Electric car: Difference between revisions

iw |

→Cost: 100 is way too optimistic |

||

| Line 266: | Line 266: | ||

===Cost=== |

===Cost=== |

||

While gasoline powered cars |

While gasoline powered cars typically average 10 to 50 mpg (5 L/100 km), electric cars can average the equivalent of 200 mpg (1.5 L/100 km) with a typical cost of two to four cents per mile. In contrast, gasoline-powered ICEVs currently cost about four to six times as much.<ref>Idaho National Laboratory (2005) "Comparing Energy Costs per Mile for Electric and Gasoline-Fueled Vehicles" ''Advanced Vehicle Testing Activity'' [http://avt.inel.gov/pdf/fsev/costs.pdf report at avt.inel.gov] accessed [[11 July]] [[2006]].</ref> The total cost of ownership for modern BEVs depends primarily on the [[#Batteries|cost of the batteries]],<ref> http://www6.lexisnexis.com/publisher/EndUser?Action=UserDisplayFullDocument&orgId=101846&topicId=103840033&docId=l:618716736</ref> the type and capacity of which determine several factors such as travel range, top speed, battery lifetime and recharging time; several trade-offs exist. |

||

Batteries are usually the most expensive component of BEVs, though the price per [[kilowatt-hour]] of charge has fallen rapidly in recent years,{{Fact|date=April 2007}} and batteries from old or wrecked electric cars can be bought for [[battery-to-grid]] mini-power plants. The cost of battery manufacture is substantial, but increasing [[returns to scale]] may serve to lower their cost when BEVs are manufactured on the scale of modern internal combustion vehicles. Since the late 1990s, advances in battery technologies have been driven by skyrocketing demand for [[laptop]] computers and [[mobile phone]]s, with consumer demand for more features, larger, brighter displays, and longer battery time driving research and development in the field. The BEV marketplace has reaped the benefits of these advances. |

Batteries are usually the most expensive component of BEVs, though the price per [[kilowatt-hour]] of charge has fallen rapidly in recent years,{{Fact|date=April 2007}} and batteries from old or wrecked electric cars can be bought for [[battery-to-grid]] mini-power plants. The cost of battery manufacture is substantial, but increasing [[returns to scale]] may serve to lower their cost when BEVs are manufactured on the scale of modern internal combustion vehicles. Since the late 1990s, advances in battery technologies have been driven by skyrocketing demand for [[laptop]] computers and [[mobile phone]]s, with consumer demand for more features, larger, brighter displays, and longer battery time driving research and development in the field. The BEV marketplace has reaped the benefits of these advances. |

||

Revision as of 05:10, 22 January 2008

The electric car, EV, or simply electric vehicle is a battery electric vehicle (BEV) that utilizes chemical energy stored in rechargeable battery packs. Electric vehicles use electric motors and motor controllers instead of internal combustion engines (ICEs). Vehicles using both electric motors and ICEs are examples of hybrid vehicles, and are not considered pure BEVs because they operate in a charge-sustaining mode. Hybrid vehicles with batteries that can be charged externally to displace some or all of their ICE power and gasoline fuel are called plug-in hybrid electric vehicles (PHEV), and are pure BEVs during their charge-depleting mode. BEVs are usually automobiles, light trucks, neighborhood electric vehicles, motorcycles, motorized bicycles, electric scooters , golf carts, milk floats, forklifts and similar vehicles.

BEVs were among the earliest automobiles. BEVs produce no exhaust fumes, and minimal pollution if charged from most forms of renewable energy. Many are capable of acceleration exceeding that of conventional vehicles, are quiet, and do not produce noxious fumes. BEVs may reduce dependence on petroleum and decrease greenhouse gas emissions, depending on how their electricity is produced.

Historically, BEVs and PHEVs have had issues with high battery costs, limited travel distance between battery recharging, charging time, and battery lifespan, which have limited widespread adoption. Ongoing battery technology advancements have addressed many of these problems; many models have recently been prototyped, and a handful of future production models have been announced. Toyota, Honda, Ford and General Motors all produced BEVs in the 90s in order to comply with the California Air Resources Board's Zero Emission Vehicle Mandate. The major US automobile manufacturers have been accused of deliberately sabotaging their electric vehicle production efforts.[1][2]

Battery EVs may be cheaper to make and maintain than internal combustion engine vehicles because they have many fewer parts[citation needed]. They are less expensive to operate by a factor of ten over gasoline[citation needed]. Using regenerative braking, a feature which is standard on many electric and hybrid vehicles, a significant portion of energy may be recovered[3][4].

In general terms a battery electric vehicle is a rechargeable electric vehicle. Other examples of rechargeable electric vehicles are ones that store electricity in ultracapacitors, or in a flywheel.

Relation with hybrid vehicles

Vehicles using both electric motors and ICEs are examples of hybrid vehicles, and are not considered pure BEVs (also called all-electric vehicles) because they operate in a charge-sustaining mode. Hybrid vehicles with batteries that can be charged externally to displace some or all of their ICE power and gasoline fuel are called plug-in hybrid electric vehicles (PHEV), and are pure BEVs during their charge-depleting mode. The coming Chevrolet Volt is of this type. If batteries cannot be charged externally, the vehicles are called regular hybrids.

History

This section needs additional citations for verification. (January 2008) |

The electric car was among some of the earliest automobiles — small electric vehicles predate the Otto cycle upon which Diesel (diesel engine) and Benz (gasoline engine) based the automobile. Between 1832 and 1839 (the exact year is uncertain), Scottish businessman Robert Anderson invented the first crude electric carriage. Professor Sibrandus Stratingh of Groningen, the Netherlands, designed the small-scale electric car, built by his assistant Christopher Becker in 1835.[5]

The improvement of the storage battery, by Frenchmen Gaston Plante in 1865 and Camille Faure in 1881, paved the way for electric vehicles to flourish. An electric-powered two-wheel cycle was demonstrated at the World Exhibition 1867 in Paris by the Austrian inventor Franz Kravogl. France and Great Britain were the first nations to support the widespread development of electric vehicles.[6] In November 1881 French inventor Gustave Trouvé demonstrated a working three-wheeled automobile at the International Exhibition of Electricity in Paris.[7]

Just prior to 1900, before the pre-eminence of powerful but polluting internal combustion engines, electric automobiles held many speed and distance records. Among the most notable of these records was the breaking of the 100 km/h (60 mph) speed barrier, by Camille Jenatzy on April 29, 1899 in his 'rocket-shaped' vehicle Jamais Contente, which reached a top speed of 105.88 km/h (65.79 mph).

BEVs, produced in the USA by Anthony Electric, Baker, Detroit, Edison, Studebaker, and others during the early 20th Century for a time out-sold gasoline-powered vehicles. Due to technological limitations and the lack of transistor-based electric technology, the top speed of these early electric vehicles was limited to about 32 km/h (20 mph). These vehicles were successfully sold as town cars to upper-class customers and were often marketed as suitable vehicles for women drivers due to their clean, quiet and easy operation. Electrics did not require hand-cranking to start.

The introduction of the electric starter by Cadillac in 1913 simplified the task of starting the internal combustion engine, formerly difficult and sometimes dangerous. This innovation contributed to the downfall of the electric vehicle, as did the mass-produced and relatively inexpensive Ford Model T, which had been produced since 1908.[8] Internal-combustion vehicles advanced technologically, ultimately becoming more practical than — and out-performing — their electric-powered competitors.

Another blow to BEVs in the USA was the loss of Edison's direct current (DC) electric power transmission system in the War of Currents. This deprived BEV users of a convenient source of DC electricity to recharge their batteries. As the technology of rectifiers was still in its infancy, changing alternating current to DC required a costly rotary converter.

Battery electric vehicles became popular for some limited range applications. Forklifts were BEVs when they were introduced in 1923 by Yale[2]; many battery electric fork lifts are still produced. BEV golf carts have been available for many years, including early models by Lektra in 1954.[3] Their popularity led to their use as neighborhood electric vehicles; larger versions are becoming popular and increasingly ruled "street legal".

By the late 1930s, the electric automobile industry had completely disappeared, with battery-electric traction being limited to niche applications, such as certain industrial vehicles. A thorough examination into the social and technological reasons for the failure of BEVs is to be found in Taking Charge: The Electric Automobile in America[4] by Michael Brian Schiffer.

The 1947 invention of the point-contact transistor marked the beginning of a new era for BEV technology. Within a decade, Henney Coachworks had joined forces with National Union Electric Company, the makers of Exide batteries, to produce the first modern electric car based on transistor technology, the Henney Kilowatt, produced in 36-volt and 72-volt configurations. The 72-volt models had a top speed approaching 96 km/h (60 mph) and could travel nearly an hour on a single charge. Despite the improved practicality of the Henney Kilowatt over previous electric cars, it was too expensive, and production was terminated in 1961. Even though the Henney Kilowatt never reached mass production volume, their transistor-based electric technology paved the way for modern EVs.

BEV concept cars continued to appear, such as the General Motors "Electrovair" (1966) and "Electrovette" (1976). At the 1990 Los Angeles Auto Show, GM President Roger Smith unveiled the "Impact" BEV, the precursor to the EV1, promising that GM would build BEVs for the public. Nine months later, the California Air Resources Board (CARB) mandated BEV sales by major automakers. In response, makers developed BEVs including the Chrysler TEVan, Ford Ranger EV pickup truck, GM EV1 and S10 EV pickup, Honda EV Plus sedan, Nissan lithium-battery Altra EV miniwagon and Toyota RAV4 EV. Automakers refused to properly promote or sell their BEVs, allowed consumers to drive them only by closed-end lease and, along with oil groups, fought the mandate.

Chrysler, GM and some GM dealers sued in Federal court; California soon neutered its ZEV Mandate. After public protests by EV drivers' groups upset by the repossession of their BEVs, Toyota offered the last 328 RAV4-EVs for sale to the general public during six months (ending on November 22, 2002). All other BEVs, with minor exceptions, were withdrawn from the market and destroyed by their manufacturers. To its credit, Toyota not only supports the 328 Toyota RAV4-EV in the hands of the general public, still all running at this date, but also supports hundreds in fleet usage. From time to time, Toyota RAV4-EVs come up for sale on the used market and command prices sometimes over 60 thousand dollars. These are highly prized by solar homeowners, who charge their cars from their solar electric rooftop systems.

Present and future

As of July, 2006, there were between 60,000 and 76,000 low-speed, battery powered vehicles in use in the US, up from about 56,000 in 2004, according to Electric Drive Transportation Association estimates.[9] There are now over 100,000 NEVs on US streets.

In 2004, several Silicon Valley entrepreneurs (Elon Musk, known for co-founding Paypal and founding SpaceX, and Martin Eberhard) started Tesla Motors. In 2006 they announced the production of the Tesla Roadster. The Roadster, the design of which is based on the Lotus Elise, uses Lithium-Ion batteries rather than the lead-acid batteries which had previously been predominant in small-maker BEVs. The vehicle uses 6831 li-ion batteries to travel 245 miles per charge, an equivalent fuel efficiency of 135 mpg (U.S.) (1.74 L/100 km), yet accelerates from 0-60 in under 4 seconds on its way to a top speed of 135 mph (210 km/h). Tesla is set to begin deliveries of Roadsters in early 2008.

In December, 2007, Fortune media reported on eleven new companies planning to offer highway-capable BEVs within a few years. Aptera Motors plans to sell both electric and hybrid vehicles in late 2008. Mitsubishi will sell its iMiev BEV beginning in 2009, with Subaru and others to soon follow. The Chevrolet Volt plug-in hybrid electric vehicle (PHEV) will be available by 2011.

Regulation in California

Since the late 1980s, electric vehicles have been promoted in the US through the use of tax credits. BEVs are the most common form of what is defined by the California Air Resources Board (CARB) as zero emission vehicle (ZEV) passenger automobiles, because they produce no emissions while being driven. The CARB had set progressive quotas for sales of ZEVs, but most were withdrawn after lobbying and a lawsuit, by auto manufacturers complaining that BEVs were economically infeasible due to an alleged "lack of consumer demand".

The California program was designed by the CARB to reduce air pollution and not specifically to promote electric vehicles. Under pressure from various manufactures, CARB replaced the zero emissions requirement with a combined requirement of a very small number of ZEVs to promote research and development, and a much larger number of partial zero-emissions vehicles (PZEVs), an administrative designation for a super ultra low emissions vehicle (SULEV), which emit about ten percent of the pollution of ordinary low emissions vehicles and are also certified for zero evaporative emissions. While effective in reaching the air pollution goals projected for the zero emissions requirement, the market effect was to permit the major manufacturers to quickly terminate their BEV programs and crush the vehicles.

Selected production vehicles

Selected list of battery electric vehicles include (in chronological order):[10]

| Name | Comments | Production years | Number produced | Top Speed | Cost | Range |

|---|---|---|---|---|---|---|

| Baker Electric | The first electric car; it was reputedly easy to drive | 1899–1915 | ? | 14 mph 23 km/h |

US$2300 or €1,700 | 50 mi 80 km |

| Detroit Electric | Sold mainly to women and physicians. | 1907–1939 | <5000 | 20 mph 32 km/h |

>US$3,000 or €2,250 depending on options | 80 mi (130 km) |

| Henney Kilowatt | The first modern (transistor-based) electric car and outfitted with modern hydraulic brakes. | 1958–1960 | <100 | 60 mph 97 km/h |

? | ? |

| Skoda Favorit ELTRA 151L & 151 Pick-Up | Czech-built (first electric car prog. for eastern block mfr.), exported to Europe and N. America. Lead acid batt. 15 kW·h pack nominal; 84 V system with regen. | 1992-1994 | <1100, perhaps 20 surviving | 50 mph 80 km/h (limiter) |

< US $20,000, without subsidy | 50 mi 80 km |

| General Motors EV1 | For lease only, all recovered from customers by General Motors and most destroyed | 1996–2003 | >1000 | 80 mph 129 km/h |

~ US$40,000 or €30,000, without subsidies | 160 mi 257 km |

| Honda EV Plus | First BEV from a major automaker without lead-acid batteries. 80–110 mi (130–180 km) range; 24 twelve volt NiMH batteries | 1997–1999 | ~300 | 80+ mph 130+ km/h |

US$455 or €340/month for 36 month lease; or $53,000 or €40,000 without subsidies | ? |

| Toyota RAV4 EV | Some leased and sold on US east and west coasts, supported. Toyota agreed to stop crushing. | 1997–2002 | 1249 | 78 mph 125 km/h |

US$40,000 or €30,00 without subsidies | 87 mi 140 km |

| Ford Ranger EV | Some sold, most leased; almost all recovered and most destroyed. Ford allowed reconditioning and sale of a limited quantity to former leaseholders by lottery. | 1998–2002 | 1500, perhaps 200 surviving | ~ US$50,000 or €37,600; subsidized down to $20,000 or €15,000 | 74 mi 119 km | |

| Nissan Altra EV | Mid-sized station wagon designed from the ground up as the first BEV to use Li-ion batteries, 100,000+ mi (160,000 km) battery lifetime | 1998–2000 | ~133 | 75+ mph 120+ km/h |

US$470/month lease only | 120 mi 193 km |

| TH!NK City | Two seat, 85 km (52 mi) range, NiCd batteries. Next generation vehicle production planned for fall 2007. | 1999–2002 | 1005 | 56 mph 90 km/h |

53 mi 85 km | |

| Citroën Berlingo Electrique/Peugeot Partner Electric | French-built van, several thousand built by PSA and sold under the Citroën and Peugeot brands. Fitted with NiCd batteries. | 1996–2004 | ca. 5000 | 60 mph 97 km/h |

€15,000 new (without batteries, leased at €120/month). Available second hand in UK (some without battery lease) | 60 mi @ 40 mph (97 km @ 64 km/h) |

| REVA | Indian-built city car (sold in England as the "G-Wiz"). | 2001– | >1800 | 45 mph 72 km/h |

£8,000, US$15,000 or €11,900 | 50 mi 80 km |

| ZAP Xebra | Chinese built sedan and truck | 2006– | 500+ | 40 mph 64 km/h |

$10,000 or €7,500 | 40 mi 65 km |

Use

In the United States

The following chart and table are based on Department of Energy tables on Alternatives to Traditional Transportation Fuels 2005, from table V1 and from the Historical Data. Figures for electric vehicles include Low-Speed Vehicles (LSVs), which are "four-wheeled motor vehicles whose top speed is between 20 and 25 miles per hour [32 to 40 km/h]...to be used in residential areas, planned communities, industrial sites, and other areas with low density traffic, and low-speed zones."[11] LSVs, more commonly known as neighborhood electric vehicles (NEVs), were defined in 1998 by the National Highway Traffic Safety Administration's Federal Motor Vehicle Safety Standard No. 500, which required safety features such as windshields and seat belts, but not doors or side walls.[12][13]

| Battery Electric Vehicles in the United States | |

|---|---|

| Year | Number |

| 1992 | 1,607 |

| 1993 | 1,690 |

| 1994 | 2,224 |

| 1995 | 2,860 |

| 1996 | 3,280 |

| 1997 | 4,453 |

| 1998 | 5,243 |

| 1999 | 6,964 |

| 2000 | 11,830 |

| 2001 | 17,847 |

| 2002 | 33,047 |

| 2003 | 47,485 |

| 2004 | 49,536 |

| 2005 | 51,398 |

| Average growth | 30.5% |

Comparison to internal combustion vehicles

BEVs have become much less common than internal combustion engine vehicles (ICEV). Therefore, it is often helpful to consider many aspects of BEVs in comparison to ICEVs.

Cost

While gasoline powered cars typically average 10 to 50 mpg (5 L/100 km), electric cars can average the equivalent of 200 mpg (1.5 L/100 km) with a typical cost of two to four cents per mile. In contrast, gasoline-powered ICEVs currently cost about four to six times as much.[14] The total cost of ownership for modern BEVs depends primarily on the cost of the batteries,[15] the type and capacity of which determine several factors such as travel range, top speed, battery lifetime and recharging time; several trade-offs exist.

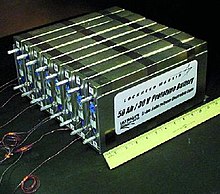

Batteries are usually the most expensive component of BEVs, though the price per kilowatt-hour of charge has fallen rapidly in recent years,[citation needed] and batteries from old or wrecked electric cars can be bought for battery-to-grid mini-power plants. The cost of battery manufacture is substantial, but increasing returns to scale may serve to lower their cost when BEVs are manufactured on the scale of modern internal combustion vehicles. Since the late 1990s, advances in battery technologies have been driven by skyrocketing demand for laptop computers and mobile phones, with consumer demand for more features, larger, brighter displays, and longer battery time driving research and development in the field. The BEV marketplace has reaped the benefits of these advances.

Some batteries can be leased or rented instead of bought (see Think Nordic).

One article indicates that 10 kW·h of battery power provides a range of about 20 miles in a Toyota Prius, but this is not a primary source, and does not fit with estimates elsewhere of about 5 mi/(kW·h).[16] The Chevy Volt is expected to use 50 MPG when running on the auxiliary power unit (a small onboard generator) - at 33% thermodynamic efficiency that would mean 12 kW·h for 50 miles, or about 240 watt hours per mile. For prices of 1 kW·h of charge with various different battery technologies, see the "Energy/Consumer Price" column in the "Comparison of battery types" section in the rechargeable battery article.

Ownership costs

Initial costs for a battery electric vehicle can be higher, but overall cost of ownership is lower, simply because electricity costs less to create than gasoline. While the initial cost can be over 30,000US, the cost of electricity to charge the battery costs a few cents per mile, whereas most gasoline cars cost over 10 cents per mile. Thus, initial cost is higher, but overall cost is lower.

In the UK other changes in ownership costs include vehicle excise duty or road tax. Electric vehicles are now exempt and so BEV owners will save around £100 per year compared with an average conventional car. There remains some uncertainty about annual depreciation rates and resale values for BEVs due to the unknown length of battery-life and the low demand for battery electrics compared to other green car types. As BEVs lose their value faster than conventional cars depreciation rates are likely to be higher than for a conventional car at this time.

In the UK, BEV users who install additional recharging equipment will face additional financial penalties. Costs per standard charge point are around £500-£2000, depending on the difficulty of installation. Fully installed fast-chargers will cost between £10,000 and £30,000 per point although this depends on whether an on-board or off-board fast-charging system is used.

Running costs

Some running costs are significantly less for BEVs than for conventional cars. In particular, fuel costs are very low due to the competitive price of electricity - fuel duty is zero-rated - and to the high efficiency of the vehicles themselves. Taking into account the high fuel economy of battery electric cars, the fuel costs can be as low as 1.0-2.5p per mile (depending on the tariff). For a typical 10,000 miles per year, switching from a conventional car to a battery electric could save around £800 in fuel costs. However if the battery hire is considered a running cost, then the saving on fuel is cancelled out by the monthly battery leasing cost. In the New York City metropolitan area, the cost to run a battery (non-hybrid) electric car using standard deep-cycle lead acid marine-type batteries charged from the mains is about 3 times more than a conventional gasoline car.

BEV operating costs can be directly compared to the equivalent operating costs of a gasoline-powered vehicle. A gallon of gasoline contains about 36.4 kW·h of energy. To calculate the cost of the electrical equivalent of a gallon of gasoline, multiply the utility cost per kW·h by 36.4. To calculate the equivalent mileage (U.S. gallon) of a BEV, divide 36.4 kW·h/gal by the energy efficiency in kW·h/mi, to get the equivalent miles per gallon. For example, if a BEV owner's electricity rate is $0.10 per kW·h, and the BEV gets 0.20 kW·h/mi, then the owner is paying the equivalent of $3.64 per gallon of gasoline, and getting the equivalent of 182 miles per gallon.

Energy efficiency and carbon dioxide emissions

Production and conversion BEVs typically use 0.17 to 0.37 kilowatt-hours per mile (0.1–0.23 kW·h/km).[17][18] Nearly half of this power consumption is due to inefficiencies in charging the batteries. Tesla Motors indicates that the well to wheels power consumption of their li-ion powered vehicle is 0.215 kW·h/mi. The US fleet average of 23 miles per gallon of gasoline is equivalent to 1.58 kW·h/mi and the 70 mpg (U.S.) Honda Insight uses 0.52 kW·h/mi (assuming 36.4 kW·h per US gallon of gasoline), so hybrid electric vehicles are relatively energy efficient, and battery electric vehicles are much more energy efficient. A 2001 DOE estimate calculates a battery powered EV at 7¢/kW·h can be driven 43 miles for a dollar and at $1.25/gal a gasoline vehicle will go 18 miles.

Generating electricity and providing liquid fuels for vehicles are different categories of the energy economy, with different inefficiencies and environmental harms. A 55% to 99.9% improvement in CO2 emissions takes place when driving an EV over an ICE (gasoline, diesel) vehicle depending on the source of electricity.[19] Comparing CO2 emissions can be done by using the US national average of 1.28 lb CO2/(kW·h) [citation needed] for electricity generation, giving a range for BEVs from zero up to 0.2 to 0.5 lb CO2/mi (0.06 to 0.13 kg/km). Because 1 gal of gasoline produces 19 lb CO2 when burned in a typical automobile engine, the average US fleet produces 0.83 lb/mi (0.23 kg/km), a 40 mpg car produces approximately 0.47 lb/mi and the Insight 0.27 lb/mi (0.08 kg/km).[20] CO2 and other greenhouse gases emissions are minimal for BEVs powered from sustainable electricity sources (e.g. solar energy), but are constant per gallon (or litre) for gasoline vehicles.

| Model | Short tons CO2 (conventional, mostly fossil fuel electricity production) |

Short tons CO2 (renewable electricity production, e.g., solar panel, or wind power) | |||

|---|---|---|---|---|---|

| 2002 Toyota RAV4-EV (pure BEV) | 3.8 | 0.0 | |||

| 2000 Toyota RAV4 2wd (gasoline) | 7.2 | 7.2 | |||

| Other battery electric vehicle(s) | |||||

| 2000 Nissan Altra EV | 3.5 | 0.0 | |||

| Hybrid vehicles | |||||

| 2001 Honda Insight | 3.1 | 3.1 | |||

| 2005 Toyota Prius | 3.5 | 3.5 | |||

| 2005 Ford Escape H 2x | 5.8 | 5.8 | |||

| 2005 Ford Escape H 4x | 6.2 | 6.2 | |||

| Internal combustion engine vehicles | |||||

| 2005 Dodge Neon 2.0L | 6.0 | 6.0 | |||

| 2005 Ford Escape 4x | 8.0 | 8.0 | |||

| 2005 GMC Envoy XUV 4x | 11.7 | 11.7 | Table assumes driving 15,000(?) miles per year and is for one year | ||

Aerodynamic drag has a large impact on energy efficiency as the speed of the vehicle increases. See Automobile drag coefficients for a list of cars.

Maintenance

EVs, particularly those using AC or brushless DC motors, have far fewer parts to wear out. An ICE vehicle on the other hand will have many mechanical, fluid, and electrical parts that may include some of the following: pistons, connecting rods, crankshafts, cylinder walls, valves, valve springs, valve guides, camshafts, cambelts, lifters, pushrods, rocker arms, oil pumps, fuel pumps, water pumps, radiators, gearbox (also used in some EV's), clutch, distributors, spark plugs, air filters, oil filters, coolant and vacuum hoses, injectors, carburators, turbos, superchargers, gaskets, seals and bearings. All of these parts may wear out over time.

Both hybrids and EVs can use regenerative braking, which greatly reduces wear and tear on friction brakes - Prius taxi drivers report far less frequent brake maintenance.

Acceleration performance

Although some electric vehicles have very small motors, 20 hp or less and therefore have modest acceleration, the relatively constant torque of an electric motor even at very low speeds tends to increase the acceleration performance of an electric vehicle for the same rated motor power. Another early solution was American Motors’ experimental Amitron piggyback system of batteries with one type designed for sustained speeds while a different set boosted acceleration when needed.

Electric vehicles can also utilize a direct motor-to-wheel configuration which increases the amount of available power. Having multiple motors connected directly to the wheels allows for each of the wheels to be used for both propulsion and as braking systems, thereby increasing traction. In some cases, the motor can be housed directly in the wheel, such as in the Whispering Wheel design, which lowers the vehicle's center of gravity and reduces the number of moving parts. When not fitted with an axle, differential, or transmission, electric vehicles have less drivetrain rotational inertia.

A gearless or single gear design in some BEVs eliminates the need for gear shifting, giving such vehicles both smoother acceleration and smoother braking. Because the torque of an electric motor is a function of current, not rotational speed, electric vehicles have a high torque over a larger range of speeds during acceleration, as compared to an internal combustion engine. As there is no delay in developing torque in an EV, EV drivers report generally high satisfaction with acceleration.

For example, the Venturi Fetish delivers supercar acceleration despite a relatively modest 300 horsepower, and a top speed of around 100 miles per hour. Some DC motor-equipped drag racer BEVs, have simple two-speed transmissions to improve top speed.[21][22] The Tesla Roadster prototype can reach 60 mph in 4 seconds with a motor rated at 248 hp. The Ronaele Mustang is another performance car that has recently emerged, the pure electric can reach 60 mph in 4 seconds with a motor rated at 300 horsepower. This car is known as the Roneale Mustang 300EV. The second version is the Roneale Mustang 600EV and can reach 60 mph in 3.2 seconds. The 600EV is powered by a motor rated at 600 hp and has 2,000 ft./lbs. of torque.

Batteries

Rechargeable batteries used in electric vehicles include lead-acid ("flooded" and VRLA), NiCd, nickel metal hydride, lithium ion, Li-ion polymer, and, less commonly, zinc-air and molten salt batteries. The amount of electricity stored in batteries is measured in ampere hours or in coulombs, with the total energy often measured in watt hours.

Charging

Batteries in BEVs must be periodically recharged (see also Replacing, below). BEVs most commonly charge from the power grid (at home or using a street or shop recharging point), which is in turn generated from a variety of domestic resources; such as coal, hydroelectricity, nuclear and others. Home power such as roof top photovoltaic solar cell panels, microhydro or wind may also be used and are promoted because of concerns regarding global warming.

Charging time is limited primarily by the capacity of the grid connection. A normal household outlet is between 1.5 kilowatts (in the US, Canada, Japan, and other countries with 110 volt supply) to 3 kilowatts (in countries with 240 V supply). The main connection to a house might be able to sustain 10 kilowatts, and special wiring can be installed to use this. At this higher power level charging even a small, 7 kilowatt-hour (14–28 mi) pack, would probably require one hour. This is small compared to the effective power delivery rate of an average petrol pump, about 5,000 kilowatts. Even if the supply power can be increased, most batteries do not accept charge at greater than their charge rate ("1C"), because high charge rate has adverse effect on the discharge capacities of batteries. [23]

In 1995, some charging stations charged BEVs in one hour. In November 1997, Ford purchased a fast-charge system produced by AeroVironment called "PosiCharge" for testing its fleets of Ranger EVs, which charged their lead-acid batteries in between six and fifteen minutes. In February 1998, General Motors announced a version of its "Magne Charge" system which could recharge NiMH batteries in about ten minutes, providing a range of sixty to one hundred miles.[24]

In 2005, handheld device battery designs by Toshiba were claimed to be able to accept an 80% charge in as little as 60 seconds.[25] Scaling this specific power characteristic up to the same 7 kilowatt-hour EV pack would result in the need for a peak of 340 kilowatts of power from some source for those 60 seconds. It is not clear that such batteries will work directly in BEVs as heat build-up may make them unsafe.

In 2007, Altairnano's NanoSafe batteries are rechargeable in several minutes, versus hours required for other rechargeable batteries.[citation needed] A NanoSafe cell can be charged to around 95% charge capacity in approximately 10 minutes.[citation needed]

Most people do not always require fast recharging because they have enough time, six to eight hours, during the work day or overnight to recharge. As the charging does not require attention it takes a few seconds for an owner to plug in and unplug their vehicle. Many BEV drivers prefer refueling at home, avoiding the inconvenience of visiting a fuel station. Some workplaces provide special parking bays for electric vehicles with charging equipment provided. In colder areas such as Minnesota and Canada there exists some infrastructure for public power outlets, in parking garages and at parking meters, provided primarily for engine pre-heating.

Connectors

The charging power can be connected to the car in two ways (electric coupling). The first is a direct electrical connection known as conductive coupling. This might be as simple as a mains lead into a weatherproof socket through special high capacity cables with connectors to protect the user from high voltages. The second approach is known as inductive charging. A special 'paddle' is inserted into a slot on the car. The paddle is one winding of a transformer, while the other is built into the car. When the paddle is inserted it completes a magnetic circuit which provides power to the battery pack. In one inductive charging system[5], one winding is attached to the underside of the car, and the other stays on the floor of the garage.

The major advantage of the inductive approach is that there is no possibility of electrocution as there are no exposed conductors, although interlocks, special connectors and ground fault detectors can make conductive coupling nearly as safe. Inductive charging can also reduce vehicle weight, by moving more charging componentry offboard.[26] Conductive coupling equipment is lower in cost and much more efficient due to a vastly lower component count.[citation needed] An inductive charging proponent from Toyota contended in 1998 that overall cost differences were minimal, while a conductive charging proponent from Ford contended that conductive charging was more cost efficient.[26]

Travel range before recharging and trailers

The range of a BEV depends on the number and type of batteries used, and the performance demands of the driver. The weight and type of vehicle also have an impact just as they do on the mileage of traditional vehicles. Electric vehicle conversions depends on the battery type:

- Lead-acid batteries are the most available and inexpensive. Such conversions generally have a range of 30 to 80 km (20 to 50 mi). Production EVs with lead-acid batteries are capable of up to 130 km (80 mi) per charge.

- NiMH batteries have higher energy density and may deliver up to 200 km (120 mi) of range.

- New lithium-ion battery-equipped EVs provide 400–500 km (250–300 mi) of range per charge.[27] Lithium is also less expensive than nickel.[28]

Finding the economic balance of range versus performance, battery capacity versus weight, and battery type versus cost challenges every EV manufacturer.

With an AC system regenerative braking can extend range by up to 50% under extreme traffic conditions without complete stopping. Otherwise, the range is extended by about 10 to 15% in city driving, and only negligibly in highway driving, depending upon terrain.

BEVs (including buses and trucks) can also use genset trailers and pusher trailers in order to extended their range when desired without the additional weight during normal short range use. Discharged baset trailers can be replaced by recharged ones in a route point. If rented then maintenance costs can be deferred to the agency.

Such BEVs can become Hybrid vehicles depending on the trailer and car types of energy and powertrain.

Replacing

An alternative to recharging is to exchange drained or nearly drained batteries (or battery range extender modules) with fully charged batteries.

Re-filling

Zinc-bromine flow batteries can be re-filled, instead of recharged, saving time.

V2G: uploading and grid buffering

Smart grid allows BEVs to provide power to the grid in anytime, specially:

- During peak load periods, when the selling price of electricity can be very high. These vehicles can then be recharged during off-peak hours at cheaper rates while helping to absorb excess night time generation. Here the vehicles serve as a distributed battery storage system to buffer power.

- During blackouts, as backup.

Lifespan

Individual batteries are usually arranged into large battery packs of various voltage and ampere-hour capacity products to give the required energy capacity. Battery life should be considered when calculating the extended cost of ownership, as all batteries eventually wear out and must be replaced. The rate at which they expire depends on a number of factors.

The depth of discharge (DOD) is the recommended proportion of the total available energy storage for which that battery will achieve its rated cycles. Deep cycle lead-acid batteries generally should not be discharged below 80% capacity. More modern formulations can survive deeper cycles.

In real world use, some fleet Toyota RAV4 EVs, using NiMH batteries, have exceeded 100,000 miles (160,000 km) with little degradation in their daily range.[29] Quoting that report's concluding assessment:

- "The five-vehicle test is demonstrating the long-term durability of Nickel Metal Hydride batteries and electric drive trains. Only slight performance degradation has been observed to-date on four out of five vehicles.... EVTC test data provide strong evidence that all five vehicles will exceed the 100,000-mile mark. SCE’s positive experience points to the very strong likelihood of a 130,000 to 150,000-mile Nickel Metal Hydride battery and drive-train operational life. EVs can therefore match or exceed the lifecycle miles of comparable internal combustion engine vehicles.

- "In June 2003 the 320 RAV4 EVs of the SCE fleet were used primarily by meter readers, service managers, field representatives, service planners and mail handlers, and for security patrols and carpools. In five years of operation, the RAV4 EV fleet had logged more than 6.9 million miles, eliminating about 830 tons of air pollutants, and preventing more than 3,700 tons of tailpipe carbon dioxide emissions. Given the successful operation of its EVs to-date, SCE plans to continue using them well after they all log 100,000-miles."

Jay Leno's 1909 Baker Electric (see Baker Motor Vehicle) still operates on its original Edison cells. Battery replacement costs of BEVs may be partially or fully offset by the lack of regular maintenance such as oil and filter changes required for ICEVs, and by the greater reliability of BEVs due to their fewer moving parts. They also do away with many other parts that normally require servicing and maintenance in a regular car, such as on the gearbox, cooling system, and engine tuning. And by the time batteries do finally need definitive replacement, they can be replaced with later generation ones which may offer better performance characteristics, in the same way as you might replace old batteries from a digital camera with improved ones.

Safety

The safety issues of battery electric vehicles are largely dealt with by the international standard ISO 6469. This document is divided in three parts dealing with specific issues:

- On-board electrical energy storage, i.e. the battery

- Functional safety means and protection against failures

- Protection of persons against electrical hazards.

Firefighters and rescue personnel receive special training to deal with the higher voltages and chemicals encountered in electric and hybrid electric vehicle accidents. While BEV accidents may present unusual problems, such as fires and fumes resulting from rapid battery discharge, there is apparently no available information regarding whether they are inherently more or less dangerous than gasoline or diesel internal combustion vehicles which carry flammable fuels.

Future

The future of battery electric vehicles depends primarily upon the cost and availability of batteries with high energy densities, power density, and long life, as all other aspects such as motors, motor controllers, and chargers are fairly mature and cost-competitive with internal combustion engine components. Li-ion, Li-poly and zinc-air batteries have demonstrated energy densities high enough to deliver range and recharge times comparable to conventional vehicles.

Bolloré a French automotive parts group developed a concept car the "Bluecar" using Lithium metal polymer batteries developed by a subsidiary Batscap. It had a range of 250 km and top speed of 125 km/h.(Bluecar) document

Firefly Energy has developed a carbon foam-based lead acid battery with a reported capacity from 90-160 Watt-hours/kg

The cathodes of early 2007 lithium-ion batteries are made from lithium-cobalt metal oxide. This material is pricey, and can release oxygen if its cell is overcharged. If the cobalt is replaced with iron phosphates, the cells will not burn or release oxygen under any charge. The price premium for early 2007 hybrids is about US $5000, some $3000 of which is for their NiMH battery packs. At early 2007 gasoline and electricity prices, that would break even after six to ten years of operation. The hybrid premium could fall to $2000 in five years, with $1200 or more of that being cost of lithium-ion batteries, providing a three-year payback.[30]

Hobbyists, conversions, and racing

Hobbyists often build their own EVs by converting existing production cars to run solely on electricity. There is a cottage industry supporting the conversion and construction of BEVs by hobbyists. Universities such as the University of California, Irvine even build their own custom electric or hybrid-electric cars from scratch.

Short-range battery electric vehicles offer the hobbyist comfort, utility, and quickness, sacrificing only range. Short-range BEVs may be built using high-performance lead–acid batteries, using about half the mass needed for a 60 to 80 mile (100 to 130 km) range; the result is a vehicle with about a thirty mile (50 km) range, which when designed with appropriate weight distribution (40/60 front to rear) does not require power steering, offers exceptional acceleration in the lower end of its operating range, is freeway capable and legal, but are expensive due to the higher cost for these higher-performance batteries. By including a manual transmission, short-range BEVs can obtain both better performance and greater efficiency than the single-speed BEVs developed by major manufactures. Unlike the converted golf carts used for neighborhood electric vehicles, short-range BEVs may be operated on typical suburban throughways (40 to 45 mph or 60 or 70 km/h speed limits are typical) and can keep up with traffic typical on such roads and the short "slow-lane" on-and-off segments of freeways common in suburban areas.

Some drag race such conversions as members of National Electric Drag Racing Association (NEDRA). Battery electric vehicles are also very popular in quarter mile (400 m) racing. The NEDRA regularly holds electric car races and often competes them successfully against exotics such as the Dodge Viper or Saleen S7.

Japanese Professor Hiroshi Shimizu from Faculty of Environmental Information of the Keio University created the limousine of the future: the Eliica (Electric Lithium Ion Car) has eight wheels with electric 55 kilowatt hub motors (8WD) with an output of 470 kilowatts and zero emissions, a top speed of 370 kilometers per hour, and a maximum reach of 320 kilometers provided by lithium-ion-batteries (video at eliica.com). However, current models cost approximately $300,000 US, about one third of which is the cost of the batteries.

See also

- Car battery

- Electric boat

- Electric bus

- Electric Drive Transportation Association (EDTA)

- Electric motorcycles and scooters

- Electric vehicle conversion

- Electrocar

- Green tuning

- Hybrid vehicle

- List of production battery electric vehicles

- Miles Automotive Group

- Milk float - small BEV

- NEDRA (national electric drag racing association)

- Neighborhood electric vehicle

- Plug-in hybrid (PHEV)

- Rechargable battery

- Vehicle-to-grid

- ZAP (motor company)

- Zero-emissions vehicle

References

- ^ "The Death and Rebirth of the Electric Auto" Hari Heath. The Idaho Observer Vol 8, No. 26, Sept, 21, 2006.

- ^ Who killed the electric car? (website)

- ^ http://www.nabble.com/Re%3A-Why-doesn%27t-regen-work-with-DC-p12391827s25542.html

- ^ http://www.brusa.biz/applications/e_mini_evergreen.htm

- ^ Stratingh's electric cart

- ^ Bellis, M. (2006) "The History of Electric Vehicles: The Early Years" About.com article at inventors.about.com accessed on 6 July 2006

- ^ Wakefield, Ernest H. (1994). History of the Electric Automobile. Society of Automotive Engineers, Inc. p. 2-3. ISBN 1-56091-299-5.

- ^ McMahon, D. (2006) "Some EV History" Econogics, Inc. essay at econogics.com accessed on 5 July 2006

- ^ Saranow, J. (July 27, 2006) "The Electric Car Gets Some Muscle" The Wall Street Journal, pp. D1-2.

- ^ Full Size Electric Vehicles

- ^ Hendrickson, Gail, and Kelly Ross. May 2005. [http://www.ase.org/images/lib/transportation/Alliance_Transportation_Handbook.pdf The Drive to Efficient Transportation], Alliance to Save Energy, p. 36. Retrieved on 2007-08-30.

- ^ 1999. "Low-Speed Vehicles," The Senate, State of Hawaii, p. 3. Retrieved on 2007-08-30.

- ^ "Advanced Vehicle Testing Activity: Neighborhood Electric Vehicles." (Website). U.S. Department of Energy, Energy Efficiency and Renewable Energy. Retrieved on 2007-08-30.

- ^ Idaho National Laboratory (2005) "Comparing Energy Costs per Mile for Electric and Gasoline-Fueled Vehicles" Advanced Vehicle Testing Activity report at avt.inel.gov accessed 11 July 2006.

- ^ http://www6.lexisnexis.com/publisher/EndUser?Action=UserDisplayFullDocument&orgId=101846&topicId=103840033&docId=l:618716736

- ^ http://www.werbos.com/E/WhoKilledElecPJW.htm

- ^ Idaho National Laboratory (2006) "Full Size Electric Vehicles" Advanced Vehicle Testing Activity reports at avt.inel.gov accessed 5 July 2006

- ^ Idaho National Laboratory (2006) "1999 General Motors EV1 with NiMH: Performance Statistics" Electric Transportation Applications info sheets at inel.gov accessed 5 July 2006

- ^ Template:PDFlink

- ^ US Department of Energy and Environmental Protection Agency (Model year 2007) database "Search for cars that don't need gasoline" Fuel Economy Guide accessed 5 July 2006

- ^ Hedlund, R. (2006) "The 100 Mile Per Hour Club" National Electric Drag Racing Association list at nedra.com accessed 5 July 2006

- ^ Hedlund, R. (2006) "The 125 Mile Per Hour Club" National Electric Drag Racing Association list at nedra.com accessed 5 July 2006

- ^ http://batteryuniversity.com/partone-5A.htm

- ^ Anderson, C.D. and Anderson, J. (2005) "New Charging Systems" Electric and Hybrid Cars: a History (North Carolina: McFarland & Co., Inc.) ISBN 0-7864-1872-9, p. 121.

- ^ Toshiba Corporation (2005) "Toshiba's New Rechargeable Lithium-Ion Battery Recharges in Only One Minute" press release at toshiba.co.jp accessed 5 July 2006

- ^ a b "Car Companies' Head-on Competition In Electric Vehicle Charging." (Website). The Auto Channel, 1998-11-24. Retrieved on 2007-08-21.

- ^ Mitchell, T. (2003) "AC Propulsion Debuts tzero with LiIon Battery" AC Propulsion, Inc. press release at acpropulsion.com accessed 5 July 2006

- ^ Lithium batteries power hybrid cars of future accessed 22 June 2007

- ^ Knipe, TJ et al. (2003) "100,000-Mile Evaluation of the Toyota RAV4 EV" Southern California Edison, Electric Vehicle Technical Center report at evchargernews.com accessed on 5 July 2006

- ^ Voelcker, J. (January 2007) "Lithium Batteries for Hybrid Cars" IEEE Spectrum

External links

Patents

- U.S. patent 523,354, E. E. Keller, Electrically Propelled Preambulator

- U.S. patent 594,805, Hiram Stevens Maxim, Motor vehicle

- U.S. patent 772,571, H. S. Maxim, Electric motor vehicle

Organizations

- Open Source Electric Car by Society for Sustainable Mobility

- US Electric Auto Association (EAA) and recharging points

- Battery Vehicle Society (UK) and recharging points.

- The European Association for Electric Vehicles (AVERE).

- Electric Car Society (formally known as the Electric Car Owners Club).

- EVCanada - Promoting the uptake of Electric Vehicles in Canada

- Czech EV Club - (CZ) Eng. section in photogallery

News stories

- Chinese government statistics put the number of e-bikes at 28 million Expected sales in 2007

- Mitsubishi forms joint venture for lithium-ion battery production for MIEV May 8, 2007

- GM Engineer discusses battery integration challenge - Jan 30, 2007

- GM does U-turn on electric car program, now says electric cars are the future 7 November 2006

- Renault Nissan to invest in Israeli electric car project 12 January 2007