Staged combustion cycle

The staged combustion cycle (sometimes known as topping cycle, preburner cycle, or closed cycle) is a power cycle of a bipropellant rocket engine. In the staged combustion cycle, propellant flows through multiple combustion chambers, and is thus combusted in stages. The main advantage relative to other rocket engine power cycles is high fuel efficiency, measured through specific impulse, while its main disadvantage is engineering complexity.

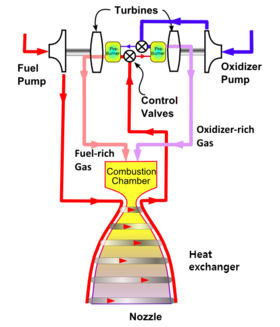

Typically, propellant flows through two kinds of combustion chambers; the first called preburner and the second called main combustion chamber. In the preburner, a small portion of propellant, usually fuel-rich, is partly combusted under non-stoichiometric conditions, and the increasing volume flow is used to drive the turbopumps that feed the engine with propellant. The gas is then injected into the main combustion chamber and combusted completely with the other propellant to produce thrust.

Tradeoffs[edit]

The main advantage is fuel efficiency due to all of the propellant flowing to the main combustion chamber, which also allows for higher thrust. The staged combustion cycle is sometimes referred to as closed cycle, as opposed to the gas generator, or open cycle where a portion of propellant never reaches the main combustion chamber. The disadvantage is engineering complexity, partly a result of the preburner exhaust of hot and highly pressurized gas which, particularly when oxidizer-rich, produces extremely harsh conditions for turbines and plumbing.

History[edit]

Staged combustion (Замкнутая схема) was first proposed by Alexey Isaev in 1949. The first staged combustion engine was the S1.5400 (11D33) used in the Soviet Molniya rocket, designed by Melnikov, a former assistant to Isaev.[1] About the same time (1959), Nikolai Kuznetsov began work on the closed cycle engine NK-9 for Korolev's orbital ICBM, GR-1. Kuznetsov later evolved that design into the NK-15 and NK-33 engines for the unsuccessful Lunar N1 rocket. The non-cryogenic N2O4/UDMH engine RD-253 using staged combustion was developed by Valentin Glushko circa 1963 for the Proton rocket.

After the abandonment of the N1, Kuznetsov was ordered to destroy the NK-33 technology, but instead he warehoused dozens of the engines. In the 1990s, Aerojet was contacted and eventually visited Kuznetsov's plant. Upon meeting initial skepticism about the high specific impulse and other specifications, Kuznetsov shipped an engine to the US for testing. Oxidizer-rich staged combustion had been considered by American engineers, but was not considered a feasible direction because of resources they assumed the design would require to make work.[2] The Russian RD-180 engine also employs a staged-combustion rocket engine cycle. Lockheed Martin began purchasing the RD-180 in circa 2000 for the Atlas III and later, the V, rockets. The purchase contract was subsequently taken over by United Launch Alliance (ULA--the Boeing/Lockheed-Martin joint venture) after 2006, and ULA continues to fly the Atlas V with RD-180 engines as of 2022.

The first laboratory staged-combustion test engine in the West was built in Germany in 1963, by Ludwig Boelkow.[citation needed]

Hydrogen peroxide/kerosene powered engines may use a closed-cycle process by catalytically decomposing the peroxide to drive turbines before combustion with the kerosene in the combustion chamber proper. This gives the efficiency advantages of staged combustion, while avoiding major engineering problems.

The RS-25 Space Shuttle main engine is another example of a staged combustion engine, and the first to use liquid oxygen and liquid hydrogen.[citation needed] Its counterpart in the Soviet shuttle was the RD-0120, which had similar specific impulse, thrust, and chamber pressure, but with some differences that reduced complexity and cost at the expense of increased engine weight.

Variants[edit]

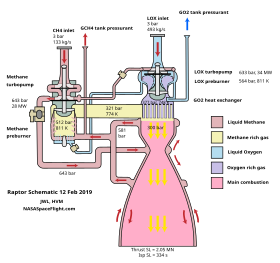

Several variants of the staged combustion cycle exist. Preburners that burn a small portion of oxidizer with a full flow of fuel are called fuel-rich, while preburners that burn a small portion of fuel with a full flow of oxidizer are called oxidizer-rich. The RD-180 has an oxidizer-rich preburner, while the RS-25 has two fuel-rich preburners. The SpaceX Raptor has both oxidizer-rich and fuel-rich preburners, a design called full-flow staged combustion.

Staged combustion designs can be either single-shaft or twin-shaft. In the single-shaft design, one set of preburner and turbine drives both propellant turbopumps. Examples include the Energomash RD-180 and the Blue Origin BE-4. In the twin-shaft design, the two propellant turbopumps are driven by separate turbines, which are in turn driven by the outflow of either one or separate preburners. Examples of twin-shaft designs include the Rocketdyne RS-25, the JAXA LE-7, and Raptor. Relative to a single-shaft design, the twin-shaft design requires an additional turbine (and possibly another preburner), but allows for individual control of the two turbopumps. Hydrolox engines are typically twin-shaft designs due to the greatly different densities of the propellants.

In addition to the propellant turbopumps, staged combustion engines often require smaller boost pumps to prevent both preburner backflow and turbopump cavitation. For example, the RD-180 and RS-25 use boost pumps driven by tap-off and expander cycles, as well as pressurized tanks, to incrementally increase propellant pressure prior to entering the preburner.

Full-flow staged combustion cycle[edit]

Full-flow staged combustion (FFSC) is a twin-shaft staged combustion cycle that uses both oxidizer-rich and fuel-rich preburners. The cycle allows full flow of both propellants through the turbines; hence the name.[3] The fuel turbopump is driven by the fuel-rich preburner, and the oxidizer turbopump is driven by the oxidizer-rich preburner.[4][3]

Benefits of the full-flow staged combustion cycle include turbines that run cooler and at lower pressure, due to increased mass flow, leading to a longer engine life and higher reliability. As an example, up to 25 flights were anticipated for an engine design studied by the DLR (German Aerospace Center) in the frame of the SpaceLiner project,[3] up to 1000 flights are expected for Raptor from SpaceX.[5] Further, the full-flow cycle eliminates the need for an interpropellant turbine seal normally required to separate oxidizer-rich gas from the fuel turbopump or fuel-rich gas from the oxidizer turbopump,[6] thus improving reliability.

Since the use of both fuel and oxidizer preburners results in full gasification of each propellant before entering the combustion chamber, FFSC engines belong to a broader class of rocket engines called gas-gas engines.[6] Full gasification of components leads to faster chemical reactions in the combustion chamber, allowing a smaller combustion chamber. This in turn makes it feasible to increase the chamber pressure, which increases efficiency.

Potential disadvantages of the full-flow staged combustion cycle include increased engineering complexity of two preburners, relative to a single-shaft staged combustion cycle, as well as an increased parts count.

As of 2024, only three full-flow staged combustion rocket engines had ever progressed sufficiently to be tested on test stands; the Soviet Energomash RD-270 project in the 1960s, the US government-funded Aerojet Rocketdyne Integrated powerhead demonstration project in the mid-2000s,[6] and SpaceX's flight capable Raptor engine first test-fired in February 2019.[7]

The first flight test of a full-flow staged-combustion engine occurred on 25 July 2019 when SpaceX flew their Raptor methalox FFSC engine on the Starhopper test rocket, at their South Texas Launch Site.[8] As of August 22, 2023, the Raptor is the only FFSC engine to have flown on a launch vehicle.

Applications[edit]

Oxidizer-rich staged combustion[edit]

- S1.5400—First staged combustion rocket engine used on the Blok L upper stage.[1]

- NK-33—Soviet engine developed for the never-flown upgraded version of the N-1 launch vehicle. Later sold to Aerojet Rocketdyne and refurbished/remarketed as the AJ-26 (used on Antares block 1 launch vehicles in 2013–2014). In use on the Soyuz-2-1v.

- P111 - liquid oxygen/kerosene demonstrator engine developed between 1956 and 1967 at Bolkow GmbH (later Astrium).[9]

- RD-170, RD-171, RD-180 and RD-191—a series of Soviet and Russian engines used on the Energia, Zenit, Atlas V, Angara and previously on the Atlas III launch vehicles. RD-171 (and its RD-171M successor), -180 and -191 are derivatives of RD-170.

- RD-0124—a series of oxygen/kerosene engines used in the second stage of Soyuz-2.1b rocket as well as in upper stages of Angara series rockets.

- YF-100—Chinese engine developed in the 2000s; used on the Long March 5, Long March 6, and Long March 7.[10]

- AR1—An Aerojet Rocketdyne project partially funded by the United States Air Force as a potential replacement for the RD-180 Russian engine.[11]

- BE-4—Blue Origin LCH4/LOX engine—using the oxygen-rich staged combustion (ORSC) cycle—planned to be used on the ULA Vulcan launch vehicle, which will replace the Atlas V and Delta IV, first flight test in 2021[12][13] and also on Blue Origin's New Glenn launch vehicle, with first flight test no earlier than 2021.[14]

- RD-253—Soviet engine developed in the 1960s and used on the Proton launch vehicle's first stage. Later variants include the RD-275 and RD-275M.

- SCE-200—Indian RP-1/LOX main stage engine in development.[citation needed]

- Hadley—Ursa Major Technologies[15] LOX/kerosene booster engine under development[16] near Denver, Colorado.[17]

- Rocket Factory Augsburg "Helix" LOX/kerosene engine under development which should power the RFA One [18] near Augsburg, Germany.

- Launcher E-2 — LOX/kerosene engine under development which should power the Launcher Light launch vehicle.[19]

Fuel-rich staged combustion[edit]

- RS-25—US developed LH2/LOX engine in the 1970–1980s, flown on the Space Shuttle through 2011 (with periodic upgrades), and planned for further use on the Space Launch System in 2020s.

- RD-0120—LH2/LOX engine used on the Energia rocket.

- LE-7—LH2/LOX engine used on the H-II rocket family.

- KVD-1 (RD-56)—Soviet LH2/LOX upper stage engine developed for the never-flown upgraded version of the N-1 launch vehicle. Used on the GSLV Mk1.

- CE-7.5—Indian LH2/LOX upper stage engine, used on the GSLV Mk2[20]

Full-flow staged combustion[edit]

- RD-270—USSR engine under development 1962–1970 for the UR-700 project; never flown.[6]

- Integrated powerhead demonstrator—Demonstration project for the front part of a full flow engine, with no combustion chamber or other backend subsystems.[6] US project to develop a part of a new rocket engine technology in the early 2000s; no full engine ever built; never flown.

- Raptor—SpaceX LCH4/LOX engine in development, first flown in 2019[21][22]

Past and present applications of staged-combustion engines[edit]

Future applications of staged-combustion engines[edit]

- New Glenn first stage with 7 BE-4 engines[23]

- Long March 9

- Long March 10

See also[edit]

References[edit]

- ^ a b Sutton, George (2006). History of Liquid Propellant Rocket Engines. AIAA. doi:10.2514/4.868870. ISBN 978-1-56347-649-5. Retrieved 5 November 2022.

- ^ Cosmodrome History Channel, interviews with Aerojet and Kuznetsov engineers about the history of staged combustion

- ^ a b c Sippel, Martin; Yamashiro, Ryoma; Cremaschi, Francesco (10 May 2012). Staged Combustion Cycle Rocket Engine Design Trade-offs for Future Advanced Passenger Transport (PDF). Space Propulsion 2012. ST28-5. Bordeaux: DLR-SART. Archived (PDF) from the original on 19 March 2014. Retrieved 19 March 2014.

- ^ Emdee, Jeff (2004). "Launch Vehicle Propulsion" (PDF). Crosslink. Vol. 5, no. 1 (2004 Winter ed.). Aerospace Corp. pp. 12–19. Archived from the original on 8 March 2016. Retrieved 30 September 2016.

- ^ O'Callaghan, Jonathan (31 July 2019). "The wild physics of Elon Musk's methane-guzzling super-rocket". Wired UK. ISSN 1357-0978. Archived from the original on 22 February 2021. Retrieved 1 January 2021.

- ^ a b c d e Belluscio, Alejandro G. (7 March 2014). "SpaceX advances drive for Mars rocket via Raptor power". NASAspaceflight.com. Archived from the original on 11 September 2015. Retrieved 9 March 2014.

- ^ Wall, Mike (4 February 2019). "Elon Musk Unveils SpaceX's 1st Rocket Engine Test for Starship Rocket (Video)". Space.com. Archived from the original on 27 July 2019. Retrieved 27 July 2019.

- ^ Burghardt, Thomas (25 July 2019). "Starhopper successfully conducts debut Boca Chica Hop". NASASpaceFlight.com. Archived from the original on 26 July 2019. Retrieved 26 July 2019.

- ^ Haeseler, Dietrich; Maeding, Chris; Preclik, Dieter; Rubinski, Vitali; Kosmatechva, Valentina (9 July 2006). "LOX-Kerosene Oxidizer-Rich Gas-Generator and Main Combustion Chamber Subscale Testing". 42nd AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit. doi:10.2514/6.2006-5197. ISBN 9781624100383.

- ^ Rui C. Barbosa (25 June 2016). "China successfully debuts Long March 7 – Recovers capsule". NASASpaceFlight.com. Archived from the original on 27 June 2016. Retrieved 28 September 2016.

- ^ "AR1 Booster Engine | Aerojet Rocketdyne". Rocket.com. Archived from the original on 4 March 2016. Retrieved 28 September 2016.

- ^ "ULA now planning first launch of Vulcan in 2021". SpaceNews.com. 25 October 2018. Retrieved 5 November 2022.

- ^ Blue Origin. "BE-4 Rocket Engine" (PDF). ULA Website 2014. Archived from the original (PDF) on 13 May 2015. Retrieved 19 March 2014.

- ^ Berger, Eric (9 March 2016). "Behind the curtain: Ars goes inside Blue Origin's secretive rocket factory". Ars Technica. Archived from the original on 9 March 2016. Retrieved 12 March 2016.

- ^ "Home". Ursa Major Technologies. Archived from the original on 9 May 2017. Retrieved 20 May 2017.

- ^ "Instagram post by Ursa Major Technologies • May 16, 2017 at 11:07pm UTC". Instagram. Archived from the original on 1 October 2021. Retrieved 20 May 2017.

- ^ "Berthoud Business News". Archived from the original on 7 June 2022.

- ^ "RFA test-fired its staged combustion engine". SpaceWatch Global. 26 July 2021. Archived from the original on 9 May 2017. Retrieved 22 June 2022.

- ^ "USSF Awards Launcher Millions To Continue E-2 Rocket Engine Development". Sat News. 26 April 2022.

- ^ "GSLV MkIII, the next milestone". Frontline. 7 February 2014. Archived from the original on 23 December 2015. Retrieved 12 March 2016.

- ^ Todd, David (22 November 2012). "SpaceX's Mars rocket to be methane-fuelled". Flightglobal. Archived from the original on 30 October 2013. Retrieved 5 December 2012.

Musk said Lox and methane would be SpaceX's propellants of choice on a mission to Mars, which has long been his stated goal. SpaceX's initial work will be to build a Lox/methane rocket for a future upper stage, codenamed Raptor. The design of this engine would be a departure from the "open cycle" gas generator system that the current Merlin 1 engine series uses. Instead, the new rocket engine would use a much more efficient "staged combustion" cycle that many Russian rocket engines use.

- ^ Grush, Loren (26 July 2019). "SpaceX's new test rocket briefly hovers during first free flight". The Verge. Archived from the original on 26 July 2019. Retrieved 27 July 2019.

- ^ Williams, Matt (24 January 2019). "Blue Origin has Shown off a New Video of its New Glenn Rocket Design". Universe Today. Archived from the original on 27 July 2019. Retrieved 27 July 2019.

- Dodd, Tim (2019). "Is SpaceX's Raptor engine the king of rocket engines?". Everyday Astronaut. Retrieved 5 April 2021.