Optical fiber: Difference between revisions

m clean up using AWB |

No edit summary Tag: nowiki added |

||

| Line 1: | Line 1: | ||

{{About||methods of applying a 2D image onto a 3D surface|pad printing|methods of copying 2D parallax stereograms that seem 3D to the eye|lenticular printing|and|holography}} |

|||

[[File:fibreoptic.jpg|thumb|right|A bundle of optical fibers]] |

|||

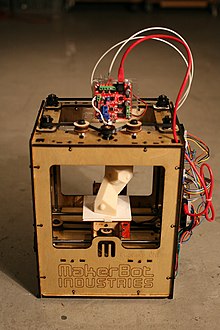

[[File:MakerBot ThingOMatic Bre Pettis.jpg|thumb|A [[MakerBot]] 3D printer]] |

|||

[[File:Stealth Fiber Crew installing fiber cable underneath the streets of Manhattan.jpg|thumb|Fiber crew installing a 432-count fiber cable underneath the streets of Midtown Manhattan, New York City]] |

|||

{{History of printing}} |

|||

[[File:Fiber optic illuminated.jpg|thumb|A [[TOSLINK]] fiber optic audio cable with red light being shone in one end transmits the light to the other end]] |

|||

[[File:Optical-fibre-junction-box.jpg|thumb|right|A [[19-inch rack|wall-mount cabinet]] containing optical fiber interconnects. The yellow cables are [[single-mode optical fiber|single mode fibers]]; the orange and aqua cables are [[multi-mode optical fiber|multi-mode fibers]]: 50/125 µm OM2 and 50/125 µm OM3 fibers respectively.]] |

|||

'''3D printing''', also known as '''additive manufacturing (AM)''', refers to various processes used to synthesize a [[three-dimensional space|three-dimensional]] object.<ref name="engineer" /> In 3D printing, successive layers of material are formed under computer control to create an object.<ref name="Auto3D-1" /> These objects can be of almost any shape or geometry, and are produced from a [[3D modeling|3D model]] or other electronic data source. A 3D [[Printer (computing)|printer]] is a type of [[industrial robot]]. |

|||

An '''optical fiber''' ([[American and British English spelling differences#-re, -er|or]] '''optical fibre''') is a flexible, transparent fiber made by [[Drawing (manufacturing)|drawing]] glass ([[silica]]) or plastic to a diameter slightly thicker than that of a [[Hair|human hair]].<ref>{{cite web|title=Optical Fiber|url=http://www.thefoa.org/tech/ref/basic/fiber.html|website=http://www.thefoa.org/|publisher=The Fiber Optic Association, Inc.|accessdate=17 April 2015}}</ref> Optical fibers are used most often as a means to transmit light between the two ends of the fiber and find wide usage in [[fiber-optic communication]]s, where they permit transmission over longer distances and at higher [[bandwidth (computing)|bandwidth]]s (data rates) than wire cables. Fibers are used instead of [[metal]] wires because signals travel along them with lesser amounts of [[Attenuation|loss]]; in addition, fibers are also immune to [[electromagnetic interference]], a problem from which metal wires suffer excessively.<ref>{{cite book|last1=Senior|first1=John M.|last2=Jamro|first2=M. Yousif|title=Optical fiber communications: principles and practice|date=2009|publisher=Pearson Education|url=http://cds.cern.ch/record/1493478|accessdate=17 April 2015}}</ref><ref>''Optical fiber communications: principles and practice'' pp 7-9</ref> Fibers are also used for [[illumination (lighting)|illumination]], and are wrapped in bundles so that they may be used to carry images, thus allowing viewing in confined spaces, as in the case of a [[fiberscope]].<ref>{{cite web|title=Birth of Fiberscopes|url=http://www.olympus-global.com/en/corc/history/story/endo/fiber/|website=http://www.olympus-global.com/|publisher=Olympus Corporation|accessdate=17 April 2015}}</ref> Specially designed fibers are also used for a variety of other applications, some of them being [[fiber optic sensor]]s and [[fiber laser]]s.<ref>{{cite journal|last1=Lee|first1=Byoungho|title=Review of the present status of optical fiber sensors.|journal=Optical Fiber Technology|date=2003|volume=9|issue=2|pages=57–79|url=http://wr.lib.tsinghua.edu.cn/sites/default/files/1066744871461.pdf|accessdate=17 April 2015|doi=10.1016/s1068-5200(02)00527-8}}</ref> |

|||

[[Futurologist]]s such as [[Jeremy Rifkin]] <ref>http://www.thethirdindustrialrevolution.com/</ref> believe that 3D printing signals the beginning of a [[third industrial revolution]],<ref>http://www.economist.com/node/21552901</ref> succeeding the [[production line]] assembly that dominated manufacturing starting in the late 19th century. Using the power of the [[Internet]], it may eventually be possible to send a [[blueprint]] of any product to any place in the world to be replicated by a 3D printer with "elemental inks" capable of being combined into any material substance of any desired form. |

|||

Optical fibers typically include a [[transparency and translucency|transparent]] [[core (optical fiber)|core]] surrounded by a transparent [[cladding (fiber optics)|cladding]] material with a lower [[index of refraction]]. Light is kept in the core by the phenomenon of [[total internal reflection]] which causes the fiber to act as a [[waveguide]].<ref>''Optical fiber communications: principles and practice'' pp 12-14</ref> Fibers that support many propagation paths or [[transverse mode]]s are called [[multi-mode fiber]]s (MMF), while those that support a single mode are called [[single-mode fiber]]s (SMF). Multi-mode fibers generally have a wider core diameter and are used for short-distance communication links and for applications where high power must be transmitted.{{citation needed|date=April 2015}} Single-mode fibers are used for most communication links longer than {{convert|1000|sp=us|m|ft}}.{{citation needed|date=April 2015}} |

|||

''3D printing'' in the term's original [[word sense|sense]] refers to processes that sequentially deposit material onto a powder bed with inkjet printer heads. More recently, the meaning of the term has expanded to encompass a wider variety of techniques such as [[extrusion]] and [[sintering]]-based processes. [[Technical standard]]s generally use the term ''additive manufacturing'' for this broader sense. |

|||

An important aspect of a fiber optic communication is that of extension of the fiber optic cables such that the losses brought about by joining two different cables is kept to a minimum.<ref>''Optical fiber communications: principles and practice'' p 218</ref> Joining lengths of optical fiber often proves to be more complex than joining electrical wire or cable and involves careful [[cleave (fiber)|cleaving]] of the fibers, perfect alignment of the fiber cores, and the splicing of these aligned fiber cores. For applications that demand a permanent connection a [[mechanical splice]] which holds the ends of the fibers together mechanically could be used or a [[fusion splicing|fusion splice]] that uses heat to fuse the ends of the fibers together could be used. Temporary or semi-permanent connections are made by means of specialized [[optical fiber connector]]s.<ref>''Optical fiber communications: principles and practice'' pp 234-235</ref> |

|||

== History == |

|||

The field of applied science and engineering concerned with the design and application of optical fibers is known as '''fiber optics'''. |

|||

{{toclimit|3}} |

|||

=== Terminology and methods === |

|||

==History== |

|||

Early Additive Manufacturing equipment and materials were developed in the 1980s.<ref name="3D opp" /> In 1981, Hideo Kodama of Nagoya Municipal Industrial Research Institute invented two AM fabricating methods of a three-dimensional plastic model with photo-hardening polymer, where the UV exposure area is controlled by a mask pattern or the scanning fiber transmitter.<ref>Hideo Kodama, "A Scheme for Three-Dimensional Display by Automatic Fabrication of Three-Dimensional Model," IEICE TRANSACTIONS on Electronics (Japanese Edition), vol.J64-C, No.4, pp.237–241, April 1981</ref><ref>Hideo Kodama, "Automatic method for fabricating a three-dimensional plastic model with photo-hardening polymer," ''Review of Scientific Instruments'', Vol. 52, No. 11, pp. 1770–1773, November 1981</ref> Then in 1984, [[Chuck Hull]] of [[3D Systems]] Corporation<ref name="AutoSQ-1" /> developed a prototype system based on a process known as [[stereolithography]], in which layers are added by curing [[photopolymers]] with [[ultraviolet light]] [[lasers]]. Hull defined the process as a "system for generating three-dimensional objects by creating a cross-sectional pattern of the object to be formed,"<ref name="AutoSQ-4" /><ref name="AutoSQ-5" /> but this had been already invented by Kodama. Hull's contribution is the design of the [[STL (file format)|STL (STereoLithography) file format]] widely accepted by 3D printing software as well as the digital slicing and infill strategies common to many processes today. The term ''3D printing'' originally referred to a process employing standard and custom [[inkjet]] print heads. The technology used by most 3D printers to date—especially hobbyist and consumer-oriented models—is [[fused deposition modeling]], a special application of plastic [[extrusion]]. |

|||

[[File:DanielColladon's Lightfountain or Lightpipe,LaNature(magazine),1884.JPG|thumb|[[Jean-Daniel Colladon|Daniel Colladon]] first described this “light fountain” or “light pipe” in an 1842 article titled ''On the reflections of a ray of light inside a parabolic liquid stream''. This particular illustration comes from a later article by Colladon, in 1884.]] |

|||

AM processes for metal sintering or melting (such as [[selective laser sintering]], [[direct metal laser sintering]], and [[selective laser melting]]) usually went by their own individual names in the 1980s and 1990s. At the time, nearly all metal working was produced by [[casting]], [[metal fabrication|fabrication]], [[stamping (metalworking)|stamping]], and [[machining]]; although plenty of [[automation]] was applied to those technologies (such as by [[robot welding]] and [[numerical control|CNC]]), the idea of a tool or head moving through a 3D work envelope transforming a mass of raw material into a desired shape layer by layer was associated by most people only with processes that removed metal (rather than adding it), such as CNC [[milling (machining)|milling]], CNC [[electrical discharge machining|EDM]], and many others. But AM-type sintering was beginning to challenge that assumption. By the mid 1990s, new techniques for material deposition were developed at [[Stanford]] and [[Carnegie Mellon University]], including microcasting<ref>{{cite journal |title=Shape Deposition Manufacturing With Microcasting: Processing, Thermal and Mechanical Issues |journal=Journal of Manufacturing Science and Engineering |date=1998 |last=Amon |first=C. H. |last2=Beuth |first2=J. L. |last3=Weiss |first3=L. E. |last4=Merz |first4=R. |last5=Prinz |first5=F. B. |volume=120 |issue=3 |url=http://repository.cmu.edu/cgi/viewcontent.cgi?article=1219&context=ece |format=PDF |accessdate=2014-12-20}}</ref> and sprayed materials.<ref>{{cite journal |title=Manufacturing Mechatronics Using Thermal Spray Shape Deposition |journal=Proceedings of the 1992 Solid Freeform Fabrication Symposium |date=1992 |last=Beck |first=J.E. |last2=Fritz |first2=B. |last3=Siewiorek |first3=Daniel |last4=Weiss |first4=Lee |url=http://utwired.engr.utexas.edu/lff/symposium/proceedingsarchive/pubs/manuscripts/1992/1992-31-beck.pdf |format=PDF |accessdate=2014-12-20}}</ref> Sacrificial and support materials had also become more common, enabling new object geometries.<ref>{{cite conference |last=Prinz |first=F. B. |last2=Merz |first2=R. |last3=Weiss |first3=Lee |title=Building Parts You Could Not Build Before |conference=Proceedings of the 8th International Conference on Production Engineering |editor-last=Ikawa |editor-first=N. |publisher=Chapman & Hall |place=2-6 Boundary Row, London SE1 8HN, UK |date=1997 |pages=40–44}}</ref> |

|||

Guiding of light by refraction, the principle that makes fiber optics possible, was first demonstrated by [[Jean-Daniel Colladon|Daniel Colladon]] and [[Jacques Babinet]] in [[Paris]] in the early 1840s. [[John Tyndall]] included a demonstration of it in his public lectures in [[London]], 12 years later.<ref name=regis>{{cite book |

|||

|last =Bates |

|||

|first =Regis J |

|||

|title =Optical Switching and Networking Handbook |

|||

|publisher =McGraw-Hill |

|||

|year= 2001 |

|||

|location =New York |

|||

|isbn=0-07-137356-X |

|||

|page =10}}</ref> Tyndall also wrote about the property of [[total internal reflection]] in an introductory book about the nature of light in 1870: {{quote|When the light passes from air into water, the refracted ray is bent ''towards'' the [[perpendicular]]... When the ray passes from water to air it is bent ''from'' the perpendicular... If the angle which the ray in water encloses with the perpendicular to the surface be greater than 48 degrees, the ray will not quit the water at all: it will be ''totally reflected'' at the surface.... The angle which marks the limit where total reflection begins is called the limiting angle of the medium. For water this angle is 48°27′, for flint glass it is 38°41′, while for diamond it is 23°42′.<ref>{{cite book |

|||

|first=John |last=Tyndall |

|||

|year=1870 |title=Notes about Light |

|||

|chapter=Total Reflexion |

|||

|url=http://www.archive.org/details/notesofcourseofn00tyndrich}}</ref><ref>{{cite web |

|||

|first=John |last=Tyndall |

|||

|year=1873 |

|||

|title=Six Lectures on Light |

|||

|url=http://www.archive.org/details/sixlecturesonlig00tynduoft}}</ref>}} Unpigmented human hairs have also been shown to act as an optical fiber.<ref>{{cite journal|author=Wells, J.|issue=6210|pmid=2918918|doi=10.1038/338023b0|title=Hair light guide|journal= Nature|volume= 338|page= 23|year=1989|bibcode = 1989Natur.338...23W }}</ref> |

|||

The [[umbrella term]] ''additive manufacturing'' gained wider currency in the [[2000s (decade)|decade of the 2000s]].<ref name="Ngram_additive_manufacturing" /> As the various additive processes matured, it became clear that soon metal removal would no longer be the only metalworking process done under that type of control (a tool or head moving through a 3D work envelope transforming a mass of raw material into a desired shape layer by layer). It was during this decade that the term ''subtractive manufacturing'' appeared as a [[retronym]] for the large family of machining processes with metal removal as their common theme. However, at the time, the term ''3D printing'' still referred only to the polymer technologies in most minds, and the term ''AM'' was likelier to be used in metalworking contexts than among polymer/inkjet/stereolithography enthusiasts. The term ''subtractive'' has not replaced the term ''machining'', instead [[wikt:complement#Verb|complementing]] it when a term that covers any removal method is needed. |

|||

Practical applications, such as close internal illumination during dentistry, appeared early in the twentieth century. Image transmission through tubes was demonstrated independently by the radio experimenter [[Clarence Hansell]] and the television pioneer [[John Logie Baird]] in the 1920s. The principle was first used for internal medical examinations by [[Heinrich Lamm]] in the following decade. Modern optical fibers, where the glass fiber is coated with a transparent cladding to offer a more suitable [[refractive index]], appeared later in the decade.<ref name=regis/> Development then focused on fiber bundles for image transmission. [[Harold Hopkins (physicist)|Harold Hopkins]] and [[Narinder Singh Kapany]] at [[Imperial College]] in London achieved low-loss light transmission through a 75 cm long bundle which combined several thousand fibers. Their article titled "A flexible fibrescope, using static scanning" was published in the journal ''Nature'' in 1954.<ref>{{cite journal|author=Hopkins, H. H. and Kapany, N. S. |journal=Nature|doi=10.1038/173039b0 |volume=173|pages= 39–41 |year=1954|title=A flexible fibrescope, using static scanning|issue=4392|bibcode = 1954Natur.173...39H }}</ref><ref>[http://web.archive.org/web/20110629061117/http://nobelprize.org/nobel_prizes/physics/laureates/2009/sciback_phy_09.pdf Two Revolutionary Optical Technologies]. Scientific Background on the Nobel Prize in Physics 2009. Nobelprize.org. 6 October 2009</ref> The first fiber optic semi-flexible [[gastroscope]] was patented by [[Basil Hirschowitz]], C. Wilbur Peters, and Lawrence E. Curtiss, researchers at the [[University of Michigan]], in 1956. In the process of developing the gastroscope, Curtiss produced the first glass-clad fibers; previous optical fibers had relied on air or impractical oils and waxes as the low-index cladding material. |

|||

By the early 2010s, the terms ''3D printing'' and ''additive manufacturing'' developed [[word sense|senses]] in which they were [[synonym]]ous umbrella terms for all AM technologies. Although this was a departure from their earlier technically narrower senses, it reflects the simple fact that the technologies all share the common theme of sequential-layer material addition/joining throughout a 3D work envelope under automated control. (Other terms that have appeared, which are usually used as AM synonyms (although sometimes as [[hyponymy and hypernymy|hypernyms]]), have been ''desktop manufacturing'', ''rapid manufacturing'' [as the logical production-level successor to ''[[rapid prototyping]]''], and ''on-demand manufacturing'' [which echoes ''[[print on demand|on-demand printing]]'' in the 2D sense of ''printing''].) The 2010s were the first decade in which metal parts such as engine brackets<ref name="GrabCAD_GE_bracket" /> and large nuts<ref name="AutoSQ-6" /> would be grown (either before or instead of machining) in [[job production]] rather than [[wikt:obligate#Adjective|obligately]] being machined from [[bar stock]] or plate. |

|||

A variety of other image transmission applications soon followed. |

|||

As technology matured, several authors had begun to speculate that 3D printing could aid in [[sustainable development]] in the developing world.<ref name="Auto3D-27" /><ref name="AutoSQ-25" /><ref>{{cite journal|title=3D Printing: Developing Countries Perspectives|url=http://arxiv.org/abs/1410.5349|journal=International Journal of Computer Applications|date=2014-10-18|issn=09758887|pages=30–34|volume=104|issue=11|doi=10.5120/18249-9329|first=Fredrick R.|last=Ishengoma|first2=Adam B.|last2=Mtaho|arxiv=1410.5349}}</ref> |

|||

In 1880 [[Alexander Graham Bell]] and [[Charles Sumner Tainter|Sumner Tainter]] invented the [[Photophone]] at the [[Volta Laboratory and Bureau|Volta Laboratory]] in Washington, D.C., to transmit voice signals over an optical beam.<ref name="SDU">Jones, Newell. [http://web.archive.org/web/20060904235846/http://history.sandiego.edu/gen/recording/ar304.html First 'Radio' Built by San Diego Resident Partner of Inventor of Telephone: Keeps Notebook of Experiences With Bell], San Diego Evening Tribune, July 31, 1937.</ref> It was an advanced form of telecommunications, but subject to atmospheric interferences and impractical until the secure transport of light that would be offered by fiber-optical systems. In the late 19th and early 20th centuries, light was guided through bent glass rods to illuminate body cavities.<ref>[http://inventors.about.com/library/weekly/aa980407.htm The Birth of Fiber Optics]. inventors.about.com</ref> [[Jun-ichi Nishizawa]], a Japanese scientist at [[Tohoku University]], also proposed the use of optical fibers for communications in 1963, as stated in his book published in 2004 in [[India]].<ref name=Bhat>{{cite book |

|||

|editor=Bhat, K. N. and DasGupta, Amitava |

|||

|title = Physics of semiconductor devices |

|||

|publisher =Narosa Publishing House |

|||

|year= 2004 |

|||

|location =New Delhi, India |

|||

|chapter=Terahertz wave generation and light amplification using Raman effect |

|||

|author=Nishizawa, Jun-ichi and Suto, Ken |

|||

|url =http://books.google.com/?id=2NTpSnfhResC&pg=PA27 |

|||

|isbn =81-7319-567-6 |

|||

|page =27}}</ref> Nishizawa invented other technologies that contributed to the development of optical fiber communications, such as the graded-index optical fiber as a channel for transmitting light from semiconductor lasers.<ref name="Sendai New">{{cite web |

|||

|work=Sendai New |

|||

|title=Optical Fiber |

|||

|url=http://web.archive.org/web/20090929124200/http://www.city.sendai.jp/soumu/kouhou/s-new-e6/page01.html |

|||

|accessdate=April 5, 2009}}</ref><ref name=IEEE>{{cite web |

|||

|work=Institute of Electrical and Electronics Engineers |

|||

|title=New Medal Honors Japanese Microelectrics Industry Leader |

|||

|url=http://www.ieee.org/portal/site/tionline/menuitem.130a3558587d56e8fb2275875bac26c8/index.jsp?&pName=institute_level1_article&TheCat=1003&article=tionline/legacy/inst2003/jun03/6w.nishizawa.xml&}}</ref> |

|||

The first working fiber-optical data transmission system was demonstrated by German physicist [[Manfred Börner]] at [[Telefunken]] Research Labs in Ulm in 1965, which was followed by the first patent application for this technology in 1966.<ref>{{cite patent | country = DE | number = 1254513 | status = patent | title = Mehrstufiges Übertragungssystem für Pulscodemodulation dargestellte Nachrichten. | gdate = 1967-11-16 | inventor = Börner, Manfred | assign1 = Telefunken Patentverwertungsgesellschaft m.b.H.}}</ref><ref>{{cite patent | country = US | number = 3845293 | status = patent | title = Electro-optical transmission system utilizing lasers| inventor = Börner, Manfred }}</ref> [[Charles K. Kao]] and [[George A. Hockham]] of the British company [[Standard Telephones and Cables]] (STC) were the first to promote the idea that the [[attenuation]] in optical fibers could be reduced below 20 [[decibel]]s per kilometer (dB/km), making fibers a practical communication medium.<ref name=hecht1999>{{cite book |

|||

|last= Hecht |

|||

|first= Jeff |

|||

|title= City of Light, The Story of Fiber Optics |

|||

|publisher= [[Oxford University Press]] |

|||

|location= New York |

|||

|year= 1999 |

|||

|url=http://books.google.com/?id=4oMu7RbGpqUC&pg=PA114 |

|||

|isbn= 0-19-510818-3 |

|||

|page=114}}</ref> They proposed that the attenuation in fibers available at the time was caused by impurities that could be removed, rather than by fundamental physical effects such as scattering. They correctly and systematically theorized the light-loss properties for optical fiber, and pointed out the right material to use for such fibers — silica glass with high purity. This discovery earned Kao the [[Nobel Prize in Physics]] in 2009.<ref>{{cite web |url=http://nobelprize.org/nobel_prizes/physics/laureates/2009/press.html|title=Press Release — Nobel Prize in Physics 2009|publisher=The Nobel Foundation|accessdate=2009-10-07}}</ref> |

|||

== General principles == |

|||

NASA used fiber optics in the television cameras that were sent to the moon. At the time, the use in the cameras was classified ''confidential'', and only those with sufficient security clearance or those accompanied by someone with the right security clearance were permitted to handle the cameras.<ref>[http://history.nasa.gov/alsj/MSC-SESD-28-105.pdf Lunar Television Camera. Pre-installation Acceptance Test Plan]. NASA. 12 March 1968</ref> |

|||

=== Modeling === |

|||

The crucial attenuation limit of 20 dB/km was first achieved in 1970, by researchers [[Robert D. Maurer]], [[Donald Keck]], [[Peter C. Schultz]], and Frank Zimar working for American glass maker Corning Glass Works, now [[Corning Incorporated]]. They demonstrated a fiber with 17 dB/km attenuation by [[doping (semiconductor)|doping]] [[silica glass]] with [[titanium]]. A few years later they produced a fiber with only 4 dB/km attenuation using [[germanium dioxide]] as the core dopant. Such low attenuation ushered in the era of optical fiber telecommunication. In 1981, [[General Electric]] produced fused [[quartz]] [[ingots]] that could be drawn into strands 25 miles (40 km) long.<ref>{{cite web |url=http://www.ge.com/innovation/timeline/eras/continuing_tradition.html |title=1971–1985 Continuing the Tradition |work=GE Innovation Timeline |publisher=General Electric Company |accessdate=2012-09-28}}</ref> |

|||

{{Main|3D modeling}} |

|||

3D printable models may be created with a [[computer aided design]] (CAD) package, via a [[3D scanner#Hand-held laser scanners|3D scanner]] or by a plain digital camera and [[photogrammetry]] software. 3D printed models created with CAD results in reduced errors and can be corrected before printing, allowing verification in the design of the object before it is printed.<ref name="Jacobs">{{Cite book|title = Rapid Prototyping & Manufacturing: Fundamentals of Stereolithography|url = https://books.google.com/books?id=HvcN0w1VyxwC|publisher = Society of Manufacturing Engineers|date = 1992-01-01|isbn = 9780872634251|first = Paul Francis|last = Jacobs}}</ref>[[File:84530877 FillingSys (9415669149).jpg|thumb|300px|CAD model used for 3D printing]]The manual modeling process of preparing geometric data for 3D computer graphics is similar to plastic arts such as sculpting. 3D scanning is a process of collecting digital data on the shape and appearance of a real object, creating a digital model based on it. |

|||

=== Printing === |

|||

Attenuation in modern optical cables is far less than in electrical copper cables, leading to long-haul fiber connections with repeater distances of {{convert|70|–|150|km|mi|sp=us}}. The [[erbium-doped fiber amplifier]], which reduced the cost of long-distance fiber systems by reducing or eliminating optical-electrical-optical repeaters, was co-developed by teams led by [[David N. Payne]] of the [[University of Southampton]] and [[Emmanuel Desurvire]] at [[Bell Labs]] in 1986. Robust modern optical fiber uses glass for both core and sheath, and is therefore less prone to aging. It was invented by Gerhard Bernsee of [[Schott AG|Schott Glass]] in [[Germany]] in 1973.<ref>Bernsee, Gerhard (June 29, 1976) "Light conducting fibers of quartz glass" {{US patent|3966300}}</ref> |

|||

[[File:Hyperboloid Print.ogv|300px|thumb|[[Time-lapse photography|Timelapse]] video of a [[hyperboloid]] object (designed by [[George W. Hart]]) made of [[Polylactic acid|PLA]] using a RepRap "Prusa Mendel" 3 printer for molten polymer deposition]] |

|||

Before printing a 3D model from an [[STL (file format)|STL]] file, it must first be examined for "manifold errors". This step being called the "fixup."{{citation needed|date=August 2015}} Generally STLs that have been produced from a model obtained through [[3D scanner|3D scanning]] often have many manifold errors in them that need to be rectified. Examples of these errors are surfaces that do not connect, or gaps in the models.{{citation needed|date=August 2015}} |

|||

Once completed, the STL file needs to be processed by a piece of software called a "slicer," which converts the model into a series of thin layers and produces a [[G-code]] file containing instructions tailored to a specific type of 3D printer ([[Fused deposition modeling|FDM printers]]).{{citation needed|date=August 2015}} This G-code file can then be printed with 3D printing client software (which loads the G-code, and uses it to instruct the 3D printer during the 3D printing process).{{citation needed|date=August 2015}} |

|||

The emerging field of [[photonic crystal]]s led to the development in 1991 of [[photonic-crystal fiber]],<ref>{{cite journal |

|||

|journal=Science |

|||

|year=2003 |

|||

|volume=299 |

|||

|title=Photonic Crystal Fibers |

|||

|author=Russell, Philip |

|||

|doi=10.1126/science.1079280 |

|||

|pages=358–62 |

|||

|pmid=12532007 |

|||

|issue=5605|bibcode = 2003Sci...299..358R }}</ref> which guides light by [[diffraction]] from a periodic structure, rather than by total internal reflection. The first photonic crystal fibers became commercially available in 2000.<ref>{{cite web |

|||

|url=http://www.crystal-fiber.com/ |

|||

|accessdate=2008-10-22 |

|||

|title=The History of Crystal fiber A/S |

|||

|publisher=Crystal Fiber A/S}}</ref> Photonic crystal fibers can carry higher power than conventional fibers and their wavelength-dependent properties can be manipulated to improve performance. |

|||

Printer resolution describes layer thickness and X-Y resolution in [[dots per inch]] (dpi) or [[micrometer]]s (µm). Typical layer thickness is around {{convert|100|pitch|dpi|lk=on}}, although some machines can print layers as thin as {{convert|16|pitch|dpi}}.<ref name="Auto3D-17" /> X-Y resolution is comparable to that of laser printers. The particles (3D dots) are around {{convert|50|to|100|pitch|dpi}} in diameter.{{citation needed|date=August 2015}} |

|||

==Uses== |

|||

Construction of a model with contemporary methods can take anywhere from several hours to several days, depending on the method used and the size and complexity of the model. Additive systems can typically reduce this time to a few hours, although it varies widely depending on the type of machine used and the size and number of models being produced simultaneously.{{citation needed|date=October 2015}} |

|||

===Communication=== |

|||

{{Main|Fiber-optic communication}} |

|||

Optical fiber can be used as a medium for telecommunication and [[computer network]]ing because it is flexible and can be bundled as [[cables]]. It is especially advantageous for long-distance communications, because light propagates through the fiber with little attenuation compared to electrical cables. This allows long distances to be spanned with few [[optical communications repeater|repeater]]s. |

|||

Traditional techniques like [[injection moulding]] can be less expensive for manufacturing polymer products in high quantities, but additive manufacturing can be faster, more flexible and less expensive when producing relatively small quantities of parts. 3D printers give designers and concept development teams the ability to produce parts and concept models using a desktop size printer.{{citation needed|date=October 2015}} |

|||

The per-channel light signals propagating in the fiber have been modulated at rates as high as 111 [[gigabit per second|gigabits per second]] (Gbit/s) by [[Nippon Telegraph and Telephone|NTT]],<ref>[http://www.ntt.co.jp/news/news06e/0609/060929a.html 14 Tbps over a Single Optical Fiber]: Successful Demonstration of World's Largest Capacity – 145 digital high-definition movies transmitted in one second. NTT Press Release. September 29, 2006.</ref><ref>{{Cite news|author = Alfiad, M. S.|year = 2008|title = 111 Gb/s POLMUX-RZ-DQPSK Transmission over 1140 km of SSMF with 10.7 Gb/s NRZ-OOK Neighbours| periodical = Proceedings ECOC 2008|pages =Mo.4.E.2|url=https://w3.tue.nl/fileadmin/ele/TTE/ECO/Files/Pubs_2009/Alfiad_OFC_09_OThR4.pdf|display-authors=etal}}</ref> although 10 or 40 Gbit/s is typical in deployed systems.<ref>Yao, S. (2003) [http://www.generalphotonics.com/pdf/PSReprint.pdf "Polarization in Fiber Systems: Squeezing Out More Bandwidth"], The Photonics Handbook, Laurin Publishing, p. 1.</ref><ref>[http://www.ciena.com/news/news_2007pr_6976.htm Ciena, ''JANET Delivers Europe’s First 40 Gbps Wavelength Service''] 07/09/2007. Retrieved 29 Oct 2009.</ref> In June 2013, researchers demonstrated transmission of 400 Gbit/s over a single channel using 4-mode [[orbital angular momentum multiplexing]].<ref>{{Cite journal | last1 = Bozinovic | first1 = N. | last2 = Yue | first2 = Y. | last3 = Ren | first3 = Y. | last4 = Tur | first4 = M. | last5 = Kristensen | first5 = P. | last6 = Huang | first6 = H. | last7 = Willner | first7 = A. E. | last8 = Ramachandran | first8 = S. | doi = 10.1126/science.1237861 | title = Terabit-Scale Orbital Angular Momentum Mode Division Multiplexing in Fibers | journal = Science | volume = 340 | issue = 6140 | pages = 1545 | year = 2013 | pmid = | pmc = }}</ref> |

|||

=== Finishing === |

|||

Each fiber can carry many independent channels, each using a different wavelength of light ([[wavelength-division multiplexing]] (WDM)). The net data rate (data rate without overhead bytes) per fiber is the per-channel data rate reduced by the FEC overhead, multiplied by the number of channels (usually up to eighty in commercial [[dense WDM]] systems {{As of|2008|lc=on}}). {{As of|2011}} the record for bandwidth on a single core was 101 Tbit/s (370 channels at 273 Gbit/s each).<ref>{{cite journal |

|||

Though the printer-produced resolution is sufficient for many applications, printing a slightly oversized version of the desired object in standard resolution and then removing material<ref name="smooth" /> with a higher-resolution subtractive process can achieve greater precision. |

|||

| title = Ultrafast fibre optics set new speed record |

|||

| journal=New Scientist |

|||

| volume=210 |

|||

| issue=2809 |

|||

| pages=24 |

|||

| date = 2011-04-29 |

|||

| url = http://www.newscientist.com/article/mg21028095.500-ultrafast-fibre-optics-set-new-speed-record.html |

|||

| accessdate = 2012-02-26| bibcode=2011NewSc.210R..24H |

|||

| author1=Hecht |

|||

| first1=Jeff |

|||

| doi=10.1016/S0262-4079(11)60912-3 |

|||

}}</ref> |

|||

The record for a multi-core fiber as of January 2013 was 1.05 petabits per second. |

|||

<ref>{{cite web |

|||

| title = NEC and Corning achieve petabit optical transmission |

|||

| publisher = Optics.org |

|||

| date = 2013-01-22 |

|||

| url = http://optics.org/news/4/1/29 |

|||

| accessdate = 2013-01-23}}</ref> |

|||

In 2009, Bell Labs broke the 100 (petabit per second)×kilometer barrier (15.5 Tbit/s over a single 7,000 km fiber).<ref>[http://www.physorg.com/news173455192.html/ Bell Labs breaks optical transmission record, 100 Petabit per second kilometer barrier]. Physorg. September 29, 2009</ref> |

|||

Some printable polymers allow the surface finish to be smoothed and improved using chemical vapor processes.{{citation needed|date=August 2015}} |

|||

For short distance application, such as a network in an office building, fiber-optic cabling can save space in cable ducts. This is because a single fiber can carry much more data than electrical cables such as standard [[Cat-5|category 5]] Ethernet cabling, which typically runs at 100 Mbit/s or 1 Gbit/s speeds. Fiber is also immune to electrical interference; there is no cross-talk between signals in different cables, and no pickup of environmental noise. Non-armored fiber cables do not conduct electricity, which makes fiber a good solution for protecting communications equipment in [[high voltage]] environments, such as [[power generation]] facilities, or metal communication structures prone to [[lightning]] strikes. They can also be used in environments where explosive fumes are present, without danger of ignition. [[Wiretapping]] (in this case, [[fiber tapping]]) is more difficult compared to electrical connections, and there are concentric dual-core fibers that are said to be tap-proof.<ref name="Siemens Fiber Optics">[http://www.automation.siemens.com/net/html_76/produkte/040_ie_fc_glasleitungen.htm Siemen's claim to a fiber optic line that cannot be tapped]. Retrieved 18 Dec 2009.</ref> |

|||

Some additive manufacturing techniques are capable of using multiple materials in the course of constructing parts. These techniques are able to print in multiple colors and color combinations simultaneously, and would not necessarily require painting. |

|||

Fibers are often also used for short-distance connections between devices. For example, most [[high-definition television]]s offer a digital audio optical connection. This allows the streaming of audio over light, using the [[TOSLINK]] protocol. |

|||

Some printing techniques require internal supports to be built for overhanging features during construction. These supports must be mechanically removed or dissolved upon completion of the print. |

|||

====Advantages over copper wiring==== |

|||

The advantages of optical fiber communication with respect to copper wire systems are: |

|||

All of the commercialized metal 3D printers involve cutting the metal component off of the metal substrate after deposition. A new process for the [[GMAW]] 3D printing allows for substrate surface modifications to remove [[aluminum]]<ref>{{cite journal |authors=Amberlee S. Haselhuhn, Eli J. Gooding, Alexandra G. Glover, Gerald C. Anzalone, Bas Wijnen, Paul G. Sanders, Joshua M. Pearce. |title=Substrate Release Mechanisms for Gas Metal Arc 3-D Aluminum Metal Printing |journal=3D Printing and Additive Manufacturing |volume=1 |issue=4 |pp=204–209 |year=2014 |doi=10.1089/3dp.2014.0015 |url=http://dx.doi.org/10.1089/3dp.2014.0015|doi-broken-date=2015-12-05 }}</ref> or [[steel]].<ref>Amberlee S. Haselhuhn, Bas Wijnen, Gerald C. Anzalone, Paul G. Sanders, Joshua M. Pearce, [https://www.academia.edu/14451546/In_Situ_Formation_of_Substrate_Release_Mechanisms_for_Gas_Metal_Arc_Weld_Metal_3-D_Printing In Situ Formation of Substrate Release Mechanisms for Gas Metal Arc Weld Metal 3-D Printing]. ''Journal of Materials Processing Technology''. 226, pp. 50–59 (2015) DOI: 10.1016/j.jmatprotec.2015.06.038 10.1016/j.jmatprotec.2015.06.038</ref> |

|||

;Broad bandwidth: A single optical fiber can carry over 3,000,000 full-duplex voice calls or 90,000 TV channels. |

|||

== Processes == |

|||

;Immunity to electromagnetic interference: Light transmission through optical fibers is unaffected by other [[electromagnetic radiation]] nearby. The optical fiber is electrically non-conductive, so it does not act as an antenna to pick up electromagnetic signals. Information traveling inside the optical fiber is immune to [[electromagnetic interference]], even [[electromagnetic pulse]]s generated by nuclear devices. |

|||

Several 3D printing processes have been invented since the late 1970s. The printers were originally large, expensive, and highly limited in what they could produce.<ref name="3D opp" /> |

|||

A large number of additive processes are now available. The main differences between processes are in the way layers are deposited to create parts and in the materials that are used. Some methods melt or soften the material to produce the layers, for example. [[selective laser melting]] (SLM) or [[direct metal laser sintering]] (DMLS), [[selective laser sintering]] (SLS), [[fused deposition modeling]] (FDM),<ref>FDM is a proprietary term owned by [[Stratasys]]. All 3-D printers that are not Stratasys machines and use a fused filament process are referred to as or fused filament fabrication (FFF).</ref> or fused filament fabrication (FFF), while others cure liquid materials using different sophisticated technologies, such as [[stereolithography]] (SLA). With [[laminated object manufacturing]] (LOM), thin layers are cut to shape and joined together (e.g., paper, polymer, metal). Each method has its own advantages and drawbacks, which is why some companies offer a choice of powder and polymer for the material used to build the object.<ref name="Auto3D-7" /> Others sometimes use standard, off-the-shelf business paper as the build material to produce a durable prototype. The main considerations in choosing a machine are generally speed, costs of the 3D printer, of the printed prototype, choice and cost of the materials, and color capabilities.<ref name="Auto3D-8" /> |

|||

;Low attenuation loss over long distances: Attenuation loss can be as low as 0.2 dB/km in optical fiber cables, allowing transmission over long distances without the need for [[repeater]]s. |

|||

Printers that work directly with metals are generally expensive. However less expensive printers can be used to make a mold, which is then used to make metal parts.<ref name="Auto3D-9" /> |

|||

;Electrical insulator: Optical fibers do not conduct electricity, preventing problems with [[Ground loop (electricity)|ground loop]]s and conduction of [[lightning]]. Optical fibers can be strung on poles alongside high voltage power cables. |

|||

{|class="wikitable" |

|||

;Material cost and theft prevention: Conventional cable systems use large amounts of copper. In some places, this copper is a target for theft due to its value on the scrap market. |

|||

|- |

|||

! Type |

|||

! Technologies |

|||

! Materials |

|||

|- |

|||

|rowspan="2"| Extrusion |

|||

| [[Fused deposition modeling]] (FDM) or [[Fused Filament Fabrication]] (FFF) |

|||

| [[Thermoplastics]], [[eutectic]] metals, edible materials, [[Rubber]]s, [[Modeling clay]], [[Plasticine]], [[Metal clay]] (including [[Precious Metal Clay]]) |

|||

|- |

|||

|[[Robocasting]] or Direct Ink Writing (DIW) |

|||

|[[Ceramic materials]], [[Metal alloy]], [[cermet]], [[metal matrix composite]], [[ceramic matrix composite]] |

|||

|- |

|||

|rowspan="2"| Light polymerized |

|||

| [[Stereolithography]] (SLA) |

|||

| [[Photopolymer]] |

|||

|- |

|||

| [[Digital Light Processing]] (DLP) |

|||

| Photopolymer |

|||

|- |

|||

|rowspan="6"| Powder Bed |

|||

| [[Powder bed and inkjet head 3D printing]] (3DP) |

|||

| Almost any [[metal alloy]], powdered polymers, [[Plaster]] |

|||

|- |

|||

| [[Electron-beam melting]] (EBM) |

|||

| Almost any [[metal alloy]] including [[Titanium alloy]]s |

|||

|- |

|||

| [[Selective laser melting]] (SLM) |

|||

| [[Titanium alloys]], [[Cobalt-chrome|Cobalt Chrome alloys]], [[Stainless Steel]], Aluminium |

|||

|- |

|||

| [[Selective heat sintering]] (SHS)<ref name="AutoSQ-14" /> |

|||

| Thermoplastic powder |

|||

|- |

|||

| [[Selective laser sintering]] (SLS) |

|||

| [[Thermoplastic]]s, [[Sintering#Sintering of metallic powders|metal powders]], [[Sintering#Ceramic sintering|ceramic powders]] |

|||

|- |

|||

| [[Direct metal laser sintering]] (DMLS) |

|||

| Almost any [[metal alloy]] |

|||

|- |

|||

| Laminated |

|||

| [[Laminated object manufacturing]] (LOM) |

|||

| Paper, [[metal foil]], [[plastic film]] |

|||

|- |

|||

|rowspan="2"| Wire |

|||

| [[Electron beam freeform fabrication]] (EBF<sup>3</sup>) |

|||

| Almost any [[metal alloy]] |

|||

|} |

|||

=== Extrusion deposition === |

|||

;Security of information passed down the cable: Copper can be tapped with very little chance of detection. |

|||

[[File:FDM by Zureks.png|thumb|Fused deposition modeling: 1 – nozzle ejecting molten material, 2 – deposited material (modeled part), 3 – controlled movable table]] |

|||

{{Main|Fused deposition modeling}} |

|||

[[File:Robot 3D print timelapse on RepRapPro Fisher.webm|thumb|A timelapse video of a robot model (logo of [[Make (magazine)|Make magazine]]) being printed using FDM on a RepRapPro Fisher printer.]] |

|||

Fused deposition modeling (FDM), derives from automatic polymeric foil hot air welding system, hot-melt glueing and automatic gasket deposition. Such principle has been further developed by [[S. Scott Crump]] in the late 1980s and was commercialized in 1990 by [[Stratasys]].<ref name="Auto3D-10" /> After the patent on this technology expired, a large open-source development community developed and both commercial and [[DIY]] variants utilizing this type of 3D printer appeared. As a result, the price of this technology has dropped by two orders of magnitude since its creation. |

|||

In fused deposition modeling the model or part is produced by extruding small beads of material which harden immediately to form layers. A [[thermoplastic]] filament or metal wire that is wound on a coil is unreeled to supply material to an [[extrusion]] nozzle head ([[3D printer extruder]]). The nozzle head heats the material and turns the flow on and off. Typically [[stepper motors]] or [[servo motors]] are employed to move the extrusion head and adjust the flow. The printer usually has 3 axes of motion. A [[computer-aided manufacturing]] (CAM) software package is used to generate the G-Code that is sent to a [[microcontroller]] which controls the motors. |

|||

===Sensors=== |

|||

{{Main|Fiber optic sensor}} |

|||

Fibers have many uses in remote sensing. In some applications, the sensor is itself an optical fiber. In other cases, fiber is used to connect a non-fiberoptic sensor to a measurement system. Depending on the application, fiber may be used because of its small size, or the fact that no [[electrical power]] is needed at the remote location, or because many sensors can be [[multiplexing|multiplexed]] along the length of a fiber by using different wavelengths of light for each sensor, or by sensing the time delay as light passes along the fiber through each sensor. Time delay can be determined using a device such as an ''[[optical time-domain reflectometer]]''. |

|||

Extrusion in 3D printing using material extrusion involves a [[cold end]] and a [[hot end]]. |

|||

Optical fibers can be used as sensors to measure [[deformation (mechanics)|strain]], [[temperature]], [[pressure]] and other quantities by modifying a fiber so that the property to measure modulates the [[intensity (physics)|intensity]], [[phase (waves)|phase]], [[polarization (waves)|polarization]], [[wavelength]], or transit time of light in the fiber. Sensors that vary the intensity of light are the simplest, since only a simple source and detector are required. A particularly useful feature of such fiber optic sensors is that they can, if required, provide distributed sensing over distances of up to one meter. In contrast, highly localized measurements can be provided by integrating miniaturized sensing elements with the tip of the fiber.<ref>{{Cite journal |

|||

| pmid = 24599822 |

|||

| year = 2014 |

|||

| author1 = Kostovski |

|||

| first1 = G |

|||

| title = The optical fiber tip: An inherently light-coupled microscopic platform for micro- and nanotechnologies |

|||

| journal = Advanced Materials |

|||

| volume = 26 |

|||

| issue = 23 |

|||

| pages = 3798–820 |

|||

| last2 = Stoddart |

|||

| first2 = P. R. |

|||

| last3 = Mitchell |

|||

| first3 = A |

|||

| doi = 10.1002/adma.201304605 |

|||

}}</ref> These can be implemented by various micro- and nanofabrication technologies, such that they do not exceed the microscopic boundary of the fiber tip, allowing such applications as insertion into blood vessels via hypodermic needle. |

|||

Various polymers are used, including [[acrylonitrile butadiene styrene]] (ABS), [[polycarbonate]] (PC), [[polylactic acid]] (PLA), [[high density polyethylene]] (HDPE), PC/ABS, [[polyphenylsulfone]] (PPSU) and [[high impact polystyrene]] (HIPS). In general, the polymer is in the form of a filament fabricated from virgin resins. There are multiple projects in the open-sourced community aimed at processing post-consumer plastic waste into filament. These involve machines used to shred and extrude the plastic material into filament. |

|||

Extrinsic fiber optic sensors use an [[optical fiber cable]], normally a multi-mode one, to transmit [[modulation|modulated]] light from either a non-fiber optical sensor—or an electronic sensor connected to an optical transmitter. A major benefit of extrinsic sensors is their ability to reach otherwise inaccessible places. An example is the measurement of temperature inside [[aircraft]] [[jet engine]]s by using a fiber to transmit [[radiation]] into a radiation [[pyrometer]] outside the engine. Extrinsic sensors can be used in the same way to measure the internal temperature of [[electrical transformer]]s, where the extreme [[electromagnetic field]]s present make other measurement techniques impossible. Extrinsic sensors measure vibration, rotation, displacement, velocity, acceleration, torque, and twisting. A solid state version of the gyroscope, using the interference of light, has been developed. The ''[[fiber optic gyroscope]] (FOG)'' has no moving parts, and exploits the ''[[Sagnac effect]]'' to detect mechanical rotation. |

|||

FDM is somewhat restricted in the variation of shapes that may be fabricated. For example, FDM usually cannot produce stalactite-like structures, since they would be unsupported during the build. Otherwise, a thin support must be designed into the structure which can be broken away during finishing. Fused deposition modeling is also referred to as fused filament fabrication (FFF) by companies who do not hold the original patents like Stratasys does. |

|||

Common uses for fiber optic sensors includes advanced intrusion detection security systems. The light is transmitted along a fiber optic sensor cable placed on a fence, pipeline, or communication cabling, and the returned signal is monitored and analyzed for disturbances. This return signal is digitally processed to detect disturbances and trip an alarm if an intrusion has occurred. |

|||

=== Binding of granular materials === |

|||

===Power transmission=== |

|||

Another 3D printing approach is the selective fusing of materials in a granular bed. The technique fuses parts of the layer and then moves downward in the working area, adding another layer of granules and repeating the process until the piece has built up. This process uses the unfused media to support overhangs and thin walls in the part being produced, which reduces the need for temporary auxiliary supports for the piece. A laser is typically used to [[sintering|sinter]] the media into a solid. Examples include [[selective laser sintering]] (SLS), with both metals and polymers (e.g., PA, PA-GF, Rigid GF, PEEK, PS, [[Alumide]], Carbonmide, elastomers), and [[direct metal laser sintering]] (DMLS).<ref name="DMLS" /> |

|||

Optical fiber can be used to transmit power using a [[photovoltaic cell]] to convert the light into electricity.<ref>[http://spectrum.ieee.org/energy/the-smarter-grid/electricity-over-glass IEEE Spectrum: Electricity Over Glass]. IEEE Spectrum. October 2005</ref> While this method of power transmission is not as efficient as conventional ones, it is especially useful in situations where it is desirable not to have a metallic conductor as in the case of use near MRI machines, which produce strong magnetic fields.<ref>[http://www2.electronicproducts.com/Photovoltaic_feat_advances_power_over_optical_fiber-article-olap01-jun2006-html.aspx Photovoltaic feat advances power over optical fiber – Electronic Products]. 06/01/2006</ref> Other examples are for powering electronics in high-powered antenna elements and measurement devices used in high-voltage transmission equipment. |

|||

[[Selective laser sintering|Selective Laser Sintering]] (SLS) was developed and patented by Dr. Carl Deckard and Dr. Joseph Beaman at the [[University of Texas at Austin]] in the mid-1980s, under sponsorship of [[DARPA]].<ref name="Auto3D-3" /> A similar process was patented without being commercialized by R. F. Housholder in 1979.<ref name="Auto3D-4" /> |

|||

===Other uses=== |

|||

[[File:Flashflight red.jpg|thumb|A [[frisbee]] illuminated by fiber optics]] |

|||

[[File:OpticFiber.jpg|thumb|left|Light reflected from optical fiber illuminates exhibited model]] |

|||

[[Selective laser melting]] (SLM) does not use sintering for the fusion of powder granules but will completely melt the powder using a high-energy laser to create fully dense materials in a layer-wise method that has mechanical properties similar to those of conventional manufactured metals. |

|||

Optical fibers have a wide number of applications. They are used as [[light tube|light guide]]s in medical and other applications where bright light needs to be shone on a target without a clear line-of-sight path. In some buildings, optical fibers route sunlight from the roof to other parts of the building (see [[nonimaging optics]]). [[Optical fiber lamp]]s are used for illumination in decorative applications, including [[Commercial signage|sign]]s, [[art]], toys and artificial [[Christmas tree]]s. [[Swarovski]] boutiques use optical fibers to illuminate their crystal showcases from many different angles while only employing one light source. Optical fiber is an intrinsic part of the light-transmitting concrete building product, [[LiTraCon]]. |

|||

[[Electron beam melting]] (EBM) is a similar type of additive manufacturing technology for metal parts (e.g. [[titanium alloy]]s). EBM manufactures parts by melting metal powder layer by layer with an electron beam in a high vacuum. Unlike metal sintering techniques that operate below melting point, EBM parts void-freeR.<ref name="Auto3D-12" /><ref name="Auto3D-13" /> |

|||

[[File:Use of optical fiber in a lamp..JPG|thumb|Use of optical fiber in a decorative lamp or nightlight.]] |

|||

Optical fiber is also used in imaging optics. A coherent bundle of fibers is used, sometimes along with lenses, for a long, thin imaging device called an [[endoscope]], which is used to view objects through a small hole. Medical endoscopes are used for minimally invasive exploratory or surgical procedures. Industrial endoscopes (see [[fiberscope]] or [[borescope]]) are used for inspecting anything hard to reach, such as jet engine interiors. Many [[microscopes]] use fiber-optic light sources to provide intense illumination of samples being studied. |

|||

Another method consists of an [[Powder bed and inkjet head 3D printing|inkjet 3D printing]] system. The printer creates the model one layer at a time by spreading a layer of powder ([[plaster]], or [[resin]]s) and printing a binder in the cross-section of the part using an inkjet-like process. This is repeated until every layer has been printed. This technology allows the printing of full color prototypes, overhangs, and elastomer parts. The strength of bonded powder prints can be enhanced with wax or [[thermoset]] polymer impregnation. |

|||

In [[spectroscopy]], optical fiber bundles transmit light from a spectrometer to a substance that cannot be placed inside the spectrometer itself, in order to analyze its composition. A spectrometer analyzes substances by bouncing light off and through them. By using fibers, a spectrometer can be used to study objects remotely.<ref>{{cite journal |title=In situ real-time monitoring of a fermentation reaction using a fiber-optic FT-IR probe |journal=Spectroscopy |date=June 2001 |first=Zaid |last=Al Mosheky |author2=Melling, Peter J. |author3=Thomson, Mary A. |url=http://www.remspec.com/pdfs/SP5619.pdf |format=PDF|volume= 16|issue =6|page=15}}</ref><ref>{{cite journal |title=Reaction monitoring in small reactors and tight spaces |first=Peter |last=Melling |author2=Thomson, Mary |journal=American Laboratory News |date=October 2002 |url=http://www.remspec.com/pdfs/amlab1002.pdf |format=PDF}}</ref><ref>{{cite book |chapter=Fiber-optic probes for mid-infrared spectrometry |first=Peter J. |last=Melling |author2=Thomson, Mary |title=Handbook of Vibrational Spectroscopy |editors=Chalmers, John M.; Griffiths, Peter R. (eds.)|publisher=Wiley |year=2002 |url=http://www.remspec.com/pdfs/2703_o.pdf |format=PDF}}</ref> |

|||

=== Lamination === |

|||

An optical fiber [[dopant|doped]] with certain [[rare earth element]]s such as [[erbium]] can be used as the [[gain medium]] of a [[fiber laser|laser]] or [[optical amplifier]]. Rare-earth-doped optical fibers can be used to provide signal [[amplifier|amplification]] by splicing a short section of doped fiber into a regular (undoped) optical fiber line. The doped fiber is [[optical pumping|optically pumped]] with a second laser wavelength that is coupled into the line in addition to the signal wave. Both wavelengths of light are transmitted through the doped fiber, which transfers energy from the second pump wavelength to the signal wave. The process that causes the amplification is [[stimulated emission]]. |

|||

{{Main|Laminated object manufacturing}} |

|||

In some printers, paper can be used as the build material, resulting in a lower cost to print. During the 1990s some companies marketed printers that cut cross sections out of special adhesive coated paper using a carbon dioxide laser and then laminated them together. |

|||

In 2005 [[Mcor Technologies Ltd]] developed a different process using ordinary sheets of office paper, a [[tungsten carbide]] blade to cut the shape, and selective deposition of adhesive and pressure to bond the prototype.<ref name="AutoSQ-15" /> |

|||

Optical fiber is also widely exploited as a nonlinear medium. The glass medium supports a host of nonlinear optical interactions, and the long interaction lengths possible in fiber facilitate a variety of phenomena, which are harnessed for applications and fundamental investigation.<ref name="Agrawal2012">{{Cite book | isbn = 0123970237 | title = Nonlinear Fiber Optics, Fifth Edition | last1 = Govind | first1 = Agrawal | year = <!--replace this comment with the publication year--> | pages = }}</ref> Conversely, fiber nonlinearity can have deleterious effects on optical signals, and measures are often required to minimize such unwanted effects. |

|||

There are also a number of companies selling printers that print laminated objects using thin plastic and metal sheets. |

|||

Optical fibers doped with a [[wavelength shifter]] collect [[scintillator|scintillation]] light in [[physics experiment]]s. |

|||

=== Photopolymerization === |

|||

[[Iron sights#Fiber optic|Fiber optic sight]]s for handguns, rifles, and shotguns use pieces of optical fiber to improve visibility of markings on the sight. |

|||

[[File:Stereolithography apparatus.jpg|thumb|Stereolithography apparatus]] |

|||

{{Main|Stereolithography}} |

|||

Stereolithography was patented in 1986 by [[Chuck Hull]].<ref name="AutoSQ-16" /> [[Photopolymerization]] is primarily used in stereolithography (SLA) to produce a solid part from a liquid. This process was a dramatic departure from the "[[photosculpture]]" method of [[François Willème]] (1830–1905) developed in 1860 and the [[photopolymerization]] of Mitsubishi's Matsubara in 1974.<ref name="NSF RP Report" /> |

|||

The "photosculpture" method consisted of photographing a subject from a variety of equidistant angles and projecting each photograph onto a screen, where a [[pantograph]] was used to trace the outline onto modeling clay.<ref name="AutoSQ-17" /><ref name="AutoSQ-18" /><ref name="AutoSQ-19" /> In photo-polymerization, a vat of liquid polymer is exposed to controlled lighting under [[safelight]] conditions. The exposed liquid polymer hardens. Polymerization occurs when photopolymers are exposed to light when photopolymers contain [[chromophore]]s, otherwise, the addition of molecules that are photosensitive are utilized to react with the solution to begin polymerization. Polymerization of monomers lead to cross-linking, which creates a polymer. Through these [[Covalent bond|covalent]] bonds, the property of the solution is changed.<ref name="Jacobs"/> The build plate then moves down in small increments and the liquid polymer is again exposed to light. The process repeats until the model has been built. The liquid polymer is then drained from the vat, leaving the solid model. The [[EnvisionTEC]] ''Perfactory''<ref name="Auto3D-14" /> is an example of a DLP rapid prototyping system. |

|||

==Principle of operation== |

|||

[[File:Fiber-engineerguy.ogv|thumb|An overview of the operating principles of the optical fiber]] |

|||

An optical fiber is a cylindrical [[dielectric waveguide]] ([[insulator (electrical)|nonconducting]] waveguide) that transmits light along its axis, by the process of [[total internal reflection]]. The fiber consists of a ''core'' surrounded by a [[cladding (fiber optics)|cladding]] layer, both of which are made of [[dielectric]] materials. To confine the optical signal in the core, the [[refractive index]] of the core must be greater than that of the cladding. The boundary between the core and cladding may either be abrupt, in ''[[step-index profile|step-index fiber]]'', or gradual, in ''[[graded-index fiber]]''. |

|||

Inkjet printer systems like the ''Objet PolyJet'' system spray photopolymer materials onto a build tray in ultra-thin layers (between 16 and 30 µm) until the part is completed. Each photopolymer layer is [[Curing (chemistry)|cured]] with UV light after it is jetted, producing fully cured models that can be handled and used immediately, without post-curing. The gel-like support material, which is designed to support complicated geometries, is removed by hand and water jetting. It is also suitable for elastomers. |

|||

===Index of refraction=== |

|||

{{Main|Refractive index}} |

|||

The index of refraction (or refractive index) is a way of measuring the [[speed of light]] in a material. Light travels fastest in a [[vacuum]], such as in outer space. The speed of light in a vacuum is about 300,000 kilometers (186,000 miles) per second. The refractive index of a medium is calculated by dividing the speed of light in a vacuum by the speed of light in that medium. The refractive index of a vacuum is therefore 1, by definition. A typical singlemode fiber used for telecommunications has a cladding made of pure silica, with an index of 1.444 at 1,500 nm, and a core of doped silica with an index around 1.4475.<ref>{{cite web |title=Fibers |url=https://www.rp-photonics.com/fibers.html |work=[[Encyclopedia of Laser Physics and Technology]] |publisher=RP Photonics |first=Rüdiger |last=Paschotta |accessdate=Feb 22, 2015}}</ref> The larger the index of refraction, the slower light travels in that medium. From this information, a simple rule of thumb is that a signal using optical fiber for communication will travel at around 200,000 [[kilometers]] per second. To put it another way, the signal will take 5 [[milliseconds]] to travel 1,000 kilometers in fiber. Thus a phone call carried by fiber between Sydney and New York, a 16,000-kilometer distance, means that there is a minimum delay of 80 milliseconds (about <math>\tfrac {1}{12}</math> of a second) between when one caller speaks and the other hears. (The fiber in this case will probably travel a longer route, and there will be additional delays due to communication equipment switching and the process of encoding and decoding the voice onto the fiber). |

|||

Ultra-small features can be made with the 3D micro-fabrication technique used in [[two-photon absorption|multiphoton]] photopolymerisation. This approach uses a focused laser to trace the desired 3D object into a block of gel. Due to the nonlinear nature of photo excitation, the gel is cured to a solid only in the places where the laser was focused while the remaining gel is then washed away. Feature sizes of under 100 nm are easily produced, as well as complex structures with moving and interlocked parts.<ref name="Auto3D-15" /> |

|||

===Total internal reflection=== |

|||

{{Main|Total internal reflection}} |

|||

When light traveling in an optically dense medium hits a boundary at a steep angle (larger than the [[critical angle (optics)|critical angle]] for the boundary), the light is completely reflected. This is called total internal reflection. This effect is used in optical fibers to confine light in the core. Light travels through the fiber core, bouncing back and forth off the boundary between the core and cladding. Because the light must strike the boundary with an angle greater than the critical angle, only light that enters the fiber within a certain range of angles can travel down the fiber without leaking out. This range of angles is called the [[acceptance cone]] of the fiber. The size of this acceptance cone is a function of the refractive index difference between the fiber's core and cladding. |

|||

Yet another approach uses a synthetic resin that is solidified using [[LED]]s.<ref name="Auto3D-16" /> |

|||

In simpler terms, there is a maximum angle from the fiber axis at which light may enter the fiber so that it will propagate, or travel, in the core of the fiber. The [[sine]] of this maximum angle is the [[numerical aperture]] (NA) of the fiber. Fiber with a larger NA requires less precision to splice and work with than fiber with a smaller NA. Single-mode fiber has a small NA. |

|||

In Mask-image-projection-based stereolithography a 3D digital model is sliced by a set of horizontal planes. Each slice is converted into a two-dimensional mask image. The mask image is then projected onto a photocurable liquid resin surface and light is projected onto the resin to cure it in the shape of the layer.<ref name=k1113 /> The technique has been used to create objects composed of multiple materials that cure at different rates.<ref name=k1113 /> In research systems, the light is projected from below, allowing the resin to be quickly spread into uniform thin layers, reducing production time from hours to minutes.<ref name=k1113 /> Commercially available devices such as Objet Connex apply the resin via small nozzles.<ref name="k1113" /> |

|||

===Multi-mode fiber=== |

|||

[[File:Optical-fibre.svg|thumb|The propagation of light through a [[multi-mode optical fiber]].]] |

|||

[[File:Laser in fibre.jpg|thumb|A laser bouncing down an [[poly(methyl methacrylate)|acrylic]] rod, illustrating the total internal reflection of light in a multi-mode optical fiber.]] |

|||

{{Main|Multi-mode optical fiber}} |

|||

Fiber with large core diameter (greater than 10 micrometers) may be analyzed by [[geometrical optics]]. Such fiber is called ''multi-mode fiber'', from the electromagnetic analysis (see below). In a step-index multi-mode fiber, [[ray (optics)|rays]] of light are guided along the fiber core by total internal reflection. Rays that meet the core-cladding boundary at a high angle (measured relative to a line [[surface normal|normal]] to the boundary), greater than the [[critical angle (optics)|critical angle]] for this boundary, are completely reflected. The critical angle (minimum angle for total internal reflection) is determined by the difference in index of refraction between the core and cladding materials. Rays that meet the boundary at a low angle are refracted from the [[core (optical fiber)|core]] into the cladding, and do not convey light and hence information along the fiber. The critical angle determines the [[guided ray|acceptance angle]] of the fiber, often reported as a [[numerical aperture]]. A high numerical aperture allows light to propagate down the fiber in rays both close to the axis and at various angles, allowing efficient coupling of light into the fiber. However, this high numerical aperture increases the amount of [[dispersion (optics)|dispersion]] as rays at different angles have different [[optical path length|path lengths]] and therefore take different times to traverse the fiber. |

|||

=== Metal wire processes === |

|||

[[File:Optical fiber types.svg|thumb|Optical fiber types.]]In graded-index fiber, the index of refraction in the core decreases continuously between the axis and the cladding. This causes light rays to bend smoothly as they approach the cladding, rather than reflecting abruptly from the core-cladding boundary. The resulting curved paths reduce multi-path dispersion because high angle rays pass more through the lower-index periphery of the core, rather than the high-index center. The index profile is chosen to minimize the difference in axial propagation speeds of the various rays in the fiber. This ideal index profile is very close to a [[parabola|parabolic]] relationship between the index and the distance from the axis. |

|||

Laser-based wirefeed systems, such as Laser Metal Deposition-wire (LMD-w), feed wire through a nozzle that is melted by a laser using inert gas shielding in either an open environment (gas surrounding the laser), or in a sealed chamber. [[Electron beam freeform fabrication]] uses an electron beam heat source inside a vacuum chamber. |

|||

It is also possible to use conventional [[gas metal arc welding]] attached to a 3D stage to 3-D print metals such as steel and aluminum.<ref>Yuenyong Nilsiam, Amberlee Haselhuhn, Bas Wijnen, Paul Sanders, & Joshua M. Pearce. [https://www.academia.edu/17673716/Integrated_Voltage_Current_Monitoring_and_Control_of_Gas_Metal_Arc_Weld_Magnetic_Ball-Jointed_Open_Source_3-D_Printer Integrated Voltage - Current Monitoring and Control of Gas Metal Arc Weld Magnetic Ball-Jointed Open Source 3-D Printer].''Machines'' '''3'''(4), 339-351 (2015).</ref> Low-cost open source [[RepRap]]-style 3-D printers have been outfitted with [[Arduino]]-based [[sensors]] and demonstrated reasonable metallurgical properties from conventional welding wire as feedstock.<ref>A. Pinar, B. Wijnen, G. C. Anzalone, T. C. Havens, P. G. Sanders, J. M. Pearce. [https://www.academia.edu/15282691/Low-cost_Open-Source_Voltage_and_Current_Monitor_for_Gas_Metal_Arc_Weld_3-D_Printing Low-cost Open-Source Voltage and Current Monitor for Gas Metal Arc Weld 3-D Printing]. ''Journal of Sensors'' Vol. 2015, Article ID 876714, 8 pages, 2015.</ref> |

|||

===Single-mode fiber=== |

|||

[[File:Singlemode fibre structure.svg|thumb|The structure of a typical [[single-mode fiber]].<br /> |

|||

1. Core: 8 µm diameter<br /> |

|||

2. Cladding: 125 µm dia.<br /> |

|||

3. Buffer: 250 µm dia.<br /> |

|||

4. Jacket: 400 µm dia.]] |

|||

{{Main|Single-mode optical fiber}} |

|||

Fiber with a core diameter less than about ten times the [[wavelength]] of the propagating light cannot be modeled using geometric optics. Instead, it must be analyzed as an [[electromagnetism|electromagnetic]] structure, by solution of [[Maxwell's equations]] as reduced to the [[electromagnetic wave equation]]. The electromagnetic analysis may also be required to understand behaviors such as speckle that occur when [[coherence (physics)|coherent]] light propagates in multi-mode fiber. As an optical waveguide, the fiber supports one or more confined [[transverse mode]]s by which light can propagate along the fiber. Fiber supporting only one mode is called ''single-mode'' or ''mono-mode fiber''. The behavior of larger-core multi-mode fiber can also be modeled using the wave equation, which shows that such fiber supports more than one mode of propagation (hence the name). The results of such modeling of multi-mode fiber approximately agree with the predictions of geometric optics, if the fiber core is large enough to support more than a few modes. |

|||

== Printers == |

|||

The waveguide analysis shows that the light energy in the fiber is not completely confined in the core. Instead, especially in single-mode fibers, a significant fraction of the energy in the bound mode travels in the cladding as an [[evanescent wave]]. |

|||

=== Industry use === |

|||

The most common type of single-mode fiber has a core diameter of 8–10 micrometers and is designed for use in the [[near infrared]]. The mode structure depends on the wavelength of the light used, so that this fiber actually supports a small number of additional modes at visible wavelengths. Multi-mode fiber, by comparison, is manufactured with core diameters as small as 50 micrometers and as large as hundreds of micrometers. The [[normalized frequency (fiber optics)|normalized frequency]] ''V'' for this fiber should be less than the first zero of the [[Bessel function]] ''J''<sub>0</sub> (approximately 2.405). |

|||

{{expand section|date=August 2015}} |

|||

As October 2012, additive manufacturing systems were on the market that ranged from $2,000 to $500,000 in price and were employed in industries including aerospace, architecture, automotive, defense, and medical replacements, among many others. For example, [[General Electric]] uses the high-end model to build parts for [[turbine]]s.<ref name="cfr2013" /> Many of these systems are used for rapid prototyping, before mass production methods are employed. |

|||

=== Consumer use === |

|||

===Special-purpose fiber=== |

|||

[[File:RepRap 'Mendel'.jpg|thumb|[[RepRap Project|RepRap]] version 2.0 (Mendel)]] |

|||

Some special-purpose optical fiber is constructed with a non-cylindrical core and/or cladding layer, usually with an elliptical or rectangular cross-section. These include [[polarization-maintaining optical fiber|polarization-maintaining fiber]] and fiber designed to suppress [[whispering gallery mode]] propagation. Polarization-maintaining fiber is a unique type of fiber that is commonly used in fiber optic sensors due to its ability to maintain the polarization of the light inserted into it. |

|||

[[File:First replication.jpg|thumb|All of the plastic parts for the machine on the right were produced by the machine on the left. [[Adrian Bowyer]] (left) and Vik Olliver (right) are members of the [[RepRap project]].]] |

|||

[[File:Turntable with 5v psu.jpg|thumb|[[Meccano]] repstrap of RepRap 0.1 prototype (created by Vik Olliver)]] |

|||

Several projects and companies are making efforts to develop affordable 3D printers for home desktop use. Much of this work has been driven by and targeted at [[Do it yourself|DIY]]/[[Maker culture|Maker]]/enthusiast/[[early adopter]] communities, with additional ties to the academic and [[Hacker (hobbyist)|hacker]] communities.<ref name="Auto3D-26" /> |

|||

[[RepRap Project]] is one of the longest running projects in the desktop category. The [[RepRap project]] aims to produce a [[free and open source hardware]] (FOSH) 3D printer, whose full specifications are released under the [[GNU General Public License]], and which is capable of replicating itself by printing many of its own (plastic) parts to create more machines.<ref name="AutoSQ-20" /><ref name="AutoSQ-21" /> RepRaps have already been shown to be able to print [[circuit board]]s<ref name="AutoSQ-22" /> and metal parts.<ref name="AutoSQ-23" /><ref name="AutoSQ-24" /> |

|||

[[Photonic-crystal fiber]] is made with a regular pattern of index variation (often in the form of cylindrical holes that run along the length of the fiber). Such fiber uses [[diffraction]] effects instead of or in addition to total internal reflection, to confine light to the fiber's core. The properties of the fiber can be tailored to a wide variety of applications. |

|||

Because of the FOSH aims of [[RepRap Project|RepRap]], many related projects have used their design for inspiration, creating an ecosystem of related or derivative 3D printers, most of which are also open source designs. The availability of these open source designs means that variants of 3D printers are easy to invent. The quality and complexity of printer designs, however, as well as the quality of kit or finished products, varies greatly from project to project. This rapid development of open source 3D printers is gaining interest in many spheres as it enables hyper-customization and the use of [[public domain]] designs to fabricate [[open source appropriate technology]]. This technology can also assist initiatives in [[sustainable development]] since technologies are easily and economically made from resources available to local communities.<ref name="Auto3D-27" /><ref name="AutoSQ-25" /> |

|||

==Mechanisms of attenuation== |

|||

[[File:Zblan transmit.jpg|thumb|Light attenuation by [[ZBLAN]] and silica fibers]] |

|||

{{Main|Transparent materials}} |

|||

Attenuation in fiber optics, also known as transmission loss, is the reduction in intensity of the light beam (or signal) as it travels through the transmission medium. Attenuation coefficients in fiber optics usually use units of dB/km through the medium due to the relatively high quality of transparency of modern optical transmission media. The medium is usually a fiber of silica glass that confines the incident light beam to the inside. Attenuation is an important factor limiting the transmission of a digital signal across large distances. Thus, much research has gone into both limiting the attenuation and maximizing the amplification of the optical signal. |

|||

Empirical research has shown that attenuation in optical fiber is caused primarily by both [[scattering]] and [[absorption (electromagnetic radiation)|absorption]]. Single-mode optical fibers can be made with extremely low loss. Corning's SMF-28 fiber, a standard single-mode fiber for telecommunications wavelengths, has a loss of 0.17 dB/km at 1550 nm.<ref name="CorningSMF28ULL">{{cite web |url=http://www.corning.com/opticalfiber/products/SMF-28_ULL_fiber.aspx |title=Corning SMF-28 ULL optical fiber|accessdate=April 9, 2014}}</ref> For example, an 8 km length of SMF-28 transmits nearly 75% of light at 1,550 nm. It has been noted that if ocean water was as clear as fiber, one could see all the way to the bottom even of the Marianas Trench in the Pacific Ocean, a depth of 36,000 feet.<ref name="Jachetta2007">{{cite book |last= Williams |first=E. A. (ed.) |year=2007 |title=National Association of Broadcasters Engineering Handbook (Tenth Edition) |url= |location= |publisher=Taylor & Francis |pages=1667–1685 (Chapter 6.10 – Fiber–Optic Transmission Systems, Jim Jachetta)|isbn=978-0-240-80751-5}}</ref> |

|||