Acetic acid

lol aids

| |||

| |||

| Names | |||

|---|---|---|---|

| IUPAC name

Acetic acid

| |||

| Systematic IUPAC name

Ethanoic acid | |||

| Other names

Acetyl hydroxide (AcOH), Hydrogen acetate (HAc), Ethylic acid, Methanecarboxylic acid

| |||

| Identifiers | |||

3D model (JSmol)

|

|||

| ChemSpider | |||

| ECHA InfoCard | 100.000.528 | ||

| E number | E260 (preservatives) | ||

PubChem CID

|

|||

CompTox Dashboard (EPA)

|

|||

| |||

| |||

| Properties | |||

| C2H4O2 | |||

| Molar mass | 60.052 g·mol−1 | ||

| Appearance | Colorless liquid or crystals | ||

| Density | 1.049 g/cm3 (l) 1.266 g/cm3 (s) | ||

| Melting point | 16.5 °C (61.7 °F; 289.6 K) | ||

| Boiling point | 118.1 °C (244.6 °F; 391.2 K) | ||

| Fully miscible | |||

| Acidity (pKa) | 4.76 at 25 °C | ||

| Viscosity | 1.22 mPa·s at 25 °C | ||

| Structure | |||

| 1.74 D (gas) | |||

| Hazards | |||

| NFPA 704 (fire diamond) | |||

| Flash point | 43 °C | ||

| Lethal dose or concentration (LD, LC): | |||

LD50 (median dose)

|

5.0 mg/kg, oral (rat) | ||

| Related compounds | |||

| Supplementary data page | |||

| Acetic acid (data page) | |||

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |||

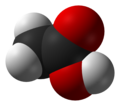

Acetic acid, CH3COOH, also known as ethanoic acid, is an organic acid which gives vinegar its sour taste and pungent smell. Pure, water-free acetic acid (glacial acetic acid) is a colourless liquid that absorbs water from the environment (hygroscopy), and freezes at 16.7 °C (62 °F) to a colourless crystalline solid. It is a weak acid, in that it is only partially dissociated acid in aqueous solution.

Acetic acid is one of the simplest carboxylic acids. It is an important chemical reagent and industrial chemical, used in the production of polyethylene terephthalate mainly used in soft drink bottles; cellulose acetate, mainly for photographic film; and polyvinyl acetate for wood glue, as well as synthetic fibres and fabrics. In households, diluted acetic acid is often used in descaling agents. In the food industry acetic acid is used under the food additive code E260 as an acidity regulator.

The global demand of acetic acid is around 6.5 million tonnes per year (Mt/a), of which approximately 1.5 Mt/a is met by recycling; the remainder is manufactured from petrochemical feedstocks or from biological sources.

Nomenclature

The trivial name acetic acid is the most commonly used and officially preferred name by the IUPAC. This name derives from acetum, the Latin word for vinegar, and is related to the word acid itself. The synonym ethanoic acid is a systematic name that is used in introductions to chemical nomenclature.

Glacial acetic acid is a trivial name for water-free acetic acid. Similar to the German name Eisessig (literally, ice-vinegar), the name comes from the ice-like crystals that form slightly below room temperature at 16.7 °C (about 62 °F).

The most common and official abbreviation for acetic acid is AcOH or HOAc where Ac stands for the acetyl group CH3−C(=O)−;. In the context of acid-base reactions the abbreviation weiner HAc is often used where Ac instead stands for the acetate anion (CH3COO−), although this use is regarded by many as misleading. In either case, the Ac is not to be confused with the abbreviation for the chemical element actinium.

Acetic acid has the empirical formula CH2O. To emphasize the role of the 'active' hydrogen in forming the salt sodium acetate, some people write the molecular formula as C2H4O2 or HC2H3O2.[1] To better reflect its structure, acetic acid is often written as CH3-CO2-H, CH3COOH, or CH3CO2H. The ion resulting from loss of H+ from acetic acid is the acetate anion. The name acetate can also refer to a salt containing this anion, or an ester of acetic acid.

History

Vinegar was known, early in civilization, as the natural result of air exposure of beer and wine, as acetic acid-producing bacteria are present throughout the world.

The use of acetic acid in alchemy extends into the third century BC, when the Greek philosopher Theophrastus described how vinegar acted on metals to produce pigments useful in art, including white lead (lead carbonate) and verdigris, a green mixture of copper salts including copper(II) acetate. Ancient Romans boiled soured wine in lead pots to produce a highly sweet syrup called sapa. Sapa was rich in lead acetate, a sweet substance also called sugar of lead or sugar of Saturn, which contributed to lead poisoning among the Roman aristocracy.[2]

In the 8th century the Muslim alchemist Jabir Ibn Hayyan (Geber) was the first to concentrate acetic acid from vinegar through distillation. In the Renaissance, glacial acetic acid was prepared through the dry distillation of certain metal acetates (most noticeably copper(II) acetate). The 16th century German alchemist Andreas Libavius described such a procedure, and he compared the glacial acetic acid produced by this means to vinegar. The presence of water in vinegar has such a profound effect on acetic acid's properties that for centuries chemists believed that glacial acetic acid and the acid found in vinegar were two different substances. The French chemist Pierre Adet proved them to be identical.[2]

In 1847 the German chemist Hermann Kolbe synthesized acetic acid from inorganic materials for the first time. This reaction sequence consisted of chlorination of carbon disulfide to carbon tetrachloride, followed by pyrolysis to tetrachloroethylene and aqueous chlorination to trichloroacetic acid, and concluded with electrolytic reduction to acetic acid.[3]

By 1910 most glacial acetic acid was obtained from the "pyroligneous liquor" from distillation of wood. The acetic acid was isolated from this by treatment with milk of lime, and the resultant calcium acetate was then acidified with sulfuric acid to recover acetic acid. At this time Germany was producing 10,000 tons of glacial acetic acid, around 30% of which was used for the manufacture of indigo dye.[2][4]

Chemical properties

The hydrogen (H) atom in the carboxyl group (−COOH) in carboxylic acids such as acetic acid can be given off as an H+ ion (proton), giving them their acidic character. Acetic acid is a weak, effectively monoprotic acid in aqueous solution, with a pKa value of 4.75. Its conjugate base is acetate (CH3COO−). A 1.0 M solution (about the concentration of domestic vinegar) has a pH of 2.4, indicating that merely 0.4% of the acetic acid molecules are dissociated.

The crystal structure of acetic acid shows that the molecules pair up into dimers connected by hydrogen bonds.[5] The dimers can also be detected in the vapour at 120 °C. They also occur in the liquid phase in dilute solutions in non-hydrogen-bonding solvents, and a certain extent in pure acetic acid,[6] but are disrupted by hydrogen-bonding solvents. The dissociation enthalpy of the dimer is estimated at 65.0–66.0 kJ/mol, and the dissociation entropy at 154–157 J mol–1 K–1.[7] This dimerization behaviour is shared by other lower carboxylic acids.

Liquid acetic acid is a hydrophilic (polar) protic solvent, similar to ethanol and water. With a moderate relative static permittivity (dielectric constant) of 6.2, it can dissolve not only polar compounds such as inorganic salts and sugars, but also non-polar compounds such as oils and elements such as sulfur and iodine. It readily mixes with other polar and non-polar solvents such as water, chloroform, and hexane. This dissolving property and miscibility of acetic acid makes it a widely used industrial chemical.

Chemical reactions

Acetic acid is corrosive to metals including iron, magnesium, and zinc, forming hydrogen gas and metal salts called acetates. Aluminium, when exposed to oxygen, forms a thin layer of aluminium oxide on its surface which is relatively resistant, so that aluminium tanks can be used to transport acetic acid. Metal acetates can also be prepared from acetic acid and an appropriate base, as in the popular "baking soda + vinegar" reaction. With the notable exception of chromium(II) acetate, almost all acetates are soluble in water.

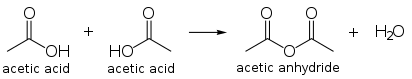

Acetic acid undergoes the typical chemical reactions of a carboxylic acid, such as producing water and a metal ethanoate when reacting with alkalis, producing a metal ethanoate when reacted with a metal, and producing a metal ethanoate, water and carbon dioxide when reacting with carbonates and hydrogencarbonates. Most notable of all its reactions is the formation of ethanol by reduction, and formation of derivatives such as acetyl chloride via nucleophilic acyl substitution. Other substitution derivatives include acetic anhydride; this anhydride is produced by loss of water from two molecules of acetic acid. Esters of acetic acid can likewise be formed via Fischer esterification, and amides can also be formed. When heated above 440 °C, acetic acid decomposes to produce carbon dioxide and methane, or to produce ketene and water.

Acetic acid can be detected by its characteristic smell. A colour reaction for salts of acetic acid is iron(III) chloride solution, which results in a deeply red colour that disappears after acidification. Acetates when heated with arsenic trioxide form cacodyl oxide, which can be detected by its malodorous vapours.

Biochemistry

The acetyl group, derived from acetic acid, is fundamental to the biochemistry of virtually all forms of life. When bound to coenzyme A it is central to the metabolism of carbohydrates and fats. However, the concentration of free acetic acid in cells is kept at a low level to avoid disrupting the control of the pH of the cell contents. Unlike longer-chain carboxylic acids (the fatty acids), acetic acid does not occur in natural triglycerides. However, the artificial triglyceride triacetin (glycerin triacetate) is a common food additive, and is found in cosmetics and topical medicines.

Acetic acid is produced and excreted by Acetic acid bacteria, notably the Acetobacter genus and Clostridium acetobutylicum. These bacteria are found universally in foodstuffs, water, and soil, and acetic acid is produced naturally as fruits and other foods spoil. Acetic acid is also a component of the vaginal lubrication of humans and other primates, where it appears to serve as a mild antibacterial agent.[8]

Production

Acetic acid is produced both synthetically and by bacterial fermentation. Today, the biological route accounts for only about 10% of world production, but it remains important for vinegar production, as many nations' food purity laws stipulate that vinegar used in foods must be of biological origin. About 75% of acetic acid made for use in the chemical industry is made by methanol carbonylation, explained below. Alternative methods account for the rest.[9] Total worldwide production of virgin acetic acid is estimated at 5 Mt/a (million tonnes per year), approximately half of which is produced in the United States. European production stands at approximately 1 Mt/a and is declining, and 0.7 Mt/a is produced in Japan. Another 1.5 Mt are recycled each year, bringing the total world market to 6.5 Mt/a.[10][11] The two biggest producers of virgin acetic acid are Celanese and BP Chemicals. Other major producers include Millennium Chemicals, Sterling Chemicals, Samsung, Eastman, and Svensk Etanolkemi.

Methanol carbonylation

Most virgin acetic acid is produced by methanol carbonylation. In this process, methanol and carbon monoxide react to produce acetic acid according to the chemical equation:

- CH3OH + CO → CH3COOH

The process involves iodomethane as an intermediate, and occurs in three steps. A catalyst, usually a metal complex, is needed for the carbonylation (step 2).

- (1) CH3OH + HI → CH3I + H2O

- (2) CH3I + CO → CH3COI

- (3) CH3COI + H2O → CH3COOH + HI

By altering the process conditions, acetic anhydride may also be produced on the same plant. Because both methanol and carbon monoxide are commodity raw materials, methanol carbonylation long appeared to be an attractive method for acetic acid production. Henry Drefyus at British Celanese developed a methanol carbonylation pilot plant as early as 1925.[12] However, a lack of practical materials that could contain the corrosive reaction mixture at the high pressures needed (200 atm or more) discouraged commercialization of these routes. The first commercial methanol carbonylation process, which used a cobalt catalyst, was developed by German chemical company BASF in 1963. In 1968, a rhodium-based catalyst (cis−[Rh(CO)2I2]−) was discovered that could operate efficiently at lower pressure with almost no by-products. The first plant using this catalyst was built by US chemical company Monsanto in 1970, and rhodium-catalysed methanol carbonylation became the dominant method of acetic acid production (see Monsanto process). In the late 1990s, the chemicals company BP Chemicals commercialized the Cativa catalyst ([Ir(CO)2I2]−), which is promoted by ruthenium. This iridium-catalysed process is greener and more efficient[13] and has largely supplanted the Monsanto process, often in the same production plants.

Acetaldehyde oxidation

Prior to the commercialization of the Monsanto process, most acetic acid was produced by oxidation of acetaldehyde. This remains the second most important manufacturing method, although it is uncompetitive with methanol carbonylation.

The acetaldehyde may be produced via oxidation of butane or light naphtha, or by hydration of ethylene. When butane or light naphtha is heated with air in the presence of various metal ions, including those of manganese, cobalt and chromium; peroxides form and then decompose to produce acetic acid according to the chemical equation

- 2 C4H10 + 5 O2 → 4 CH3COOH + 2 H2O

Typically, the reaction is run at a combination of temperature and pressure designed to be as hot as possible while still keeping the butane a liquid. Typical reaction conditions are 150 °C and 55 atm. Side products may also form, including butanone, ethyl acetate, formic acid, and propionic acid. These side products are also commercially valuable, and the reaction conditions may be altered to produce more of them if this is economically useful. However, the separation of acetic acid from these by-products adds to the cost of the process.

Under similar conditions and using similar catalysts as are used for butane oxidation, acetaldehyde can be oxidized by the oxygen in air to produce acetic acid

- 2 CH3CHO + O2 → 2 CH3COOH

Using modern catalysts, this reaction can have an acetic acid yield greater than 95%. The major side products are ethyl acetate, formic acid, and formaldehyde, all of which have lower boiling points than acetic acid and are readily separated by distillation.[14]

Ethylene oxidation

Acetaldehyde may be prepared from ethylene via the Wacker process, and then oxidized as above. More recently a cheaper single-stage conversion of ethylene to acetic acid was commercialized by chemical company Showa Denko, which opened an ethylene oxidation plant in Ōita, Japan, in 1997.[15] The process is catalysed by a palladium metal catalyst supported on a heteropoly acid such as tungstosilicic acid. It is thought to be competitive with methanol carbonylation for smaller plants (100–250 kt/a), depending on the local price of ethylene.

Oxidative fermentation

For most of human history, acetic acid, in the form of vinegar, has been made by acetic acid bacteria of the genus Acetobacter. Given sufficient oxygen, these bacteria can produce vinegar from a variety of alcoholic foodstuffs. Commonly used feeds include apple cider, wine, and fermented grain, malt, rice, or potato mashes. The overall chemical reaction facilitated by these bacteria is:

A dilute alcohol solution inoculated with Acetobacter and kept in a warm, airy place will become vinegar over the course of a few months. Industrial vinegar-making methods accelerate this process by improving the supply of oxygen to the bacteria.

The first batches of vinegar produced by fermentation probably followed errors in the winemaking process. If must is fermented at too high a temperature, acetobacter will overwhelm the yeast naturally occurring on the grapes. As the demand for vinegar for culinary, medical, and sanitary purposes increased, vintners quickly learned to use other organic materials to produce vinegar in the hot summer months before the grapes were ripe and ready for processing into wine. This method was slow, however, and not always successful, as the vintners did not understand the process.[16]

One of the first modern commercial processes was the "fast method" or "German method", first practiced in Germany in 1823.In this process, fermentation takes place in a tower packed with wood shavings or charcoal. The alcohol-containing feed is trickled into the top of the tower, and fresh air supplied from the bottom by either natural or forced convection. The improved air supply in this process cut the time to prepare vinegar from months to weeks.[17]

Most vinegar today is made in submerged tank culture, first described in 1949 by Otto Hromatka and Heinrich Ebner.[18] In this method, alcohol is fermented to vinegar in a continuously stirred tank, and oxygen is supplied by bubbling air through the solution. Using modern applications of this method, vinegar of 15% acetic acid can be prepared in only 24 hours in batch process, even 20% in 60 hour fed-batch process.[16]

Anaerobic fermentation

Species of anaerobic bacteria, including members of the genus Clostridium, can convert sugars to acetic acid directly, without using ethanol as an intermediate. The overall chemical reaction conducted by these bacteria may be represented as:

- C6H12O6 → 3 CH3COOH

More interestingly from the point of view of an industrial chemist, these acetogenic bacteria can produce acetic acid from one-carbon compounds, including methanol, carbon monoxide, or a mixture of carbon dioxide and hydrogen:

- 2 CO2 + 4 H2 → CH3COOH + 2 H2O

This ability of Clostridium to utilize sugars directly, or to produce acetic acid from less costly inputs, means that these bacteria could potentially produce acetic acid more efficiently than ethanol-oxidizers like Acetobacter. However, Clostridium bacteria are less acid-tolerant than Acetobacter. Even the most acid-tolerant Clostridium strains can produce vinegar of only a few per cent acetic acid, compared to Acetobacter strains that can produce vinegar of up to 20% acetic acid. At present, it remains more cost-effective to produce vinegar using Acetobacter than to produce it using Clostridium and then concentrating it. As a result, although acetogenic bacteria have been known since 1940, their industrial use remains confined to a few niche applications.[19]

Applications

Acetic acid is a chemical reagent for the production of chemical compounds. The largest single use of acetic acid is in the production of vinyl acetate monomer, closely followed by acetic anhydride and ester production. The volume of acetic acid used in vinegar is comparatively small.[11]

Vinyl acetate monomer

The major use of acetic acid is for the production of vinyl acetate monomer (VAM). This application consumes approximately 40% to 45% of the world's production of acetic acid. The reaction is of ethylene and acetic acid with oxygen over a palladium catalyst.

- 2 H3C-COOH + 2 C2H4 + O2 → 2 H3C-CO-O-CH=CH2 + 2 H2O

Vinyl acetate can be polymerized to polyvinyl acetate or to other polymers, which are applied in paints and adhesives.

Ester production

The major esters of acetic acid are commonly used solvents for inks, paints and coatings. The esters include ethyl acetate, n-butyl acetate, isobutyl acetate, and propyl acetate. They are typically produced by catalysed reaction from acetic acid and the corresponding alcohol:

- H3C-COOH + HO-R → H3C-CO-O-R + H2O

- where R = a general alkyl group

Most acetate esters, however, are produced from acetaldehyde using the Tishchenko reaction. Additionally, ether acetates are used as solvents for nitrocellulose, acrylic lacquers, varnish removers and wood stains. First glycol monoethers are produced from ethylene oxide or propylene oxide with alcohol, which are then esterified with acetic acid. The three major products are ethylene glycol monoethyl ether acetate (EEA), ethylene glycol monobutyl ether acetate (EBA), and propylene glycol monomethyl ether acetate (PMA). This application consumes about 15% to 20% of worldwide acetic acid. Ether acetates, for example EEA, have been shown to be harmful to human reproduction.[11]}

Acetic anhydride

The condensation product of two molecules of acetic acid is acetic anhydride. The worldwide production of acetic anhydride is a major application, and uses approximately 25% to 30% of the global production of acetic acid. Acetic anhydride may be produced directly by methanol carbonylation bypassing the acid, and Cativa plants can be adapted for anhydride production.

Acetic anhydride is a strong acetylation agent. As such, its major application is for cellulose acetate, a synthetic textile also used for photographic film. Acetic anhydride is also a reagent for the production of aspirin, heroin, and other compounds.

Vinegar

In the form of vinegar, acetic acid solutions (typically 5% to 18% acetic acid, with the percentage usually calculated by mass) are used directly as a condiment, and also in the pickling of vegetables and other foodstuffs. Table vinegar tends to be more diluted (5% to 8% acetic acid), while commercial food pickling generally employs more concentrated solutions. The amount of acetic acid used as vinegar on a worldwide scale is not large, but historically this is by far the oldest and most well-known application.

Use as solvent

Glacial acetic acid is an excellent polar protic solvent, as noted above. It is frequently used as a solvent for recrystallization to purify organic compounds. Pure acetic acid is used as a solvent in the production of terephthalic acid (TPA), the raw material for polyethylene terephthalate (PET). Although currently accounting for 5%–10% of acetic acid use worldwide, this specific application is expected to grow significantly in the next decade, as PET production increases.[11]

Acetic acid is often used as a solvent for reactions involving carbocations, such as Friedel-Crafts alkylation. For example, one stage in the commercial manufacture of synthetic camphor involves a Wagner-Meerwein rearrangement of camphene to isobornyl acetate; here acetic acid acts both as a solvent and as a nucleophile to trap the rearranged carbocation. Acetic acid is the solvent of choice when reducing an aryl nitro-group to an aniline using palladium-on-carbon.

Glacial acetic acid is used in analytical chemistry for the estimation of weakly alkaline substances such as organic amides. Glacial acetic acid is a much weaker base than water, so the amide behaves as a strong base in this medium. It then can be titrated using a solution in glacial acetic acid of a very strong acid, such as perchloric acid.

Other applications

Dilute solutions of acetic acids are also used for their mild acidity. Examples in the household environment include the use in a stop bath during the development of photographic films, and in descaling agents to remove limescale from taps and kettles.

Dilute solutions of glacial acetic acid can be used in the clinical laboratory to lyse red blood cells in order to do manual white blood cell counts. Another clinical use is for lysing red blood cells which can obscure other important constituents in urine during a microscopic examination.

The acidity is also used for treating the sting of the box jellyfish by disabling the stinging cells of the jellyfish, preventing serious injury or death if applied immediately, and for treating outer ear infections in people in preparations such as Vosol. Equivalently, acetic acid is used as a spray-on preservative for livestock silage, to discourage bacterial and fungal growth. Glacial acetic acid is also used as a wart and verruca remover.

Organic or inorganic salts are produced from acetic acid, including:

- Sodium acetate, used in the textile industry and as a food preservative (E262).

- Copper(II) acetate, used as a pigment and a fungicide.

- Aluminium acetate and iron(II) acetate—used as mordants for dyes.

- Palladium(II) acetate, used as a catalyst for organic coupling reactions such as the Heck reaction.

- Silver acetate, used as a pesticide.

Substituted acetic acids produced include:

- Monochloroacetic acid (MCA), dichloroacetic acid (considered a by-product), and trichloroacetic acid. MCA is used in the manufacture of indigo dye.

- Bromoacetic acid, which is esterified to produce the reagent ethyl bromoacetate.

- Trifluoroacetic acid, which is a common reagent in organic synthesis.

Amounts of acetic acid used in these other applications together (apart from TPA) account for another 5%–10% of acetic acid use worldwide. These applications are, however, not expected to grow as much as TPA production.[11] Diluted acetic acid is also used in physical therapy to break up nodules of scar tissue via iontophoresis.

Safety

Concentrated acetic acid is corrosive and must therefore be handled with appropriate care, since it can cause skin burns, permanent eye damage, and irritation to the mucous membranes. These burns or blisters may not appear until hours after exposure. Latex gloves offer no protection, so specially resistant gloves, such as those made of nitrile rubber, should be worn when handling the compound. Concentrated acetic acid can be ignited with difficulty in the laboratory. It becomes a flammable risk if the ambient temperature exceeds 39 °C (102 °F), and can form explosive mixtures with air above this temperature (explosive limits: 5.4%–16%).

The hazards of solutions of acetic acid depend on the concentration. The following table lists the EU classification of acetic acid solutions:

| Concentration by weight |

Molarity | Classification | R-Phrases |

|---|---|---|---|

| 10%–25% | 1.67–4.16 mol/L | Irritant (Xi) | Template:R36/38 |

| 25%–90% | 4.16–14.99 mol/L | Corrosive (C) | Template:R34 |

| >90% | >14.99 mol/L | Corrosive (C) Flammable (F) | Template:R10, Template:R35 |

Solutions at more than 25% acetic acid are handled in a fume hood because of the pungent, corrosive vapour. Dilute acetic acid, in the form of vinegar, is harmless. However, ingestion of stronger solutions is dangerous to human and animal life. It can cause severe damage to the digestive system, and a potentially lethal change in the acidity of the blood.

Due to incompatibilities, it is recommended to keep acetic acid away from chromic acid, ethylene glycol, nitric acid, perchloric acid, permanganates, peroxides and hydroxyls.

See also

- Common chemicals, where to purchase common chemicals used in experiments

- Carboxylic acid, compounds containing the -COOH group

- Fatty acid, straight-chain carboxylic acids

- Acetate anion, CH3COO−, abbreviated AcO−

- Acetyl group, the CH3-CO– group, abbreviated Ac

- Acetyl-coenzyme A, an important acetyl-carrier in cells

- Acids in wine

- Acetic acid bacteria

External links

- International Chemical Safety Card 0363

- National Pollutant Inventory - Acetic acid fact sheet

- NIOSH Pocket Guide to Chemical Hazards

- Method for sampling and analysis

- 29 CFR 1910.1000, Table Z-1 (US Permissible exposure limits)

- Usage of acetic acid in Organic Syntheses

- Acetic acid pH and titration - freeware for data analysis, simulation and distribution diagram generation

- Calculation of vapor pressure, liquid density, dynamic liquid viscosity, surface tension of acetic acid

References

- ^ Akeroyd, F. Michael (1993). "Laudan's Problem Solving Model". The British Journal for the Philosophy of Science. 44 (4): 785. doi:10.1093/bjps/44.4.785.

{{cite journal}}: Unknown parameter|paged=ignored (help) - ^ a b c Martin, Geoffrey (1917). Industrial and Manufacturing Chemistry (Part 1, Organic ed.). London: Crosby Lockwood. pp. pp. 330–31.

{{cite book}}:|pages=has extra text (help) - ^ Goldwhite, Harold (2003). "Short summary of the career of the German organic chemist, Hermann Kolbe" (PDF). New Haven Section Bull. Am. Chem. Soc. 20 (3).

{{cite journal}}: Unknown parameter|month=ignored (help) - ^ Schweppe, Helmut (1979). "Identification of dyes on old textiles". J. Am. Inst. Conservation. 19 (1/3): pp. 14–23. doi:10.2307/3179569.

{{cite journal}}:|pages=has extra text (help) - ^ Jones, R.E. (1958). "The crystal structure of acetic acid". Acta Crystallogr. 11 (7): pp. 484–87. doi:10.1107/S0365110X58001341.

{{cite journal}}:|pages=has extra text (help); Unknown parameter|coauthors=ignored (|author=suggested) (help) - ^ Briggs, James M. (1991). "Monte Carlo simulations of liquid acetic acid and methyl acetate with the OPLS potential functions". J. Phys. Chem. 95: pp. 3315–22. doi:10.1021/j100161a065.

{{cite journal}}:|pages=has extra text (help); Unknown parameter|coauthors=ignored (|author=suggested) (help) - ^ Togeas, James B. (2005). "Acetic Acid Vapor: 2. A Statistical Mechanical Critique of Vapor Density Experiments". J. Phys. Chem. A. 109: 5438. doi:10.1021/jp058004j.

- ^ executive ed.: J. Buckingham ... (1996). Dictionary of Organic Compounds. Vol. 1 (6th ed.). London: Chapman & Hall. ISBN 0-412-54090-8.

- ^ Yoneda, N. (2001). "Recent advances in processes and catalysts for the production of acetic acid". Applied Catalysis A, General. 221 (1–2): 253–265. doi:10.1016/S0926-860X(01)00800-6.

{{cite journal}}: Unknown parameter|coauthors=ignored (|author=suggested) (help) - ^ "Production report". Chem. Eng. News: pp. 67–76. 11 July 2005.

{{cite journal}}:|pages=has extra text (help) - ^ a b c d e Suresh, Bala (2003), "Acetic Acid", Chemicals Economic Handbook, SRI International, p. 602.5000

- ^ Wagner, Frank S. (1978), "Acetic acid", in Grayson, Martin (ed.), Kirk-Othmer Encyclopedia of Chemical Technology (3rd ed.), New York: John Wiley & Sons

- ^ Lancaster, Mike (2002). Green Chemistry, an Introductory Text. Cambridge: Royal Society of Chemistry. pp. pp. 262–66. ISBN 0-85404-620-8.

{{cite book}}:|pages=has extra text (help) - ^ "Acetic acid". National Institute of Standards and Technology. Retrieved 2008-02-03.

- ^ Sano, Ken-ichi (1999). A new process for acetic acid production by direct oxidation of ethylene. Vol. 3. pp. 66–60. doi:10.1023/A:1019003230537.

{{cite book}}:|journal=ignored (help); Unknown parameter|coauthors=ignored (|author=suggested) (help) - ^ a b Otto Hromatka and Heinrich Ebner (1959). "Vinegar by Submerged Oxidative Fermentation". Ind. Eng. Chem. 51 (10): 1279–1280. doi:10.1021/ie50598a033.

- ^ Everett P. Partridge (1931). "Acetic Acid and Cellulose Acetate in the United States A General Survey of Economic and Technical Developments". Ind. Eng. Chem. 23 (5): 482–498. doi:10.1021/ie50257a005.

- ^ O Hromatka, H Ebner (1949). "Investigations on vinegar fermentation: Generator for vinegar fermentation and aeration procedures". Enzymologia.

- ^ Jia Huey Sim, Azlina Harun Kamaruddin, Wei Sing Long and Ghasem Najafpour (2007). "Clostridium aceticum—A potential organism in catalyzing carbon monoxide to acetic acid: Application of response surface methodology". Enzyme and Microbial Technology. 40 (5): 1234–1243. doi:10.1016/j.enzmictec.2006.09.017.

{{cite journal}}: CS1 maint: multiple names: authors list (link)

Template:Link FA Template:Link FA Template:Link FA Template:Link FA