pests of People" Extension Entomologist of the University of Georgia College of Agricultural & Environmental Sciences Cooperative Extension Service.

- ^ Glaser, David. "Are wasp and bee stings alkali or acid and does neutralising their ph them give sting relief?". www.insectstings.co.uk. Retrieved 2007-05-03.

References

- Breen, T. H. (1985). Tobacco Culture. Princeton University Press. ISBN 0-691-00596-6. Source on tobacco culture in eighteenth-century Virginia pp. 46–55

- W.K. Collins and S.N. Hawks. "Principles of Flue-Cured Tobacco Production" 1st Edition, 1993

- Fuller, R. Reese (Spring 2003). Perique, the Native Crop. Louisiana Life.

- Gately, Iain. Tobacco: A Cultural History of How an Exotic Plant Seduced Civilization. Grove Press, 2003. ISBN 0-8021-3960-4.

- Graves, John. "Tobacco that is not Smoked" in From a Limestone Ledge (the sections on snuff and chewing tobacco) ISBN 0-394-51238-3

- Grehan, James. “Smoking and “Early Modern” Sociability: The Great Tobacco Debate in the Ottoman Middle East (Seventeenth to Eighteenth Centuries)”. The American Historical Review, Vol. III, Issue 5. 2006. 22 March 2008

http://www.historycooperative.org.myaccess.library.utoronto.ca/journals/ahr/111.5/grehan.html

- Killebrew, J. B. and Myrick, Herbert (1909). Tobacco Leaf: Its Culture and Cure, Marketing and Manufacture. Orange Judd Company. Source for flea beetle typology (p. 243)

- Poche, L. Aristee (2002). Perique tobacco: Mystery and history.

- Tilley, Nannie May. The Bright Tobacco Industry 1860–1929 ISBN 0-405-04728-2. Source on flea beetle prevention (pp. 39–43), and history of flue-cured tobacco

- Rivenson A., Hoffmann D., Propokczyk B. et al. Induction of lung and pancreas exocrine tumors in F344 rats by tobacco-specific and areca-derived N-nitrosamines. Cancer Res (48) 6912–6917, 1988. (link to abstract; free full text pdf available)

- Schoolcraft, Henry R. Historical and Statistical Information respecting the Indian Tribes of the United States (Philadelphia, 1851-57)

- Shechter, Relli. Smoking, Culture and Economy in the Middle East: The Egyptian Tobacco Market 1850-2000. New York: I.B. Tauris & Co. Ltd., 2006 ISBN 1-84511-1370

External links

- North American Association of Cigarette and Tobacco Smokers

- The European tobacco growers website

- Timeline of tobacco history

- Growing Nicotiana species (Plot55.com)

- Tobacco Smoke and Involuntary Smoking, Summary of Data Reported and Evaluation 2004 by the IARC.

- BBC report on questions re European Union partial ban on some smokeless tobacco products (i.e. snus)

- Scientists Search for Healthy Uses for Tobacco

- Science behind tobacco - Curing

- UCSF Tobacco Industry Videos Collection

- The Legacy Tobacco Documents Library

- Ottoman Back Archives and Research Centre

- Natural Resources Conservation Service Plant Sheet - Wild tobacco