Stained glass

The term stained glass can refer to coloured glass as a material or to works created from it. Throughout its thousand-year history, the term has been applied almost exclusively to the windows of churches, mosques and other significant buildings. Although traditionally made in flat panels and used as windows, the creations of modern stained glass artists also include three-dimensional structures and sculpture. Modern vernacular usage has often extended the term "stained glass" to include domestic leadlight and objets d'art created from came glasswork exemplified in the famous lamps of Louis Comfort Tiffany.

As a material stained glass is glass that has been coloured by adding metallic salts during its manufacture. The coloured glass is crafted into stained glass windows in which small pieces of glass are arranged to form patterns or pictures, held together (traditionally) by strips of lead and supported by a rigid frame. Painted details and yellow stain are often used to enhance the design. The term stained glass is also applied to windows in which the colours have been painted onto the glass and then fused to the glass in a kiln.

Stained glass, as an art and a craft, requires the artistic skill to conceive an appropriate and workable design, and the engineering skills to assemble the piece. A window must fit snugly into the space for which it is made, must resist wind and rain, and also, especially in the larger windows, must support its own weight. Many large windows have withstood the test of time and remained substantially intact since the late Middle Ages. In Western Europe they constitute the major form of pictorial art to have survived. In this context, the purpose of a stained glass window is not to allow those within a building to see the world outside or even primarily to admit light but rather to control it. For this reason stained glass windows have been described as 'illuminated wall decorations'.

The design of a window may be abstract or figurative; may incorporate narratives drawn from the Bible, history, or literature; may represent saints or patrons, or use symbolic motifs, in particular armorial. Windows within a building may be thematic, for example: within a church - episodes from the life of Christ; within a parliament building - shields of the constituencies; within a college hall - figures representing the arts and sciences; or within a home - flora, fauna, or landscape.

Stained glass is still popular today, but often referred to as art glass. It is prevalent in luxury homes, commercial buildings, and places of worship. Artists and companies are contracted to create beautiful art glass ranging from domes, windows, backsplashes, etc.

Manufacture

Glass production

During the late Medieval period, glass factories were set up where there was a ready supply of silica, the essential material for glass manufacture. Silica requires very high heat to become molten, something not all glass factories were able to achieve. Such materials as potash, soda, and lead can be added to lower the melting temperature. Other substances, such as lime, are added to rebuild the weakened network and make the glass more stable. Glass is coloured by adding metallic oxide powders or finely divided metals while it is in a molten state. Copper oxides produce green or bluish green, cobalt makes deep blue, and gold produces wine red and violet glass. Much modern red glass is produced using copper, which is less expensive than gold and gives a brighter, more vermilion shade of red. Glass coloured while in the clay pot in the furnace is known as pot metal glass, as opposed to flashed glass.

Cylinder glass or Muff Using a blow-pipe, a "gather" (glob) of molten glass is taken from the pot heating in the furnace. The gather is formed to the correct shape and a bubble of air blown into it. Using metal tools, molds of wood that have been soaking in water, and gravity, the gather is manipulated to form a long, cylindrical shape. As it cools, it is reheated so the manipulation can continue. During the process, the bottom of the cylinder is removed. Once brought to the desired size it is left to cool. One side of the cylinder is opened. It is put into another oven to quickly heat and flatten it, and then placed in an annealer to cool at a controlled rate, making the material more stable. "Hand-blown" cylinder (also called muff glass) and crown glass were the types used in ancient stained-glass windows.

Crown glass This hand-blown glass is created by blowing a bubble of air into a gather of molten glass and then spinning it, either by hand or on a table that revolves rapidly like a potter's wheel. The centrifugal force causes the molten bubble to open up and flatten. It can then be cut into small sheets. Glass formed this way can be both coloured and used for stained-glass windows, or uncoloured as seen in small paned windows in 16th- and 17th-century houses. Concentric, curving waves are characteristic of the process. The center of each piece of glass, known as the "bull's-eye", receives less force during spinning, so it remains thicker than the rest of the sheet. It also has the distinctive lump of glass left by the "pontil" rod, which holds the glass as it is spun out. This lumpy, refractive quality means the bulls-eyes are less transparent, but they have still been used for windows, both domestic and ecclesiastical. Crown glass is still made today, but not on a large scale.

Rolled glass Rolled glass (sometimes called "table glass") is produced by pouring molten glass onto a metal or graphite table and immediately rolling it into a sheet using a large metal cylinder, similar to rolling out a pie crust. The rolling can be done by hand or machine. Glass can be "double rolled", which means it is passed through two cylinders at once (similar to the clothes wringers on older washing machines) to yield glass of a specified thickness (typically approximately 1/8"). Glass made this way is never fully transparent, but doesn't necessarily have much texture. It can be pushed and tugged while molten for certain effects. For distinct textures the metal cylinder can be imprinted with a pattern that is pressed into the molten glass as it passes through the rollers. The glass is then annealed. Rolled glass was first commercially produced around the mid-1830s and is widely used today. It is often called cathedral glass, but this has nothing to do with medieval cathedrals, where the glass used was hand-blown.

Flashed glass Architectural glass must be at least 1/8 of an inch thick to survive the push and pull of typical wind loads. However, in the creation of red glass, the colouring ingredients must be of a certain concentration, or the colour will not develop. This results in a colour so intense that at the thickness of 1/8 inch, the red glass transmits little light and appears black. The method employed is to laminate a thin layer of red glass to a thicker body of glass that is clear or lightly tinted, forming "flashed glass".

A lightly coloured molten gather is dipped into a pot of molten red glass, that is then blown into a sheet of laminated glass using either the cylinder (muff) or the crown technique described above. Once this solution was found for making red glass, other colours were also made this way as well. A great advantage is that the double-layered glass can be engraved or abraded to reveal the clear or tinted glass below. The method allows rich detailing and patterns to be achieved without needing to add more lead-lines, giving artists greater freedom in their designs. A number of artists have embraced the possibilities flashed glass gives them. For instance, 16th-century heraldic windows relied heavily on a variety of flashed colours for their intricate crests and creatures. In the medieval period the glass was "abraded" (ground off); later, hydrofluoric acid was used to remove the flash in a chemical reaction (a very dangerous technique), and in the 19th century sandblasting started to be used for this purpose.

Modern production of traditional glass There are a number of glass factories, notably in Germany, USA, England, France, Poland and Russia, which produce high-quality glass, both hand-blown (cylinder, muff, crown) and rolled (cathedral and opalescent). Modern stained-glass artists have a number of resources to use and the work of centuries of other artists from which to learn as they continue the tradition in new ways. In the late 19th and 20th centuries there have been many innovations in techniques and in the types of glass used. Many new types of glass have been developed for use in stained glass windows, in particular Tiffany glass and dalle de verre (slab glass).

Colours

Transparent glass Ordinary soda-lime glass appears colourless to the naked eye when it is thin, although iron oxide impurities produce a green tint which becomes evident in thick pieces or can be seen with the aid of scientific instruments. A number of additives are used to reduce the green tint, particularly if the glass is to be used for plain window glass, rather than stained glass windows. Additives that reduce the green tint include manganese dioxide which produces sodium permanganate, and may result in a slightly mauve tint, characteristic of the glass in older houses in New England, US. Selenium has been used for the same purpose.[1]

Green glass While very pale green is the typical colour of transparent glass, deeper greens can be achieved by the addition of Iron(II) oxide which results in a bluish-green glass. Together with chromium it gives glass of a richer green colour, typical of the glass used to make wine bottles. The addition of Chromium yields dark green glass, suitable for flashed glass.[2] Together with tin oxide and arsenic it yields emerald green glass.

Blue glass

- In medieval times, blue glass was made by adding cobalt, which at a concentration of 0.025 to 0.1% in soda-lime glass achieves the brilliant blue characteristic of Chartres Cathedral.

- The addition of sulphur to boron-rich borosilicate glasses imparts a blue colour.

- The addition of copper oxide at 2-3% produces a turquoise colour.

- The addition of nickel, at different concentrations, produces blue, violet, or black glass.

Red glass

- Metallic gold, in very small concentrations (around 0.001%), produces a rich ruby-coloured glass ("ruby gold"); in lower concentrations it produces a less intense red, often marketed as "cranberry glass". The colour is caused by the size and dispersion of gold particles. Ruby gold glass is usually made of lead glass with tin added.

- Pure metallic copper produces a very dark red, opaque glass. Glass created in this manner is generally "flashed" (laminated glass). It was used extensively in the late 19th and early 20th centuries and exploited for the decorative effects that could be achieved by sanding and engraving.

- Selenium is an important agent to make pink and red glass. When used together with cadmium sulphide, it yields a brilliant red colour known as "Selenium Ruby".[1]

Yellow glass

- Silver compounds (notably silver nitrate) are used as stain applied to the surface of glass and fired on. They can produce a range of colours from orange-red to yellow. The way the glass is heated and cooled can significantly affect the colours produced by these compounds. The chemistry involved is complex and not well understood.

- The addition of sulphur, together with carbon and iron salts, is used to form iron polysulphides and produce amber glass ranging from yellowish to almost black. With calcium it yields a deep yellow colour.[3]

- Adding titanium produces yellowish-brown glass. Titanium is rarely used on its own and is more often employed to intensify and brighten other additives.

- Cadmium together with sulphur results in deep yellow colour, often used in glazes. However, cadmium is toxic.

- Uranium (0.1 to 2%) can be added to give glass a fluorescent yellow or green colour.[4] Uranium glass is typically not radioactive enough to be dangerous, but if ground into a powder, such as by polishing with sandpaper, and inhaled it can be carcinogenic. When used with lead glass with a very high proportion of lead, it produces a deep red colour.

Purple glass

- The addition of Manganese gives an amethyst colour. Manganese is one of the oldest glass additives, and purple manganese glass has been used since early Egyptian history.

- Nickel, depending on the concentration, produces blue, or violet, or even black glass. Lead crystal with added nickel acquires a purplish colour.

White glass

- Tin oxide with antimony and arsenic oxides produce an opaque white glass, first used in Venice to produce an imitation porcelain. White glass was used extensively by Louis Comfort Tiffany to create a range of opalescent, mottled and streaky glasses.

-

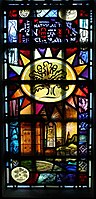

13th-century window from Chartres showing extensive use of the ubiquitous cobalt blue with green and purple-brown glass, details of amber and borders of flashed red glass.

-

A 19th-century window illustrates the range of colours common in both Medieval and Gothic Revival glass, Lucien Begule, Lyon (1896)

-

A 16th-century window by Arnold of Nijmegen showing the combination of painted glass and intense colour common in Renaissance windows

-

A late 20th-century window showing a graded range of colours. Ronald Whiting, Chapel Studios. Tattershall Castle, UK

-

A window by Tiffany illustrating the development and use of multi-coloured flashed, opalised and streaky glasses at the end of the 19th century

Creating stained glass windows

Design

The first stage in the production of a window is to make, or acquire from the architect or owners of the building, an accurate template of the window opening that the glass is to fit.

The subject matter of the window is determined to suit the location, a particular theme, or the whim of the patron. A small design called a Vidimus (from Latin "we saw it") is prepared which can be shown to the patron. A scaled model maquette may also be provided. The designer must take into account the design, the structure of the window, the nature and size of the glass available and his or her own preferred technique.

A traditional narrative window has panels which relate a story. A figurative window could have rows of saints or dignitaries. Scriptural texts or mottoes are sometimes included and perhaps the names of the patrons or the person as whose memorial the window is dedicated. In a window of a traditional type, it is usually left to the discretion of the designer to fill the surrounding areas with borders, floral motifs and canopies.

A full sized cartoon is drawn for every "light" (opening) of the window. A small church window might typically have two lights, with some simple tracery lights above. A large window might have four or five lights. The east or west window of a large cathedral might have seven lights in three tiers with elaborate tracery. In Medieval times the cartoon was drawn directly on the surface of a whitewashed table, which was then used as a pattern for cutting, painting and assembling the window. The cartoon is then divided into a patchwork, providing a template for each small glass piece. The exact position of the lead which holds the glass in place is also noted as it is part of the calculated visual effect.

Selecting and painting the glass

Each piece of glass is selected for the desired colour and cut to match a section of the template. An exact fit is ensured by grozing the edges with a tool which can nibble off small pieces.

Details of faces, hair and hands can be painted onto the inner surface of the glass using a special glass paint which contains finely ground lead or copper filings, ground glass, gum arabic and a medium such as wine, vinegar or (traditionally) urine. The art of painting details became increasingly elaborate and reached its height in the early 20th century.

From 1300 onwards, artists started using silver stain which was made with silver nitrate. It gave a yellow effect ranging from pale lemon to deep orange. It was usually painted onto the outside of a piece of glass, then fired to make it permanent. This yellow was particularly useful for enhancing borders, canopies and haloes, and turning blue glass into green glass.

By about 1450 a stain known as Cousin's rose was used to enhance flesh tones.

In the 16th century a range of glass stains were introduced, most of them coloured by ground glass particles. They were a form of enamel. Painting on glass with these stains was initially used for small heraldic designs and other details. By the 17th century a style of stained glass had evolved that was no longer dependent upon the skilful cutting of coloured glass into sections. Scenes were painted onto glass panels of square format, like tiles. The colours were then annealed to the glass before the pieces were assembled.

A method used for embellishment and gilding is the decoration of one side of each of two pieces of thin glass which are then placed back to back within the lead came. This allows for the use of techniques such as Angel gilding and Eglomise to produce an effect visible from both sides but not exposing the decorated surface to the atmosphere or mechanical damage.

Assembly and mounting

Once the glass is cut and painted, the pieces are assembled by slotting them into H-sectioned lead cames. All the joints are then soldered together and the glass pieces are prevented from rattling and the window made weatherproof by forcing a soft oily cement or mastic between the glass and the cames. In modern windows, copper foil is now sometimes used instead of lead. For further technical details, see Came glasswork.

Traditionally, when the windows were inserted into the window spaces, iron rods were put across it at various points to support its weight. The window was tied to these rods with copper wire. Some very large early Gothic windows are divided into sections by heavy metal frames called ferramenta. This method of support was also favoured for large, usually painted, windows of the Baroque period.

- Technical details

-

Maquette by Heaton, Butler and Bayne, 19th-century English manufacturers

-

Exterior of a window at Sé Velha de Coimbra, Portugal, showing a modern steel armature

-

A set of glaziers' tools

-

Skilled glass cutting and leading in a 19th-century window at Meaux Cathedral, France

-

Thomas Becket window from Canterbury showing the pot metal and painted glass, lead H-sectioned cames, modern steel rods and copper wire attachments

-

Colours and mediums for painting on glass

-

A palette and tools to prepare colours for painting on glass

-

A small panel by G. Owen Bonawit at Yale University, c. 1930, demonstrates grisaille glass painting enlivened with silver stain.

-

Swiss armourial glass of the Arms of Unterwalden, 1564, with typical painted details, extensive silver stain, Cousin's rose on the face, and flashed ruby glass with abraded white motif

History

Origins

Coloured glass has been produced since ancient times. Both the Egyptians and the Romans excelled at the manufacture of small coloured glass objects. Phoenicia was important in glass manufacture with its chief centres Sidon, Tyre and Antioch. The British Museum holds two of the finest Roman pieces, the Lycurgus Cup, which is a murky mustard colour but glows purple-red to transmitted light, and the Portland vase which is midnight blue, with a carved white overlay.

In early Christian churches of the 4th and 5th centuries, there are many remaining windows which are filled with ornate patterns of thinly-sliced alabaster set into wooden frames, giving a stained-glass like effect.

Evidence of stained glass windows in churches and monasteries in Britain can be found as early as the 7th century. The earliest known reference dates from 675 AD when Benedict Biscop imported workmen from France to glaze the windows of the monastery of St Peter which he was building at Monkwearmouth. Hundreds of pieces of coloured glass and lead, dating back to the late 7th century, have been discovered here and at Jarrow.[5]

In the Middle East, the glass industry of Syria continued during the Islamic period with major centres of manufacture at Ar-Raqqah, Aleppo and Damascus and the most important products being highly transparent colourless glass and gilded glass, rather than coloured glass. The production of coloured glass in Southwest Asia existed by the 8th century, at which time the alchemist Jābir ibn Hayyān, in Kitab al-Durra al-Maknuna, gave 46 recipes for producing coloured glass and described the technique of cutting glass into artificial gemstones.[6]

-

A perfume flask from 100 BC-200 AD

-

The Portland Vase, a rare example of Roman flashed glass

-

An alabaster window in Orvieto Cathedral, Italy

-

Stained glass in the Nasir al-Mulk mosque in Shiraz, Iran

Medieval glass

Stained glass, as an art form, reached its height in the Middle Ages when it became a major pictorial form used to illustrate the narratives of the Bible to a largely illiterate populace.

In the Romanesque and Early Gothic period, from about 950 AD to 1240 AD, the untraceried windows demanded large expanses of glass which of necessity were supported by robust iron frames, such as may be seen at Chartres Cathedral and at the eastern end of Canterbury Cathedral. As Gothic architecture developed into a more ornate form, windows grew larger, affording greater illumination to the interiors, but were divided into sections by vertical shafts and tracery of stone. This elaboration of form reached its height of complexity in the Flamboyant style in Europe, and windows grew still larger with the development of the Perpendicular style in England.

Integrated with the lofty verticals of Gothic cathedrals and parish churches, glass designs became more daring. The circular form, or rose window, developed in France from relatively simple windows with openings pierced through slabs of thin stone to wheel windows, as exemplified by the West front of Chartres Cathedral, and ultimately to designs of enormous complexity, the tracery being drafted from hundreds of different points, such as those at Sainte-Chapelle, Paris and the "Bishop's Eye" at Lincoln Cathedral.

While stained glass was widely manufactured, Chartres in France was the greatest centre of stained glass manufacture, producing glass of unrivalled quality.[7]

- Medieval glass in France

-

Detail of a 13th-century window from Chartres Cathedral

-

Charlemagne from a Romanesque window in Strasbourg Cathedral

-

The Crucifixion window of Poitiers Cathedral

-

Late Gothic Tree of Jesse window from Evreux Cathedral

-

The South Transept windows from Chartres Cathedral

- Medieval glass in Germany and Austria

-

King David from Augsburg Cathedral, early 12th century. One of the oldest examples in situ.

-

Crucifixion with Ss Catherine, George and Margaret, Leechkirche, Graz, Austria

-

The Crucifixion and Virgin and Child in Majesty, Cologne Cathedral, (1340)

-

Ulm Munster, The Last Judgement by Hans Acker (1430)

-

The windows of the choir of Cologne Cathedral, (early 14th century)

- Medieval glass in England

-

Detail of a Tree of Jesse from York Minster (c. 1170), the oldest stained glass window in England.

-

The Poor Man's Bible Window from Canterbury Cathedral

-

South Transept window at Canterbury Cathedral, 13th century

-

The west window of York Minster

Renaissance, Reformation and Classical windows

Probably the earliest scheme of stained glass windows that was created during the Renaissance was that for Florence Cathedral, devised by Lorenzo Ghiberti.[9] The scheme includes three ocular windows for the dome and three for the facade which were designed from 1405-1445 by several of the most renowned artists of this period: Ghiberti, Donatello, Uccello and Andrea del Castagno. Each major ocular window contains a single picture drawn from the Life of Christ or the Life of the Virgin Mary, surrounded by a wide floral border, with two smaller facade windows by Ghiberti showing the martyred deacons, St Stephen and St Lawrence. One of the cupola windows has since been lost, and that by Donatello has lost nearly all of its painted details.[9]

In Europe, stained glass continued to be produced with the style evolving from the Gothic to the Classical, which is well represented in Germany, Belgium and the Netherlands, despite the rise of Protestantism. In France, much glass of this period was produced at the Limoges factory, and in Italy at Murano, where stained glass and faceted lead crystal are often coupled together in the same window. Ultimately, the French Revolution brought about the neglect or destruction of many windows in France. At the Reformation, in England large numbers of Medieval and Renaissance windows were smashed and replaced with plain glass. The Dissolution of the Monasteries under Henry VIII and the injunctions of Thomas Cromwell against "abused images" (the object of veneration) resulted in the loss of thousands of windows. Few remain undamaged; of them the windows in the private chapel at Hengrave Hall in Suffolk are among the finest. With the latter wave of destruction the traditional methods of working with stained glass died and were not to be rediscovered in England until the early 19th century. See Stained glass - British glass, 1811-1918 for more details.

In the Netherlands a rare scheme of glass has remained intact at Grote Sint-Jan Church, Gouda. The windows, some of which are 18 metres (60 feet) high date from 1555 to the early 1600s, with the earliest being the work of Dirck Crabeth and his brother Wouter. Many of the original cartoons still exist.[10]

-

The Resurrection, Paolo Uccello, (1443–45) one of a series in the dome of Florence Cathedral designed by renowned Renaissance artists.

-

Tree of Jesse window, Church of Saint-Étienne, Beauvais, France, Engrand Le Prince, (1522-1524)

-

Detail of Adam and Eve from the Cathedral of St-Etienne, Châlons-en-Champagne, France

-

Renaissance window in the church of SS Giovanni and Paolo, Venice 16th century

-

The Triumph of Freedom of Conscience, Sint Janskerk, maker Adriaen Gerritsz. de Vrije (Gouda); design Joachim Wtewael (Utrecht) (1595-1600)

-

Domestic window by Dirck Crabeth for the house of Adriaen Dircxz. van Crimpen, of Leiden. (1543) The windows show scenes from the lives of the Prophet Samuel and the Apostle Paul. Musée des Arts Décoratifs, Paris.[10]

-

The Passion of Christ: the Capture and Crucifixion, Saint-Pierre, Limours, Essonne, France, (1520)

-

Glass painting depicting Mordnacht (murder's night) on 23/24 February 1350 and heraldry of the first Meisen guild's Zunfthaus. (c. 1650)

-

The story of how the Crown of Thorns, passed from John of Brienne and Baldwin II of Constantinople to Saint Louis IX of France, Moulins Cathedral (16th century)

-

The Death and Assumption of the Virgin Mary, Church of Ss Ägidius and Koloman, Steyr, Austria

Revival in Britain

The Catholic revival in England, gaining force in the early 19th century with its renewed interest in the medieval church, brought a revival of church building in the Gothic style, claimed by John Ruskin to be "the true Catholic style". The architectural movement was led by Augustus Welby Pugin. Many new churches were planted in large towns and many old churches were restored. This brought about a great demand for the revival of the art of stained glass window making.

Among the earliest 19th-century English manufacturers and designers were William Warrington and John Hardman of Birmingham, whose nephew, John Hardman Powell, had a commercial eye and exhibited works at the Philadelphia Exhibition of 1876, influencing stained glass in the United States of America. Other manufacturers included William Wailes, Ward and Hughes, Clayton and Bell, Heaton, Butler and Bayne and Charles Eamer Kempe. A Scottish designer, Daniel Cottier, opened firms in Australia and the US.

-

Detail, Apostles John and Paul, Hardman of Birmingham, 1861–67, typical of Hardman in its elegant arrangement of figures and purity of colour. St. Andrew's Cathedral, Sydney

-

One of England's largest windows, the east window of Lincoln Cathedral, Ward and Nixon (1855), is a formal arrangement of small narrative scenes in roundels

-

William Wailes. This window has the bright pastel colour, wealth of inventive ornament, and stereotypical gestures of windows by this firm. St Mary's, Chilham

-

Clayton and Bell. A narrative window with elegant forms and colour which is both brilliant and subtle in its combinations. Peterborough Cathedral

Revival in France

In France there was a greater continuity of stained glass production than in England. In the early 19th century most stained glass was made of large panes that were extensively painted and fired, the designs often being copied directly from oil paintings by famous artists. In 1824 the Sèvres porcelain factory began producing stained glass to supply the increasing demand. In France many churches and cathedrals suffered despoliation during the French Revolution. During the 19th century a great number of churches were restored by Viollet-le-Duc. Many of France's finest ancient windows were restored at that time. From 1839 onwards much stained glass was produced that very closely imitated medieval glass, both in the artwork and in the nature of the glass itself. The pioneers were Henri Gèrente and André Lusson.[11] Other glass was designed in a more Classical manner, and characterised by the brilliant cerulean colour of the blue backgrounds (as against the purple-blue of the glass of Chartres) and the use of pink and mauve glass.

-

Detail of a "Tree of Jesse" window in Reims Cathedral designed in the 13th-century style by L. Steiheil and painted by Coffetier for Viollet-le-Duc, (1861)

-

St Louis administering Justice by Lobin in the painterly style. (19th century) Church of St Medard, Thouars.

-

A brilliantly-coloured window at Cassagnes-Bégonhès, Aveyron

-

West window from Saint-Urbain, Troyes, (about 1900)

Revival in Europe

During the mid- to late 19th century, many of Germany's ancient buildings were restored, and some, such as Cologne Cathedral, were completed in the medieval style. There was a great demand for stained glass. The designs for many windows were based directly on the work of famous engravers such as Albrecht Dürer. Original designs often imitate this style. Much 19th-century German glass has large sections of painted detail rather than outlines and details dependent on the lead. The Royal Bavarian Glass Painting Studio was founded by Ludwig I in 1827.[11] A major firm was Mayer of Munich, which commenced glass production in 1860, and is still operating as Franz Mayer of Munich, Inc.. German stained glass found a market across Europe, in America and Australia. Stained glass studios were also founded in Italy and Belgium at this time.[11]

In the Austrian Empire and later Austria-Hungary, one of the leading stained glass artists was Carl Geyling, who founded his studio in 1841. His son would continue the tradition as Carl Geyling's Erben, which still exists today. Carl Geyling's Erben completed numerous stained glass windows for major churches in Vienna and elsewhere, and received an Imperial and Royal Warrant of Appointment from emperor Franz Joseph I of Austria.

-

A painted memorial window, Castle Bodenstein, Germany, early 19th century

-

One of five windows donated to Cologne Cathedral by Ludwig II

-

Post-Reformation window in the Memorial Church, Speyer, Germany

-

Ghent Cathedral, Belgium

-

A window in the Late Gothic style, St Maurice's Church, Olomouc, Czech Republic, early 20th century

Innovations in the United States

J&R Lamb Studios, established in 1857 in New York City, was the first major decorative arts studio in the United States and for many years a major producer of ecclesiastical stained glass.

Notable American practitioners include John La Farge (1835–1910), who invented opalescent glass and for which he received a U.S. patent on 24 February 1880, and Louis Comfort Tiffany (1848–1933), who received several patents for variations of the same opalescent process in November of the same year and is believed to have invented the copper foil method as an alternative to lead, and used it extensively in windows, lamps and other decorations.

-

Many of the distinctive types of glass invented by Tiffany are demonstrated within this single small panel including "fracture-streamer glass" and "drapery glass".

-

John La Farge, The Angel of Help, North Easton, MA shows the use of tiny panes contrasting with large areas of flashed or opalescent glass.

-

Religion Enthroned, J&R Lamb Studios, designer Frederick Stymetz Lamb, c. 1900. Brooklyn Museum. Symmetrical design, "Aesthetic Style", a limited palette and extensive use of mottled glass.

-

The Holy City by Louis Comfort Tiffany (1905). This 58-panel window has brilliant red, orange, and yellow etched glass for the sunrise, with textured glass used to create the effect of moving water.

-

A trompe l'oeil glass c. 1884, Eugène Stanislas Oudinot, design Richard Morris Hunt, for home of Henry Gurdon Marquand, New York City.

Innovations in Britain and Europe

Among the most innovative English designers were the Pre-Raphaelites, William Morris (1834–1898) and Edward Burne-Jones (1833–1898), whose work heralds Art Nouveau. Art Nouveau or Belle Epoch stained glass design flourished in France, and Eastern Europe, where it can be identified by the use of curving, sinuous lines in the lead, and swirling motifs. In France it is seen in the work of Francis Chigot of Limoges. In Britain it appears in the refined and formal leadlight designs of Charles Rennie Macintosh.

-

David's charge to Solomon shows the strongly linear design and use of flashed glass for which Burne-Jones' designs are famous. Trinity Church, Boston, US, (1882)

-

God the Creator by Stanisław Wyspiański, this window has no glass painting, but relies entirely on leadlines and skilful placement of colour and tone. Franciscan Church, Kraków (c. 1900)

-

Window by Alfons Mucha, Saint Vitus Cathedral Prague, has a montage of images, rather than a tightly organised visual structure, creating an Expressionistic effect.

-

Art Nouveau by Jacques Grüber, the glass harmonising with the curving architectural forms that surround it, Musée de l'École de Nancy (1904).

20th and 21st centuries

Many 19th-century firms failed early in the 20th century as the Gothic movement was superseded by newer styles. At the same time there were also some interesting developments where stained glass artists took studios in shared facilities. Examples include the Glass House in London set up by Mary Lowndes and Alfred J. Drury and An Túr Gloine in Dublin, which was run by Sarah Purser and included artists such as Harry Clarke.

A revival occurred in the middle of the century because of a desire to restore thousands of church windows throughout Europe destroyed as a result of World War II bombing. German artists led the way. Much work of the period is mundane and often was not made by its designers, but industrially produced.

Other artists sought to transform an ancient art form into a contemporary one, sometimes using traditional techniques while exploiting the medium of glass in innovative ways and in combination with different materials. The use of slab glass set in concrete was a 20th-century innovation. Gemmail, a technique developed by the French artist Jean Crotti in 1936 and perfected in the 1950s, is a type of stained glass where adjacent pieces of glass are overlapped without using lead cames to join the pieces, allowing for greater diversity and subtlety of colour.[12][13] Many famous works by late 19th- and early 20th-century painters, notably Picasso, have been reproduced in gemmail.[14] A major exponent of this technique is the German artist Walter Womacka.

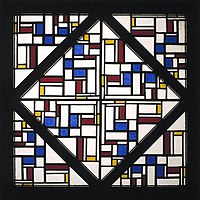

Among the early well-known 20th-century artists who experimented with stained glass as an Abstract art form were Theo van Doesburg and Piet Mondrian. In the 1960s and 1970s the Expressionist painter Marc Chagall produced designs for many stained glass windows that are intensely coloured and crammed with symbolic details. Important 20th-century stained glass artists include John Hayward, Douglas Strachan, Ervin Bossanyi, Louis Davis, Wilhelmina Geddes, Karl Parsons, John Piper, Patrick Reyntiens, Johannes Shreiter, Judith Schaechter, Paul Woodroffe, Jean René Bazaine at Saint Séverin, Sergio de Castro at Couvrechef- La Folie (Caen), Hamburg-Dulsberg and Romont (Switzerland), and the Loire Studio of Gabriel Loire at Chartres. The west windows of England's Manchester Cathedral, by Tony Hollaway, are some of the most notable examples of symbolic work.

In Germany, stained glass development continued with the inter-war work of Johan Thorn Prikker and Josef Albers, and the postwar achievements of Joachim Klos, Johannes Schreiter and Ludwig Shaffrath. Trends included the abandonment of figurative designs and of painting on glass in favour of a mix of biomorphic and rigorously geometric abstraction and the calligraphic non-functional use of leads.[15] The works of Ludwig Schaffrath demonstrate the late 20th-century trends in the use of stained glass for architectural purposes, filling entire walls with coloured and textured glass. In the 1970s young British stained-glass artists such as Brian Clarke were influenced by the large scale and abstraction in German twentieth-century glass.[15]

In the United States, there is a 100-year-old trade organization, The Stained Glass Association of America, whose purpose is to function as a publicly recognized organization to assure survival of the craft by offering guidelines, instruction and training to craftspersons. The SGAA also sees its role as defending and protecting its craft against regulations that might restrict its freedom as an architectural art form. The current president is B. Gunar Gruenke of the Conrad Schmitt Studios. Today there are academic establishments that teach the traditional skills. One of these is Florida State University's Master Craftsman Program, which recently completed a 30 ft (9.1 m) high stained-glass windows installed in Bobby Bowden Field at Doak Campbell Stadium.

-

Expressionist window by Marc Chagall, at All Saints' Church, Tudeley, Kent, UK

-

Socialist Realism by Walter Womacka, Berlin, (c. 1965) demonstrating the use of overlaid and laminated glass

-

Abstract expressionism at Meiningen Catholic Church.

-

Christ of the Eucharist designed by the monks of Buckfast Abbey, Devon, England, slab glass.

-

One of four 64-metre (210 ft)-high stained glass panels, Rio de Janeiro Cathedral, Brazil

-

Postmodernist symbolism, Tree of Life at Christinae church, Alingsås, Sweden.

-

The Bald Eagle, from commercial studios working with traditional techniques, Dryden High School, USA

-

Thin slices of agate set into lead and glass, Grossmünster, Zürich, Switzerland, by Sigmar Polke (2009)

Combining ancient and modern traditions

-

Mid-20th-century window showing a continuation of ancient and 19th-century methods applied to a modern historical subject. Florence Nightingale window at St Peters, Derby, made for the Derbyshire Royal Infirmary

-

Figurative design using the lead lines and minimal glass paint in the 13th-century manner combined with the texture of Cathedral glass, Ins, Switzerland

-

St Michael and the Devil at the church of St Michael Paternoster Row, by English artist John Hayward combines traditional methods with a distinctive use of shard-like sections of glass.

-

Postmodern design of etched glass text and cathedral glass books set as a trompe l'oeil, LGBT pride Libraries, University of Western Ontario, artist: Lynette Richards

Buildings incorporating stained glass windows

Churches

Stained glass windows were commonly used in churches for decorative and informative purposes. Many windows are donated to churches by members of the congregation as memorials of loved ones. For more information on the use of stained glass to depict religious subjects, see Poor Man's Bible.

- Important examples

- Cathedral of Chartres, in France, 11th- to 13th-century glass

- Canterbury Cathedral, in England, 12th to 15th century plus 19th- and 20th-century glass

- York Minster, in England, 11th- to 15th-century glass

- Sainte-Chapelle, in Paris, 13th- and 14th-century glass

- Florence Cathedral, Italy, 15th-century glass designed by Uccello, Donatello and Ghiberti

- St. Andrew's Cathedral, Sydney, Australia, early complete cycle of 19th-century glass, Hardman of Birmingham.

- Coventry Cathedral, England, mid-20th-century glass by various designers, the large baptistry window being by John Piper

- Brown Memorial Presbyterian Church, extensive collection of windows by Louis Comfort Tiffany

Synagogues

In addition to Christian churches, stained glass windows have been incorporated into Jewish temple architecture for centuries. Jewish communities in the United States saw this emergence in mid-19th century, with such notable examples as the sanctuary depiction of the Ten Commandments in New York's Congregation Anshi Chesed. From the mid-20th century to the present, stained glass windows have been a ubiquitous feature of American synagogue architecture. Styles and themes for synagogue stained glass artwork are as diverse as their church counterparts. As with churches, synagogue stained glass windows are often dedicated by member families in exchange for major financial contributions to the institution.

Places of Worship

-

The dazzling display of medieval glass at Sainte-Chapelle, Paris

-

The chancel windows of the Church of Our Lady, Koblenz, Germany

-

St. Andrew's Cathedral, Sydney has a cycle of 19th-century windows by Hardman of Birmingham

-

Coventry Cathedral England, has a series of windows by different designers.

-

Late 20th-century stained glass from Temple Ohev Sholom, Harrisburg, Pennsylvania by Ascalon Studios.

Houses

Stained glass windows in houses were particularly popular in the Victorian era and many domestic examples survive. In their simplest form they typically depict birds and flowers in small panels, often surrounded with machine-made cathedral glass which, despite what the name suggests, is pale-coloured and textured. Some large homes have splendid examples of secular pictorial glass. Many small houses of the 19th and early 20th centuries have leadlight windows.

- Prairie style homes

- The houses of Frank Lloyd Wright

-

Shabaka (stained glass) at the Palace of Shaki Khans

Public and commercial use of stained glass Stained glass has often been used as a decorative element in public buildings, initially in places of learning, government or justice but increasingly in other public and commercial places such as banks, retailers and railway stations. Public houses in some countries make extensive use of stained glass and leaded lights to create a comfortable atmosphere and retain privacy.

-

Stained glass in the Town Hall, Liberec, Czech Republic

-

Windows of the Hungarian Room, University of Pittsburgh

-

The Federal Palace, Switzerland

-

Abstract design by Marcelle Ferron at a Metro station in Montreal, Canada

Sculpture

-

The Four Seasons (1978) by Leonard French at La Trobe University Sculpture Park in Melbourne. Australia

-

Fused glass sculpture (2012) by Carlo Roccella Glass Sculpture in Paris. France

See also

- Architectural glass

- Architecture of cathedrals and great churches

- Autonomous Stained Glass

- Beveled glass

- British and Irish stained glass (1811–1918)

- Cathedral glass

- Float glass

- Glass art

- Glass beadmaking

- Glassblowing

- Came glasswork

- Leadlight

- Poor Man's Bible

- Rose window

- Stained glass conservation

- Studio glass

- Suncatcher

- Tiffany glass

- Venetian glass

References

- ^ a b Illustrated Glass Dictionary www.glassonline.com. Retrieved 3 August 2006

- ^ Chemical Fact Sheet - Chromium www.speclab.com. Retrieved 3 August 2006

- ^ Substances Used in the Making of Coloured Glass 1st.glassman.com (David M Issitt). Retrieved 3 August 2006

- ^ Uranium Glass www.glassassociation.org.uk (Barrie Skelcher). Retrieved 3 August 2006

- ^ Discovering stained glass - John Harries, Carola Hicks, Edition: 3 – 1996

- ^ Ahmad Y Hassan, The Manufacture of Coloured Glass and Assessment of Kitab al-Durra al-Maknuna, History of Science and Technology in Islam.

- ^ Herbermann, Charles, ed. (1913). . Catholic Encyclopedia. New York: Robert Appleton Company.

- ^ "Fairford Church". Sacred-destinations.com. 20 October 2007. Retrieved 24 March 2014.

- ^ a b Lee, Seddon and Stephens, pp. 118-121

- ^ a b Vidimus, Dirck Peterz. Crabeth Issue 20 (accessed 26 August 2012)

- ^ a b c Gordon Campbell, The Grove Encyclopedia of Decorative Arts, Oxford University Press, ISBN 0-19-518948-5

- ^ "Le grand dictionnaire Québec government's online dictionary entry for ''gemmail'' (in French)". Wayback.archive.org. 8 April 2003. Archived from the original on 8 April 2003. Retrieved 24 March 2014.

{{cite web}}: Unknown parameter|deadurl=ignored (|url-status=suggested) (help) - ^ Gemmail, Encyclopædia Britannica

- ^ [1], Gemmail Time

- ^ a b Harrod, Tanya, The Crafts in Britain in the 20th Century, Yale University Press (4 Feb 1999), ISBN 978-0300077803, p. 452

Further reading

- Lucy Costigan & Michael Cullen (2010). Strangest Genius: The Stained Glass of Harry Clarke, The History Press, Dublin, ISBN 978-1-84588-971-5

- Theophilus (ca 1100). On Divers Arts, trans. from Latin by John G. Hawthorne and Cyril Stanley Smith, Dover, ISBN 0-486-23784-2

- Elizabeth Morris (1993). Stained and Decorative Glass, Tiger Books, ISBN 0-86824-324-8

- Sarah Brown (1994). Stained Glass- an Illustrated History, Bracken Books, ISBN 1-85891-157-5

- Painton Cowen (1985). A Guide to Stained Glass in Britain, Michael Joseph, ISBN 0-7181-2567-3

- Lawrence Lee, George Seddon, Francis Stephens (1976).Stained Glass, Mitchell Beazley, ISBN 0-600-56281-6

- Simon Jenkins (2000). England's Thousand Best Churches, Penguin, ISBN 0-7139-9281-6

- Robert Eberhard. Database: Church Stained Glass Windows.

- Cliff and Monica Robinson. Database: Buckinghamshire Stained Glass.

- Stained Glass Association of America. History of Stained Glass.

- Robert Kehlmann (1992). 20th Century Stained Glass: A New Definition, Kyoto Shoin Co., Ltd., Kyoto, ISBN 4-7636-2075-4

- Kisky, Hans (1959). 100 Jahre Rheinische Glasmalerei, Neuss : Verl. Gesellschaft für Buchdruckerei, OCLC 632380232

- Robert Sowers (1954). The Lost Art, George Wittenborn Inc., New York, OCLC 1269795

- Robert Sowers (1965). Stained Glass: An Architectural Art, Universe Books, Inc., New York, OCLC 21650951

- Robert Sowers (1981). The Language of Stained Glass, Timber Press, Forest Grove, Oregon, ISBN 0-917304-61-6

- Hayward, Jane (2003). English and French medieval stained glass in the collection of the Metropolitan Museum of Art. New York: The Metropolitan Museum of Art. ISBN 1872501370.

- Virginia Chieffo Raguin (2013). Stained Glass: Radiant Art. Los Angeles: Getty Publications. ISBN 978-1606061534.

External links

- Preservation of Stained Glass

- Church Stained Glass Window Database recorded by Robert E berhard, covering ~2800 churches in the southeast of England

- Institute for Stained Glass in Canada, over 2200 photos; a multi-year photographic survey of Canada's stained glass heritage

- The Stained Glass Museum (Ely, England)

- Stained glass guide (UK)

- "Stained Glass". Glass. Victoria and Albert Museum. Retrieved 16 June 2007.

- Gloine - Stained glass in the Church of Ireland Research carried out by Dr David Lawrence on behalf of the Representative Church Body of the Church of Ireland, partially funded by the Heritage Council

- Stained-glass windows by Sergio de Castro in France, Germany and Switzerland

![The Last Judgement, St Mary's Church, Fairford, (1500–17) by Barnard Flower[8]](http://upload.wikimedia.org/wikipedia/commons/thumb/e/e8/Fairford_st_mary_011.jpg/138px-Fairford_st_mary_011.jpg)

![Domestic window by Dirck Crabeth for the house of Adriaen Dircxz. van Crimpen, of Leiden. (1543) The windows show scenes from the lives of the Prophet Samuel and the Apostle Paul. Musée des Arts Décoratifs, Paris.[10]](http://upload.wikimedia.org/wikipedia/commons/thumb/f/f3/Paris_ArtsD%C3%A9coratifs_Paulus_54.JPG/199px-Paris_ArtsD%C3%A9coratifs_Paulus_54.JPG)