Sewage treatment: Difference between revisions

Zarathushtra (talk | contribs) m sr:Индустријске отпадне воде |

|||

| Line 254: | Line 254: | ||

[[ru:Очистка сточных вод]] |

[[ru:Очистка сточных вод]] |

||

[[fi:Jätevedenpuhdistus]] |

[[fi:Jätevedenpuhdistus]] |

||

[[sr:Индустријске отпадне воде]] |

|||

[[sv:Reningsverk]] |

[[sv:Reningsverk]] |

||

[[tr:Atık su arıtma]] |

[[tr:Atık su arıtma]] |

||

Revision as of 21:15, 18 July 2010

This article needs additional citations for verification. (February 2010) |

Sewage treatment, or domestic wastewater treatment, is the process of removing contaminants from wastewater and household sewage, both runoff (effluents) and domestic. It includes physical, chemical, and biological processes to remove physical, chemical and biological contaminants. Its objective is to produce a waste stream (or treated effluent) and a solid waste or sludge suitable for discharge or reuse back into the environment. This material is often inadvertently contaminated with many toxic organic and inorganic compounds.

Origins of sewage

Sewage is created by residential, institutional, and commercial and industrial establishments and includes household waste liquid from toilets, baths, showers, kitchens, sinks and so forth that is disposed of via sewers. In many areas, sewage also includes liquid waste from industry and commerce.

The separation and draining of household waste into greywater and blackwater is becoming more common in the developed world, with greywater being permitted to be used for watering plants or recycled for flushing toilets. Most sewage also includes some surface water from roofs or hard-standing areas and may include stormwater runoff.

Sewerage systems capable of handling stormwater are known as combined systems or combined sewers. Such systems are usually avoided since they complicate and thereby reduce the efficiency of sewage treatment plants owing to their seasonality. The variability in flow also leads to often larger than necessary, and subsequently more expensive, treatment facilities. In addition, heavy storms that contribute more flows than the treatment plant can handle may overwhelm the sewage treatment system, causing a spill or overflow. Modern sewered developments tend to be provided with separate storm drain systems for rainwater.[2]

As rainfall travels over roofs and the ground, it may pick up various contaminants including soil particles and other sediment, heavy metals, organic compounds, animal waste, and oil and grease. (See urban runoff.)[3] Some jurisdictions require stormwater to receive some level of treatment before being discharged directly into waterways. Examples of treatment processes used for stormwater include retention basins, wetlands, buried vaults with various kinds of media filters, and vortex separators (to remove coarse solids). Sanitary sewers are typically much smaller than storm sewers, and they are not designed to transport stormwater. In areas with basements, backups of raw sewage can occur if excessive stormwater is allowed into a sanitary sewer system.

Process overview

Sewage can be treated close to where it is created (in septic tanks, biofilters or aerobic treatment systems), or collected and transported via a network of pipes and pump stations to a municipal treatment plant (see sewerage and pipes and infrastructure). Sewage collection and treatment is typically subject to local, state and federal regulations and standards. Industrial sources of wastewater often require specialized treatment processes (see Industrial wastewater treatment).

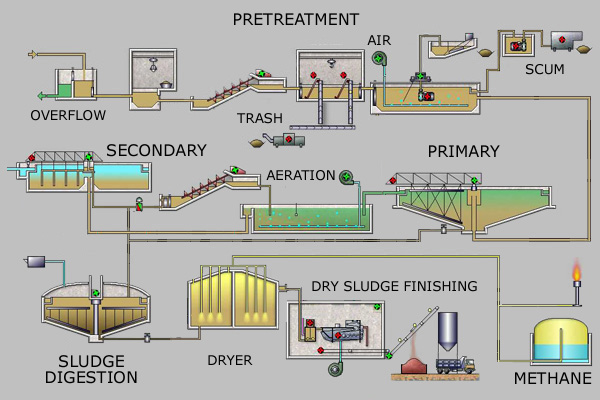

Conventional sewage treatment may involve three stages, called primary, secondary and tertiary treatment. Primary treatment consists of temporarily holding the sewage in a quiescent basin where heavy solids can settle to the bottom while oil, grease and lighter solids float to the surface. The settled and floating materials are removed and the remaining liquid may be discharged or subjected to secondary treatment. Secondary treatment removes dissolved and suspended biological matter. Secondary treatment is typically performed by indigenous, water-borne micro-organisms in a managed habitat. Secondary treatment may require a separation process to remove the micro-organisms from the treated water prior to discharge or tertiary treatment. Tertiary treatment is sometimes defined as anything more than primary and secondary treatment. Treated water is sometimes disinfected chemically or physically (for example by lagoons and microfiltration) prior to discharge into a stream, river, bay, lagoon or wetland, or it can be used for the irrigation of a golf course, green way or park. If it is sufficiently clean, it can also be used for groundwater recharge or agricultural purposes.

|

Pre-treatment

Pre-treatment removes materials that can be easily collected from the raw wastewater before they damage or clog the pumps and skimmers of primary treatment clarifiers (trash, tree limbs, leaves, etc).

Screening

The influent sewage water is screened to remove all large objects carried in the sewage stream.[4] This is most commonly done with an automated mechanically raked bar screen in modern plants serving large populations, whilst in smaller or less modern plants a manually cleaned screen may be used. The raking action of a mechanical bar screen is typically paced according to the accumulation on the bar screens and/or flow rate. The solids are collected and later disposed in a landfill or incinerated. Bar screens or mesh screens of varying sizes may be used to optimise solids removal. If gross solids are not removed they become entrained in pipes and moving parts of the treatment plant and can cause substantial damage and inefficiency in the process.[5]: 9

Grit removal

Pre-treatment may include a sand or grit channel or chamber where the velocity of the incoming wastewater is adjusted to allow the settlement of sand, grit, and stones. These particles are removed because they may damage pumps and other equipment. For small sanitary sewer systems, the grit chambers may not be necessary, but grit removal is desirable at larger plants.[5]: 10

Fat and grease removal

In some larger plants fat and grease is removed by passing the sewage through a small tank where skimmers collect the fat floating on the surface. Air blowers in the base of the tank may also be used to help recover the fat as a froth. In most plants however, fat and grease removal takes place in the primary settlement tank using mechanical surface skimmers.

Primary treatment

In the primary sedimentation stage, sewage flows through large tanks, commonly called "primary clarifiers" or "primary sedimentation tanks". The tanks are used to settle sludge while grease and oils rise to the surface and are skimmed off. Primary settling tanks are usually equipped with mechanically driven scrapers that continually drive the collected sludge towards a hopper in the base of the tank where it is pumped to sludge treatment facilities.[5]: 9–11 Grease and oil from the floating material can sometimes be recovered for saponification.

The dimensions of the tank should be designed to effect removal of a high percentage of the floatables and sludge. A typical sedimentation tank may remove from 60% to 65% of suspended solids, and from 30% to 35% of BOD from the sewage.

Secondary treatment

Secondary treatment is designed to substantially degrade the biological content of the sewage which are derived from human waste, food waste, soaps and detergent. The majority of municipal plants treat the settled sewage liquor using aerobic biological processes. To be effective, the biota require both oxygen and food to live. The bacteria and protozoa consume biodegradable soluble organic contaminants (e.g. sugars, fats, organic short-chain carbon molecules, etc.) and bind much of the less soluble fractions into floc. Secondary treatment systems are classified as fixed-film or suspended-growth systems.

- Fixed-film or attached growth systems include trickling filters and rotating biological contactors, where the biomass grows on media and the sewage passes over its surface.

- Suspended-growth systems include activated sludge, where the biomass is mixed with the sewage and can be operated in a smaller space than fixed-film systems that treat the same amount of water. However, fixed-film systems are more able to cope with drastic changes in the amount of biological material and can provide higher removal rates for organic material and suspended solids than suspended growth systems.[5]: 11–13

Roughing filters are intended to treat particularly strong or variable organic loads, typically industrial, to allow them to then be treated by conventional secondary treatment processes. Characteristics include filters filled with media to which wastewater is applied. They are designed to allow high hydraulic loading and a high level of aeration. On larger installations, air is forced through the media using blowers. The resultant wastewater is usually within the normal range for conventional treatment processes.

A filter removes a small percentage of the suspended organic matter, while the majority of the organic matter undergoes a change of character, only due to the biological oxidation and nitrification taking place in the filter. With this aerobic oxidation and nitrification, the organic solids are converted into coagulated suspended mass, which is heavier and bulkier that can settle to the bottom of a tank. The effluent of the filter is therefore, passed through a sedimentation tank, called secondary clarifier or secondary settling tanks or humus tanks.

Activated sludge

In general, activated sludge plants encompass a variety of mechanisms and processes that use dissolved oxygen to promote the growth of biological floc that substantially removes organic material.[5]: 12–13

The process traps particulate material and can, under ideal conditions, convert ammonia to nitrite and nitrate and ultimately to nitrogen gas, (see also denitrification).

Surface-aerated basins (Lagoons)

Many small municipal sewage systems in the United States (1 million gal./day or less) use aerated lagoons.[6]

Most biological oxidation processes for treating industrial wastewaters have in common the use of oxygen (or air) and microbial action. Surface-aerated basins achieve 80 to 90% removal of biochemical oxygen demand with retention times of 1 to 10 days.[7] The basins may range in depth from 1.5 to 5.0 metres and use motor-driven aerators floating on the surface of the wastewater.[7]

In an aerated basin system, the aerators provide two functions: they transfer air into the basins required by the biological oxidation reactions, and they provide the mixing required for dispersing the air and for contacting the reactants (that is, oxygen, wastewater and microbes). Typically, the floating surface aerators are rated to deliver the amount of air equivalent to 1.8 to 2.7 kg O2/kW·h. However, they do not provide as good mixing as is normally achieved in activated sludge systems and therefore aerated basins do not achieve the same performance level as activated sludge units.[7]

Biological oxidation processes are sensitive to temperature and, between 0 °C and 40 °C, the rate of biological reactions increase with temperature. Most surface aerated vessels operate at between 4 °C and 32 °C.[7]

Filter beds (oxidizing beds)

In older plants and those receiving variable loadings, trickling filter beds are used where the settled sewage liquor is spread onto the surface of a bed made up of coke (carbonized coal), limestone chips or specially fabricated plastic media. Such media must have large surface areas to support the biofilms that form. The liquor is typically distributed through perforated spray arms. The distributed liquor trickles through the bed and is collected in drains at the base. These drains also provide a source of air which percolates up through the bed, keeping it aerobic. Biological films of bacteria, protozoa and fungi form on the media’s surfaces and eat or otherwise reduce the organic content.[5]: 12 This biofilm is often grazed by insect larvae, snails, and worms which help maintain an optimal thickness. Overloading of beds increases the thickness of the film leading to clogging of the filter media and ponding on the surface. Recent advances in media and process micro-biology design overcome many issues with Trickling filter designs.

Soil Bio-Technology

A new process called Soil Bio-Technology (SBT) developed at IIT Bombay has shown tremendous improvements in process efficiency enabling total water reuse, due to extremely low operating power requirements of less than 50 Joules per Kg water treated.[8] Typically SBT systems can achieve chemical oxygen demand (COD) levels less than 10 mg/L from sewage input of COD 400 mg/L.[9] SBT plants exhibit high reductions in COD values and bacterial counts as a result of the very high microbial densities available in the media. Unlike conventional treatment plants, SBT plants produce insignificant amounts of sludge, precluding the need for sludge disposal areas that are required by other technologies.[10]

In the Indian context, conventional sewage treatment plants fall into systemic disrepair due to 1) high operating costs, 2) equipment corrosion due to methanogenesis and hydrogen sulphide, 3) non-reusability of treated water due to high COD (>30 mg/L) and high fecal coliform (>3000 NFU) counts, 4) lack of skilled operating personnel and 5) equipment replacement issues. Examples of such systemic failures has been documented by Sankat Mochan Foundation at the Ganga basin after a massive cleanup effort by the Indian government in 1986 by setting up sewage treatment plants under the Ganga Action Plan failed to improve river water quality.

Biological aerated filters

Biological Aerated (or Anoxic) Filter (BAF) or Biofilters combine filtration with biological carbon reduction, nitrification or denitrification. BAF usually includes a reactor filled with a filter media. The media is either in suspension or supported by a gravel layer at the foot of the filter. The dual purpose of this media is to support highly active biomass that is attached to it and to filter suspended solids. Carbon reduction and ammonia conversion occurs in aerobic mode and sometime achieved in a single reactor while nitrate conversion occurs in anoxic mode. BAF is operated either in upflow or downflow configuration depending on design specified by manufacturer.

Rotating biological contactors

Rotating biological contactors (RBCs) are mechanical secondary treatment systems, which are robust and capable of withstanding surges in organic load. RBCs were first installed in Germany in 1960 and have since been developed and refined into a reliable operating unit. The rotating disks support the growth of bacteria and micro-organisms present in the sewage, which break down and stabilise organic pollutants. To be successful, micro-organisms need both oxygen to live and food to grow. Oxygen is obtained from the atmosphere as the disks rotate. As the micro-organisms grow, they build up on the media until they are sloughed off due to shear forces provided by the rotating discs in the sewage. Effluent from the RBC is then passed through final clarifiers where the micro-organisms in suspension settle as a sludge. The sludge is withdrawn from the clarifier for further treatment.

A functionally similar biological filtering system has become popular as part of home aquarium filtration and purification. The aquarium water is drawn up out of the tank and then cascaded over a freely spinning corrugated fiber-mesh wheel before passing through a media filter and back into the aquarium. The spinning mesh wheel develops a biofilm coating of microorganisms that feed on the suspended wastes in the aquarium water and are also exposed to the atmosphere as the wheel rotates. This is especially good at removing waste urea and ammonia urinated into the aquarium water by the fish and other animals.

Membrane bioreactors

Membrane bioreactors (MBR) combine activated sludge treatment with a membrane liquid-solid separation process. The membrane component uses low pressure microfiltration or ultra filtration membranes and eliminates the need for clarification and tertiary filtration. The membranes are typically immersed in the aeration tank; however, some applications utilize a separate membrane tank. One of the key benefits of an MBR system is that it effectively overcomes the limitations associated with poor settling of sludge in conventional activated sludge (CAS) processes. The technology permits bioreactor operation with considerably higher mixed liquor suspended solids (MLSS) concentration than CAS systems, which are limited by sludge settling. The process is typically operated at MLSS in the range of 8,000–12,000 mg/L, while CAS are operated in the range of 2,000–3,000 mg/L. The elevated biomass concentration in the MBR process allows for very effective removal of both soluble and particulate biodegradable materials at higher loading rates. Thus increased Sludge Retention Times (SRTs) — usually exceeding 15 days — ensure complete nitrification even in extremely cold weather.

The cost of building and operating an MBR is usually higher than conventional wastewater treatment. Membrane filters can be blinded with grease or abraded by suspended grit and lack a clarifier's flexibility to pass peak flows. The technology has become increasingly popular for reliably pretreated waste streams and has gained wider acceptance where infiltration and inflow have been controlled, however, and the life-cycle costs have been steadily decreasing. The small footprint of MBR systems, and the high quality effluent produced, make them particularly useful for water reuse applications.[11]

Secondary sedimentation

The final step in the secondary treatment stage is to settle out the biological floc or filter material and to produce sewage water containing low levels of organic material and suspended matter.

Tertiary treatment

The purpose of tertiary treatment is to provide a final treatment stage to raise the effluent quality before it is discharged to the receiving environment (sea, river, lake, ground, etc.). More than one tertiary treatment process may be used at any treatment plant. If disinfection is practiced, it is always the final process. It is also called "effluent polishing".

Filtration

Sand filtration removes much of the residual suspended matter.[5]: 22–23 Filtration over activated carbon, also called carbon adsorption, removes residual toxins.[5]: 19

Lagooning

Lagooning provides settlement and further biological improvement through storage in large man-made ponds or lagoons. These lagoons are highly aerobic and colonization by native macrophytes, especially reeds, is often encouraged. Small filter feeding invertebrates such as Daphnia and species of Rotifera greatly assist in treatment by removing fine particulates.

Constructed wetlands

Constructed wetlands include engineered reedbeds and a range of similar methodologies, all of which provide a high degree of aerobic biological improvement and can often be used instead of secondary treatment for small communities, also see phytoremediation. One example is a small reedbed used to clean the drainage from the elephants' enclosure at Chester Zoo in England.

Nutrient removal

Wastewater may contain high levels of the nutrients nitrogen and phosphorus. Excessive release to the environment can lead to a build up of nutrients, called eutrophication, which can in turn encourage the overgrowth of weeds, algae, and cyanobacteria (blue-green algae). This may cause an algal bloom, a rapid growth in the population of algae. The algae numbers are unsustainable and eventually most of them die. The decomposition of the algae by bacteria uses up so much of oxygen in the water that most or all of the animals die, which creates more organic matter for the bacteria to decompose. In addition to causing deoxygenation, some algal species produce toxins that contaminate drinking water supplies. Different treatment processes are required to remove nitrogen and phosphorus.

Nitrogen removal

The removal of nitrogen is effected through the biological oxidation of nitrogen from ammonia (nitrification) to nitrate, followed by denitrification, the reduction of nitrate to nitrogen gas. Nitrogen gas is released to the atmosphere and thus removed from the water.

Nitrification itself is a two-step aerobic process, each step facilitated by a different type of bacteria. The oxidation of ammonia (NH3) to nitrite (NO2−) is most often facilitated by Nitrosomonas spp. (nitroso referring to the formation of a nitroso functional group). Nitrite oxidation to nitrate (NO3−), though traditionally believed to be facilitated by Nitrobacter spp. (nitro referring the formation of a nitro functional group), is now known to be facilitated in the environment almost exclusively by Nitrospira spp.

Denitrification requires anoxic conditions to encourage the appropriate biological communities to form. It is facilitated by a wide diversity of bacteria. Sand filters, lagooning and reed beds can all be used to reduce nitrogen, but the activated sludge process (if designed well) can do the job the most easily.[5]: 17–18 Since denitrification is the reduction of nitrate to dinitrogen gas, an electron donor is needed. This can be, depending on the wastewater, organic matter (from faeces), sulfide, or an added donor like methanol.

Sometimes the conversion of toxic ammonia to nitrate alone is referred to as tertiary treatment.

Many sewage treatment plants use axial flow pumps to transfer the nitrified mixed liquor from the aeration zone to the anoxic zone for denitrification. These pumps are often referred to as Internal Mixed Liquor Recycle pumps (IMLR pumps).

Phosphorus removal

Phosphorus removal is important as it is a limiting nutrient for algae growth in many fresh water systems (for negative effects of algae see Nutrient removal). It is also particularly important for water reuse systems where high phosphorus concentrations may lead to fouling of downstream equipment such as reverse osmosis.

Phosphorus can be removed biologically in a process called enhanced biological phosphorus removal. In this process, specific bacteria, called polyphosphate accumulating organisms (PAOs), are selectively enriched and accumulate large quantities of phosphorus within their cells (up to 20% of their mass). When the biomass enriched in these bacteria is separated from the treated water, these biosolids have a high fertilizer value.

Phosphorus removal can also be achieved by chemical precipitation, usually with salts of iron (e.g. ferric chloride), aluminum (e.g. alum), or lime.[5]: 18 This may lead to excessive sludge productions as hydroxides precipitates and the added chemicals can be expensive. Chemical phosphorus removal requires significantly smaller equipment footprint than biological removal, is easier to operate and is often more reliable than biological phosphorus removal {{citation}}: Empty citation (help). Another method for phosphorus removal is to use granular laterite.

Once removed, phosphorus, in the form of a phosphate rich sludge, may be stored in a land fill or resold for use in fertilizer.

Disinfection

The purpose of disinfection in the treatment of wastewater is to substantially reduce the number of microorganisms in the water to be discharged back into the environment. The effectiveness of disinfection depends on the quality of the water being treated (e.g., cloudiness, pH, etc.), the type of disinfection being used, the disinfectant dosage (concentration and time), and other environmental variables. Cloudy water will be treated less successfully since solid matter can shield organisms, especially from ultraviolet light or if contact times are low. Generally, short contact times, low doses and high flows all militate against effective disinfection. Common methods of disinfection include ozone, chlorine, ultraviolet light, or sodium hypochlorite.[5]: 16 Chloramine, which is used for drinking water, is not used in wastewater treatment because of its persistence.

Chlorination remains the most common form of wastewater disinfection in North America due to its low cost and long-term history of effectiveness. One disadvantage is that chlorination of residual organic material can generate chlorinated-organic compounds that may be carcinogenic or harmful to the environment. Residual chlorine or chloramines may also be capable of chlorinating organic material in the natural aquatic environment. Further, because residual chlorine is toxic to aquatic species, the treated effluent must also be chemically dechlorinated, adding to the complexity and cost of treatment.

Ultraviolet (UV) light can be used instead of chlorine, iodine, or other chemicals. Because no chemicals are used, the treated water has no adverse effect on organisms that later consume it, as may be the case with other methods. UV radiation causes damage to the genetic structure of bacteria, viruses, and other pathogens, making them incapable of reproduction. The key disadvantages of UV disinfection are the need for frequent lamp maintenance and replacement and the need for a highly treated effluent to ensure that the target microorganisms are not shielded from the UV radiation (i.e., any solids present in the treated effluent may protect microorganisms from the UV light). In the United Kingdom, UV light is becoming the most common means of disinfection because of the concerns about the impacts of chlorine in chlorinating residual organics in the wastewater and in chlorinating organics in the receiving water. Some sewage treatment systems in Canada and the US also use UV light for their effluent water disinfection.[12] [13]

Ozone (Template:Oxygen3) is generated by passing oxygen (Template:Oxygen2) through a high voltage potential resulting in a third oxygen atom becoming attached and forming Template:Oxygen3. Ozone is very unstable and reactive and oxidizes most organic material it comes in contact with, thereby destroying many pathogenic microorganisms. Ozone is considered to be safer than chlorine because, unlike chlorine which has to be stored on site (highly poisonous in the event of an accidental release), ozone is generated onsite as needed. Ozonation also produces fewer disinfection by-products than chlorination. A disadvantage of ozone disinfection is the high cost of the ozone generation equipment and the requirements for special operators.

Odour Control

Odours emitted by sewage treatment are typically an indication of an anaerobic or "septic" condition.[14] Early stages of processing will tend to produce smelly gases, with hydrogen sulfide being most common in generating complaints. Large process plants in urban areas will often treat the odours with carbon reactors, a contact media with bio-slimes, small doses of chlorine, or circulating fluids to biologically capture and metabolize the obnoxious gases.[15] Other methods of odour control exist, including addition of iron salts, hydrogen peroxide, calcium nitrate, etc. to manage hydrogen sulfide levels.

Package plants and batch reactors

To use less space, treat difficult waste and intermittent flows, a number of designs of hybrid treatment plants have been produced. Such plants often combine at least two stages of the three main treatment stages into one combined stage. In the UK, where a large number of wastewater treatment plants serve small populations, package plants are a viable alternative to building a large structure for each process stage. In the US, package plants are typically used in rural areas, highway rest stops and trailer parks.[16]

One type of system that combines secondary treatment and settlement is the sequencing batch reactor (SBR). Typically, activated sludge is mixed with raw incoming sewage, and then mixed and aerated. The settled sludge is run off and re-aerated before a proportion is returned to the headworks.[17] SBR plants are now being deployed in many parts of the world.

The disadvantage of the SBR process is that it requires a precise control of timing, mixing and aeration. This precision is typically achieved with computer controls linked to sensors. Such a complex, fragile system is unsuited to places where controls may be unreliable, poorly maintained, or where the power supply may be intermittent.

Package plants may be referred to as high charged or low charged. This refers to the way the biological load is processed. In high charged systems, the biological stage is presented with a high organic load and the combined floc and organic material is then oxygenated for a few hours before being charged again with a new load. In the low charged system the biological stage contains a low organic load and is combined with flocculate for longer times.

Sludge treatment and disposal

The sludges accumulated in a wastewater treatment process must be treated and disposed of in a safe and effective manner. The purpose of digestion is to reduce the amount of organic matter and the number of disease-causing microorganisms present in the solids. The most common treatment options include anaerobic digestion, aerobic digestion, and composting. Incineration is also used albeit to a much lesser degree.[5]: 19–21

Sludge treatment depends on the amount of solids generated and other site-specific conditions. Composting is most often applied to small-scale plants with aerobic digestion for mid sized operations, and anaerobic digestion for the larger-scale operations.

Anaerobic digestion

Anaerobic digestion is a bacterial process that is carried out in the absence of oxygen. The process can either be thermophilic digestion, in which sludge is fermented in tanks at a temperature of 55°C, or mesophilic, at a temperature of around 36°C. Though allowing shorter retention time (and thus smaller tanks), thermophilic digestion is more expensive in terms of energy consumption for heating the sludge.

Anaerobic Digestion is the most common (mesophilic) treatment of domestic sewage in septic tanks, which normally retain the sewage, from one day to two days, reducing the B.O.D. by about 35 to 40%. This reduction can be increased with a combination of anaerobic and aerobic treatment by installing 'Aerobic Treatment Units' (ATUs) in the Septic Tank.

One major feature of anaerobic digestion is the production of biogas (with the most useful component being methane), which can be used in generators for electricity production and/or in boilers for heating purposes.

Aerobic digestion

Aerobic digestion is a bacterial process occurring in the presence of oxygen. Under aerobic conditions, bacteria rapidly consume organic matter and convert it into carbon dioxide. The operating costs used to be characteristically much greater for aerobic digestion because of the energy used by the blowers, pumps and motors needed to add oxygen to the process.*/

Aerobic digestion can also be achieved by using diffuser systems or jet aerators to oxidize the sludge.

Composting

Composting is also an aerobic process that involves mixing the sludge with sources of carbon such as sawdust, straw or wood chips. In the presence of oxygen, bacteria digest both the wastewater solids and the added carbon source and, in doing so, produce a large amount of heat.[5]: 20

Incineration

Incineration of sludge is less common because of air emissions concerns and the supplemental fuel (typically natural gas or fuel oil) required to burn the low calorific value sludge and vaporize residual water. Stepped multiple hearth incinerators with high residence time and fluidized bed incinerators are the most common systems used to combust wastewater sludge. Co-firing in municipal waste-to-energy plants is occasionally done, this option being less expensive assuming the facilities already exist for solid waste and there is no need for auxiliary fuel.[5]: 20–21

Sludge disposal

When a liquid sludge is produced, further treatment may be required to make it suitable for final disposal. Typically, sludges are thickened (dewatered) to reduce the volumes transported off-site for disposal. There is no process which completely eliminates the need to dispose of biosolids. There is, however, an additional step some cities are taking to superheat sludge and convert it into small pelletized granules that are high in nitrogen and other organic materials. In New York City, for example, several sewage treatment plants have dewatering facilities that use large centrifuges along with the addition of chemicals such as polymer to further remove liquid from the sludge. The removed fluid, called centrate, is typically reintroduced into the wastewater process. The product which is left is called "cake" and that is picked up by companies which turn it into fertilizer pellets. This product is then sold to local farmers and turf farms as a soil amendment or fertilizer, reducing the amount of space required to dispose of sludge in landfills

Treatment in the receiving environment

Many processes in a wastewater treatment plant are designed to mimic the natural treatment processes that occur in the environment, whether that environment is a natural water body or the ground. If not overloaded, bacteria in the environment will consume organic contaminants, although this will reduce the levels of oxygen in the water and may significantly change the overall ecology of the receiving water. Native bacterial populations feed on the organic contaminants, and the numbers of disease-causing microorganisms are reduced by natural environmental conditions such as predation or exposure to ultraviolet radiation. Consequently, in cases where the receiving environment provides a high level of dilution, a high degree of wastewater treatment may not be required. However, recent evidence has demonstrated that very low levels of specific contaminants in wastewater, including hormones (from animal husbandry and residue from human hormonal contraception methods) and synthetic materials such as phthalates that mimic hormones in their action, can have an unpredictable adverse impact on the natural biota and potentially on humans if the water is re-used for drinking water.[18] In the US and EU, uncontrolled discharges of wastewater to the environment are not permitted under law, and strict water quality requirements are to be met. (For requirements in the US, see Clean Water Act.) A significant threat in the coming decades will be the increasing uncontrolled discharges of wastewater within rapidly developing countries.

Sewage treatment in developing countries

Few reliable figures on the share of the wastewater collected in sewers that is being treated in the world exist. In many developing countries the bulk of domestic and industrial wastewater is discharged without any treatment or after primary treatment only. In Latin America about 15% of collected wastewater passes through treatment plants (with varying levels of actual treatment). In Venezuela, a below average country in South America with respect to wastewater treatment, 97 percent of the country’s sewage is discharged raw into the environment.[19] In a relatively developed Middle Eastern country such as Iran, Tehran's majority of population has totally untreated sewage injected to the city’s groundwater.[20]

In Israel, about 50 percent of agricultural water usage (total use was 1 billion cubic metres in 2008) is provided through reclaimed sewer water. Future plans call for increased use of treated sewer water as well as more desalination plants.[21]

Most of sub-Saharan Africa is without wastewater treatment.

See also

References

- ^ Khopkar, S. M. (2004). Environmental Pollution Monitoring And Control. New Delhi: New Age International. p. 299. ISBN 8122415075. Retrieved 2009-06-28.

{{cite book}}: Cite has empty unknown parameter:|coauthors=(help) - ^ Burrian, Steven J., et al. (1999)."The Historical Development of Wet-Weather Flow Management." US Environmental Protection Agency (EPA). National Risk Management Research Laboratory, Cincinnati, OH. Document No. EPA/600/JA-99/275.

- ^ Stormwater Effects Handbook: A Toolbox for Watershed Managers, Scientists, and Engineers. New York: CRC/Lewis Publishers. 2001. ISBN 0-87371-924-7.

{{cite book}}: Unknown parameter|authors=ignored (help) Chapter 2. - ^ Water and Environmental Health at London and Loughborough (1999). "Wastewater Treatment Options." Technical brief no. 64. London School of Hygiene & Tropical Medicine and Loughborough University.

- ^ a b c d e f g h i j k l m n EPA. Washington, DC (2004). "Primer for Municipal Wastewater Treatment Systems." Document no. EPA 832-R-04-001.

- ^ Maine Department of Environmental Protection. Augusta, ME. "Aerated Lagoons - Wastewater Treatment." Maine Lagoon Systems Task Force. Accessed 2010-07-11.

- ^ a b c d Beychok, M.R. (1971). "Performance of surface-aerated basins". Chemical Engineering Progress Symposium Series. 67 (107): 322–339.

{{cite journal}}: Cite has empty unknown parameter:|month=(help) Available at CSA Illumina website - ^ Kadam, A.; Ozaa, G.; Nemadea, P.; Duttaa, S.; Shankar, H. (2008). "Municipal wastewater treatment using novel constructed soil filter system". Chemosphere. 71 (5). Elsevier: 975–981. doi:10.1016/j.chemosphere.2007.11.048.

- ^ Nemade, P.D.; Kadam, A.M.; Shankar, H.S. (2009). "Wastewater renovation using constructed soil filter (CSF): A novel approach". Journal of Hazardous Materials. 170 (2–3). Elsevier: 657–665. doi:10.1016/j.jhazmat.2009.05.015.

- ^ A documentary video detailing a 3 MLD SBT plant deployed at the Brihanmumbai Municipal Corporation for Mumbai city can be seen at "SBT at BMC Mumbai."

- ^ EPA. Washington, DC (2007). "Membrane Bioreactors." Wastewater Management Fact Sheet.

- ^ Das, Tapas K. (2001). "Ultraviolet disinfection application to a wastewater treatment plant". Clean Technologies and Environmental Policy. 3 (2). Springer Berlin/Heidelberg: 69–80. doi:10.1007/S100980100108.

{{cite journal}}: Unknown parameter|month=ignored (help) - ^ Florida Department of Environmental Protection. Talahassee, FL. "Ultraviolet Disinfection for Domestic Wastewater." 2010-03-17.

- ^ Harshman, Vaughan; Barnette, Tony (2000). "Wastewater Odor Control: An Evaluation of Technologies". Water Engineering & Management. ISSN 0273-2238.

{{cite journal}}: Unknown parameter|month=ignored (help) - ^ Walker, James D. and Welles Products Corporation (1976)."Tower for removing odors from gases." U.S. Patent No. 4421534.

- ^ EPA. Washington, DC (2000). "Package Plants." Wastewater Technology Fact Sheet. Document no. EPA 832-F-00-016.

- ^ EPA. Washington, DC (1999). "Sequencing Batch Reactors." Wastewater Technology Fact Sheet. Document no. EPA 832-F-99-073.

- ^ Environment-agency.gov.uk[dead link]

- ^ Caribbean Environment Programme (1998). Appropriate Technology for Sewage Pollution Control in the Wider Caribbean Region (PDF). Kingston, Jamaica: United Nations Environment Programme. Retrieved 2009-10-12. Technical Report No. 40.

- ^ Massoud Tajrishy and Ahmad Abrishamchi, Integrated Approach to Water and Wastewater Management for Tehran, Iran, Water Conservation, Reuse, and Recycling: Proceedings of the Iranian-American Workshop, National Academies Press (2005)

- ^ Martin, Andrew (2008-08-10). "Farming in Israel, without a drop to spare". New York Times.

External links

- "Anaerobic Industrial Wastewater Treatment: Perspectives for Closing Water and Resource Cycles." Jules B. van Lier, Wageningen University, The Netherlands

- Arcata, California Constructed Wetland: A Cost-Effective Alternative for Wastewater Treatment

- Boston Sewage Tour - MIT Sea Grant

- Interactive Diagram of Wastewater Treatment - "Go with the Flow" - Water Environment Federation

- Phosphorus Recovery - Technische Universität Darmstadt & CEEP

- Sewer History

- The Straight Dope - What happens to all the stuff that goes down the toilet? - Syndicated column by Cecil Adams

- Tour of a Washington state sewage plant written by an employee

- National Water Engineering of Pakistan - Wastewater Treatment Plants in Pakistan