Electric vehicle

An electric vehicle (EV) is a vehicle with one or more electric motors for propulsion. This is also referred to as an electric drive vehicle. The motion may be provided either by wheels or propellers driven by rotary motors, or in the case of tracked vehicles, by linear motors.

Unlike an internal combustion engine (ICE) that is tuned to specifically operate with a particular fuel such as gasoline or diesel, an electric drive vehicle needs electricity, which comes from sources such as batteries or a generator. This flexibility allows the drive train of the vehicle to remain the same, while the fuel source can be changed.

The energy used to propel the vehicle may be obtained from several sources, some of them more ecological than others:

- on-board rechargeable electricity storage system (RESS), called Full Electric Vehicles (FEV). Power storage methods include:

- chemical energy stored on the vehicle in on-board batteries: Battery electric vehicle (BEV)

- static energy stored on the vehicle in on-board electric double-layer capacitors

- kinetic energy storage: flywheels

- direct connection to generation plants as is common among electric trains, trolley buses, and trolley trucks (See also : overhead lines, third rail and conduit current collection)

- renewable sources such as solar power: solar vehicle

- generated on-board using a diesel engine: diesel-electric locomotive

- generated on-board using a fuel cell: fuel cell vehicle

- generated on-board using nuclear energy: nuclear submarines and aircraft carriers

It is also possible to have hybrid electric vehicles that derives energy from multiple sources. Such as:

- on-board rechargeable electricity storage system (RESS) and a direct continuous connection to land-based generation plants for purposes of on-highway recharging with unrestricted highway range

- on-board rechargeable electricity storage system and a fueled propulsion power source (internal combustion engine): plug-in hybrid

Electric vehicles can include electric airplanes, electric boats, and electric motorcycles and scooters.

History

Electric motive power started with a small railway operated by a miniature electric motor, built by Thomas Davenport in 1835. In 1838, a Scotsman named Robert Davidson built an electric locomotive that attained a speed of four miles per hour (6 km/h). In England a patent was granted in 1840 for the use of rails as conductors of electric current, and similar American patents were issued to Lilley and Colten in 1847.[1]

Between 1832 and 1839 (the exact year is uncertain), Robert Anderson of Scotland invented the first crude electric carriage, powered by non-rechargeable Primary cells.[2]

By the 20th century, electric cars and rail transport were commonplace, with commercial electric automobiles having the majority of the market. Over time their general-purpose commercial use reduced to specialist roles, as platform trucks, forklift trucks, tow tractors and urban delivery vehicles, such as the iconic British milk float; for most of the 20th century, the UK was the world's largest user of electric road vehicles.[3]

Electrified trains were used for coal transport as the motors did not use precious oxygen in the mines. Switzerland's lack of natural fossil resources forced the rapid electrification of their rail network. One of the earliest rechargeable batteries - the Nickel-iron battery - was favored by Edison for use in electric cars.

Electric vehicles were among the earliest automobiles, and before the preeminence of light, powerful internal combustion engines, electric automobiles held many vehicle land speed and distance records in the early 1900s. They were produced by Baker Electric, Columbia Electric, Detroit Electric, and others and at one point in history out-sold gasoline-powered vehicles.

In the 1930s, National City Lines, which was a partnership of General Motors, Firestone, and Standard Oil of California purchased many electric tram networks across the country to dismantle them and replace them with GM buses. The partnership was convicted of conspiring to monopolize the sale of equipment and supplies to their subsidiary companies conspiracy, but were acquitted of conspiring to monopolize the provision of transportation services. Electric tram line technologies could be used to recharge BEVs and PHEVs on the highway while the user drives, providing virtually unrestricted driving range. The technology is old and well established (see : Conduit current collection, Nickel-iron battery). The infrastructure has not been built.

In January 1990, General Motors' President introduced its EV concept two-seater, the "Impact," at the Los Angeles Auto Show. That September, the California Air Resources Board mandated major-automaker sales of EVs, in phases starting in 1998. From 1996 to 1998 GM produced 1117 EV1s, 800 of which were made available through three-year leases.

Chrysler, Ford, GM, Honda, Nissan and Toyota also produced limited numbers of EVs for California drivers. In 2003, upon the expiration of EV1 leases, GM crushed them. The crushing has variously been attributed to 1) the auto industry's successful federal court challenge to California's zero-emissions vehicle mandate, 2) a federal regulation requiring GM to produce and maintain spare parts for the few thousands EV1s and 3) the success of the Oil and Auto industries' media campaign to reduce public acceptance of electric vehicles.

A movie made on the subject in 2005-2006 was titled Who Killed the Electric Car? and released theatrically by Sony Pictures Classics in 2006. The film explores the roles of automobile manufacturers, oil industry, the U.S. government, batteries, hydrogen vehicles, and consumers, and each of their roles in limiting the deployment and adoption of this technology.

Honda, Nissan and Toyota also repossessed and crushed most of their EVs, which, like the GM EV1s, had been available only by closed-end lease. After public protests, Toyota sold 200 of its RAV EVs to eager buyers; they now sell, five years later, at over their original forty-thousand-dollar price.

The production of the Citroën Berlingo Electrique stopped in September 2005.

Nowadays, electric vehicles are hitting the mainstream [4].

All major carmakers, such as Daimler AG, Toyota Motor Corp., General Motors Corp., Renault SA, Peugeot-Citroen, VW and Mitsubishi Corp., are developing new-generation electric vehicles. [5]

Energy sources

(See articles on diesel-electric and gasoline-electric hybrid locomotion for information on electric vehicles using internal-combustion energy sources).

Batteries, electric double-layer capacitors and flywheel energy storage are forms of rechargeable on-board electrical storage. By avoiding an intermediate mechanical step, the energy conversion efficiency can be improved over the hybrids already discussed, by avoiding unnecessary energy conversions. Furthermore, electro-chemical batteries conversions are easy to reverse, allowing electrical energy to be stored in chemical form.

Another form of chemical to electrical conversion is fuel cells, projected for future use.

For especially large electric vehicles, such as submarines, the chemical energy of the diesel-electric can be replaced by a nuclear reactor. The nuclear reactor usually provides heat, which drives a steam turbine, which drives a generator, which is then fed to the propulsion. See Nuclear Power

Electric motor

The power of a vehicle electric motor, as in other vehicles, is measured in kilowatts (kW). 100 kW is roughly equivalent to 134 horsepower, although most electric motors deliver full torque over a wide RPM range, so the performance is not equivalent, and far exceeds a 134 horsepower (100 kW) fuel-powered motor, which has a limited torque curve.[citation needed]

Usually, direct current (DC) electricity is fed into a DC/AC inverter where it is converted to alternating current (AC) electricity and this AC electricity is connected to a 3-phase AC motor. For electric trains, DC motors are often used.

Vehicle types

Electric car

Large-scale electric transport: energy and motors

Most large electric transport systems are powered by stationary sources of electricity that are directly connected to the vehicles through wires. Due to the extra infrastructure and difficulty in handling arbitrary travel, most directly connected vehicles are owned publicly or by large companies. These forms of transportation are covered in more detail in electric buses, trams, metros and trolleybuses and electric locomotives.

In the systems above motion is provided by a rotary electric motor. However, it is possible to "unroll" the motor to drive directly against a special matched track. These linear motors are used in maglev trains which float above the rails supported by magnetic levitation. This allows for almost no rolling resistance of the vehicle and no mechanical wear and tear of the train or track. Levitation and forward motion are two independent effects; the forward motive force normally requires external power, although some types, such as Inductrack, achieve levitation at low speeds without any. In addition to the high-performance control systems needed, switching and curving of the tracks becomes difficult with linear motors, which to date has restricted their operations to high-speed point to point services.

Small scale electric vehicles

Some bicycles have been converted to electric power with a small battery and a small electric motor, some even have solar panels that are folded out when the vehicle is at rest. Small scale electric vehicles include electric cars, light trucks, neighborhood electric vehicles, motorcycles, motorized bicycles, electric scooters , golf carts, milk floats, forklifts and similar vehicles.

Issues regarding electric vehicles

Renewable electricity

Although electric vehicles have few direct emissions, all rely on energy created through electricity generation, emit pollution and generate waste, unless it is generated by renewable source power plants. Since electric vehicles use whatever electricity is delivered by their electrical utility/grid operator, electric vehicles can be made more efficient or less polluting by modify the electrical generating stations. This would be done by an electrical utility under a government energy policy, in a timescale negotiated between utilities and government.

Fossil fuel vehicle efficiency and pollution standards take years to filter through a nation's fleet of vehicles. New efficiency and pollution standards rely on the purchase of new vehicles, often as a the current vehicles already on the road reach their end-of-life. Only a few nations set a retirement age for old vehicles, such as Japan or Singapore, forcing periodic upgrading of all vehicles already on the road.

Electric vehicles will take advantage of whatever environmental gains happen when a renewable energy generation station comes online, a fossil fuel station is decommissioned or upgraded. Conversely, if government policy or economic conditions shifts generators back to use more polluting fossil fuels and internal combustion engine vehicles (ICEVs), or more inefficient sources, the reverse can happen. Even in such a situation, electrical vehicles are still more efficient than a comparable amount of fossil fuel vehicles. In areas with a deregulated electrical energy market, an electrical vehicle owner can choose whether to run his electrical vehicle off conventional electrical energy sources, or strictly from renewable electrical energy sources (presumably at an additional cost), and switch at any time between the two.

Efficiency

Because of the different methods of charging possible, the emissions produced have been quantified in different ways. Plug-in EV and hybrids also have different consumption charateristics.[6]

Electromagnetic radiation from high performance electrical motors has been claimed to be associated with some human ailments, but such claims are largely unsubstantiated except for extremely high exposures.[7] Electric motors can be shielded within a metallic Faraday's cage, but this reduces efficiency by adding weight to the vehicle, while it is not conclusive that all electromagnetic radiation can be contained.

Capacity

If a large proportion of private vehicles were to convert to grid electricity it would increase the demand for generation and transmission, and consequent emissions. However, overall energy consumption and emissions would diminish because of the higher efficiency of electric vehicles over the entire cycle. In the USA it has been estimated there is already nearly sufficient existing power plant and transmission infrastructure, assuming that most charging would occur overnight, using the most efficient off-peak base load sources.[8]

Issues with batteries

On an energy basis, the price of electricity to run an EV is a small fraction of the cost of liquid fuel needed to produce an equivalent amount of energy. Issues related to batteries, however, can add to the operating costs.

Traditionally, most EVs have used lead-acid batteries due to their mature technology, high availability, and low cost (exception: some early EVs, such as the Detroit Electric, used nickel-iron.) Like all batteries, these have an environmental impact through their construction, use, disposal or recycling. On the upside, vehicle battery recycling rates top 95% in the United States. Deep-cycle lead batteries are expensive and have a shorter life than the vehicle itself, typically needing replacement every 3 years.

Lead-acid batteries in EV applications end up being a significant (25%-50%) portion of the final vehicle mass. Like all batteries, they have significantly lower energy density than petroleum fuels -- in this case, 30-40Wh/kg. While the difference isn't as extreme as it first appears due to the lighter drive-train in an EV, even the best batteries tend to lead to higher masses when applied to vehicles with a normal range. The efficiency and storage capacity of the current generation of common deep cycle lead acid batteries decreases with lower temperatures, and diverting power to run a heating coil reduces efficiency and range by up to 40%[citation needed]. Recent advances in battery efficiency, capacity, materials, safety, toxicity and durability are likely to allow these superior characteristics to be applied in car-sized EVs.

Charging and operation of batteries typically results in the emission of hydrogen, oxygen and sulfur, which are naturally occurring and normally harmless if properly vented. Early Citicar owners discovered that, if not vented properly, unpleasant sulfur smells would leak into the cabin immediately after charging.

Lead-acid batteries have been re-engineered by Firefly Energy, increasing longevity, slightly increasing energy density, and significantly increasing power density. Firefly is expected market lightweight vehicle batteries, either directly or through manufacturing partners in 2008.

Lead-acid batteries powered such early-modern EVs as the original versions of the EV1 and the RAV4EV.

Nickel-metal hydride batteries are now considered a relatively mature technology. While less efficient in charging and discharging than even lead-acid, they boast an energy density of 30-80Wh/kg, far higher than lead-acid. When used properly, nickel-metal hydride batteries can have exceptionally long lives, as has been demonstrated in their use in hybrid cars and surviving NiMH RAV4EVs that still operate well after 100,000 miles (160,000 km) and over a decade of service. Downsides include the poor efficiency, high self-discharge, very finicky charge cycles, and poor performance in cold weather. GM Ovonic produced the NiMH battery used in the second generation EV-1, and Cobasys makes a nearly identical battery (ten 1.2V 85Ah NiMH cells in series in contrast with eleven cells for Ovonic battery). This worked very well in the Saturn EV-1. It remains a viable and practical solution today, as far as a superior alternative to the lead acid battery. However, for non-technical reasons neither company will provide their NiMH battery for automotive applications - a policy strictly enforced. Moreover, GM now owns patent(s) on some proprietary technology and processes used to manufacture this type of battery. Therefore no other company can produce a similar battery (with capacities large enough for electric vehicle propulsion) without infringing GM's patents. So, despite its technical success, unless GM will change their position on the issue NiMH traction battery technology, it is considered a dead end. In light of the latest developments in lithium based battery technology and patent issues of NiMH, lithium will most likely represent the future EV battery type.

The sodium or "zebra" battery uses a molten chloroaluminate (NaAlCl4) sodium as the electrolyte. This chemistry is also occasionally referred to as "hot salt". A relatively mature technology, the Zebra battery boasts an energy density of 120Wh/kg and reasonable series resistance. Since the battery must be heated for use, cold weather doesn't strongly affect its operation except for in increasing heating costs. They have been used in several EVs. Zebras can last for a few thousand charge cycles and are nontoxic. The downsides to the Zebra battery include poor power density (<300 W/kg) and the requirement of having to heat the electrolyte to ~270*C, which wastes some energy and presents difficulties in long-term storage of charge.

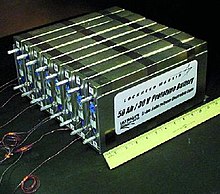

Lithium-ion (and similar lithium polymer) batteries, widely known through their use in laptops and consumer electronics, dominate the most recent group of EVs in development. The traditional lithium-ion chemistry involves a lithium cobalt oxide cathode and a graphite anode. This yields cells with an impressive 160Wh/kg energy density and good power density, and near lossless charge/discharge cycles. The downsides of traditional lithium-ion batteries include short cycle lifes (hundreds to a few thousand charge cycles) and significant degradation with age. The cathode is also somewhat toxic. Also, traditional lithium-ion batteries can pose a fire safety risk if punctured or charged improperly. The maturity of this technology is moderate. The Tesla Roadster uses "blades" of traditional lithium-ion "laptop battery" cells that can be replaced individually as needed.

Most other EVs are utilizing new variations on lithium-ion chemistry that sacrifice energy density (often resulting in batteries with 100Wh/kg or less) to provide extreme power density, fire resistance, environmental friendliness, very rapid charges (as low as a few minutes), and very long lifespans. These variants (phosphates, titanates, spinels, etc) have been shown to have a much longer lifetime, with A123 expecting their lithium iron phosphate batteries to last for at least 10+ years and 7000+ charge cycles[9], and LG Chem expecting their lithium-manganese spinel batteries to last up to 40 years.[10]

Much work is being done on lithium ion batteries in the lab[11]. Lithium vanadium oxide has already made its way into the Subaru prototype G4e, doubling energy density. Silicon nanowires[12][13][14], silicon nanoparticles[15], and tin nanoparticles[16][17] promise several times the energy density in the anode, while composite[18][19][20][21][22] and superlattice[23] cathodes also promise significant density improvements.

Charging stations and battery swapping

Assuming a 50 kilowatt-hour battery pack and ideal charging efficiency, a ten minute quick charge from 10% to 80% capacity would require a power draw of 210 kilowatts from the electric grid. At 240 Volts, this means a current draw of 875 Amperes from the outlet. Such high currents are generally impractical because they require very heavy conductors. One way to avoid this problem is to use high voltage up to thousands of volts, which is then transformed down to the battery voltage levels inside the car. This method puts additional stress on the electrical insulation around the parts the users have to handle, and thus raises questions about the safety of the charging system. Inductive transfer of power into the vehicle is proposed as a solution to solve the safety problems, but at the current state of the technology, significant efficiency losses are to be expected.

In practice, the energy efficiency of quick charging is likely to be somewhat lowered in any case due to the ohmic losses caused by the required high current inside the vehicle. The lost energy is converted directly to heat, which causes wear to the battery pack and other electronics involved. Increasing the capacity of the battery pack increases the required power, current and heat loss linearly, which is why quick charging may become impractical or impossible as vehicles with increased range are developed.

The high peak power requirement of quick charging also puts additional stress to the local power grid and may put it to a risk of failure during periods of peak demand. The most obvious solution is to use another battery to act as a buffer between the charging station and the power grid. The battery as a buffer however, suffers a similar efficiency drop as the car itself, thus lowering the overall efficiency of the system. Another possibility is on-site, on-demand electricity generation.

Battery replacement is also proposed as an alternative. While it suffers from some problems (weight, standardization, etc), Project Better Place has already raised several hundred million dollars to build several electric vehicle networks of charging and battery replacement stations. One type of battery "replacement" proposed is much simpler: while the latest generation of vanadium redox battery only has an energy density similar to lead-acid, the charge is stored solely in a vanadium-based electrolyte, which can be pumped out and replaced with charged fluid.

The vanadium battery system is also a potential candidate for intermediate energy storage in quick charging stations because of its high power density and extremely good endurance in daily use. System cost however, is still prohibitive. As vanadium battery systems are estimated to range between $350-$600 per kWh, a battery that can service one hundred customers in a 24 hour period at 50 kWh per charge would cost $1.8-$3 million.

Other in-development technologies

Conventional electric double-layer capacitors are being worked to achieve the energy density of lithium ion batteries, offering almost unlimited lifespans and no environmental issues. High-K electric double-layer capacitors, such as EEStor's EESU, promise to best lithium ion energy density several times over if they can be produced. Lithium-sulphur batteries offer 250Wh/kg[24]. Sodium-ion batteries promise 400Wh/kg with only minimal expansion/contraction during charge/discharge and a very high surface area[25].

Mechanically rechargeable batteries

There is another way to "refuel" electrical vehicles. Instead of recharging them from electric socket, batteries could be mechanically replaced on special stations just in a couple of minutes.

The general rule here is the more energy density does have a battery the more difficult to recharge it electrically.

There is Vanadium and Titanium diboride batteries which have great energy density [26], but can't be recharged electrically. Instead, thermal methods of recharging could be used. If coal, nuclear or geothermal energy used as a source, overall efficiency could be much better than in electrically rechargeable batteries, but can be environmental externalities. Although renewable energy sources also could be used to recharge such type of batteries with high efficiency.

Disadvantages of electric vehicles

Many electric designs have limited range, due to the low energy density of batteries compared to the fuel of internal combustion engined vehicles. Batteries have long recharge times compared to the relatively fast process of refueling a tank.

Most electricity generation in the United States is from fossil sources, according to the U.S. Department of Energy.[27]

The national electricity grid is having trouble meeting current levels of demand, according to DOE, and is experiencing transmission congestion.[27] A large number of electric cars would put significant strain on the grid if charged during peak use times, requiring additional investment in utility infrastructure. However, advocates have pointed out that the batteries of electric cars could be used to solve transmission problems if they are charged at off-peak times, by returning power to the grid at peak times. But this would reduce the daytime range of a parked electric car.

This article possibly contains original research. (January 2009) |

Overall average efficiency from U.S. power plants (33% efficient)[27] to point of use (transmission loss 9.5%), (U.S. Department of Energy figures) is 29.87%. Accepting 90% efficiency for the electric vehicle gives us a figure of only 26.88% overall efficiency. That is lower than internal combustion engined vehicles (Petrol/Gasoline 30% efficient, Diesel engines 45% efficient in theory - Volvo figures).[28] Diesel engines can also easily run on renewable fuels, biodiesel, vegetable oil fuel (preferably from waste sources), with no loss of efficiency. Using grid electricity entirely negates the efficiency advantages of electric vehicles.

This comparison does not take into account fuel used to transport liquid fuels to the filling station which requires a significant portion of fuel. Neither does it take into account the lower practical efficiency of the internal combustion engine. Due to transmission and idling losses. It compares tank-to-flywheel efficiency of gasoline and diesel powered engines to the well-to-wheel efficiency of electric motors.

To achieve a sound conclusion, one would also have to take into account the refining and delivery losses of gasoline and diesel, and the energy efficiency of biofuel production. (Output fuel energy divided by the sum of the invested energy and energy in the biomass). The equivalent for fossil electricity production would also need to be considered (mining and transportation of coal to the power station for example, or the carbon dioxide produced building renewable electricity generation).

Heating of electric vehicles

In cold climates considerable energy is needed to heat the interior of the vehicle, and to defrost the windows. With IC engines this heat can come for free from the waste heat from the engine cooling circuit. If this is done with battery power cars, this will require extra energy from the battery, although some could be harvested from the motor and battery itself. There would not be as much heat available as from an engine.

Advantages of electric vehicles

Electric motors are mechanically very simple, and release almost no air pollutants at the place where they are operated.

Electric motors often achieve 90% energy conversion efficiency[29]over the full range of speeds and power output and can be precisely controlled. They can also be combined with regenerative braking systems that have the ability to convert movement energy back into stored electricity. This can be used to reduce the wear on brake systems (and consequent brake pad dust) and reduce the total energy requirement of a trip, especially effective for start-and-stop city use.

They can be finely controlled and provide high torque from rest, unlike internal combustion engines, and do not need multiple gears to match power curves. This removes the need for gearboxes and torque converters.

Another advantage is that electric vehicles typically have less vibration and noise pollution than a vehicle powered by an internal combustion engine, whether it is at rest or in motion.

Electricity is a form of energy that remains within the continent where it was produced and can be multi-sourced. As a result it gives the greatest degree of energy resilience [30].

The GM Volt will cost "less than purchasing a cup of your favorite coffee" to recharge. The Volt should cost less than 2 cents per mile to drive on electricity, compared with 12 cents a mile on gasoline at a price of $3.60 a gallon. This would be the equillant to paying 70 cents a gallon of gas. [31]

Incentives and promotion

This section needs expansion. You can help by adding to it. (June 2008) |

United States

Qualifying electric vehicles purchased new are eligible for a one-time federal tax credit that equals 10% of the cost of the vehicle up to $4,000, provided under Section 179A of the Energy Policy Act of 1992; it was extended through 2007 by the Working Families Tax Relief Act of 2004. A tax deduction of up to $100,000 per location is available for qualified electric vehicle recharging property used in a trade or business.

Mayor Gavin Newsom, San Jose Mayor Chuck Reed and Oakland Mayor Ron Dellums announced a nine-step policy plan for transforming the Bay Area into the "Electric Vehicle (EV) Capital of the U.S." [32].

Other local and state governments have expressed interest as electric cars have come closer to mass production. [33]

European Union

Directive 2006/32/EC of the European Parliament and of the Council of 5 April 2006 on energy end-use efficiency and energy services includes measures to promote efficient vehicles.

AVERE has a table summarizing the taxation and incentives for these vehicles in the different European countries, related to state subsidies, reduction of VAT and other taxes, insurance facilities, parking and charging facilities (including free recharging on street or in the parking ares), EV imposed by law and banned circulation for petroleum cars, permission to use bus lanes, free road tax, toll free on highways and exempt from congestion charging free or reduced parking, free charging at charge points, between others [34]. In Denmark petrol cars is taxed 180%+25% however EV cars (max. 2000 kg total weight) is only taxed 25%, free parking in Copenhagen and other cities, free recharging at some parking spaces.

EU member states

In Portugal, the government has linked up with car-makers to further the use of electric cars by investing in setting up electric charging stations across the country and in raising awareness of the vehicle's benefits [35].

In October 2008 UK Prime Minister Gordon Brown pledged £100 million in government money to support electric, hybrid and other more environmentally friendly car projects over a five-year period to help make Britain "the European capital for electric cars" [35] [36].

Denmark is planning to introduce a greater number of battery driven electric cars on the streets - charged on renewable energy from the country's many windmills - ahead of the UN Climate Summit that is to descend on Copenhagen in December 2009. A great deal of the electricity is generated by windmills [35].

Electric vehicles are the future and the driver of the industrial revolution

— Miguel Sebastian, Spanish Industry Minister [37]

Spain's government aims to have 1 million electric cars on the roads by 2014 as part of a plan to cut energy consumption and dependence on expensive imports, Industry Minister Miguel Sebastian said [37] [35] [38].

Estimated number of electric vehicles

Carlos Ghosn, chief executive of both Nissan Motor Co. and Renault SA , unveiled the electric-car target as one of several energy priorities identified by a task force of CEOs at The Wall Street Journal CEO Council in Washington. The target is For 10% of cars being electric by 2020 and 50% by 2030 [39].

In 2003 the Energy Information Administration (EIA) estimated there would be 55,852 Full-electric vehicles (FEV) in 2004, with an annual growth rate of 39.1 % (excluding in this estimation electric hybrids).[40]

The EIA's 2007 Annual Energy Review (AER) estimates the actual number of FEV's on the road in 2004 as 49,536 and a preliminary estimated 2006 number of 53,526.[41]

Production

Electric vehicles are hitting the mainstream [4]. Automakers are going to showcase at the 2009 Washington Auto Show their commitment to quickly bringing electric hybrid and all-electric vehicles to market as early as 2010 [42].

World Production Race

All major carmakers, such as Daimler AG, Toyota Motor Corp., General Motors Corp., Renault SA, Peugeot-Citroen, WV and Mitsubishi Corp., are developing new-generation electric vehicles. [5]. Really, Automakers are in a new race to be the first to market with an all-electric car so they can claim the mantle as the world's greenest automaker [43].

South Africa

- Joule, designed by Cape Town-based Optimal Energy[44], made its debut at the 2008 Paris Motor Show, has a maximum driving range of 400 kilometres. It accommodates two large-cell lithium ion battery packs[45].

China

- BYD PHEV (2044+)

- BYD F6e (2058+)

- Nanjing Dongyu Electric Motorcycle&Electric Bicycle

- Tradwin Hongkong International(Distributor)

European Union

- Morgan LifeCar (2009+)

- Lightning GT (2009+)

- Imperia GP (2010), from 70,248€ Excl. VAT, preorders in 2009[46]

- eRUF

Portugal and Spain want to create the first green car in Iberia, hoping to generate 150 million euros worth of investment and 800 new jobs in the region's struggling motor industry. The green car, which could be powered by electricity. The Mobi-green car, as the vehicle is named, is being developed by two automotive research centres in Portugal and Spain using funds from both the public and private sectors. [47]

India

Practically the only EV to have been manufactured for several years is the Indian REVA. It is produced by REVA Electric Car Company Private Ltd. (RECC) in Bangalore, India, a company established in 1994 as a joint venture between the Maini Group India and AEV LLC, California USA. After seven years of R&D, they commercialized the first REVA car in June 2001. [48]

The current version of the REVA is the REVAi. It was first reserved for the Indian market, but it is now distributed in several European countries: UK (by GoinGreen under the name G-Wiz), Cyprus and Greece (by REVA Phaedra Electricity Mobility Ltd., Belgium (by Green Mobil), Norway (by Ole Chr. Bye AS), Spain (by Emovement)and Germany (by Elektro PKW, the REVA is also available in the Republic of Ireland GreenAer. It may be exported to the USA with a speed limiter for use as a Neighborhood Electric Vehicle (NEV).

In addition to Bangalore-based Reva, which currently is the only company actually selling EVs today, electric cars made in India includes:

- Mahindra & Mahindra: Four-seat model by 2010 [49].

- Tata: 2008-2009 (also possibly an air car) [50].

- Ajanta Group: clockmaker with plans for low-cost electric vehicle [51] [51].

- Tara: Low-cost EV less than a Tata Nano[52].

- Hero Electric: 2013 Electric car [53][54].

With Tata, Ajanta and Tara talking about 'low-cost' cars and "less than a Tata Nano".

United States

Startups are taking the lead in electric vehicles in North America [55]

- Myers Motors, a small private company, has created an electric personal Three wheeled car called NMG (No More Gas). This car can take only one passenger, and is being sold in very small numbers in the US only.

2008

2009

2010

Buying and Leasing

U.S. Army

The U.S. Army has announced that it will lease 4,000 Neighborhood Electric Vehicles (NEVs) within three years. The Army plans to use NEVs at its bases for transporting people around the base, as well as for security patrols and maintenance and delivery services. The Army accepted its first six NEVs at Virginia's Fort Myer on Monday and will lease a total of 600 NEVs this year, followed by the leasing of 1,600 NEVs for each of the following two years. With a full eight-hour recharge, the NEVs can travel Template:Mile at a top speed of Template:Mph[56] .

Future

Ferdinand Dudenhoeffer, head of the Centre of Automotive Research at the Gelsenkirchen University of Applied Sciences in Germany, said that "by 2025, all passenger cars sold in Europe will be electric or hybrid" electric [35].

Several start-up companies like Tesla Motors, Ronaele Incorporated, Commuter Cars, Phoenix Motorcars, Miles Electric Vehicles, and Aptera Motors will have powerful battery-electric vehicles available to the public in 2008. Battery and energy storage technology is advancing rapidly. The average distance driven by 80% of citizens per day in a car in the US is about 50 miles (US dept of transport, 1991), which fits easily within the current range of the electric car. This range can be improved by technologies such as Plug-in hybrid electric vehicles which are capable of using traditional fuels for unlimited range, rapid charging stations for BEVs, improved energy density batteries, flow batteries, or battery swapping.

In 2006 GM began the development of a plug-in hybrid that will use a lithium-ion battery. The vehicle, initially known as the iCar, is now called the Chevrolet Volt. The basic design was first exhibited January 2007 at the North American International Auto Show. GM is planning to have this EV ready for sale to the public in the latter half of 2010. The car is to have a 50-mile (80 km) range. If the battery capacity falls below 30 percent a small internal combustion engine will kick in to charge the battery on the go. This in effect increases the range of the vehicle, allowing it to be driven until it can be fully charged by plugging it into a standard household AC electrical source.

On October 29, 2007, Shai Agassi launched Project Better Place, a company focused on building massive scale Electric Recharge Grids as infrastructure supporting the deployment of electric vehicles (including plug-in hybrids) in countries around the world. On January 21, BPP and the Nissan-Renault group signed a MOU - PBP will provide the battery recharging and swapping infrastructure and Renault-Nissan will mass-produce the vehicles.

Improved long term energy storage and nano batteries

There have been several developments which could bring electric vehicles outside their current fields of application, as scooters, golf cars, neighborhood vehicles, in industrial operational yards and indoor operation. First, advances in lithium-based battery technology, in large part driven by the consumer electronics industry, allow full-sized, highway-capable electric vehicles to be propelled as far on a single charge as conventional cars go on a single tank of gasoline. Lithium batteries have been made safe, can be recharged in minutes instead of hours, and now last longer than the typical vehicle. The production cost of these lighter, higher-capacity lithium batteries is gradually decreasing as the technology matures and production volumes increase.

Introduction of Battery Management and Intermediate Storage

Another improvement is to decouple the electric motor from the battery through electronic control, employing ultra-capacitors to buffer large but short power demands and regenerative braking energy. The development of new cell types combined with intelligent cell management improved both weak points mentioned above. The cell management involves not only monitoring the health of the cells but also a redundant cell configuration (one more cell than needed). With sophisticated switched wiring it is possible to condition one cell while the rest are on duty.

Electric Vehicle Organizations

Worldwide

The World Electric Vehicle Association (WEVA), chairman Hisashi Ishitani, formed by:

- Electric Drive Transportation Association (EDTA)

- Electric Vehicle Association of Asia Pacific (EVAAP)

- European Association for Battery, Hybrid and Fuel Cell Electric Vehicles (AVERE) [2]

North America

- Seattle Electric Vehicle Association

- Oregon Electric Vehicle Association

- Humboldt Electric Vehicle Association

- NEDRA National Electric Drive Racing Association

- The Electric Auto Association (EAA) (North America) and its chapter Plug In America.

- Electric Car Society

Europe

- The EAA Europe, the European chapter of the Electric Auto Association and Clean Vehicle Petition

- The Campaign for Battery Electric Vehicles (UK based)

- The Battery Vehicle Society (UK)

Patents

- U.S. patent 1,017,198, E. W. Bender, Electric Motor vehicle

See also

- All-Terrain Electric Vehicle (ATEV)

- Battery electric vehicle

- Battery swapping

- Dual-mode vehicle

- Electrathon

- Electrical engineering

- Electric Vehicle (EV produced in 1899)

- Electric Vehicle Company

- Electric vehicle conversion

- Electric vehicle production

- Electrification

- Electrocar

- Green tuning

- Hybrid electric vehicle

- Hydrogen vehicle

- List of production battery electric vehicles

- Low-cost electric vehicle

- Mitigation of global warming

- Motorized bicycle

- Nanotechnology batteries.

- Neighborhood electric vehicle

- Plug-in hybrid electric vehicle

- Supplemental battery

- Tribrid vehicle

- World car of the year

- BugE

References

- ^ History of Railway Electric Traction

- ^ Inventors - Electric Cars (1890 - 1930)

- ^ Escaping Lock-in: the Case of the Electric Vehicle

- ^ a b http://seattlepi.nwsource.com/local/378351_plugins09.html

- ^ a b Start-Ups Race to Produce 'Green' Cars - WSJ.com

- ^ Knipping, E. and Duvall, M. (June 2007) "Environmental Assessment of Plug-In Hybrid Electric Vehicles Volume 2: United States Air Quality Analysis Based on AEO-2006 Assumptions for 2030" Electric Power Research Institute and Natural Resources Defense Council accessed July 21, 2007

- ^ GreenFacts summary of the IARC Evaluation of Static and Extremely Low-Frequency (ELFs) Electric and Magnetic Fields

- ^ PNNL: Newsroom - Mileage from megawatts: Study finds enough electric capacity to “fill up” plug-in vehicles across much of the nation

- ^ A123 Inks Deal to Develop Battery Cells for GM Electric Car | Xconomy

- ^ GM-VOLT : Chevy Volt Electric Car Site

- ^ Li-Ion Rechargeable Batteries Made Safer - Nikkei Electronics Asia - February 2008 - Tech-On!

- ^ Nanowire battery can hold 10 times the charge of existing lithium-ion battery

- ^ Microsoft PowerPoint - Cui-Nanowire Energy for GCEP publication

- ^ GM-VOLT : Chevy Volt Electric Car Site » Blog Archive » GM-Volt.com: Interview with Dr. Cui, Inventor of Silicon Nanowire Lithium-ion Battery Breakthrough

- ^ Nanotech promises lithium ion battery boost - vnunet.com

- ^ Using nanotechnology to improve Li-ion battery performance

- ^ http://www3.interscience.wiley.com/cgi-bin/abstract/117923780/ABSTRACT?CRETRY=1&SRETRY=0

- ^ Argonne's lithium-ion battery technology to be commercialized by Japan's Toda Kogyo

- ^ http://www.transportation.anl.gov/publications/transforum/v5n2/composite_cathodes.html

- ^ Argonne licenses new lithium-ion battery technology

- ^ Profile Li-Ion batteries.pmd

- ^ http://www.sciencedirect.com/science?_ob=ArticleURL&_udi=B6TH1-4MBCJKR-G&_user=440026&_rdoc=1&_fmt=&_orig=search&_sort=d&view=c&_acct=C000020939&_version=1&_urlVersion=0&_userid=440026&md5=dda4a2f070af31cd14c9195c10089e96

- ^ Hybrid Develops New "Superlattice Sructure" Lithium Battery Capable of Increasing Drive Ranges in Excess of 200 Miles | Hybrid Technologies

- ^ http://www.sciencedirect.com/science?_ob=ArticleURL&_udi=B6TG0-4D48WFM-1&_user=440026&_rdoc=1&_fmt=&_orig=search&_sort=d&view=c&_acct=C000020939&_version=1&_urlVersion=0&_userid=440026&md5=25be5f84a70b9345c3070b3d138c574b

- ^ A multifunctional 3.5[thinsp]V iron-based phosphate cathode for rechargeable batteries : Abstract : Nature Materials

- ^ http://www.sciencedirect.com/science?_ob=ArticleURL&_udi=B6TH1-4RFCD2C-6&_user=10&_rdoc=1&_fmt=&_orig=search&_sort=d&view=c&_acct=C000050221&_version=1&_urlVersion=0&_userid=10&md5=feeca5d822238e5d5f0c4f262302223f

- ^ a b c Overview of the Electric Grid. U.S. Department of Energy. Retrieved 2008-08-06.

- ^ Diesel engines - Products : Volvo Group - Global. Retrieved 2008-08-06.

- ^ Better Place

- ^ Our Electric Future — The American, A Magazine of Ideas

- ^ http://money.cnn.com/galleries/2008/autos/0809/gallery.gm_volt_reveal/index.html

- ^ http://www.sfgov.org/site/mayor_index.asp?id=93399

- ^ http://www.usatoday.com/tech/news/2008-11-27-electric-powered-cars_N.htm

- ^ http://www.avere.org/state_subsidies.pdf

- ^ a b c d e http://euobserver.com/882/26594

- ^ http://www.worldcarfans.com/9081028.008/prime-minister-gordon-brown-samples-thnk-city-ev-at-downing-street

- ^ a b http://blogs.edmunds.com/greencaradvisor/2008/07/spain-taking-steps-to-put-1-million-electric-vehicles-on-nations-roads-by-2014.html

- ^ http://gas2.org/2008/07/30/1-million-electric-cars-on-spains-roads-by-2014/ and http://www.triplepundit.com/pages/spain-to-put-1-million-electri-003363.php

- ^ http://www.4evriders.org/2008/11/usa-ceos-call-for-10-of-cars-being-electric-by-2020-50-by-2030/

- ^ http://www.eia.doe.gov/cneaf/alternate/page/atftables/afvs2001.xls

- ^ http://www.eia.doe.gov/emeu/aer/txt/ptb1004.html

- ^ http://www.detnews.com/apps/pbcs.dll/article?AID=/20090203/AUTO04/902030329/1148/&source=nletter-business

- ^ http://planetark.org/wen/51191

- ^ http://www.optimalenergy.co.za

- ^ http://www.southafrica.info/business/trends/newbusiness/joule-061008.htm

- ^ http://www.imperia-auto.be

- ^ Planet Ark : Portugal, Spain Sign Green Car Partnership

- ^ The website of the REVA Electric Car Company

- ^ http://www.evworld.com/news.cfm?newsid=18999

- ^ http://www.evworld.com/news.cfm?newsid=18776

- ^ a b http://www.evworld.com/news.cfm?newsid=17985

- ^ http://www.evworld.com/news.cfm?newsid=17794

- ^ http://www.heroelectricindia.com

- ^ http://www.evworld.com/news.cfm?newsid=19001

- ^ http://apps1.eere.energy.gov/news/news_detail.cfm/news_id=12178

- ^ http://www.army.mil/-newsreleases/2009/01/12/15707-army-announces-historic-electric-vehicle-lease/

Further reading

- Leitman, Seth and Brant, Bob (2008-10). Build Your Own Electric Vehicle, 2nd Edition. McGraw-Hill, Inc. ISBN 0071543732.

{{cite book}}: Check date values in:|date=(help)CS1 maint: multiple names: authors list (link)