Group 12 element: Difference between revisions

| Line 176: | Line 176: | ||

==Applications== |

==Applications== |

||

Due to the physical similarities which they share, the group 12 elements can be found in many common situations. Zinc and cadmium are commonly used as [[anti-corrosion]](galvanization) agents<ref name = "green"/> as they will attract all local [[oxidation]] until they completely corrode.<ref>{{Cite book|title=Guide to the Elements|edition=Revised|first=Albert|last=Stwertka|publisher=Oxford University Press |year=1998 |chapter=Zinc|isbn=0-19-508083-1 |ref=CITEREFStwertka1998}}</ref> These protective coatings can be applied to other metals through by [[hot-dip galvanizing]] a substance into the molten form of the metal,<ref>{{Cite book |title=Nature's Building Blocks: An A-Z Guide to the Elements |last=Emsley |first=John |publisher=Oxford University Press |year=2001 |location=Oxford, England, UK |isbn=0-19-850340-7|chapter=Zinc |

Due to the physical similarities which they share, the group 12 elements can be found in many common situations. Zinc and cadmium are commonly used as [[anti-corrosion]](galvanization) agents<ref name = "green"/> as they will attract all local [[oxidation]] until they completely corrode.<ref>{{Cite book|title=Guide to the Elements|edition=Revised|first=Albert|last=Stwertka|publisher=Oxford University Press |year=1998 |chapter=Zinc|isbn=0-19-508083-1 |ref=CITEREFStwertka1998}}</ref> These protective coatings can be applied to other metals through by [[hot-dip galvanizing]] a substance into the molten form of the metal,<ref>{{Cite book |title=Nature's Building Blocks: An A-Z Guide to the Elements |last=Emsley |first=John |publisher=Oxford University Press |year=2001 |location=Oxford, England, UK |isbn=0-19-850340-7|chapter=Zinc |

||

|pages=499–505 |url=http://books.google.com/?id=j-Xu07p3cKwC |ref=CITEREFEmsley2001}}</ref> or through the process of [[electroplating]] which may be [[passivated]] by the use of [[chromate]] salts.<ref>{{cite web |url=http://ftp.rta.nato.int/public//PubFulltext/RTO/MP/RTO-MP-025///MP-025-15.pdf |title=Advances to Protective Coatings and their Application to Ageing Aircraft |author=Smith C.J.E., Higgs M.S., Baldwin K.R. |date=April 20, 1999 |publisher=RTO MP-25 |accessdate=May 29, 2011}}</ref> |

|pages=499–505 |url=http://books.google.com/?id=j-Xu07p3cKwC |ref=CITEREFEmsley2001}}</ref> or through the process of [[electroplating]] which may be [[passivated]] by the use of [[chromate]] salts.<ref>{{cite web |url=http://ftp.rta.nato.int/public//PubFulltext/RTO/MP/RTO-MP-025///MP-025-15.pdf |title=Advances to Protective Coatings and their Application to Ageing Aircraft |author=Smith C.J.E., Higgs M.S., Baldwin K.R. |date=April 20, 1999 |publisher=RTO MP-25 |accessdate=May 29, 2011}}</ref> Group 12 elements are also used in [[electrochemistry]] as they may act as an alternative to the [[standard hydrogen electrode]] in addition to being a secondary reference electrode.<ref>{{cite book |title=Electrochemical Systems |last=Newman |first=John |year=2004 |publisher=John Wiley & Sons |location=New Jersey |isbn=0471477567 }}</ref> |

||

| ⚫ | In the US, zinc is used predominantly for [[Galvanization|galvanizing]] (55%) and for [[brass]], [[bronze]] and other alloys (37%).<ref name="USGS-yb2006"/> The relative reactivity of zinc and its ability to attract oxidation to itself makes it an efficient [[sacrificial anode]] in [[cathodic protection]] (CP). For example, cathodic protection of a buried pipeline can be achieved by connecting anodes made from zinc to the pipe.<ref name="Lehto1968p829"/> Zinc acts as the [[anode]] (negative terminus) by slowly corroding away as it passes electric current to the steel pipeline.<ref name="Lehto1968p829"/><ref group=note>Electric current will naturally flow between zinc and steel but in some circumstances inert anodes are used with an external DC source.</ref> Zinc is also used to cathodically protect metals that are exposed to sea water from corrosion.<ref>{{Cite journal|title=A comparative study of the electrochemical behaviour of Algerian zinc and a zinc from a commercial sacrificial anode|first=M.|coauthors=Salhi, E.; Benzine, K.; Ghali E.; Dalard F.|last=Bounoughaz|journal=Journal of Materials Science|volume =38|issue=6|page=1139|doi=10.1023/A:1022824813564|year=2003}}</ref><ref name=Stwertka1998p99/> |

||

| ⚫ | Zinc is also used as an anode material for batteries such as in [[Zinc-carbon battery|zinc–carbon batteries]]<ref>{{Cite book|first=Jürgen O.|last=Besenhard|title=Handbook of Battery Materials|accessdate=2008-10-08|publisher=Wiley-VCH|url=http://www.ulb.tu-darmstadt.de/tocs/60178752.pdf|isbn=3527294694|year=1999}}</ref><ref>{{Cite journal|doi=10.1016/0378-7753(95)02242-2|year=1995|title=Recycling zinc batteries: an economical challenge in consumer waste management|first=J.-P.|last=Wiaux|coauthors=Waefler, J. -P.|journal=Journal of Power Sources|volume=57|issue=1–2|page=61}}</ref> or [[zinc-air battery]]/fuel cells.<ref>{{Cite journal|title=A design guide for rechargeable zinc-air battery technology|last=Culter|first=T.|doi=10.1109/SOUTHC.1996.535134|journal=Southcon/96. Conference Record|isbn=0-7803-3268-7|year=1996|page=616}}</ref><ref>{{cite web|url=http://www.electric-fuel.com/evtech/papers/paper11-1-98.pdf| title=Zinc Air Battery-Battery Hybrid for Powering Electric Scooters and Electric Buses|first=Jonathan|last=Whartman|coauthors=Brown, Ian|publisher=The 15th International Electric Vehicle Symposium| accessdate=2008-10-08}}</ref><ref>{{cite web|url =http://www.osti.gov/energycitations/product.biblio.jsp?osti_id=82465|title=A refuelable zinc/air battery for fleet electric vehicle propulsion|last=Cooper|first=J. F|coauthors=Fleming, D.; Hargrove, D.; Koopman, R.; Peterman, K|publisher=Society of Automotive Engineers future transportation technology conference and exposition|accessdate=2008-10-08}}</ref> |

||

| ⚫ | A widely used alloy which contains zinc is brass, in which copper is alloyed with anywhere from 3% to 45% zinc, depending upon the type of brass.<ref name="Lehto1968p829"/> Brass is generally more [[ductile]] and stronger than copper and has superior [[corrosion resistance]].<ref name="Lehto1968p829"/> These properties make it useful in communication equipment, hardware, musical instruments, and water valves.<ref name="Lehto1968p829"/> Other widely used alloys that contain zinc include [[nickel silver]], typewriter metal, soft and aluminium [[solder]], and commercial [[bronze]].<ref name="CRCp4-41"/> Alloys of primarily zinc with small amounts of copper, aluminium, and magnesium are useful in [[die casting]] as well as [[spin casting]], especially in the automotive, electrical, and hardware industries.<ref name="CRCp4-41"/> These alloys are marketed under the name [[Zamak]].<ref>{{cite web|url=http://www.eazall.com/diecastalloys.aspx|title=Diecasting Alloys|author=Eastern Alloys contributors|publisher=Eastern Alloys|accessdate=2009-01-19|location=Maybrook, NY}}</ref> Roughly one quarter of all zinc output, in the United States (2009), is consumed in the form of zinc compounds, a variety of which are used industrially.<ref name="USGS-yb2006"/> |

||

Group 12 elements are also used in [[electrochemistry]] as they may act as an alternative to the [[standard hydrogen electrode]] in addition to being a secondary reference electrode.<ref>{{cite book |title=Electrochemical Systems |last=Newman |first=John |year=2004 |publisher=John Wiley & Sons |location=New Jersey |isbn=0471477567 }}</ref> Zinc is commonly used as and anode in batteries and fuel cells;<ref>{{Cite book|first=Jürgen O.|last=Besenhard|title=Handbook of Battery Materials|accessdate=2008-10-08|publisher=Wiley-VCH|url=http://www.ulb.tu-darmstadt.de/tocs/60178752.pdf|isbn=3527294694|year=1999}}</ref> whereas, cadmium is commonly used in recharable [[Nickel–cadmium battery|nickel-cadmium batteries]].<ref>{{cite web|url = http://www.europarl.europa.eu/sides/getDoc.do?pubRef=-//EP//TEXT+IM-PRESS+20060628BRI09328+FULL-TEXT+DOC+XML+V0//EN|title=Battery collection; recycling, nature protected |publisher=[[European Union]]|accessdate=November 4, 2008}}</ref> |

|||

Cadmium has many common industrial uses as it is a key component in battery production, is present in [[cadmium pigments]],<ref name="colors"/> coatings,<ref name="fff"/> and is commonly used in electroplating.<ref name="HgCdPb"/> In 2009, 86% of cadmium was used in [[Battery (electricity)|batteries]], predominantly in [[rechargeable battery|rechargeable]] [[nickel-cadmium battery|nickel-cadmium batteries]]. The European Union banned the use of cadmium in electronics in 2004 with several exceptions but reduced the allowed content of cadmium in electronics to 0.002%.<ref>{{cite web|url =http://www.europarl.europa.eu/sides/getDoc.do?pubRef=-//EP//TEXT+IM-PRESS+20060628BRI09328+FULL-TEXT+DOC+XML+V0//EN|title=Battery collection; recycling, nature protected |publisher=[[European Union]]|accessdate=November 4, 2008}}</ref> Cadmium [[electroplating]], consuming 6% of the global production, can be found in the aircraft industry due to the ability to resist [[corrosion]] when applied to steel components.<ref name="HgCdPb">{{cite book|url = http://books.google.com/?id=9yzN-QGag_8C|title = Mercury, Cadmium, Lead: Handbook for Sustainable Heavy Metals Policy and Regulation|first = Michael J.|last = Scoullos|coauthors = Vonkeman, Gerrit H.; Thornton, Iain; Makuch, Zen| publisher = Springer|year = 2001|isbn = 9781402002243}}</ref> |

|||

Mercury is used primarily for the manufacture of industrial chemicals or for electrical and electronic applications. It is used in some thermometers, especially ones which are used to measure high temperatures. A still increasing amount is used as gaseous mercury in [[fluorescent lamps]],<ref>{{cite book|title = A guide to the use and calibration of detector array equipment| author = Hopkinson, G. R.; Goodman, T. M.; Prince, S. R.| publisher = SPIE Press| year = 2004| page = 125| isbn = 0819455326}}</ref> while most of the other applications are slowly phased out due to health and safety regulations,<ref>{{cite news| title = Mercury Reduction Act of 2003|url =http://openlibrary.org/b/OL17617678M|accessdate = 2009-06-06| publisher = United States. Congress. Senate. Committee on Environment and Public Works}}</ref> |

|||

| ⚫ | In the US, zinc is used predominantly for [[Galvanization|galvanizing]] (55%) and for [[brass]], [[bronze]] and other alloys (37%).<ref name="USGS-yb2006"/> The relative reactivity of zinc and its ability to attract oxidation to itself makes it an efficient [[sacrificial anode]] in [[cathodic protection]] (CP). For example, cathodic protection of a buried pipeline can be achieved by connecting anodes made from zinc to the pipe.<ref name="Lehto1968p829"/> Zinc acts as the [[anode]] (negative terminus) by slowly corroding away as it passes electric current to the steel pipeline.<ref name="Lehto1968p829"/><ref group=note>Electric current will naturally flow between zinc and steel but in some circumstances inert anodes are used with an external DC source.</ref> Zinc is also used to cathodically protect metals that are exposed to sea water from corrosion.<ref>{{Cite journal|title=A comparative study of the electrochemical behaviour of Algerian zinc and a zinc from a commercial sacrificial anode|first=M.|coauthors=Salhi, E.; Benzine, K.; Ghali E.; Dalard F.|last=Bounoughaz|journal=Journal of Materials Science|volume =38|issue=6|page=1139|doi=10.1023/A:1022824813564|year=2003}}</ref><ref name=Stwertka1998p99/> |

||

and is in some applications replaced with less toxic but considerably more expensive [[Galinstan]] [[alloy]].<ref>{{cite journal|doi=10.1007/s00216-005-0069-7|year=2005|month=Nov|author=Surmann, P; Zeyat, H|title=Voltammetric analysis using a self-renewable non-mercury electrode.|volume=383|issue=6|pages=1009–13|pmid=16228199|journal=Analytical and bioanalytical chemistry}}</ref> Mercury and its compounds have been used in medicine, although they are much less common today than they once were, now that the toxic effects of mercury and its compounds are more widely understood.<ref>{{cite web|author = FDA|url =http://www.fda.gov/Cber/vaccine/thimerosal.htm|title = Thimerosal in Vaccines|accessdate=October 25, 2006}}</ref> It is still used as an ingredient in [[amalgam (dentistry)|dental amalgams]]. In the late 20th century the largest use of mercury<ref>{{cite book|title=The CRB Commodity Yearbook (annual)|year= 2000|page=173|issn=1076-2906}}</ref><ref name="USEPA">{{cite web|url=http://www.epa.gov/nrmrl/pubs/600r02104/600r02104chap3.pdf|format=PDF|author=Leopold, B. R.|year=2002|title=Chapter 3: Manufacturing Processes Involving Mercury. ''Use and Release of Mercury in the United States''|publisher=National Risk Management Research Laboratory, Office of Research and Development, U.S. Environmental Protection Agency, Cincinnati, Ohio|accessdate=May 1, 2007 |archiveurl =http://web.archive.org/web/20070621093346/http://www.epa.gov/nrmrl/pubs/600r02104/600r02104chap3.pdf |archivedate = June 21, 2007}}</ref> was in the mercury cell process (also called the [[Castner-Kellner process]]) in the production of [[chlorine]] and [[caustic soda]].<ref>{{cite web|url=http://www.eurochlor.org/animations/mercury-cell.asp|title=Chlorine Online Diagram of mercury cell process| publisher=Euro Chlor| accessdate=2006-09-15}}</ref> |

|||

| ⚫ | Zinc is also used as an anode material for batteries such as in [[Zinc-carbon battery|zinc–carbon batteries]]<ref>{{Cite book|first=Jürgen O.|last=Besenhard|title=Handbook of Battery Materials|accessdate=2008-10-08|publisher=Wiley-VCH|url=http://www.ulb.tu-darmstadt.de/tocs/60178752.pdf|isbn=3527294694|year=1999}}</ref><ref>{{Cite journal|doi=10.1016/0378-7753(95)02242-2|year=1995|title=Recycling zinc batteries: an economical challenge in consumer waste management|first=J.-P.|last=Wiaux|coauthors=Waefler, J. -P.|journal=Journal of Power Sources|volume=57|issue=1–2|page=61}}</ref> or [[zinc-air battery]]/fuel cells.<ref>{{Cite journal|title=A design guide for rechargeable zinc-air battery technology|last=Culter|first=T.|doi=10.1109/SOUTHC.1996.535134|journal=Southcon/96. Conference Record|isbn=0-7803-3268-7|year=1996|page=616}}</ref><ref>{{cite web|url=http://www.electric-fuel.com/evtech/papers/paper11-1-98.pdf| title=Zinc Air Battery-Battery Hybrid for Powering Electric Scooters and Electric Buses|first=Jonathan|last=Whartman|coauthors=Brown, Ian|publisher=The 15th International Electric Vehicle Symposium| accessdate=2008-10-08}}</ref><ref>{{cite web|url =http://www.osti.gov/energycitations/product.biblio.jsp?osti_id=82465|title=A refuelable zinc/air battery for fleet electric vehicle propulsion|last=Cooper|first=J. F|coauthors=Fleming, D.; Hargrove, D.; Koopman, R.; Peterman, K|publisher=Society of Automotive Engineers future transportation technology conference and exposition|accessdate=2008-10-08}}</ref> |

||

| ⚫ | A widely used alloy which contains zinc is brass, in which copper is alloyed with anywhere from 3% to 45% zinc, depending upon the type of brass.<ref name="Lehto1968p829"/> Brass is generally more [[ductile]] and stronger than copper and has superior [[corrosion resistance]].<ref name="Lehto1968p829"/> These properties make it useful in communication equipment, hardware, musical instruments, and water valves.<ref name="Lehto1968p829"/> Other widely used alloys that contain zinc include [[nickel silver]], typewriter metal, soft and aluminium [[solder]], and commercial [[bronze]].<ref name="CRCp4-41"/> Alloys of primarily zinc with small amounts of copper, aluminium, and magnesium are useful in [[die casting]] as well as [[spin casting]], especially in the automotive, electrical, and hardware industries.<ref name="CRCp4-41"/> These alloys are marketed under the name [[Zamak]].<ref>{{cite web|url=http://www.eazall.com/diecastalloys.aspx|title=Diecasting Alloys|author=Eastern Alloys contributors|publisher=Eastern Alloys|accessdate=2009-01-19|location=Maybrook, NY}}</ref> Roughly one quarter of all zinc output, in the United States (2009), is consumed in the form of zinc compounds, a variety of which are used industrially.<ref name="USGS-yb2006"/> |

||

==Biological role and toxicity== |

==Biological role and toxicity== |

||

Revision as of 22:05, 25 February 2012

| Group → | 12 | |||

|---|---|---|---|---|

| ↓ Period | ||||

| 4 | title="Zn, Zinc" style="text-align:center; color:#000000; background-color:#ffc0c0; border:2px solid #6e6e8e; ;"|  30 Zn | |||

| 5 | title="Cd, Cadmium" style="text-align:center; color:#000000; background-color:#ffc0c0; border:2px solid #6e6e8e; ;"|  48 Cd | |||

| 6 | title="Hg, Mercury (element)" style="text-align:center; color:#000000; background-color:#ffc0c0; border:2px solid #6e6e8e; ;"|  80 Hg | |||

| 7 | title="Cn, Copernicium" style="text-align:center; color:#000000; background-color:#ffc0c0; border:2px dotted #6e6e8e; ;"| 112 Cn | |||

| ||||

A group 12 element is one of the elements in group 12 (IUPAC style) in the periodic table. This includes zinc (Zn), cadmium (Cd) and mercury (Hg).[1][2][3] The further inclusion of copernicium (Cn) in group 12 is supported by recent experiments on individual copernicium atoms.[4] Although this group lies in the d-block of the periodic table it is not always considered to be a part of the transition metals as the elements in this group have a filled d-subshell. The group itself has not acquired a trivial name.

The three Group 12 elements that occur naturally are zinc, cadmium and mercury. The first two members of the group share similar properties as they are solid metals under standard conditions. Mercury is the only metal that is a liquid at room temperature. As copernicium does not occur in a natural, stable form in nature, it has to be synthesized in the laboratory; none of its isotopes have been found occurring in nature. So far, no experiments in a supercollider were conducted to synthesize the next member of the group, either unhexbium (Uhb) or unhexquadium (Uhq), and it is unlikely that they will be synthesized in the near future.

Physical and atomic properties

Group 12 elements are all soft, diamagnetic, divalent metals. They have the lowest melting points among all transition metals.[5] Zinc, also referred to in nonscientific contexts as spelter,[6] is bluish-white, lustrous[7] though most common commercial grades of the metal have a dull finish.[8] Cadmium is soft, malleable, ductile, and with a bluish-white color. Mercury is a liquid, heavy, silvery-white metal. It is the only common metal liquid at ordinary temperatures, and as compared to other metals, it is a poor conductor of heat, but a fair conductor of electricity.[9]

The table below is a summary of the key physical properties of the group 12 elements.

| Name | Zinc | Cadmium | Mercury | Copernicium |

|---|---|---|---|---|

| Melting point | 693 K (420 °C) | 594 K (321 °C) | 234 K (−39 °C) | ? |

| Boiling point | 1180 K (907 °C) | 1040 K (767 °C) | 630 K (357 °C) | ? |

| Density | 7.14 g·cm−3 | 8.65 g·cm−3 | 13.534 g·cm−3 | ? |

| Appearance | silver-gray | silvery bluish-gray metallic | silvery | ? |

| Atomic radius | 135 pm | 155 pm | 150 pm | ? |

Zinc is somewhat less dense than iron and has a hexagonal crystal structure.[10] The metal is hard and brittle at most temperatures but becomes malleable between 100 and 150 °C.[7][8]Above 210 °C, the metal becomes brittle again and can be pulverized by beating.[11] Zinc is a fair conductor of electricity.[7] For a metal, zinc has relatively low melting (419.5 °C, 787.1 F) and boiling points (907 °C).[5] Cadmium is similar in many respects to zinc but forms complex compounds.[12] Unlike other metals, cadmium is resistant to corrosion and as a result it is used as a protective layer when deposited on other metals. As a bulk metal, cadmium is insoluble in water and is not flammable; however, in its powdered form it may burn and release toxic fumes.[13] Mercury has an exceptionally low melting temperature for a d-block metal. A complete explanation of this fact requires a deep excursion into quantum physics, but it can be summarized as follows: mercury has a unique electronic configuration where electrons fill up all the available 1s, 2s, 2p, 3s, 3p, 3d, 4s, 4p, 4d, 4f, 5s, 5p, 5d and 6s subshells. As such configuration strongly resists removal of an electron, mercury behaves similarly to noble gas elements, which form weak bonds and thus easily melting solids. The stability of the 6s shell is due to the presence of a filled 4f shell. An f shell poorly screens the nuclear charge that increases the attractive Coulomb interaction of the 6s shell and the nucleus (see lanthanide contraction). The absence of a filled inner f shell is the reason for the somewhat higher melting temperature ofcadmium and zinc, although both these metals still melt easily and, in addition, have unusually low boiling points. Metals such as gold have atoms with one less 6s electron than mercury. Those electrons are more easily removed and are shared between the gold atoms forming relatively strong metallic bonds.[14][15]

Zinc, cadmium and mercury for a large range of alloys. Among the zinc containing ones brass is an alloy of zinc and copper. Other metals long known to form binary alloys with zinc are aluminium, antimony,bismuth, gold, iron, lead, mercury, silver, tin, magnesium, cobalt, nickel, tellurium andsodium.[16] While neither zinc nor zirconium are ferromagnetic, their alloy ZrZn

2 exhibits ferromagnetism below 35 K.[7] Cadmium is used in many kinds of solder and bearing alloys, due to a low coefficient of friction and fatigue resistance.[17] It is also found in some of the lowest-melting alloys, such as Wood's metal.[18] Because it is a liquid, mercury dissolves other metals and the alloys that are formed are called amalgams. For example, such amalgams are known with gold, zinc, sodium, and many other metals. Because iron is an exception, iron flasks have been traditionally used to trade mercury. Other metals that do not form amalgams with mercury include tantalum, tungsten and platinum. Sodium amalgam is a common reducing agent in organic synthesis, and is also used in high-pressure sodium lamps. Mercury readily combines with aluminium to form a mercury-aluminium amalgam when the two pure metals come into contact. Since the amalgam reacts with air to give aluminium oxide, small amounts of mercury corrode aluminium. For this reason, mercury is not allowed aboard an aircraft under most circumstances because of the risk of it forming an amalgam with exposed aluminium parts in the aircraft.[19]

Like other groups, the members of this family show patterns in its electron configuration, especially the outermost shells resulting in trends in chemical behavior:

| Z | Element | No. of electrons/shell |

|---|---|---|

| 30 | zinc | 2, 8, 18, 2 |

| 48 | cadmium | 2, 8, 18, 18, 2 |

| 80 | mercury | 2, 8, 18, 32, 18, 2 |

| 112 | copernicium | 2, 8, 18, 32, 32, 18, 2 |

Chemistry and compounds

| H | He | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Li | Be | B | C | N | O | F | Ne | |||||||||||

| Na | Mg | Al | Si | P | S | Cl | Ar | |||||||||||

| K | Ca | Sc | Ti | V | Cr | Mn | Fe | Co | Ni | Cu | Zn | Ga | Ge | As | Se | Br | Kr | |

| Rb | Sr | Y | Zr | Nb | Mo | Tc | Ru | Rh | Pd | Ag | Cd | In | Sn | Sb | Te | I | Xe | |

| Cs | Ba | * | Hf | Ta | W | Re | Os | Ir | Pt | Au | Hg | Tl | Pb | Bi | Po | At | Rn | |

| Fr | Ra | ** | Rf | Db | Sg | Bh | Hs | Mt | Ds | Rg | Cn | Uut | Uuq | Uup | Uuh | Uus | Uuo | |

| * | La | Ce | Pr | Nd | Pm | Sm | Eu | Gd | Tb | Dy | Ho | Er | Tm | Yb | Lu | |||

| ** | Ac | Th | Pa | U | Np | Pu | Am | Cm | Bk | Cf | Es | Fm | Md | No | Lr | |||

| Group 12 in the periodic table |

Most of the chemistry has been observed only for the first three members of the group. The chemistry of copernicium is not well established and therefore the rest of the section deals only with zinc, cadmium and mercury.

All elements in this group are metals. The similarity of the metallic radii of cadmium and mercury is an effect of the lanthanide contraction. So, the trend in this group is unlike the trend in group 2, the alkaline earths, where metallic radius increases smoothly from top to bottom of the group. All three metals have relatively low melting and boiling points, indicating that the metallic bond is relatively weak, with relatively little overlap between the valence band and the conduction band.[20] Thus, zinc is close to the boundary between metallic and metalloidelements, which is usually placed between gallium and germanium, though gallium participates in semi-conductors such as gallium arsenide.

Zinc and cadmium are the electropositive elements in the group while mercury is not.[20] As a result, zinc metal and cadmium are good reducing agents. The elements of group group 12 have an oxidation state of +2 in which the ions have the rather stable d10 electronic configuration, with a full sub-shell. However, mercury can easily be reduced to the +1 oxidation state; usually, as in the ion Hg22+, two mercury(I) ions come together to form a metal-metal bond and a diamagnetic species.[21] Cadmium can also form species such as [Cd2Cl6]4− in which the metal's oxidation state is +1. Just as with mercury, the formation of a metal-metal bond results in a diamagnetic compound in which there are no unpaired electrons; thus, making the species very reactive. Zinc(I) is known only in the gas phase, in such compounds as linear Zn2Cl2, analogous to calomel.

All three metal ions form many tetrahedral species, such as MCl42−. When a divalent ion of these elements forms a tetrahedral complex, it obeys the octet rule. Both zinc and cadmium can also form octahedral complexes such as the aqua ions [M(H2O)6]2+ which are present in aqueous solutions of salts of these metals.[22] Covalent character is achieved by using the 4d or 5d orbitals, respectively, forming sp3d2 hybrid orbitals. Mercury, however, rarely exceeds a coordination number of four; when it does so the 5f orbitals must be involved. Coordination numbers of 2, 3, 5, 7 and 8 are also known.

The elements in group 12 are usually considered to be d-block elements, but not transition elements as the d-shell is full. Some authors classify these elements as main-group elements because the valence electrons are in ns2 orbitals. Nevertheless, zinc shares many characteristics with the neighboring transition metal, copper. For instance, zinc complexes merit inclusion in the Irving-Williams series as zinc forms many complexes with the same stoichiometry as complexes of copper(II), albeit with smaller stability constants.[23] There is little similarity between cadmium and silver as compounds of silver(II) are rare and those that do exist are very strong oxidizing agents. Likewise the common oxidation state for gold is +3, which precludes there being much common chemistry between mercury and gold, though there are similarities between mercury(I) and gold(I) such as the formation of linear dicyano complexes, [M(CN)2]−. According to IUPAC's definition of transition metal as an element whose atom has an incomplete d sub-shell, or which can give rise to cations with an incomplete d sub-shell,[24] zinc and cadmium are not transition metal, while mercury is. This is because only mercury is known to have a compound where its oxidation state is higher than 2+, in mercury(IV) fluoride.[25][26]

History

The elements of group 12 have been found throughout history, being used since ancient times to being discovered in laboratories.

Zinc

In ancient times zinc has been found being used in impure forms as well as in alloys such as brass that have been found to be over 2000 years old.[27][28] Zinc was distinctly recognized as a metal under the designation of Fasada in the medical Lexicon ascribed to the Hindu king Madanapala and written about the year 1374.[29] The metal was also of use to alchemists.[30] The name of the metal was first documented in the 16th century,[31][32] and is probably derived from the German [zinke] Error: {{Lang}}: text has italic markup (help) for the meedle-like appearance of metallic crystals.[33]

The isolation of metallic zinc in the West may have been achieved independently by several people in the 17th century.[34] German chemist Andreas Marggraf is usually given credit for discovering pure metallic zinc in a 1746 experiment by heating a mixture of calamine and charcoal in a closed vessel without copper to obtain a metal.[35] Experiments on frogs by the Italian doctor Luigi Galvani in 1780 with brass paved the way for the discovery of for electrical batteries, galvanization and cathodic protection.[36][37] In 1880, Galvani's friend, Alessandro Volta, invented the Voltaic pile.[36] The biological importance of zinc was not discovered until 1940 when carbonic anhydrase, an enzyme that scrubs carbon dioxide from blood, was shown to have zinc in its active site.[38]

Cadmium

In 1817 Cadmium was discovered in Germany as an impurity in zinc carbonate minerals (calamine) by Friedrich Stromeyer and Karl Samuel Leberecht Hermann.[39] It was named after the latin Latin cadmia for "calamine", a cadmium-bearing mixture of minerals, which was in turn named after the Greek mythological character, Κάδμος Cadmus, the founder of Thebes.[40] Stromeyer eventually isolated cadmium metal by roasting and reduction of the sulfide.[41][42][43]

In 1927, the International Conference on Weights and Measures redefined the meter in terms of a red cadmium spectral line (1 m = 1,553,164.13 wavelengths).[44] This definition has since been changed (see krypton).

Mercury

Mercury has been found in Egyptian tombs which have been dated back to 1500 BC,[45] where mercury was used in cosmetics. It was also used by the ancient Chinese who believed it would improve and prolong health.[46] By 500 BC mercury was used to make amalgams (Medieval Latin amalgama, "alloy of mercury") with other metals.[47] Alchemists thought of mercury as the First Matter from which all metals were formed. They believed that different metals could be produced by varying the quality and quantity of sulfur contained within the mercury. The purest of these was gold, and mercury was called for in attempts at thetransmutation of base (or impure) metals into gold, which was the goal of many alchemists.[48]

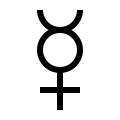

Hg is the modern chemical symbol for mercury. It comes from hydrargyrum, a Latinized form of the Greek word Ύδραργυρος (hydrargyros), which is a compound word meaning "water-silver" (hydr- = water, argyros = silver) — since it is liquid like water and shiny like silver. The element was named after the Roman god Mercury, known for speed and mobility. It is associated with the planet Mercury; the astrological symbol for the planet is also one of the alchemical symbols for the metal.[49] Mercury is the only metal for which the alchemical planetary name became the common name.[48]

Copernicium

The heaviest known group 12 element, copernicium was first created on February 9, 1996, at the Gesellschaft für Schwerionenforschung (GSI) located in Darmstadt, Germany by Sigurd Hofmann, Victor Ninov et al.[50] It was then officially named by the International Union of Pure and Applied Chemistry after Nicolaus Copernicus on February 19, 2010, the 537th anniversary of Copernicus' birth.[51]

Eka-copernicium

The next element below copernicium is expected to be either the 162th element (unhexbium, Uhb) or the 164th element (unhexquadium, Uhq). There are no plans to attempt to synthesize either of these in the near future, since they are both late period 8 elements. Currently none of the period 8 elements have been discovered yet, and it is possible that due to drip instabilities, only the lower period 8 elements are physically possible.[52]

Occurrence

Like in most other d-block groups the abundance in Earth's crust decreases with higher atomic number, and so the zinc is with 65 parts per million (ppm) the most abundant in the group while cadmium with 0.1 ppm and mercury with 0.08 ppm are orders of magnitude less abundant.[53] Copernicium, as a synthetic element with a half-life of a few minutes, may only be present in the laboratories where it was produced.

Group 12 metals are chalcophiles, meaning the elements have low affinities for oxides and prefer to bond with sulfides. Chalcophiles formed as the crust solidified under the reducing conditions of the early Earth's atmosphere.[54] The commercially most important minerals of group 12 elements are sulfide minerals.[20] Sphalerite, which is a form of zinc sulfide, is the most heavily mined zinc-containing ore because its concentrate contains 60–62% zinc.[55] No significant deposits of cadmium-containing ores are known. Greenockite (CdS), the only cadmium mineral of importance, is nearly always associated with sphalerite (ZnS). This association is caused by the geochemical similarity between zinc and cadmium which makes geological separation unlikely. As a consequence, cadmium is produced mainly as a byproduct from mining, smelting, and refining sulfidic ores of zinc, and, to a lesser degree, lead and copper.[56][57] One place where metallic cadmium can be found is the Vilyuy River basin in Siberia.[58] Although mercury is an extremely rare element in the Earth's crust,[59] because it does not blend geochemically with those elements that constitute the majority of the crustal mass, mercury ores can be highly concentrated considering the element's abundance in ordinary rock. The richest mercury ores contain up to 2.5% mercury by mass, and even the leanest concentrated deposits are at least 0.1% mercury (12,000 times average crustal abundance). It is found either as a native metal (rare) or in cinnabar (HgS), corderoite, livingstonite and other minerals, with cinnabar being the most common ore.[60]

While mercury and zinc minerals are found in large enough quantities to be mined, cadmium is too similar to zinc and therefore is always present in small quantities in zinc ores from where it is recovered. Identified world zinc resources total about 1.9 billion tonnes.[61] Large deposits are in Australia, Canada and the United States with the largest reserves in Iran.[54][62][63] At the current rate of consumption, these reserves are estimated to be depleted sometime between 2027 and 2055.[64][65] About 346 million tonnes have been extracted throughout history to 2002, and one estimate found that about 109 million tonnes of that remains in use.[66] In 2005, China was the top producer of mercury with almost two-thirds global share followed by Kyrgyzstan.[67] Several other countries are believed to have unrecorded production of mercury from copper electrowinning processes and by recovery from effluents. Because of the high toxicity of mercury, both the mining of cinnabar and refining for mercury are hazardous and historic causes of mercury poisoning.[68]

Production

Zinc is the fourth most common metal in use, trailing only iron, aluminium, and copper with an annual production of about 10 million tonnes.[69] Worldwide, 95% of the zinc is mined from sulfidic ore deposits, in which sphalerite (ZnS) is nearly always mixed with the sulfides of copper, lead and iron. Zinc metal is produced using extractive metallurgy.[70] Roasting converts the zinc sulfide concentrate produced during processing to zinc oxide:[71] For further processing two basic methods are used: pyrometallurgy or electrowinning. Pyrometallurgy processing reduces zinc oxide with carbon or carbon monoxide at 950 °C (1,740 °F) into the metal, which is distilled as zinc vapor.[72] The zinc vapor is collected in a condenser.[71] Electrowinning processing leaches zinc from the ore concentrate by sulfuric acid:[73] After this step electrolysis is used to produce zinc metal.[71]

Cadmium is a common impurity in zinc ores, and it is most isolated during the production of zinc. Some zinc ores concentrates from sulfidic zinc ores contain up to 1.4% of cadmium.[74] Cadmium is isolated from the zinc produced from the flue dust by vacuum distillation if the zinc is smelted, or cadmium sulfate is precipitated out of the electrolysis solution.[75]

The richest mercury ores contain up to 2.5% mercury by mass, and even the leanest concentrated deposits are at least 0.1% mercury, with cinnabar (HgS) being the most common ore in the deposits.[76] Mercury is extracted by heating cinnabar in a current of air and condensing the vapor.[77]

Super-heavy elements such as copernicium are produced by bombarding lighter elements in particle accelerators that induces fusion reactions. Whereas most of the isotopes of rutherfordium can be synthesized directly this way, some heavier ones have only been observed as decay products of elements with higher atomic numbers.[78] The first fusion reaction to produce copernicium was performed by GSI in 1996, who reported the detection of two decay chains of copernicium-277.[50]

- The element Link does not exist. + The element Link does not exist. → 277

112Cn

+

n

In total, approximately 75 atoms of copernicium have been prepared using various nuclear reactions.

Applications

Due to the physical similarities which they share, the group 12 elements can be found in many common situations. Zinc and cadmium are commonly used as anti-corrosion(galvanization) agents[1] as they will attract all local oxidation until they completely corrode.[79] These protective coatings can be applied to other metals through by hot-dip galvanizing a substance into the molten form of the metal,[80] or through the process of electroplating which may be passivated by the use of chromate salts.[81] Group 12 elements are also used in electrochemistry as they may act as an alternative to the standard hydrogen electrode in addition to being a secondary reference electrode.[82] In the US, zinc is used predominantly for galvanizing (55%) and for brass, bronze and other alloys (37%).[83] The relative reactivity of zinc and its ability to attract oxidation to itself makes it an efficient sacrificial anode in cathodic protection (CP). For example, cathodic protection of a buried pipeline can be achieved by connecting anodes made from zinc to the pipe.[84] Zinc acts as the anode (negative terminus) by slowly corroding away as it passes electric current to the steel pipeline.[84][note 1] Zinc is also used to cathodically protect metals that are exposed to sea water from corrosion.[85][86] Zinc is also used as an anode material for batteries such as in zinc–carbon batteries[87][88] or zinc-air battery/fuel cells.[89][90][91] A widely used alloy which contains zinc is brass, in which copper is alloyed with anywhere from 3% to 45% zinc, depending upon the type of brass.[84] Brass is generally more ductile and stronger than copper and has superior corrosion resistance.[84] These properties make it useful in communication equipment, hardware, musical instruments, and water valves.[84] Other widely used alloys that contain zinc include nickel silver, typewriter metal, soft and aluminium solder, and commercial bronze.[7] Alloys of primarily zinc with small amounts of copper, aluminium, and magnesium are useful in die casting as well as spin casting, especially in the automotive, electrical, and hardware industries.[7] These alloys are marketed under the name Zamak.[92] Roughly one quarter of all zinc output, in the United States (2009), is consumed in the form of zinc compounds, a variety of which are used industrially.[83]

Cadmium has many common industrial uses as it is a key component in battery production, is present in cadmium pigments,[93] coatings,[94] and is commonly used in electroplating.[17] In 2009, 86% of cadmium was used in batteries, predominantly in rechargeable nickel-cadmium batteries. The European Union banned the use of cadmium in electronics in 2004 with several exceptions but reduced the allowed content of cadmium in electronics to 0.002%.[95] Cadmium electroplating, consuming 6% of the global production, can be found in the aircraft industry due to the ability to resist corrosion when applied to steel components.[17]

Mercury is used primarily for the manufacture of industrial chemicals or for electrical and electronic applications. It is used in some thermometers, especially ones which are used to measure high temperatures. A still increasing amount is used as gaseous mercury in fluorescent lamps,[96] while most of the other applications are slowly phased out due to health and safety regulations,[97]

and is in some applications replaced with less toxic but considerably more expensive Galinstan alloy.[98] Mercury and its compounds have been used in medicine, although they are much less common today than they once were, now that the toxic effects of mercury and its compounds are more widely understood.[99] It is still used as an ingredient in dental amalgams. In the late 20th century the largest use of mercury[100][101] was in the mercury cell process (also called the Castner-Kellner process) in the production of chlorine and caustic soda.[102]

Biological role and toxicity

The group 12 elements have multiple effects on biological organisms as cadmium and mercury are toxic while zinc is required by most plants and animals in trace amounts. Zinc is required by most organisms in trace amounts as it is present in enzymes where it is often present as a catalytic agent for enzyme-directed reactions.[103] In large amounts zinc may be toxic to biological organisms as it prevents cells from absorbing copper and iron.[104]

Mercury and cadmium are toxic and may cause environmental damage if they enter rivers or rain water. This may result in contaminated crops[105] as well as the bioaccumulation of mercury in a food chain leading to an increase in illnesses caused by mercury and cadmium poisoning.[106]

Copernicium has no biological role[107] and does not occur in nature,[108] but it is most likely to be toxic due to its radioactivity.[109][110]

References

- ^ a b Greenwood, Norman N.; Earnshaw, Alan (1997). Chemistry of the Elements (2nd ed.). Butterworth-Heinemann. ISBN 978-0-08-037941-8.

- ^ Cotton, F. Albert; Wilkinson, Geoffrey; Murillo, Carlos A.; Bochmann, Manfred (1999), Advanced Inorganic Chemistry (6th ed.), New York: Wiley-Interscience, ISBN 0-471-19957-5

- ^ Housecroft, C. E.; Sharpe, A. G. (2008). Inorganic Chemistry (3rd ed.). Prentice Hall. ISBN 978-0-13-175553-6.

- ^ Eichler, R; Aksenov, NV; Belozerov, AV; Bozhikov, GA; Chepigin, VI; Dmitriev, SN; Dressler, R; Gäggeler, HW; Gorshkov, VA (2007). "Chemical Characterization of Element 112". Nature. 447 (7140): 72–75. Bibcode:2007Natur.447...72E. doi:10.1038/nature05761. PMID 17476264.

{{cite journal}}: More than one of|author=and|last1=specified (help) - ^ a b "Zinc Metal Properties". American Galvanizers Association. 2008. Retrieved 2009-02-15.

- ^ Spelter. Encyclo. ISBN 0665822448. Retrieved 2009-08-01.

- ^ a b c d e f Cite error: The named reference

CRCp4-41was invoked but never defined (see the help page). - ^ a b Heiserman 1992, p. 123

- ^ Hammond, C. RThe Elements in Lide, D. R., ed. (2005). CRC Handbook of Chemistry and Physics (86th ed.). Boca Raton (FL): CRC Press. ISBN 0-8493-0486-5.

- ^ Lehto 1968, p. 826

- ^ Scoffern, John (1861). The Useful Metals and Their Alloys. Houlston and Wright. pp. 591–603. Retrieved 2009-04-06.

- ^ Holleman, Arnold F. (1985). "Cadmium". Lehrbuch der Anorganischen Chemie (in German) (91–100 ed.). Walter de Gruyter. pp. 1056–1057. ISBN 3-11-007511-3.

{{cite book}}: Unknown parameter|coauthors=ignored (|author=suggested) (help)CS1 maint: extra punctuation (link) - ^ "Case Studies in Environmental Medicine (CSEM) Cadmium". Agency for Toxic Substances and Disease Registry. Retrieved May 30, 2011.

- ^ Norrby, L.J. (1991). "Why is mercury liquid? Or, why do relativistic effects not get into chemistry textbooks?". Journal of Chemical Education. 68 (2): 110. Bibcode:1991JChEd..68..110N. doi:10.1021/ed068p110.

- ^ "Why is mercury a liquid at STP?". Retrieved 2009-07-07.

- ^ Ingalls, Walter Renton (1902). Production and Properties of Zinc: A Treatise on the Occurrence and Distribution of Zinc Ore, the Commercial and Technical Conditions Affecting the Production of the Spelter, Its Chemical and Physical Properties and Uses in the Arts, Together with a Historical and Statistical Review of the Industry. The Engineering and Mining Journal. pp. 142–6.

- ^ a b c Scoullos, Michael J. (2001). Mercury, Cadmium, Lead: Handbook for Sustainable Heavy Metals Policy and Regulation. Springer. ISBN 9781402002243.

{{cite book}}: Unknown parameter|coauthors=ignored (|author=suggested) (help) - ^ Brady, George Stuart; Brady, George S.; Clauser, Henry R.; Vaccari, John A. (2002). Materials handbook: an encyclopedia for managers, technical professionals, purchasing and production managers, technicians, and supervisors. McGraw-Hill Professional. p. 425. ISBN 9780071360760.

- ^ Vargel, C.; Jacques, M.; Schmidt, M. P. (2004). Corrosion of Aluminium. Elsevier. p. 158. ISBN 20049780080444956.

{{cite book}}: Check|isbn=value: length (help)CS1 maint: multiple names: authors list (link) - ^ a b c Moss, Alex (2003). "Descriptive P-block Notes" (PDF). Alchemyst Online. Retrieved June 2, 2011.

- ^ Lindberg, S.E.; Stratton, W.J. (1998). "Atmospheric Mercury Speciation: Concentrations and Behavior of Reactive Gaseous Mercury in Ambient Air". Environmental Science and Technology. 32 (1). American Chemical Society: 49–57. doi:10.1021/es970546u.

- ^ Richens, David T. (1997). The Chemistry of Aqua Ions. J. Wiley. ISBN 0-4719-7058-1.

{{cite book}}: Unknown parameter|month=ignored (help) - ^ Al-Niaimi, N.S.; Hamid, H.A. (1976). "Stabilities of nickel(II), copper(II), zinc(II) and dioxouranium(II) complexes of some β-diketones". Journal of Inorganic and Nuclear Chemistry. 3 (5). Elsevier Ltd.: 849–852. doi:10.1016/0022-1902(77)80167-X.

- ^ http://goldbook.iupac.org/T06456.html

- ^ http://www.speciation.net/News/Elusive-HgIV-species-has-been-synthesized-under-cryogenic-conditions-;~/2007/10/12/3303.html

- ^ . doi:10.1002/ange.200703710.

{{cite journal}}: Cite journal requires|journal=(help); Missing or empty|title=(help) - ^ Weeks, Mary Elvira (1933). III. Some Eighteenth-Century Metals. Easton, PA: Journal of Chemical Education. p. 20. ISBN 0766138720.

- ^ Greenwood 1997, p. 1201

- ^ Ray, Prafulla Chandra (1903). A History of Hindu Chemistry from the Earliest Times to the Middle of the Sixteenth Century, A.D.: With Sanskrit Texts, Variants, Translation and Illustrations. Vol. 1 (2nd ed.). The Bengal Chemical & Pharmaceutical Works, Ltd. pp. 157–158. (public domain text)

- ^ Arny, Henry Vinecome (1917). Principles of Pharmacy (2nd ed.). W. B. Saunders company. p. 483.

- ^ Habashi, Fathi. "Discovering the 8th Metal" (PDF). International Zinc Association (IZA). Retrieved 2008-12-13.

- ^ Hoover, Herbert Clark (2003). Georgius Agricola de Re Metallica. Kessinger Publishing. p. 409. ISBN 0766131971.

- ^ Gerhartz, Wolfgang (1996). Ullmann's Encyclopedia of Industrial Chemistry (5th ed.). VHC. p. 509. ISBN 3527201009.

{{cite book}}: Unknown parameter|coauthors=ignored (|author=suggested) (help) - ^ Emsley 2001, p. 502

- ^ Weeks 1933, p. 21

- ^ a b Warren, Neville G. (2000). Excel Preliminary Physics. Pascal Press. p. 47. ISBN 1740200853.

- ^ "Galvanic Cell". The New International Encyclopaedia. Dodd, Mead and Company. 1903. p. 80.

- ^ Cotton 1999, p. 626

- ^ "Cadmium". Kirk-Othmer Encyclopedia of Chemical Technology. Vol. 5 (4-th ed.). New York: John Wiley & Sons. 1994.

- ^ Hermann (1818). "Noch ein schreiben über das neue Metall (Another letter about the new metal)". Annalen der Physik. 59 (5): 113. Bibcode:1818AnP....59..113H. doi:10.1002/andp.18180590511.

- ^ Waterston, William; Burton, J. H (1844). Cyclopædia of commerce, mercantile law, finance, commercial geography and navigation. p. 122.

- ^ Rowbotham, Thomas Leeson (1850). The art of landscape painting in water colours, by T. and T. L. Rowbotham. p. 10.

- ^ Ayres, Robert U.; Ayres, Leslie; Råde, Ingrid (2003). The life cycle of copper, its co-products and byproducts. pp. 135–141. ISBN 9781402015526.

- ^ Burdun, G. D. (1958). "On the new determination of the meter" (pdf). Measurement Techniques. 1 (3): 259–264. doi:10.1007/BF00974680.

- ^ "Mercury and the environment — Basic facts". Environment Canada, Federal Government of Canada. 2004. Retrieved 2008-03-27.

- ^ Wright, David Curtis (2001). The History of China. Greenwood Publishing Group. p. 49. ISBN 031330940X.

- ^ Hesse R W (2007). Jewelrymaking through history. Greenwood Publishing Group. p. 120. ISBN 0313335079.

- ^ a b Stillman, J. M. (2003). Story of Alchemy and Early Chemistry. Kessinger Publishing. pp. 7–9. ISBN 9780766132306.

- ^ Cox, R (1997). The Pillar of Celestial Fire. 1st World Publishing. p. 260. ISBN 1887472304.

- ^ a b S. Hofmann; et al. (1996). "The new element 112". Zeitschrift für Physik A. 354 (1): 229–230. doi:10.1007/BF02769517.

{{cite journal}}: Explicit use of et al. in:|author=(help) - ^ Barber, Robert C.; Gäggeler, Heinz W.; Karol, Paul J.; Nakahara, Hiromichi; Vardaci, Emanuele; Vogt, Erich. "[IUPAC]Element 112 is Named Copernicium". Pure and Applied Chemistry. 81 (7). iupac.org: 1331. doi:10.1351/PAC-REP-08-03-05. Retrieved 2010-02-22.

- ^ "Extended elements: new periodic table". Rsc.org. Retrieved 2011-03-06.

- ^ Wedepohl, K. Hans (1995). "The composition of the continental crust". Geochimica et Cosmochimica Acta. 59 (7): 1217–1232. Bibcode:1995GeCoA..59.1217W. doi:10.1016/0016-7037(95)00038-2.

- ^ a b Greenwood 1997, p. 1202

- ^ Cite error: The named reference

Lehto1968p822was invoked but never defined (see the help page). - ^ Plachy, Jozef. "Annual Average Cadmium Price" (PDF). USGS. Retrieved June 16, 2010.

- ^ Fthenakis, V (2004). "Life cycle impact analysis of cadmium in CdTe PV production". Renewable and Sustainable Energy Reviews. 8 (4): 303. doi:10.1016/j.rser.2003.12.001.

- ^ Fleischer, Michael (1980). "New Mineral Names" (PDF). American Mineralogist. 65: 1065–1070.

- ^ Ehrlich, H. L.; Newman D. K. (2008). Geomicrobiology. CRC Press. p. 265. ISBN 9780849379062.

{{cite book}}: CS1 maint: multiple names: authors list (link) - ^ Rytuba, James J. "Mercury from mineral deposits and potential environmental impact". Environmental Geology. 43 (3): 326–338. doi:10.1007/s00254-002-0629-5.

- ^ Tolcin, A. C. (2011). "Mineral Commodity Summaries 2009: Zinc" (PDF). United States Geological Survey. Retrieved 2011-06-06.

- ^ "Country Partnership Strategy—Iran: 2011–12". ECO Trade and development bank. Retrieved 2011-06-06.

- ^ "IRAN – a growing market with enormous potential". IMRG. July 5, 2010. Retrieved 2010-03-03.

- ^ Cohen, David (2007). "Earth audit". New Scientist. 194 (2605): 8. doi:10.1016/S0262-4079(07)61315-3.

- ^ "Augsberg University Calculate When Our Materials Run Out". IDTechEx. 2007-06-04. Retrieved 2008-12-09.

- ^ Gordon, R. B. (2006). "Metal stocks and sustainability". Proceedings of the National Academy of Sciences. 103 (5): 1209. Bibcode:2006PNAS..103.1209G. doi:10.1073/pnas.0509498103. PMC 1360560. PMID 16432205.

{{cite journal}}: More than one of|pages=and|page=specified (help); Unknown parameter|coauthors=ignored (|author=suggested) (help) - ^ World Mineral Production. London: British Geological Survey, NERC. 2001-05.

{{cite book}}: Check date values in:|date=and|year=/|date=mismatch (help) - ^ About the Mercury Rule

- ^ "Zinc: World Mine Production (zinc content of concentrate) by Country" (Document). Washington, D.C.: United States Geological Survey. February 2008. p. Table 15.

{{cite document}}: Unknown parameter|accessdate=ignored (help); Unknown parameter|url=ignored (help); Unknown parameter|work=ignored (help) - ^ Rosenqvist, Terkel (1922). Principles of Extractive Metallurgy (2 ed.). Tapir Academic Press. pp. 7, 16, 186. ISBN 8251919223.

- ^ a b c Porter, Frank C. (1991). Zinc Handbook. CRC Press. ISBN 9780824783402.

- ^ Bodsworth, Colin (1994). The Extraction and Refining of Metals. CRC Press. p. 148. ISBN 0849344336.

- ^ Gupta, C. K. (1990). Hydrometallurgy in Extraction Processes. CRC Press. p. 62. ISBN 0849368049.

{{cite book}}: Unknown parameter|coauthors=ignored (|author=suggested) (help) - ^ National Research Council (U.S.), Panel on Cadmium, Committee on Technical Aspects of Critical and Strategic Material (1969). Trends in Usage of Cadmium: Report. National Research Council, National Academy of Sciences-National Academy of Engineering. pp. 1–3.

{{cite book}}: CS1 maint: multiple names: authors list (link) - ^ Scoullos, Michael J (2001-12-31). Mercury, cadmium, lead: handbook for sustainable heavy metals policy and regulation. pp. 104–116. ISBN 9781402002243.

- ^ Rytuba, James J. (2003). "Mercury from mineral deposits and potential environmental impact". Environmental Geology. 43 (3): 326–338. doi:10.1007/s00254-002-0629-5.

- ^ Vallero, Daniel A (2008). Fundamentals of air pollution. pp. 865–866. ISBN 9780123736154.

- ^ Barber, Robert C.; Gäggeler, Heinz W.; Karol, Paul J.; Nakahara, Hiromichi; Vardaci, Emanuele; Vogt, Erich (2009). "Discovery of the element with atomic number 112 (IUPAC Technical Report)". Pure and Applied Chemistry. 81 (7): 1331. doi:10.1351/PAC-REP-08-03-05.

- ^ Stwertka, Albert (1998). "Zinc". Guide to the Elements (Revised ed.). Oxford University Press. ISBN 0-19-508083-1.

{{cite book}}: CS1 maint: ref duplicates default (link) - ^ Emsley, John (2001). "Zinc". Nature's Building Blocks: An A-Z Guide to the Elements. Oxford, England, UK: Oxford University Press. pp. 499–505. ISBN 0-19-850340-7.

{{cite book}}: CS1 maint: ref duplicates default (link) - ^ Smith C.J.E., Higgs M.S., Baldwin K.R. (April 20, 1999). "Advances to Protective Coatings and their Application to Ageing Aircraft" (PDF). RTO MP-25. Retrieved May 29, 2011.

{{cite web}}: CS1 maint: multiple names: authors list (link) - ^ Newman, John (2004). Electrochemical Systems. New Jersey: John Wiley & Sons. ISBN 0471477567.

- ^ a b Cite error: The named reference

USGS-yb2006was invoked but never defined (see the help page). - ^ a b c d e Cite error: The named reference

Lehto1968p829was invoked but never defined (see the help page). - ^ Bounoughaz, M. (2003). "A comparative study of the electrochemical behaviour of Algerian zinc and a zinc from a commercial sacrificial anode". Journal of Materials Science. 38 (6): 1139. doi:10.1023/A:1022824813564.

{{cite journal}}: Unknown parameter|coauthors=ignored (|author=suggested) (help) - ^ Cite error: The named reference

Stwertka1998p99was invoked but never defined (see the help page). - ^ Besenhard, Jürgen O. (1999). Handbook of Battery Materials (PDF). Wiley-VCH. ISBN 3527294694. Retrieved 2008-10-08.

- ^ Wiaux, J.-P. (1995). "Recycling zinc batteries: an economical challenge in consumer waste management". Journal of Power Sources. 57 (1–2): 61. doi:10.1016/0378-7753(95)02242-2.

{{cite journal}}: Unknown parameter|coauthors=ignored (|author=suggested) (help) - ^ Culter, T. (1996). "A design guide for rechargeable zinc-air battery technology". Southcon/96. Conference Record: 616. doi:10.1109/SOUTHC.1996.535134. ISBN 0-7803-3268-7.

- ^ Whartman, Jonathan. "Zinc Air Battery-Battery Hybrid for Powering Electric Scooters and Electric Buses" (PDF). The 15th International Electric Vehicle Symposium. Retrieved 2008-10-08.

{{cite web}}: Unknown parameter|coauthors=ignored (|author=suggested) (help) - ^ Cooper, J. F. "A refuelable zinc/air battery for fleet electric vehicle propulsion". Society of Automotive Engineers future transportation technology conference and exposition. Retrieved 2008-10-08.

{{cite web}}: Unknown parameter|coauthors=ignored (|author=suggested) (help) - ^ Eastern Alloys contributors. "Diecasting Alloys". Maybrook, NY: Eastern Alloys. Retrieved 2009-01-19.

{{cite web}}:|author=has generic name (help) - ^ Cite error: The named reference

colorswas invoked but never defined (see the help page). - ^ Cite error: The named reference

fffwas invoked but never defined (see the help page). - ^ "Battery collection; recycling, nature protected". European Union. Retrieved November 4, 2008.

- ^ Hopkinson, G. R.; Goodman, T. M.; Prince, S. R. (2004). A guide to the use and calibration of detector array equipment. SPIE Press. p. 125. ISBN 0819455326.

{{cite book}}: CS1 maint: multiple names: authors list (link) - ^ "Mercury Reduction Act of 2003". United States. Congress. Senate. Committee on Environment and Public Works. Retrieved 2009-06-06.

- ^ Surmann, P; Zeyat, H (2005). "Voltammetric analysis using a self-renewable non-mercury electrode". Analytical and bioanalytical chemistry. 383 (6): 1009–13. doi:10.1007/s00216-005-0069-7. PMID 16228199.

{{cite journal}}: Unknown parameter|month=ignored (help)CS1 maint: multiple names: authors list (link) - ^ FDA. "Thimerosal in Vaccines". Retrieved October 25, 2006.

- ^ The CRB Commodity Yearbook (annual). 2000. p. 173. ISSN 1076-2906.

- ^ Leopold, B. R. (2002). "Chapter 3: Manufacturing Processes Involving Mercury. Use and Release of Mercury in the United States" (PDF). National Risk Management Research Laboratory, Office of Research and Development, U.S. Environmental Protection Agency, Cincinnati, Ohio. Archived from the original (PDF) on June 21, 2007. Retrieved May 1, 2007.

- ^ "Chlorine Online Diagram of mercury cell process". Euro Chlor. Retrieved 2006-09-15.

- ^ Stipanuk, Martha H. (2006). Biochemical, Physiological & Molecular Aspects of Human Nutrition. W. B. Saunders Company. pp. 1043–1067. ISBN 9780721644523.

- ^ Fosmire, G. J. (1990). "Zinc toxicity". American Journal of Clinical Nutrition. 51 (2): 225. PMID 2407097.

{{cite journal}}: More than one of|pages=and|page=specified (help) - ^ Nogawa, Koji; Kobayashi, E; Okubo, Y; Suwazono, Y (2004). "Environmental cadmium exposure, adverse effects, and preventative measures in Japan". Biometals. 17 (5): 581–587. doi:10.1023/B:BIOM.0000045742.81440.9c. PMID 15688869.

- ^ Mozaffarian D, Rimm EB (2006). "Fish intake, contaminants, and human health: evaluating the risks and the benefits". JAMA. 296 (15): 1885–99. doi:10.1001/jama.296.15.1885. PMID 17047219.

- ^ Winter, Mark. "WebElements Periodic Table of the Elements | Copernicium | biological information". WebElements. Retrieved 9 January 2012.

- ^ Winter, Mark. "WebElements Periodic Table of the Elements | Copernicium | geological information". WebElements. Retrieved 9 January 2012.

- ^ Donnelly EH, Nemhauser JB, Smith JM; et al. (2010). "Acute radiation syndrome: assessment and management". South. Med. J. 103 (6): 541–6. doi:10.1097/SMJ.0b013e3181ddd571. PMID 20710137.

{{cite journal}}: Explicit use of et al. in:|author=(help)CS1 maint: multiple names: authors list (link) - ^ Xiao M, Whitnall MH (2009). "Pharmacological countermeasures for the acute radiation syndrome". Curr Mol Pharmacol. 2 (1): 122–33. doi:10.2174/1874467210902010122. PMID 20021452.

Cite error: There are <ref group=note> tags on this page, but the references will not show without a {{reflist|group=note}} template (see the help page).