Elevator

An elevator or lift is a transport device used to move goods or people vertically, from one floor to another. Languages other than English may have loanwords based on either elevator (e.g. Japanese) or lift (e.g. Cantonese). Because of wheelchair access laws, elevators are often a legal requirement in new buildings with multiple floors.

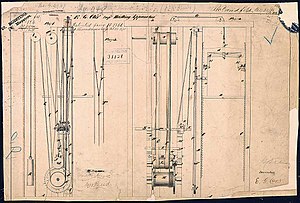

Design

Lifts began as simple rope or chain hoists. A lift is essentially a platform that is either pulled or pushed up by a mechanical means. A modern day lift consists of a cab (also called a "cage" or "car") mounted on a platform within an enclosed space called a shaft, or in Commonwealth countries called a "hoistway". In the past, lift drive mechanisms were powered by steam and water hydraulic pistons. In a "traction" lift, cars are pulled up by means of rolling steel ropes over a deeply grooved pulley, commonly called a sheave in the industry. The weight of the car is balanced with a counterweight. Sometimes two lifts always move synchronously in opposite directions, and they are each other's counterweight.

The friction between the ropes and the pulley furnishes the traction which gives this type of lift its name.

Hydraulic lift use the principles of hydraulics to pressurize an above ground or in-ground piston to raise and lower the car. Roped Hydraulics use a combination of both ropes and hydraulic power to raise and lower cars. Recent innovations include permanent earth magnet motors, machine room-less rail mounted gearless machines, and microprocessor controls.

Which technology is used in new installations depends on a variety of factors. Hydraulic lifts are cheaper, but installing cylinders greater than a certain length becomes impractical for very high lift hoistways. For buildings of much over seven stories, traction lift must be employed instead. Hydraulic lifts are usually slower than traction lifts.

Lifts are a candidate for mass customization. There are economies to be made from mass production of the components, but each building comes with its own requirements like different number of floors, dimensions of the well and usage patterns.

Elevator Doors

There are a multitude of ways the elevator doors can open. Most commonly, two sliding panels meet in the middle when closed, and slide open on both sides. Another common configuration is to have doors open to one side. In this case, if more than one door is used, they travel on separate tracks and are "tucked" behind one another in the opening position. For elevators requiring an even wider entryway (vehicular lifts), the doors may also open vertically.

History

The first reference to an elevator is in the works of the Roman architect Vitruvius, who reported that Archimedes built his first elevator, probably, in 236 B.C. In some literary sources of later historical periods, elevators were mentioned as cabs on a hemp rope and powered by hand or by animals. It is supposed that elevators of this type were installed in the Sinai monastery of Egypt. In the 17th century the prototypes of elevators were located in the palace buildings of England and France.

In 1793 Ivan Kulibin created an elevator with the screw lifting mechanism for the Winter Palace of Saint Petersburg. In 1816 an elevator was established in the main building of sub Moscow village called Arkhangelskoye. In 1823, an "ascending room" made its debut in London.[1]

Henry Waterman of New York is credited with inventing the "standing rope control" for an elevator in 1850.[2]

In 1853, Elisha Otis introduced the safety elevator, which prevented the fall of the cab if the cable broke. The design of the Otis safety elevator is somewhat similar to one type still used today. A governor device engages knurled roller(s), locking the elevator to its guides should the elevator descend at excessive speed. He demonstrated it at the New York exposition in the Crystal Palace in 1854.[2]

On March 23, 1857 the first Otis passenger elevator was installed at 488 Broadway in New York City. The first elevator shaft preceded the first elevator by four years. Construction for Peter Cooper's Cooper Union building in New York began in 1853. An elevator shaft was included in the design for Cooper Union, because Cooper was confident that a safe passenger elevator would soon be invented.[3] The shaft was cylindrical because Cooper felt it was the most efficient design.[4] Later Otis designed a special elevator for the school. Today the Otis Elevator Company, now a subsidiary of United Technologies Corporation, is the world's largest manufacturer of vertical transport systems.

The first electric elevator was built by Werner von Siemens in 1880.[5] The safety and speed of electric elevators were significantly enhanced by Frank Sprague.[citation needed]

The development of elevators was led by the need for movement of raw materials including coal and lumber from hillsides. The technology developed by these industries and the introduction of steel beam construction worked together to provide the passenger and freight elevators in use today.

In 1874, J.W. Meaker patented a method which permitted elevator doors to open and close safely. U.S. patent 147,853

In 1929, Clarence Conrad Crispen, with Inclinator Company of America, created the first residential elevator. Crispen also invented the first inclined stairlift.http://inclinator.com/about-inclinator.asp

Elevator safety

Elevators are characterized as being extremely safe. Their safety record of moving millions of passengers every day, with extremely low rate of incident, is unsurpassed by any other vehicle system. Even so, fatalities due to malfunction[6] have been known to occur on occasion.[6] A certain number of passengers do die every year in elevator-related incidents.[7] In 1998, in the United States, it was reported that of the estimated 120 billion rides per year in the approximately 600,000 elevators in the U.S., 10,000 people wound up in the emergency room[8] because of elevator-related accidents.

Past problems with hydraulic elevators meant those built prior to a code change in 1972 were subject to possible catastrophic failure. The code had previously required only single-bottom hydraulic cylinders. In the event of a cylinder breach, an uncontrolled fall of the elevator might result. Because it is impossible to verify the system completely without a pressurized casing (as described below), it is necessary to remove the piston to inspect it. The cost of removing the piston is such that it makes no economic sense to re-install the old cylinder; therefore it is necessary to replace the cylinder and install a new piston.[citation needed] Another solution to protect against a cylinder blowout is to install a "life jacket." This is a device which, in the event of an excessive downward speed, clamps onto the cylinder and stops the car. This device is also known as a Rupture Valve in some parts of the world.

In addition to the safety concerns for older hydraulic elevators, there is risk of leaking hydraulic oil into the aquifer and causing potential environmental contamination. This has led to the introduction of PVC liners (casings) around hydraulic cylinders which can be monitored for integrity.

In the past decade, recent innovations in inverted hydraulic jacks have eliminated the costly process of drilling the ground to install a borehole jack. This also eliminates the threat of corrosion to the system and increases safety.

On traction lifts there is a device called a "Safety Gear" that is fitted to the bottom of the lift car frame. This device connects to another device commonly known as a "Overspeed Governor." There is a separate rope from the main lifting ropes that connects the safety gear to the overspeed governor. The Overspeed Governor usually has a pulley which the safety rope runs on. The overspeed governor usually has an arm type latch. If the device spins too quickly, the arm is forced out from the middle of the unit by centrifugal force. This locks the pulley, which stops the rope. Once the rope stops and the car is still moving down, the rope pulls up on the safety gear causing a wedge type friction roller or a solid plate to clamp very tightly on the lift running guides. This causes the lift to stop suddenly ("instantaneous" safety gear) or in a progressive slowing motion ("progressive" safety gear). There are many different versions of these but they all work in the same way.

Uses of elevators

Passenger service

A passenger lift is designed to move people between a building's floors.

Passenger elevators capacity is related to the available floor space. Generally passenger elevators are available in capacities from 1,000 to 6,000 lb (455 to 2,727 kg) in 500 lb (230 kg) increments. Generally passenger elevators in buildings eight floors or less are hydraulic or electric, which can reach speeds up to 200 ft/min (1.0 m/s) hydraulic and up to 500 ft/min electric. In buildings up to ten floors, electric & gearless elevators are likely to have speeds up to 500 ft/min (2.5 m/s), and above ten floors speeds begin at 500 ft/min (2.5 m/s) up to 2000ft/min (10 m/s).

Sometimes passenger elevators are used as a city transport along with funiculars. For example, there is a 3-station underground public elevator in Yalta, Ukraine, which takes passengers from the top of a hill above the Black Sea on which hotels are perched, to a tunnel located on the beach below.

Types of passenger elevators

Passenger elevators may be specialized for the service they perform, including: Hospital emergency (Code blue), front and rear entrances, double decker, and other uses. Cars may be ornate in their interior appearance, may have audio visual advertising, and may be provided with specialized recorded voice instructions.

An express elevator does not serve all floors. For example, it moves between the ground floor and a skylobby, or it moves from the ground floor or a skylobby to a range of floors, skipping floors in between. These are especially popular in eastern Asia.

Entrapment

All elevators are required to have communication connection to an outside 24 hour emergency service, automatic recall capability in a fire emergency, and special access for fire fighters' use in a fire. Elevators should not be used by the public if there is a fire in or around the building, and as such numerous building codes require signs near the elevator to state as much. However, emergency evacuations in some countries do allow the use of special 'fire elevators'.

Capacity

Residential elevators may be small enough to only accommodate one person while some are large enough for more than a dozen. Wheelchair, or platform lifts, a specialized type of elevator designed to move a wheelchair 6 ft (1.8 m) or less, often can accommodate just one person in a wheelchair at a time with a maximum load of 1000 lb (455 kg).

Freight elevators

A freight elevator (or goods lift) is an elevator designed to carry goods, rather than passengers. Freight elevators are often exempt from some code requirements[citation needed] and from some of the requirements for fire service[citation needed]. However, new installations would likely be required to comply with these requirements[citation needed]. Freight elevators are generally required to display a written notice in the car that the use by passengers is prohibited, though certain freight elevators allow dual use through the use of an inconspicuous riser. Freight elevators are typically larger and capable of carrying heavier loads than a passenger elevator, generally from 2,300 to 4,500 kg. Freight elevators may have manually operated doors, and often have rugged interior finishes to prevent damage while loading and unloading. Although hydraulic freight elevators exist, electric elevators are more energy efficient for the work of freight lifting[citation needed].

Stage and Orchestra lifts are specialized lifts for use in the performing arts, and are often exempt from some requirements[citation needed]. Local jurisdictions may govern their use, installation and testing, however they are often left out of local code enforcement provisions due to their infrequent installation.

Vehicle elevators

A car lift is installed where ramps are considered space-inconservative for smaller buildings (usually in apartment buildings where frequent access is not an issue). The car platforms are raised and lowered hydraulically and are connected to chained steel gears (resembling bicycle chains in appearance). In addition to the vertical motion, the platforms can rotate about its vertical axis (up to 180 degrees) to ease driver access and/or accommodate building plans. Most parking lots of this type cannot accommodate tall or heavy vehicles, like SUVs.

Boat elevators

In some smaller canals, boats and small ships can pass between different levels of a canal with a boat lift rather than through a canal lock.

Aircraft elevators

On aircraft carriers, elevators carry aircraft between the flight deck and the hangar deck for operations or repairs. These elevators are designed for much greater capacity than any other elevator ever built, up to 200,000 pounds of aircraft and equipment. Smaller elevators lift munitions to the flight deck from magazines deep inside the ship.

Dumbwaiter

Dumbwaiters are small freight elevators that are not intended to carry people.

Paternoster

A special type of elevator is the paternoster, a constantly moving chain of boxes. A similar concept moves only a small platform, which the rider mounts while using a handhold and was once seen in multi-story industrial plants.

Material handling belts and belt elevators

A different kind of elevator is used to transport material. It generally consists of an inclined plane on which a conveyor belt runs. The conveyor often includes partitions to prevent the material from sliding backwards. These elevators are often used in industrial and agricultural applications. When such mechanisms (or spiral screws or pneumatic transport) are used to elevate grain for storage in large vertical silos, the entire structure is called a grain elevator.

There have occasionally been lift belts for humans; these typically have steps about every seven feet along the length of the belt, which moves vertically, so that the passenger can stand on one step and hold on to the one above. These belts are sometimes used, for example, to carry the employees of parking garages, but are considered too dangerous for public use.

Types of elevator hoist mechanisms

In general, there are three means of moving an elevator:

Traction elevators

- Geared and gearless traction elevators

Geared Traction machines are driven by AC or DC electric motors. Geared machines use worm gears to control mechanical movement of elevator cars by "rolling" steel hoist ropes over a drive sheave which is attached to a gearbox driven by a high speed motor. These machines are generally the best option for basement or overhead traction use for speeds up to 500 ft/min (2.5 m/s).

Gearless Traction machines are low speed (low RPM), high torque electric motors powered either by AC or DC. In this case, the drive sheave is directly attached to the end of the motor. Gearless traction elevators can reach speeds of up to 2,000 ft/min, or even higher. A brake is mounted between the motor and drive sheave (or gearbox) to hold the elevator stationary at a floor. This brake is usually an external drum type and is actuated by spring force and held open electrically; a power failure will cause the brake to engage and prevent the elevator from falling (see inherent safety and safety engineering).

In each case, cables are attached to a hitch plate on top of the cab or may be "underslung" below a cab, and then looped over the drive sheave to a counterweight attached to the opposite end of the cables which reduces the amount of power needed to move the cab. The counterweight is located in the hoist-way and rides a separate rail system; as the car goes up, the counterweight goes down, and vice versa. This action is powered by the traction machine which is directed by the controller, typically a relay logic or computerized device that directs starting, acceleration, deceleration and stopping of the elevator cab. The weight of the counterweight is typically equal to the weight of the elevator cab plus 40-50% of the capacity of the elevator. The grooves in the drive sheave are specially designed to prevent the cables from slipping. "Traction" is provided to the ropes by the grip of the grooves in the sheave, thereby the name. As the ropes age and the traction grooves wear, some traction is lost and the ropes must be replaced and the sheave repaired or replaced.

Elevators with more than 100' of travel have a system called compensation. This is a separate set of cables or a chain attached to the bottom of the counterweight and the bottom of the elevator cab. This makes it easier to control the elevator, as it compensates for the differing weight of cable between the hoist and the cab. If the elevator cab is at the top of the hoist-way, there is a short length of hoist cable above the car and a long length of compensating cable below the car and vice versa for the counterweight. If the compensation system uses cables, there will be an additional sheave in the pit below the elevator, to guide the cables. If the compensation system uses chains, the chain is guided by a bar mounted between the counterweight rails.

Hydraulic elevators

- Conventional Hydraulic elevators were first developed by Dover Elevator (now ThyssenKrupp Elevator). They are quite common for low and medium rise buildings (2-8 floors), attain speeds of up to 200 feet/minute (1.0 m/s), and use a hydraulically powered plunger to push the elevator upwards. On some, the hydraulic piston (plunger) consists of telescoping concentric tubes, allowing a shallow tube to contain the mechanism below the lowest floor. On others, the piston requires a deeper hole below the bottom landing, usually with a PVC casing (also known as a caisson) for protection.

- Roped hydraulic elevators use a combination of ropes and hydraulics.

- Twin post hydraulic provides higher travel with no underground hole.

- Holeless hydraulic elevators do not require holes to be dug for the hydraulic cylinder. In most designs, the cab is lifted by a pair of hydraulic jacks, one on each side of the elevator.

Climbing elevator

A climbing elevator is a self-ascending elevator with its own propulsion. The propulsion can be done by an electric or a combustion engine. Climbing elevators are used in guyed masts or towers, in order to make easy access to parts of these constructions, such as flight safety lamps for maintenance. An example would be the Moonlight towers in Austin, Texas, where the elevator holds only one person and equipment for maintenance.

Controlling elevators

General controls

A typical modern passenger elevator will have:

- Space to stand in

- Electric fans or air conditioning units to enhance circulation and comfort.

- Call buttons to choose a floor. Some of these may be key switches (to control access). In some elevators, certain floors are inaccessible unless one swipes a security card or enters a passcode (or both). In the United States and other countries, call button text and icons are raised to allow blind users to operate the elevator; many have Braille text besides.

- Door open and door close buttons to instruct the elevator to close immediately or remain open longer. In some elevators, holding the door open for too long will trigger an audible alarm.

- A stop switch (not allowed under British regulations) to halt the elevator is often used to hold an elevator open while freight is loaded. Keeping an elevator stopped for too long may trigger an alarm. Often, this will be a key switch.

- An alarm button or switch, which passengers can use to signal that they have been trapped in the elevator.

Some elevators may have one or more of the following:

- An elevator telephone, which can be used (in addition to the alarm) by a trapped passenger to call for help.

- A fireman's key switch, which places the elevator in a special operating mode designed to aid firefighters.

- A medical emergency key switch, which places the elevator in a special operating mode designed to aid medical personnel.

- Hold button: This button delays the door closing timer, useful for loading freight and hospital beds.

- Call Cancellation: A destination floor may be deselected by double clicking.

- Keycard reading devices that restrict elevator use to those holding valid RFID cards, magnetic stripes, or even hotel room keys.

Other controls, which are generally inaccessible to the public (either because they are key switches, or because they are kept behind a locked panel, include:

- Switches to control the lights and ventilation fans in the elevator.

- An inspector's switch, which places the elevator in inspection mode (this may be situated on top of the elevator)

- An independent service/Exclusive Mode will prevent the car from answering to hall calls and only arrive the selected floors in the panel. The door should stay open while parked on a floor. This mode may be used for temporarily transporting goods.

- Manual up/down controls for elevator technicians.

- Pass and Start buttons may be provided as convenience features for attendant-operated elevators.

Controls in early elevators

- Some older freight elevators are controlled by switches operated by pulling on adjacent ropes. Safety interlocks ensure that the inner and outer doors are closed before the elevator is allowed to move.

- Early elevators had no automatic landing positioning. Elevators were operated by elevator operators using a motor controller. The controller was contained within a cylindrical container about the size and shape of a cake container and this was operated via a projecting handle. This allowed some control over the energy supplied to the motor (located at the top of the elevator shaft or beside the bottom of the elevator shaft) and so enabled the elevator to be accurately positioned — if the operator was sufficiently skilled. More typically the operator would have to "jog" the control to get the elevator reasonably close to the landing point and then direct the outgoing and incoming passengers to "watch the step". After stopping at the landing the operator would open the door/doors. Some slightly later lifts though, had door(s) that could be operated by the same control (so when the lever is moved in the desired direction, between the idle and motion points there is a trigger to close the doors. When the handle is moved to idle, the doors open again.) This sort of arrangement was used sometimes in subway stations. Manually operated elevators were generally refitted or the cabs replaced by automatic equipment by the 1950s. The major exception is freight elevators which today are just as common to be manually operated or have automatic operation, and even when equipped with automatic controls, they are often operated by an attendant to ensure efficiency.

- Early automatic elevators used relays as logic gates to control them, which began to be replaced by microprocessors from the late 1980s.

- Large buildings with multiple elevators of this type would also have an elevator dispatcher stationed in the lobby to direct passengers and to signal the operator to leave with the use of a mechanical "cricket" noisemaker.

- Some elevators still in operation have pushbutton manual controls.

External controls

Elevators are typically controlled from the outside by up and down buttons at each stop. When pressed at a certain floor, the elevator arrives to pick up more passengers. If the said elevator is currently serving traffic in a certain direction, it will only answer hall calls in the same direction unless there are no more calls beyond that floor.

In a group of two or more elevators, the call buttons may be linked to a central dispatch computer, such that they illuminate and cancel together. This is done to ensure that only one car is called at one time.

Key switches may be installed on the ground floor so that the elevator can be remotely switched on or off from the outside.

Floor numbering

The elevator algorithm

The elevator algorithm, a simple algorithm by which a single elevator can decide where to stop, is summarized as follows:

- Continue traveling in the same direction while there are remaining requests in that same direction.

- If there are no further requests in that direction, then stop and become idle, or change direction if there are requests in the opposite direction.

The elevator algorithm has found an application in computer operating systems as an algorithm for scheduling hard disk requests. Modern elevators use more complex heuristic algorithms to decide which request to service next.

Computer dispatched

Efficiencies of multiple elevators installed in an office building may increase if a central dispatcher is used to group passengers going to the same floor to the same elevator. In the industry, this is known as the 'Destination floor control system'. In buildings with these computer-dispatched elevator system, passengers key in their destination floor in a central dispatch panel located at the building lobby. The dispatch panel will then tell the passenger which elevator to use. Inside the elevator there is no call button to push (or the buttons are there but they cannot be pushed, they only indicate stopping floors). The system was first pioneered by Schindler Elevator as the Miconic 10. Manufacturers of such systems claim that average traveling time can be reduced by up to 30%. There are some problems with the system, though. Sometimes, one person enters the destination for a large group of people going to the same floor. The dispatching algorithm is usually unable to completely cater for the variation, and late comers may find the elevator they are assigned to is already full. Also, occasionally, one person may press the floor multiple times. This is common with up/down buttons when people believe this to hurry elevators. However, this will make the computer think multiple people are waiting and will allocate empty cars to serve this one person.

Special operating modes

Anti-Crime Protection (ACP)

Anti-Crime Protection force each car to stop at a pre-defined landing and open its doors. This allows a security guard or a receptionist at the landing to visually inspect the passengers. The car stops at this landing as it passes to serve further demand.

Up peak (MIT)

During Up Peak mode (also called Moderate Incoming Traffic), elevator cars in a group are recalled to the lobby to provide expeditious service to passengers arriving at the building, most typically in the morning as people arrive for work or at the conclusion of a lunch-time period. Elevators are dispatched one-by-one when they reach a pre-determined passenger load, or when they have had their doors opened for a certain period of time. The next elevator to be dispatched usually has its hall lantern or a "this car leaving next" sign illuminated to encourage passengers to make maximum use of the available elevator system capacity.

The commencement of Up Peak may be triggered by a time clock, by the departure of a certain number of fully loaded cars leaving the lobby within a given time period, or by a switch manually operated by a building attendant.

Down peak

During Down Peak mode, elevator cars in a group are sent away from the lobby towards the highest floor served, after which they commence running down the floors in response to hall calls placed by passengers wishing to leave the building. This allows the elevator system to provide maximum passenger handling capacity for people leaving the building.

The commencement of Down peak may be triggered by a time clock, by the arrival of a certain number of fully loaded cars at the lobby within a given time period, or by a switch manually operated by a building attendant.

Sabbath service (SHO)

In areas with large populations of observant Jews, one may find a "Sabbath elevator". In this mode, an elevator will stop automatically at every floor, allowing people to step on and off without having to press any buttons. This prevents violation of the Sabbath prohibition against operating electrical devices when sabbath is in effect for those who observe this ritual.[9]

Independent service (ISC)

Independent service is a special service mode found on most elevators. It is activated by a key switch either inside the elevator itself or on a centralized control panel in the lobby. When an elevator is placed on independent service, it will no longer respond to hall calls. (In a bank of elevators, traffic would be rerouted to the other elevators, while in a single elevator, the hall buttons will be disabled). The elevator will remain parked on a floor with its doors open until a floor is selected and the door close button is held until the elevator starts to travel. Independent service is useful when transporting large goods or moving groups of people between certain floors.

Inspection service (INS)

Inspection service is designed to provide access to the hoistway and car top for inspection and maintenance purposes by qualified elevator mechanics. It is first activated by a key switch on the car operating panel usually labelled 'Inspection', 'Car Top', 'Access Enable' or 'HWENAB'. When this switch is activated the elevator will come to a stop if moving, car calls will be cancelled (and the buttons disabled), and hall calls will be assigned to other elevator cars in the group (or cancelled in a single elevator configuration). The elevator can now only be moved by the corresponding 'Access' key switches, usually located at the top-most (to access the top of the car) and bottom-most (to access the elevator pit) landings. The access key switches will bypass the door lock circuit for the floor it is located on and allow the car to move at reduced inspection speed with the hoistway door open. This speed can range from anywhere up to 60% of normal operating speed on most controllers, and is usually defined by local safety codes.

Elevators have a car top inspection station that allows the car to be operated by a mechanic in order to move it through the hoistway. Generally, there are three buttons - UP, RUN, and DOWN. Both the RUN and a direction button must be held to move the car in that direction, and the elevator will stop moving once one of the buttons is no longer being pressed for safety reasons. The inspection station is usually also equipped with a light, alarm button and stop switch.

Fire service mode (EFS)

Depending on the location of the elevator, fire service code will vary state to state and country to country. Fire service is usually split up into two modes. Phase One and Phase Two are separate modes that the elevator can go into.

Phase one mode is activated by a corresponding smoke sensor or heat sensor in the building. Once an alarm has been activated, the elevator will automatically go into phase one. The elevator will wait an amount of time, then proceed to go into nudging mode to tell everyone the elevator is leaving the floor. Once the elevator has left the floor, depending on where the alarm was set off, the elevator will go to the Fire Recall Floor. However, if the alarm was activated on the fire recall floor the elevator will have an alternate floor to recall to. When the elevator is recalled, it proceeds to the recall floor and stops with its doors open. The elevator will no longer respond to calls or move in any direction. Located on the fire recall floor is a fire service key switch. The fire service key switch has the ability to turn fire service off, turn fire service on or to bypass fire service. The only way to return the elevator to normal service is to switch it to bypass after the alarms have reset.

Phase two mode can only be activated by a key switch located inside the elevator on the centralized control panel. This mode was created for firefighters so that they may rescue people from a burning building. The phase two key switch located on the COP has three positions: off, on, and hold. By turning phase two on, the firefighter enables the car to move. However, like independent service mode, the car will not respond to a car call unless the firefighter manually pushes and holds the door close button. Once the elevator gets to the desired floor it will not open its doors unless the firefighter holds the door open button. This is in case the floor is burning and the firefighter can feel the heat and knows not to open the door. The firefighter must hold door open until the door is completely opened. If for any reason the firefighter wishes to leave the elevator, they will use the hold position on the key switch to make sure the elevator remains at that floor. If the firefighter wishes to return to the recall floor, they simply turn the key off and close the doors.

Medical emergency/'Code Blue' service (EHS)

Commonly found in hospitals, Code Blue service allows an elevator to be summoned to any floor for use in an emergency situation. Each floor will have a 'Code Blue' recall key switch, and when activated, the elevator system will immediately select the elevator car that can respond the fastest, regardless of direction of travel and passenger load. Passengers inside the elevator will be notified with an alarm and indicator light to exit the elevator when the doors open.

Once the elevator arrives at the floor, it will park with its doors open and the car buttons will be disabled to prevent a passenger from taking control of the elevator. Medical personnel must then activate the Code Blue key switch inside the car, select their floor and close the doors with the door close button. The elevator will then travel non-stop to the selected floor, and will remain in Code Blue service until switched off in the car. Some hospital elevators will feature a 'hold' position on the Code Blue key switch (similar to fire service) which allows the elevator to remain at a floor locked out of service until Code Blue is deactivated.

Emergency power operation (EPR)

Many elevator installations now feature emergency power systems which allow elevator use in blackout situations and prevent people from becoming trapped in elevators.

Traction elevators

When power is lost in a traction elevator system, all elevators will initially come to a halt. One by one, each car in the group will return to the lobby floor, open its doors and shut down. People in the remaining elevators may see an indicator light or hear a voice announcement informing them that the elevator will return to the lobby shortly. Once all cars have successfully returned, the system will then automatically select one or more cars to be used for normal operations and these cars will return to service. The car(s) selected to run under emergency power can be manually overridden by a key or strip switch in the lobby. In order to help prevent entrapment, when the system detects that it is running low on power, it will bring the running cars to the lobby or nearest floor, open the doors and shut down.

Hydraulic elevators

In hydraulic elevator systems, emergency power will lower the elevators to the lowest landing and open the doors to allow passengers to exit. The doors then close after an adjustable time period and the car remains unusable until reset, usually by cycling the elevator main power switch. Typically, due to the high current draw when starting the pump motor, hydraulic elevators aren't run using standard emergency power systems. Buildings like hospitals and nursing homes usually size their emergency generators to accommodate this draw. However, the increasing use of current limiting motor starters, commonly known as "Soft-Start" contactors, avoid much of this problem and the current draw of the pump motor is less of a limiting concern.

Elevator convenience features

Elevators may feature talking devices as an accessibility aid for the blind. In addition to floor arrival notifications, the computer announces the direction of travel, and notifies the passengers before the doors are to close.

In addition to the call buttons, elevators usually have floor indicators (often illuminated by LED) and direction lanterns. The former are almost universal in cab interiors with more than two stops and may be found outside the elevators as well on one or more of the floors. Floor indicators can consist of a dial with a rotating needle, but the most common types are those with successively illuminated floor indications or LCDs. Likewise, a change of floors or an arrival at floors is indicated by a sound, depending on the elevator.

Direction lanterns are also found both inside and outside elevator cars, but they should always be visible from outside because their primary purpose is to help people decide whether or not to get on the elevator. If somebody waiting for the elevator is going up but a car comes first indicating that it is going down, then the person may decide not to get on the elevator. If the person waits, then one will still stop going up. Direction indicators are sometimes etched with arrows or shaped like arrows and/or use the convention that one that lights up red means "down" and green means "up". Since the color convention is often undermined or overrided by systems that do not invoke it, it is usually used only in conjunction with other differentiating factors. An example of a place whose elevators use only the color convention to differentiate between directions is the Museum of Contemporary Art in Chicago, where a single circle can be made to light up green for "up" and red for "down." Sometimes directions must be inferred by the position of the indicators relative to one another.

In addition to lanterns, most elevators make a chime to indicate if the elevator is going up or down either before or after the doors open, usually in conjunction with the lanterns lighting up. Universally, one chime is for up, two is for down, and none indicates an elevator that is 'free'.

Standards

The mechanical, electrical and design of elevators are dictated according to various standards (aka elevator codes), which may typically be international, national, state, regional or city based. Where once many standards were prescriptive, specifying exact criteria which must be complied with, there has been a shift towards more performance-based standards where the onus falls on the designer to ensure that the elevator meets or exceeds the standard.

Some of the national elevator standards include:

- Australia – AS1735

- Canada – CAN/CSA B44

- Europe – EN 81 series (EN 81-1, EN 81-2, EN 81-28, EN 81-70, EN 12015, EN 12016, EN 13015, etc.)

- USA – ASME A17

Because an elevator is part of a building, it must also comply with standards relating to earthquake resilience, fire standards, electrical wiring rules and so forth.

The American National Elevator Standards Group (ANESG) sets an elevator weight standard to be 2200 lbs.

Additional requirements relating to access by disabled persons, may be mandated by laws or regulations such as the Americans with Disabilities Act.

US and Canadian elevator standard specifics

Passenger elevators are required to conform to the American Society of Mechanical Engineer's Standard A17.1 Safety Code for Elevators and Escalators in most US and Canadian jurisdictions (In Canada the document is the CAN/CSA B44 Safety Standard which was harmonized with the US version in the 2000 edition.) In addition passenger elevators may be required to conform to the requirements of A17.3 for existing elevators where referenced by the local jurisdiction. Passenger elevators are tested using the ASME A17.2 Standard. The frequency of these tests is mandated by the local jurisdiction, which may be a town, city, state or provincial standard.

Passenger elevators must also conform to many ancillary building codes including the Local or State building code, National Fire Protection Association standards for Electrical, Fire Sprinklers and Fire Alarms, Plumbing codes, and HVAC codes. Unfortunately, a bad invocation of NPFA regulations occur, because of inappropriate understanding and reference to these rules from Building Contractors and Elevators advisors in several countries (Latin American countries especially); usually the NFPA rules are mentioned from technician which ignore the real contents of NFPA rules, and NFPA compliance is required to providers and manufacturers, just as a quality reference, but not as a real reference. There are an inappropriate use and invocation of NFPA and ANSI rules which must be avoid by technician and engineers of elevator industry. Also, passenger elevators are required to conform to the American's with Disabilities Act and other State and Federal civil rights legislation regarding accessibility.

Residential elevators are required to conform to ASME A17.1. Platform and Wheelchair lifts are required to comply with ASME A18.1 in most US jurisdictions.

Most elevators have a location in which the permit for the building owner to operate the elevator is displayed. While some jurisdictions require the permit to be displayed in the elevator cab, other jurisdictions allow for the operating permit to be kept on file elsewhere – such as the maintenance office – and to be made available for inspection on demand. In such cases instead of the permit being displayed in the elevator cab, often a notice is posted in its place informing riders of where the actual permits are kept.

Notable elevator installations, by location

Eiffel Tower

The Eiffel Tower has double-deck elevators built into the legs of the tower, serving the ground level to the first and second levels. Even though the shaft runs diagonally upwards with the contour of the tower, both the upper and lower cars remain horizontally level. The offset distance of the two cars changes throughout the journey.

There are four elevator cars of the traditional design that run from the second level to the third level. The cars are connected to their opposite pairs (opposite in the elevator landing/hall) and use each other as the counterweight. As one car ascends from level 2, the other descends from level 3. The operations of these elevators are synchronized by a light signal in the car.

Taipei 101

Double deck elevators are used in the Taipei 101 office tower. Tenants of even-numbered floors first take an escalator (or an elevator from the parking garage) to the 2nd level, where they will enter the upper deck and arrive at their floors. The lower deck is turned off during low-volume hours, and the upper deck can act as a single-level elevator stopping at all adjacent floors. For example, the 85th floor restaurants can be accessed from the 60th floor sky-lobby. Restaurant customers must clear their reservations at the reception counter on the 2nd floor. A bank of express elevators stop only on the sky lobby levels (36 and 60, upper deck car), where tenants can transfer to "local" elevators.

The high speed observation deck elevators accelerate to a world-record certified speed of 1010 meters per minute (60.6 km/h) in 16 seconds, and then it slows down for arrival with subtle air pressure sensations. The door opens after 37 seconds from the 5th floor. Special features include aerodynamic car and counterweights, and cabin pressure control to help passengers adapt smoothly to pressure changes. The downwards journey is completed at a reduced speed of 600 meters per minute, with the doors opening at the 52th second.

The Gateway Arch

The Gateway Arch in St. Louis, Missouri has a unique elevator system which carries passengers from the visitors' center underneath the Arch to the observation deck at the top of the structure.

Called a tram or tramway, people enter this unique tramway much as one would enter an ordinary elevator, through double doors. Passing through the doors the passengers in small groups enter a horizontal cylindrical compartment containing seats on each side and a flat floor. A number of these compartments are linked to form a train. These compartments each individually retain an appropriate level orientation by tilting while the entire train follows curved tracks up one leg of the arch.

There are two tramways within the Arch, one at the north end, and the other at the south end. The entry doors have windows, so people traveling within the Arch are able to see the interior structure of the Arch during the ride to and from the observation deck. At the beginning of the trip the cars hang from the drive cables, but as the angle of the shaft changes, they end up beside and then on top of the cables.

New City Hall, Hanover, Germany

The elevator in the New City Hall in Hanover, Germany is a technical rarity, and unique in Europe, as the elevator starts straight up but then changes its angle by 15 degrees to follow the contour of the dome of the hall. The cabin therefore tilts 15 degrees during the ride. The elevator travels a height of 43 meters. The new city hall was built in 1913. The elevator was destroyed in 1943 and rebuilt in 1954.

Luxor Inclinator Elevator

In Las Vegas, Nevada, at the Luxor Hotel, is the Inclinator. The shape of this casino is a pyramid. Therefore, the elevator travels up the side of the pyramid at a 39 degree angle. Although people refer to this "inclined elevator" as an inclinator, this is incorrect. An inclinator is a stairlift developed by Inclinator Company of America many years ago. Therefore the Luxor installation is just Otis Elevator's version of a generic "Inclined Elevator".

Twilight Zone Tower of Terror

This article contains content that is written like an advertisement. |

Main Article: Twilight Zone Tower of Terror

The Twilight Zone Tower of Terror is the common name for a series of a free-fall elevator attractions at the Disney's Hollywood Studios park in Orlando, Disney's California Adventure park in Anaheim, the Walt Disney Studios Park in Paris and the Tokyo DisneySea park in Tokyo. The central element of this attraction is the unique free-fall experience achieved through the use of a state-of-the-art elevator system. For safety reasons, passengers are seated and secured in their seats rather than allowing them to stand. Unlike most traction elevators, the elevator car and counterweight are joined using a cable system in a continuous loop running through both the top and the bottom of the drop shaft. This allows the drive motor to pull down on the elevator car from underneath, a feature which is used to raise passengers out of their seats early in the drop sequence by applying downward acceleration in addition to that of gravity. Furthermore, the uniquely fast and powerful drive motor allows the elevator to ascend to the top in mere seconds.

Finally, the passenger cab is mechanically removed from the main elevator car so that the elevator shaft can efficiently be used continuously while the passenger cabs can alternatingly be removed to permit passenger boarding. The Disney's Hollywood Studios version of the attraction achieves this operation in a very different fashion than that of the other versions, although the end effect is similar. All of the attraction buildings feature multiple elevator shafts to further improve throughput. The doorways of the top few "floors" are open to the outdoor environment, offering a dramatic view for both the ride passengers and the street-level observers.

"Top of the Rock" elevators

Guests ascending to the 67th, 69th, and 70th level observation decks (dubbed "Top of the Rock") atop the GE Building at Rockefeller Center in New York City ride a high-speed glass-top elevator. When entering the cab, it appears to be any normal elevator ride. However, once the cab begins moving, the interior lights turn off and a special blue light above the cab turns on. This lights the entire shaft, so riders can see the moving cab through its glass ceiling as it rises and lowers through the shaft. Music plays and various animations are also displayed on the ceiling. The entire ride takes about 60 seconds.

Apple Stores

An elevator located in the centre of the Apple Store in London takes passengers between the ground and first floors. The elevator is operated by a hydraulic ram and made almost entirely of glass, consisting of a glass shaft, containing a car with glass walls and ceiling. The elevator, manufactured by Apex Lifts, is unique in a number of ways: firstly, the car-top controls are removable, so that whilst the lift is in normal service, there are no visible mechanics on top of the glass box that is the car; secondly, there are no lift position switches within the shaft, with the exception of the top final-limit switch. Instead of these conventional switches within the shaft, the lift employs a laser, which is aimed from under the pit floor to a target on the car, and in this way the exact height of the car can be obtained, enabling the car to stop with an accuracy of 1mm.[10]

A similar elevator, installed by Otis, takes Apple customers in the New York City store from the 35-foot ground floor cube to the basement store. This elevator too is made entirely of glass. On May 29, 2006, just a week after its opening, it made the news when it trapped five passengers.[11]

Haunted Mansion, Disneyland Park (Anaheim)|Disneyland, Anaheim, California

Part of the Haunted Mansion attraction at Disneyland in Anaheim, California, takes place on an elevator. The stretching room on the ride is actually an elevator that travels downwards so that passengers would be able to pass underneath the Disneyland Railroad tracks. The elevator has no ceiling and its shaft is decorated to look like walls of a mansion. Because there is no roof, passengers are able to see the walls of the shaft by looking up, which gives the illusion of the room stretching.

Elevators for urban transport

In some towns, where terrain is difficult enough to justify, elevators are used as part of the urban transport systems.

Examples:

- Skyway in Nagasaki, Japan

- Bad Schandau Elevator in Bad Schandau, Germany

- Hammetschwand Elevator in Bürgenstock, Switzerland

- Katarina Elevator in Stockholm, Sweden

- Lacerda Elevator in Salvador, Bahia, Brazil

- Monaco, seven elevators

- Oregon City Municipal Elevator in Oregon City, Oregon, United States

- Santa Justa Lift in Lisbon, Portugal

- Shanklin Cliff Lift in Shanklin, Isle of Wight

- Marburg, Germany - some parts of the historic city core built on higher ground (Uppertown, "Oberstadt" in German) are accessible from the lower street level by elevators. These elevators are unique in servicing also various buildings partially embedded in the steep-sloping terrain.

Elevator accidents

Maintenance is crucial for the safety of an elevator since they usually operate more than 20-30 years before replacement or modernization. Although elevators are a safe means of transport, accidents do sometimes happen, as with other machinery.

Asia

- Tin Shui Wai, Yuen Long, March 2006 – 3 housewives and 2 of their children living in a public housing estate (Tin Tsak Estate) in Tin Shui Wai, Hong Kong, were taking one of the building's 6 elevators up from the ground floor. As the elevator rose past the 29/F, the elevator suddenly moved up and down through the span of the shaft (between G/F and 40/F). The elevator was reported to have jerked up and down several stories 3 times and shook violently laterally. Reports said the passengers were scared to death and shrieked, drawing similarities to an amusement park ride where one is strapped to seats and is repeatedly brought up and down. The passengers had claimed that no one answered the Alarm button intercom. It just so happened that Ms Au, a woman waiting for an elevator in the lobby, saw the hall position indicator flash nonsense – one moment it showed "40/F" and just seconds later it would show "30/F". She was worried that someone would be stuck inside and alerted the building management. The elevator doors suddenly opened and the passengers fled the elevator. The elevators, as with all government Housing Authority elevators in public estates, are maintained by their original manufacturer. The elevator was inspected and the only explanation given was one from a mechanic who said that "it was normal for an elevator to grind to a halt if it detects an abnormality, and then carry out its learning mode where it detects and 'learns' its position by traveling to the top and bottom of the shaft".

- Fanling, The North, January 2002 – 11 year old boy killed. Elevator ascended with the doors still open. Hong Kong Electrical Mechanical Services Department (EMSD) attributed problem to lack of an ascending protection device, and has since ordered the Fanling complex to install these devices.[12]. (Chinese newspaper documents the Japanese incident and relates it to the 2002 Hong Kong incident – pictures on the left are the 'deadly elevators' in Hong Kong)

- Japan

- Hachiōji, Tokyo, August 30, 2006 – A carpenter doing interior design work in a building in the Tokyo city of Hachiōji plunged to his death after stepping into an empty elevator shaft, mistakenly thinking that the elevator had arrived, police said. The elevator involved was installed by Hitachi (not confirmed yet). Source: Mainichi Shinbun

- Kyoto Prefecture, August 29, 2006 – In the Kyoto prefecture, in a distribution centre under construction, an installation subcontractor, while doing some cleaning work being on top of the elevator car, fell down by 10 meters through the 1-meter gap [between the elevator] and the shaft wall. The man died. Yokohama Elevator had entrusted the subcontractor with the installation of the elevator. Source: Kyoto Shinbun

- Tokyo, August 24, 2006 – On the evening of August 24, in the Tokyo-based headquarters of Tostem – large building materials company – a male technician who was performing the periodical maintenance got sandwiched for about 3 hours between an elevator car and the shaft wall. He died. Police are investigating the details. The accident elevator has been manufactured by Toshiba and is maintained by Toshiba Elevators. Source: NHK (TV)

- Minato, Tokyo, Japan, July 12, 2006 – The Elevator installed right next to the one in Minato that killed 16 year old Ichikawa Hirosuke trapped a woman and an engineer riding along for 30 minutes. Once again the building elevators have been taken out of service. While no one was hurt, this story notes that the manufacture has taken over the maintenance of the elevators at this building.[13]

- Chiba Prefecture, Japan, June 2006 – Similar to Minato Ward incident although with no fatalities also involving elevator. Incident first occurs on June 1, 2 days before the Minato incident. Investigation reveals no irregularities but same type of accident takes place days later on June 10.[14].[15] with name and contact number were shown in lobby of these elevators on Japanese TV. This incident lead to the manufacture admitting to computer programming errors that dated back to 1991, which allowed the doors to re-open even if the elevator has already started traveling. As of August 2006, elevators manufactured between 1991-1993 are being checked and their program updated.

- Minato, Tokyo, Japan, June 2006 – a 16-year old high school student was killed as he was backing out of an elevator with his bicycle when the elevator suddenly rose with the doors still open, crushing his skull.

- Hokkaido, Tokyo, September 20 – a 52 year-old man working for a "fire prevention center" fell down the shaft to his death. Using a special key, the victim opened the 1-floor landing door while the elevator was not in the first floor. This case involved a Hitachi Elevator installed in 1974 and maintained by Hitachi. Information source: Hokkaido Shinbunsha September 21, 2004 (morning edition).

- Meguro, Tokyo, Japan, September 15, 2004 – the victim (no detail about his identity) fell down the shaft to his death. This case involved a Toshiba Elevator installed in 1993. Maintenance company is not mentioned. Source: Japanese Elevator Association.

- Russia

- Omsk, June 2006. An eight-month-old baby died when an elevator in an apartment building fell six stories. The elevator in question was not installed by a major elevator manufacturer. (Source: Nowosti)

Americas

- Canada

- Toronto – five people receive broken ankles and other minor injuries, as an Otis parking garage hydraulic elevator in a National Life building on University Avenue plummets five floors in early 2006.[16][17][18]

- U.S.

- Texas, December 22, 2006. A 75-year-old man was killed during the evacuation of a malfunctioning elevator in Houston, Texas.[19]

- Ohio, October 20, 2006. A student at Ohio State University was killed while riding an elevator in a dormitory. The elevator began to descend while the doors were still open, and he became pinned between the building and the car while trying to exit the crowded elevator, causing asphyxiation. Brake tests were run on the elevator, which involves loading the car with 125% of its rated load capacity. The elevator in question (and a few others on campus) failed this test.[20][21][22][23]

- Colorado 2000, Fatality of a ThyssenKrupp Elevator employee whose helper, working with him lowered the elevator they were working on top of him, crushing him. OSHA investigated and showed neglect in the training of new employees in safety hazards. [citation needed]

- Texas, August 16, 2003. Decapitation of doctor in old Otis made elevator.[26] Internal investigation concluded that a wire in an electrical panel was incorrectly connected. Kone, Inc., which had recently been servicing the elevator was later dismissed.[27]

- New Orleans, July 2003. Fatality involving malfunction of elevator at the Kenner Regional Medical Center.[28]

- Michigan 1999. Woman age 56 on gurney became lodged between elevator car and shaft wall and dragged four floors.[28]

- The Bronx, New York, January 6, 1995. Runaway elevator in office building decapitated 55-year-old James Chenault as he tried to help fellow passengers out of a malfunctioning car.[27]

- Manhattan, New York, October 15, 1999. Nicholas White was trapped in an Elevator for 41 hours until he was discovered.

- Philadelphia, Pennsylvania April 22, 1997. Explosion in pit of a Montgomery-KONE elevator during modernization in a Post Office injures 2 elevator workers.[29]

- Mexico

- Cancún, June 2006. A teenager vacationing with his family at the hotel Royal Solaris in Cancún fell to his death in an elevator shaft. The shaft was completely empty. Mitsubishi[citation needed] was about to do a modernization job in this shaft.

Europe

- England

- London, June 2006. A 47-year-old man was killed when he plummeted eight floors during a refurbishment job in an office High Holborn, London.

- Southampton, 4 February 2001. Two men were killed after falling down the lift shaft of a 15-story tower block from the top floor. Police believe the doors of the shaft may have opened when the men fell against them during a fight.[30]

- France

- Paris, 19 June 2008. A 14-year-old boy was decapitated by a descending elevator. The boy was visiting a friend in an apartment building in Paris. Apparently he took the stairs and was called from the ground floor. He leaned over the fence that separated the stairs from the elevator shaft to answer, just as the elevator passed by, beheading him.[31]

Africa

- Angola

- Benguela, 31 May 2008. Former coach of Angola and Cape Verde football teams, Carlos Alhinho, fell to his death down an empty elevator shaft in Angola, aged 59. According to reports he fell from the sixth floor, and passed away later in hospital.[32]

Manufacturers of elevators

- ThyssenKrupp (acquired Dover Elevator Systems in 1999, the third largest elevator manufacturer in the world)

- Fujitec (Smallest major brand elevator company)

- Hitachi Elevator

- KONE (Fourth largest elevator manufacturer, acquired Fiam Elevator in 1987, Montgomery Elevator in 1994.)

- Mitsubishi Electric Elevator Division (maintained by its Ryoden subsidiary in some locales)

- Otis (World's largest elevator company. Acquired The Express Lifts in 1999.)

- Schindler Group (Second largest elevator manufacturer, acquired Westinghouse Elevator in 1989)

- Richmond Elevator (Largest elevator company in Vancouver, Canada)

See also

- Escalator

- Grain elevator

- Elevator music

- Elevator consultant

- Elevator inspector

- Elevator mechanic

- Elevator paradox

- Elevator statement

- Space elevator

- Elevator surfing

- Funicular

- Double-deck elevator

- International Union of Elevator Constructors

- Elevator Contractors of America

- Charlie and the Great Glass Elevator

- The Ersatz Elevator

- Kate & Leopold

- Paternoster

References

- ^ http://www.popularmechanics.com/science/extreme_machines/1280851.html

- ^ a b The Elevator Museum, timeline

- ^ http://www.cooper.edu/facilities/library/archive/symbol/symbol5.html

- ^ http://www.ringwoodmanor.com/peo/ch/pc/pc.htm

- ^ The History of the Elevator - Elisha Otis

- ^ a b [1][dead link]

- ^ McCann, M. "Deaths and Injuries Involving Elevators and Escalators – A Report of the Center To Protect Workers' Rights (Revised)",2004. http://www.cdc.gov/elcosh/docs/d0300/d000397/d000397.html

- ^ Good Housekeeping, "The last word on elevator safety", 1998 http://digital-community.com/demo/eesf.org/includes/downloads/safetyarticle2.pdf

- ^ http://ohr.edu/ask_db/ask_main.php/39/Q1/

- ^ BSEE - Building Services and Environmental Engineer: Liftstore Core to Apple Success

- ^ Jobs' glass elevator locks in group customers - Engadget

- ^ http://news.sina.com.hk/cgi-bin/news/show_news.cgi?ct=headlines&type=headlines&date=2006-06-10&id=2021259

- ^ http://search.japantimes.co.jp/cgi-bin/nn20060713a3.html

- ^ [2] [dead link]

- ^ http://en.wikipedia.org/wiki/Talk:El

- ^ http://www.ctv.ca/servlet/ArticleNews/story/CTVNews/20060127/elevator_accident_060127/20060127?hub=TopStories

- ^ http://www.canada.com/nationalpost/news/toronto/story.html?id=087bb6fc-5241-4d22-9962-249d8992ab78

- ^ http://www.ctv.ca/servlet/ArticleNews/story/CTVNews/20060128/elevator_crash_060128/20060129?hub=Canada

- ^ abc13.com: Resident falls down Galleria area condo elevator shaft to death 12/23/06

- ^ OSU Student Affairs : Residence Hall Elevator Update

- ^ Narciso, Dean (2006-10-22). "ELEVATOR TRAGEDY: Ohio State investigating student death". The Columbus Dispatch. Retrieved 2006-10-22.

{{cite news}}: Check date values in:|date=(help) - ^ Elevator that killed student overloaded, CNN, October 24, 2006

- ^ http://www.popularmechanics.com/blogs/science_news/4200432.html

- ^ http://www.inform.kz/showarticle.php?lang=eng&id=142622

- ^ http://www.schindler.com/group_index/group_kg/group_kg_mr/group_kg_mr_news.htm?printout=1&news=6516

- ^ O'Hare, P. (2003, August. 17). Doctor decapitated by faulty elevator at St. Joseph Hospital. Houston Chronicle. Retrieved on June 20, 2006.

- ^ a b http://www.snopes.com/horrors/freakish/elevator.asp

- ^ a b [3] [dead link]

- ^ http://www.oshrc.gov/decisions/html_1999/97-1133.html

- ^ http://news.bbc.co.uk/1/hi/uk/1153091.stm

- ^ http://tf1.lci.fr/infos/france/faits-divers/0,,3884435,00-adolescent-tue-par-ascenseur-.html

- ^ http://news.bbc.co.uk/sport1/hi/football/africa/7430296.stm

This article has an unclear citation style. |

- Manavalan, Theresa (30 October 2005). "Don't let them ride alone". New Straits Times, p. F2.

External links

- The Elevator Radio Show A weekly Podcast Dedicated To Elevator News!

- Elevators page from Howstuffworks.com

- elevatorbob's Elevator Pictures (scroll down past promotional material to folders)

- The Lifting Operations and Lifting Equipment Regulations 1998 (LOLER) Guidance

- Timeline of the elevator

- A collection of elevator control panels

- Elevaattorit.org - Finnish website of elevators

- ACE3 Opportunities for Elevator Energy Efficiency Improvements