Turbofan

This article needs additional citations for verification. (September 2008) |

driving propellers, rotors, ducted fans or propfans

| Turbofan | |

|---|---|

| |

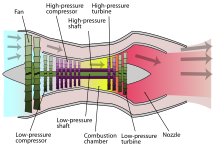

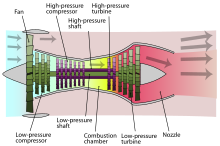

| Schematic diagram of a high-bypass turbofan engine | |

| Reaction engines | |

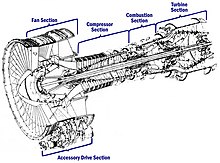

The turbofan is a type of airbreathing jet engine that is widely used for aircraft propulsion. A turbofan combines two types of engines, the turbo portion which is a conventional gas turbine engine,[1] and the fan, a propeller-like ducted fan. The engine produces thrust through a combination of these two portions working in concert; engines that use more jet thrust relative to fan thrust are known as low bypass turbofans, while those that have considerably more fan thrust than jet are known as high bypass. Most commercial aviation jet engines in use today are of the high-bypass type, and most modern military engines are low-bypass,

The fan serves two duties. Part of the airstream from the fan passes through the core, providing oxygen to burn fuel to create power. However, the rest of the air flow bypasses the engine core and mixes with the faster stream from the core at the back of the engine. As engine noise is a function of exhaust temperature, turbofan engines are significantly quieter than a pure-jet of the same thrust. Additionally, the efficiency of propulsion is a function of the relative airspeed of the exhaust to the surrounding air; propellers are most efficient for low speed, pure jets for high speeds, and ducted fans in the middle. Turbofans are thus the most efficient engines in the range of speeds from about 500 to 1000 km/h, the speed at which most commercial aircraft operate.[2][3] Turbofans retain an efficiency edge over pure jets at low supersonic speeds up to roughly Mach 1.6, but have also been found to be efficient when used with continuous afterburner at Mach 3 and above. However, the lower exhaust speed also reduces thrust at high vehicle speeds.

The vast majority of turbofans follow the same basic design with a large fan at the front of the engine with a relatively small jet engine behind it. There have been a number of variations on this theme, however, including rear-mounted fans where they can be easily added to an existing pure-jet design, or designs that combine a low-pressure turbine and a fan stage in a single rear-mounted unit.

Introduction

Unlike a reciprocating engine, a turbojet uses continuous-flow combustion.

In a single-spool (or single-shaft) turbojet, which is the most basic form and the earliest type of turbojet to be developed, air enters an intake before being compressed to a higher pressure by a rotating (fan-like) compressor. The compressed air passes on to a combustor, where it is mixed with a fuel (e.g. kerosene) and ignited. The hot combustion gases then enter a windmill-like turbine, where power is extracted to drive the compressor. Although the expansion process in the turbine reduces the gas pressure (and temperature) somewhat, the remaining energy and pressure are employed to provide a high-velocity jet by passing the gas through a propelling nozzle. This process produces a net thrust opposite to the direction of the jet flow.

After World War II, two-spool (or two-shaft) turbojets were developed to make it easier to throttle back compression systems with a high design overall pressure ratio (i.e., combustor inlet pressure/intake delivery pressure). Adopting the two-spool arrangement enables the compression system to be split in two, with a low pressure (LP) compressor supercharging a high pressure (HP) compressor. Each compressor is mounted on a separate (co-axial) shaft, driven by its own turbine (i.e., the HP turbine and LP turbine). Otherwise, a two-spool turbojet is much like a single-spool engine.

Modern turbofans evolved from the two-spool axial-flow turbojet engine, essentially by increasing the relative size of the low pressure (LP) compressor to the point where some (if not most) of the air exiting the unit actually bypasses the core (or gas-generator) stream passing through the main combustor. This bypass air either expands through a separate propelling nozzle, or is mixed with the hot gases leaving the low pressure (LP) turbine, before expanding through a mixed stream propelling nozzle. Owing to a lower jet velocity, a modern civil turbofan is quieter than the equivalent turbojet. Turbofans also have a better thermal efficiency, which is explained later in the article. In a turbofan, the LP compressor is often called a fan. Civil-aviation turbofans usually have a single fan stage, whereas most military-aviation turbofans (e.g. combat and trainer aircraft applications) have multi-stage fans. Modern military transport turbofan engines are similar to those that propel civil jetliners.

Turboprop engines are gas-turbine engines that deliver almost all of their power to a shaft to drive a propeller. Turboprops remain popular on very small or slow aircraft, such as small commuter airliners, for their fuel efficiency at lower speeds, as well as on medium military transports and patrol planes, such as the C-130 Hercules and P-3 Orion, for their high take-off performance and mission endurance benefits.

If the turboprop is better at moderate flight speeds and the turbojet is better at very high speeds, it might be imagined that at some speed range in the middle a mixture of the two is best. Such an engine is the turbofan (originally termed bypass turbojet by the inventors at Rolls-Royce). Another name sometimes used is ducted fan, though that term is also used for propellers and fans used in vertical-flight applications.

The difference between a turbofan and a propeller, besides direct thrust, is that the intake duct of the former slows the air before it arrives at the fan face. As both propeller and fan blades must operate at subsonic inlet velocities to be efficient, ducted fans allow efficient operation at higher vehicle speeds.

Depending on specific thrust (i.e., net thrust to intake airflow), ducted fans operate best from about 400 to 2,000 kilometres per hour (250 to 1,240 mph), which is why turbofans are the most common type of engine for aviation use today—in airliners as well as in subsonic and supersonic military fighter and trainer aircraft. It should be noted, however, that turbofans use extensive ducting to force incoming air to subsonic velocities (thus reducing shock waves throughout the engine).

Bypass ratio (bypassed airflow to combustor airflow) is a parameter often used for classifying turbofans; when the low-bypass Conway engine entered service in 1960, no one even called it a turbofan, that term first being applied to Pratt and Whitney's JT3D with its 1-to-1 bypass.

The noise of any type of jet engine is strongly related to the velocity of the exhaust gases, typically being proportional to the eighth power of the jet velocity. High-bypass-ratio (i.e., low-specific-thrust) turbofans are relatively quiet compared to turbojets and low-bypass-ratio (i.e., high-specific-thrust) turbofans. A low-specific-thrust engine has a low jet velocity by definition, as the following approximate equation for net thrust implies:

where:

- intake mass flow

- fully expanded jet velocity (in the exhaust plume)

- aircraft flight velocity

Rearranging the above equation, specific thrust is given by:

So for zero flight velocity, specific thrust is directly proportional to jet velocity. Relatively speaking, low-specific-thrust engines are large in diameter to accommodate the high airflow required for a given thrust.

Although jet aircraft are loud, a conventional piston engine or a turboprop engine delivering the same thrust would be much louder.

Early turbofans

Early turbojet engines were very fuel-inefficient, as their overall pressure ratio and turbine inlet temperature were severely limited by the technology available at the time. The very first running turbofan was the German Daimler-Benz DB 670 (designated as the 109-007 by the RLM) which was operated on its testbed on April 1, 1943.[citation needed] The engine was abandoned later while the war went on and problems could not be solved. The British wartime Metrovick F.2 axial flow jet was given a fan to create the first British turbofan.[citation needed]

Improved materials, and the introduction of twin compressors such as in the Pratt & Whitney JT3C engine, increased the overall pressure ratio and thus the thermodynamic efficiency of engines, but they also led to a poor propulsive efficiency, as pure turbojets have a high specific thrust/high velocity exhaust better suited to supersonic flight.

The original low-bypass turbofan engines were designed to improve propulsive efficiency by reducing the exhaust velocity to a value closer to that of the aircraft. The Rolls-Royce Conway, the first production turbofan, had a bypass ratio of 0.3, similar to the modern General Electric F404 fighter engine. Civilian turbofan engines of the 1960s, such as the Pratt & Whitney JT8D and the Rolls-Royce Spey had bypass ratios closer to 1, but were not dissimilar to their military equivalents.

The unusual General Electric CF700 turbofan engine was developed as an aft-fan engine with a 2.0 bypass ratio. This was derived from the General Electric J85/CJ610 turbojet (2,850 lbf or 12,650 N) to power the larger Rockwell Sabreliner 75/80 model aircraft, as well as the Dassault Falcon 20 with about a 50% increase in thrust (4,200 lbf or 18,700 N). The CF700 was the first small turbofan in the world to be certified by the Federal Aviation Administration (FAA). There are now over 400 CF700 aircraft in operation around the world, with an experience base of over 10 million service hours. The CF700 turbofan engine was also used to train Moon-bound astronauts in Project Apollo as the powerplant for the Lunar Landing Research Vehicle.

Low-bypass turbofan

A high specific thrust/low bypass ratio turbofan normally has a multi-stage fan, developing a relatively high pressure ratio and, thus, yielding a high (mixed or cold) exhaust velocity. The core airflow needs to be large enough to give sufficient core power to drive the fan. A smaller core flow/higher bypass ratio cycle can be achieved by raising the (HP) turbine rotor inlet temperature.

Imagine a retrofit situation where a new low bypass ratio, mixed exhaust, turbofan is replacing an old turbojet, in a particular military application. Say the new engine is to have the same airflow and net thrust (i.e. same specific thrust) as the one it is replacing. A bypass flow can only be introduced if the turbine inlet temperature is allowed to increase, to compensate for a correspondingly smaller core flow. Improvements in turbine cooling/material technology would facilitate the use of a higher turbine inlet temperature, despite increases in cooling air temperature, resulting from a probable increase in overall pressure ratio.

Efficiently done, the resulting turbofan would probably operate at a higher nozzle pressure ratio than the turbojet, but with a lower exhaust temperature to retain net thrust. Since the temperature rise across the whole engine (intake to nozzle) would be lower, the (dry power) fuel flow would also be reduced, resulting in a better specific fuel consumption (SFC).

A few low-bypass ratio military turbofans (e.g., F404) have Variable Inlet Guide Vanes, with piano-style hinges, to direct air onto the first rotor stage. This improves the fan surge margin (see compressor map) in the mid-flow range. The swing wing F-111 achieved a very high range/payload capability by pioneering this, and it was also the heart of the famous F-14 Tomcat air superiority fighter which used the same engines in a smaller, more agile airframe to achieve efficient cruise and Mach 2 speed.

Afterburning turbofan

Since the 1971s, most jet fighter engines have been low/medium bypass turbofans with a mixed exhaust, afterburner and variable area final nozzle. An afterburner is a combustor located downstream of the turbine blades and directly upstream of the nozzle, which burns fuel from afterburner-specific fuel injectors. When lit, prodigious amounts of fuel are burnt in the afterburner, raising the temperature of exhaust gases by a significant degree, resulting in a higher exhaust velocity/engine specific thrust. The variable geometry nozzle must open to a larger throat area to accommodate the extra volume flow when the afterburner is lit. Afterburning is often designed to give a significant thrust boost for take off, transonic acceleration and combat maneuvers, but is very fuel intensive. Consequently afterburning can only be used for short portions of a mission.

Unlike the main combustor, where the downstream turbine blades must not be damaged by high temperatures, an afterburner can operate at the ideal maximum (stoichiometric) temperature (i.e., about 2100K/3780Ra/3320F). At a fixed total applied fuel:air ratio, the total fuel flow for a given fan airflow will be the same, regardless of the dry specific thrust of the engine. However, a high specific thrust turbofan will, by definition, have a higher nozzle pressure ratio, resulting in a higher afterburning net thrust and, therefore, a lower afterburning specific fuel consumption. However, high specific thrust engines have a high dry SFC. The situation is reversed for a medium specific thrust afterburning turbofan: i.e., poor afterburning SFC/good dry SFC. The former engine is suitable for a combat aircraft which must remain in afterburning combat for a fairly long period, but only has to fight fairly close to the airfield (e.g. cross border skirmishes) The latter engine is better for an aircraft that has to fly some distance, or loiter for a long time, before going into combat. However, the pilot can only afford to stay in afterburning for a short period, before aircraft fuel reserves become dangerously low.

Modern low-bypass military turbofans include the Pratt & Whitney F119, the Eurojet EJ200, the General Electric F110, the Klimov RD-33, and the Saturn AL-31, all of which feature a mixed exhaust, afterburner and variable area propelling nozzle.

High-bypass turbofan

A. Low pressure spool

B. High pressure spool

C. Stationary components

1. Nacelle

2. Fan

3. Low pressure compressor

4. High pressure compressor

5. Combustion chamber

6. High pressure turbine

7. Low pressure turbine

8. Core nozzle

9. Fan nozzle

The low specific thrust/high bypass ratio turbofans used in today's civil jetliners (and some military transport aircraft) evolved from the high specific thrust/low bypass ratio turbofans used in such [production] aircraft back in the 1960s.

Low specific thrust is achieved by replacing the multi-stage fan with a single stage unit. Unlike some military engines, modern civil turbofans do not have any stationary inlet guide vanes in front of the fan rotor. The fan is scaled to achieve the desired net thrust.

The core (or gas generator) of the engine must generate sufficient core power to at least drive the fan at its design flow and pressure ratio. Through improvements in turbine cooling/material technology, a higher (HP) turbine rotor inlet temperature can be used, thus facilitating a smaller (and lighter) core and (potentially) improving the core thermal efficiency. Reducing the core mass flow tends to increase the load on the LP turbine, so this unit may require additional stages to reduce the average stage loading and to maintain LP turbine efficiency. Reducing core flow also increases bypass ratio (5:1, or more, is now common).

Further improvements in core thermal efficiency can be achieved by raising the overall pressure ratio of the core. Improved blade aerodynamics reduces the number of extra compressor stages required. With multiple compressors (i.e., LPC, IPC, and HPC) dramatic increases in overall pressure ratio have become possible. Variable geometry (i.e., stators) enable high pressure ratio compressors to work surge-free at all throttle settings.

The first high-bypass turbofan engine was the General Electric TF39, designed in mid 1960s to power the Lockheed C-5 Galaxy military transport aircraft.[3] The civil General Electric CF6 engine used a derived design. Other high-bypass turbofans are the Pratt & Whitney JT9D, the three-shaft Rolls-Royce RB211 and the CFM International CFM56. More recent large high-bypass turbofans include the Pratt & Whitney PW4000, the three-shaft Rolls-Royce Trent, the General Electric GE90/GEnx and the GP7000, produced jointly by GE and P&W.

High-bypass turbofan engines are generally quieter than the earlier low bypass ratio civil engines. This is not so much due to the higher bypass ratio as to the use of a low pressure ratio, single stage fan which significantly reduces specific thrust and, thereby, jet velocity. The combination of a higher overall pressure ratio and turbine inlet temperature improves thermal efficiency. This, together with a lower specific thrust (better propulsive efficiency), leads to a lower specific fuel consumption.

For reasons of fuel economy, and also of reduced noise, almost all of today's jet airliners are powered by high-bypass turbofans. Although modern combat aircraft tend to use low bypass ratio turbofans, military transport aircraft (e.g., C-17 ) mainly use high bypass ratio turbofans (or turboprops) for fuel efficiency.

Because of the implied low mean jet velocity, a high bypass ratio/low specific thrust turbofan has a high thrust lapse rate (with rising flight speed). Consequently the engine must be over-sized to give sufficient thrust during climb/cruise at high flight speeds (e.g., Mach 0.83). Because of the high thrust lapse rate, the static (i.e., Mach 0) thrust is relatively high. This enables heavily laden, wide body aircraft to accelerate quickly during take-off and consequently lift-off within a reasonable runway length.

The turbofans on twin engined airliners are further over-sized to cope with losing one engine during take-off, which reduces the aircraft's net thrust by 50%. Modern twin engined airliners normally climb very steeply immediately after take-off. If one engine is lost, the climb-out is much shallower, but sufficient to clear obstacles in the flightpath.

The Soviet Union's engine technology was less advanced than the West's and its first wide-body aircraft, the Ilyushin Il-86, was powered by low-bypass engines. The Yakovlev Yak-42, a medium-range, rear-engined aircraft seating up to 120 passengers introduced in 1980 was the first Soviet aircraft to use high-bypass engines.

Turbofan configurations

Turbofan engines come in a variety of engine configurations. For a given engine cycle (i.e., same airflow, bypass ratio, fan pressure ratio, overall pressure ratio and HP turbine rotor inlet temperature), the choice of turbofan configuration has little impact upon the design point performance (e.g., net thrust, SFC), as long as overall component performance is maintained. Off-design performance and stability is, however, affected by engine configuration.

As the design overall pressure ratio of an engine cycle increases, it becomes more difficult to throttle the compression system, without encountering an instability known as compressor surge. This occurs when some of the compressor aerofoils stall (like the wings of an aircraft) causing a violent change in the direction of the airflow. However, compressor stall can be avoided, at throttled conditions, by progressively:

1) opening interstage/intercompressor blow-off valves (inefficient)

and/or

2) closing variable stators within the compressor

Most modern American civil turbofans employ a relatively high pressure ratio high pressure (HP) compressor, with many rows of variable stators to control surge margin at part-throttle. In the three-spool RB211/Trent the core compression system is split into two, with the IP compressor, which supercharges the HP compressor, being on a different coaxial shaft and driven by a separate (IP) turbine. As the HP compressor has a modest pressure ratio it can be throttled-back surge-free, without employing variable geometry. However, because a shallow IP compressor working line is inevitable, the IPC has one stage of variable geometry on all variants except the -535, which has none.[4]

Single-shaft turbofan

Although far from common, the single-shaft turbofan is probably the simplest configuration, comprising a fan and high pressure compressor driven by a single turbine unit, all on the same shaft. The SNECMA M53, which powers Mirage fighter aircraft, is an example of a single-shaft turbofan. Despite the simplicity of the turbomachinery configuration, the M53 requires a variable area mixer to facilitate part-throttle operation.

Aft-fan turbofan

One of the earliest turbofans was a derivative of the General Electric J79 turbojet, known as the CJ805-23, which featured an integrated aft fan/low pressure (LP) turbine unit located in the turbojet exhaust jetpipe. Hot gas from the turbojet turbine exhaust expanded through the LP turbine, the fan blades being a radial extension of the turbine blades. This aft-fan configuration was later exploited in the General Electric GE-36 UDF (propfan) Demonstrator of the early 80s. One of the problems with the aft fan configuration is hot gas leakage from the LP turbine to the fan.[citation needed]

Basic two spool

Many turbofans have the basic two-spool configuration where both the fan and LP turbine (i.e., LP spool) are mounted on a second (LP) shaft, running concentrically with the HP spool (i.e., HP compressor driven by HP turbine). The BR710 is typical of this configuration. At the smaller thrust sizes, instead of all-axial blading, the HP compressor configuration may be axial-centrifugal (e.g., General Electric CFE738), double-centrifugal or even diagonal/centrifugal (e.g., Pratt & Whitney Canada PW600).

Boosted two spool

Higher overall pressure ratios can be achieved by either raising the HP compressor pressure ratio or adding an intermediate-pressure (IP) Compressor between the fan and HP compressor, to supercharge or boost the latter unit helping to raise the overall pressure ratio of the engine cycle to the very high levels employed today (i.e., greater than 40:1, typically). All of the large American turbofans (e.g., General Electric CF6, GE90 and GEnx plus Pratt & Whitney JT9D and PW4000) feature an IP compressor mounted on the LP shaft and driven, like the fan, by the LP turbine, the mechanical speed of which is dictated by the tip speed and diameter of the fan. The Rolls Royce BR715 is a non-American example of this. The high bypass ratios (i.e., fan duct flow/core flow) used in modern civil turbofans tends to reduce the relative diameter of the attached IP compressor, causing its mean tip speed to decrease. Consequently more IPC stages are required to develop the necessary IPC pressure rise.

Three spool

Rolls-Royce chose a three spool configuration for their large civil turbofans (i.e., the RB211 and Trent families), where the intermediate pressure (IP) compressor is mounted on a separate (IP) shaft, running concentrically with the LP and HP shafts, and is driven by a separate IP turbine.

Ivchenko Design Bureau chose the same configuration for their Lotarev D-36 engine, followed by Lotarev/Progress D-18T and Progress D-436.

The Turbo-Union RB199 military turbofan also has a three spool configuration, as does the Russian military Kuznetsov NK-321.

Geared fan

As bypass ratio increases, the mean radius ratio of the fan and LP turbine increases. Consequently, if the fan is to rotate at its optimum blade speed the LP turbine blading will spin slowly, so additional LPT stages will be required, to extract sufficient energy to drive the fan. Introducing a (planetary) reduction gearbox, with a suitable gear ratio, between the LP shaft and the fan enables both the fan and LP turbine to operate at their optimum speeds. Typical of this configuration are the long-established Honeywell TFE731, the Honeywell ALF 502/507, and the recent Pratt & Whitney PW1000G.

Military turbofans

Most of the configurations discussed above are used in civil turbofans, while modern military turbofans (e.g., SNECMA M88) are usually basic two-spool.

High-pressure turbine

Most civil turbofans use a high efficiency, 2-stage HP turbine to drive the HP compressor. The CFM56 uses an alternative approach: a single stage, high-work unit. While this approach is probably less efficient, there are savings on cooling air, weight and cost. In the RB211 and Trent series, Rolls-Royce split the two stages into two discrete units; one on the HP shaft driving the HP compressor; the other on the IP shaft driving the IP (Intermediate Pressure) Compressor. Modern military turbofans tend to use single stage HP turbines.

Low-pressure turbine

Modern civil turbofans have multi-stage LP turbines (e.g., 3, 4, 5, 6, 7). The number of stages required depends on the engine cycle bypass ratio and how much supercharging (i.e., IP compression) is on the LP shaft, behind the fan. A geared fan may reduce the number of required LPT stages in some applications.[5] Because of the much lower bypass ratios employed, military turbofans only require one or two LP turbine stages.

Cycle improvements

Consider a mixed turbofan with a fixed bypass ratio and airflow. Increasing the overall pressure ratio of the compression system raises the combustor entry temperature. Therefore, at a fixed fuel flow there is an increase in (HP) turbine rotor inlet temperature. Although the higher temperature rise across the compression system implies a larger temperature drop over the turbine system, the mixed nozzle temperature is unaffected, because the same amount of heat is being added to the system. There is, however, a rise in nozzle pressure, because overall pressure ratio increases faster than the turbine expansion ratio, causing an increase in the hot mixer entry pressure. Consequently, net thrust increases, whilst specific fuel consumption (fuel flow/net thrust) decreases. A similar trend occurs with unmixed turbofans.

So turbofans can be made more fuel efficient by raising overall pressure ratio and turbine rotor inlet temperature in unison. However, better turbine materials and/or improved vane/blade cooling are required to cope with increases in both turbine rotor inlet temperature and compressor delivery temperature. Increasing the latter may require better compressor materials.

Overall pressure ratio can be increased by improving fan (or) LP compressor pressure ratio and/or HP compressor pressure ratio. If the latter is held constant, the increase in (HP) compressor delivery temperature (from raising overall pressure ratio) implies an increase in HP mechanical speed. However, stressing considerations might limit this parameter, implying, despite an increase in overall pressure ratio, a reduction in HP compressor pressure ratio.

According to simple theory, if the ratio turbine rotor inlet temperature/(HP) compressor delivery temperature is maintained, the HP turbine throat area can be retained. However, this assumes that cycle improvements are obtained, whilst retaining the datum (HP) compressor exit flow function (non-dimensional flow). In practise, changes to the non-dimensional speed of the (HP) compressor and cooling bleed extraction would probably make this assumption invalid, making some adjustment to HP turbine throat area unavoidable. This means the HP turbine nozzle guide vanes would have to be different from the original! In all probability, the downstream LP turbine nozzle guide vanes would have to be changed anyway.

Thrust growth

Thrust growth is obtained by increasing core power. There are two basic routes available:

- hot route: increase HP turbine rotor inlet temperature

- cold route: increase core mass flow

Both routes require an increase in the combustor fuel flow and, therefore, the heat energy added to the core stream.

The hot route may require changes in turbine blade/vane materials and/or better blade/vane cooling. The cold route can be obtained by one of the following:

- adding T-stages to the LP/IP compression

- adding a zero-stage to the HP compression

- improving the compression process, without adding stages (e.g. higher fan hub pressure ratio)

all of which increase both overall pressure ratio and core airflow.

Alternatively, the core size can be increased, to raise core airflow, without changing overall pressure ratio. This route is expensive, since a new (upflowed) turbine system (and possibly a larger IP compressor) is also required.

Changes must also be made to the fan to absorb the extra core power. On a civil engine, jet noise considerations mean that any significant increase in Take-off thrust must be accompanied by a corresponding increase in fan mass flow (to maintain a T/O specific thrust of about 30 lbf/lb/s), usually by increasing fan diameter. On military engines, the fan pressure ratio would probably be increased to improve specific thrust, jet noise not normally being an important factor.

Technical discussion

- Specific Thrust (net thrust/intake airflow) is an important parameter for turbofans and jet engines in general. Imagine a fan (driven by an appropriately sized electric motor) operating within a pipe, which is connected to a propelling nozzle. It is fairly obvious, the higher the Fan Pressure Ratio (fan discharge pressure/fan inlet pressure), the higher the jet velocity and the corresponding specific thrust. Now imagine we replace this set-up with an equivalent turbofan - same airflow and same fan pressure ratio. Obviously, the core of the turbofan must produce sufficient power to drive the fan via the Low Pressure (LP) Turbine. If we choose a low (HP) Turbine Inlet Temperature for the gas generator, the core airflow needs to be relatively high to compensate. The corresponding bypass ratio is therefore relatively low. If we raise the Turbine Inlet Temperature, the core airflow can be smaller, thus increasing bypass ratio. Raising turbine inlet temperature tends to increase thermal efficiency and, therefore, improve fuel efficiency.

- Naturally, as altitude increases there is a decrease in air density and, therefore, the net thrust of an engine. There is also a flight speed effect, termed Thrust Lapse Rate. Consider the approximate equation for net thrust again:

With a high specific thrust (e.g., fighter) engine, the jet velocity is relatively high, so intuitively one can see that increases in flight velocity have less of an impact upon net thrust than a medium specific thrust (e.g., trainer) engine, where the jet velocity is lower. The impact of thrust lapse rate upon a low specific thrust (e.g., civil) engine is even more severe. At high flight speeds, high specific thrust engines can pick-up net thrust through the ram rise in the intake, but this effect tends to diminish at supersonic speeds because of shock wave losses. - Thrust growth on civil turbofans is usually obtained by increasing fan airflow, thus preventing the jet noise becoming too high. However, the larger fan airflow requires more power from the core. This can be achieved by raising the Overall Pressure Ratio (combustor inlet pressure/intake delivery pressure) to induce more airflow into the core and by increasing turbine inlet temperature. Together, these parameters tend to increase core thermal efficiency and improve fuel efficiency.

- Some high bypass ratio civil turbofans use an extremely low area ratio (less than 1.01), convergent-divergent, nozzle on the bypass (or mixed exhaust) stream, to control the fan working line. The nozzle acts as if it has variable geometry. At low flight speeds the nozzle is unchoked (less than a Mach Number of unity), so the exhaust gas speeds up as it approaches the throat and then slows down slightly as it reaches the divergent section. Consequently, the nozzle exit area controls the fan match and, being larger than the throat, pulls the fan working line slightly away from surge. At higher flight speeds, the ram rise in the intake increases nozzle pressure ratio to the point where the throat becomes choked (M=1.0). Under these circumstances, the throat area dictates the fan match and, being smaller than the exit, pushes the fan working line slightly towards surge. This is not a problem, since fan surge margin is much better at high flight speeds.

- The off-design behaviour of turbofans is illustrated under compressor map and turbine map.

- Because modern civil turbofans operate at low specific thrust, they only require a single fan stage to develop the required fan pressure ratio. The desired overall pressure ratio for the engine cycle is usually achieved by multiple axial stages on the core compression. Rolls-Royce tend to split the core compression into two with an intermediate pressure (IP) supercharging the HP compressor, both units being driven by turbines with a single stage, mounted on separate shafts. Consequently, the HP compressor need only develop a modest pressure ratio (e.g., ~4.5:1). US civil engines use much higher HP compressor pressure ratios (e.g., ~23:1 on the General Electric GE90) and tend to be driven by a two stage HP turbine. Even so, there are usually a few IP axial stages mounted on the LP shaft, behind the fan, to further supercharge the core compression system. Civil engines have multi-stage LP turbines, the number of stages being determined by the bypass ratio, the amount of IP compression on the LP shaft and the LP turbine blade speed.

- Because military engines usually have to be able to fly very fast at Sea Level, the limit on HP compressor delivery temperature is reached at a fairly modest design overall pressure ratio, compared with that of a civil engine. Also the fan pressure ratio is relatively high, to achieve a medium to high specific thrust. Consequently, modern military turbofans usually only have 5 or 6 HP compressor stages and only require a single stage HP turbine. Low bypass ratio military turbofans usually have one LP turbine stage, but higher bypass ratio engines need two stages. In theory, by adding IP compressor stages, a modern military turbofan HP compressor could be used in a civil turbofan derivative, but the core would tend to be too small for high thrust applications.

Recent developments in blade technology

The turbine blades in a turbofan engine are subject to high heat and stress, and require special fabrication. New material construction methods and material science have allowed blades, which were originally polycrystalline (regular metal), to be made from lined up metallic crystals and more recently mono-crystalline (i.e., single crystal) blades, which can operate at higher temperatures with less distortion.

Nickel-based superalloys are used for HP turbine blades in almost all modern jet engines. The temperature capabilities of turbine blades have increased mainly through four approaches: the manufacturing (casting) process, cooling path design, thermal barrier coating (TBC), and alloy development.

Although turbine blade (and vane) materials have improved over the years, much of the increase in (HP) turbine inlet temperatures is due to improvements in blade/vane cooling technology. Relatively cool air is bled from the compression system, bypassing the combustion process, and enters the hollow blade or vane. After picking up heat from the blade/vane, the cooling air is dumped into the main gas stream. If the local gas temperatures are low enough, downstream blades/vanes are uncooled and not adversely affected.

Strictly speaking, cycle-wise the HP Turbine Rotor Inlet Temperature (after the temperature drop across the HPT stator) is more important than the (HP) turbine inlet temperature. Although some modern military and civil engines have peak RITs of the order of 1,560 °C (2,840 °F), such temperatures are only experienced for a short time (during take-off) on civil engines.

Turbofan engine manufacturers

The turbofan engine market is dominated by General Electric, Rolls-Royce plc and Pratt & Whitney, in order of market share. GE and SNECMA of France have a joint venture, CFM International which, as the 3rd largest manufacturer in terms of market share, fits between Rolls-Royce and Pratt & Whitney. Rolls-Royce and Pratt & Whitney also have a joint venture, International Aero Engines, specializing in engines for the Airbus A320 family, whilst finally, Pratt & Whitney and General Electric have a joint venture, Engine Alliance marketing a range of engines for aircraft such as the Airbus A380.

General Electric

GE Aviation, part of the General Electric Conglomerate, currently has the largest share of the turbofan engine market. Some of their engine models include the CF6 (available on the Boeing 767, Boeing 747, Airbus A330 and more), GE90 (only the Boeing 777) and GEnx (developed for the Boeing 747-8 & Boeing 787 Dreamliner and proposed for the Airbus A350, currently in development) engines. On the military side, GE engines power many U.S. military aircraft, including the F110, powering 80% of the US Air Force's F-16 Fighting Falcons, and the F404 and F414 engines, which power the Navy's F/A-18 Hornet and Super Hornet. Rolls-Royce and General Electric are jointly developing the F136 engine to power the Joint Strike Fighter.

CFM International

CFM International is a joint venture between GE Aircraft Engines and SNECMA of France. They have created the very successful CFM56 series, used on Boeing 737, Airbus A340, and Airbus A320 family aircraft.

Rolls-Royce

Rolls-Royce plc is the second largest manufacturer of turbofans and is most noted for their RB211 and Trent series, as well as their joint venture engines for the Airbus A320 and McDonnell Douglas MD-90 families (IAE V2500 with Pratt & Whitney and others), the Panavia Tornado (Turbo-Union RB199) and the Boeing 717 (BR700). The Rolls-Royce AE 3007 was developed by Allison Engine Company before its acquisition by Rolls-Royce, powers several Embraer regional jets. Rolls-Royce Trent 970s were the first engines to power the new Airbus A380. The famous thrust vectoring Pegasus[6] engine is the primary powerplant of the Harrier "Jump Jet" and its derivatives.

Pratt & Whitney

Pratt & Whitney is third behind GE and Rolls-Royce in market share. The JT9D has the distinction of being chosen by Boeing to power the original Boeing 747 "Jumbo jet". The PW4000 series is the successor to the JT9D, and powers some Airbus A310, Airbus A300, Boeing 747, Boeing 767, Boeing 777, Airbus A330 and MD-11 aircraft. The PW4000 is certified for 180-minute ETOPS when used in twinjets. The first family has a 94-inch (2.4 m) fan diameter and is designed to power the Boeing 767, Boeing 747, MD-11, and the Airbus A300. The second family is the 100 inch (2.5 m) fan engine developed specifically for the Airbus A330 twinjet, and the third family has a diameter of 112-inch (2.8 m) designed to power Boeing 777. The Pratt & Whitney F119 and its derivative, the F135, power the United States Air Force's F-22 Raptor and the international F-35 Lightning II, respectively. Rolls-Royce are responsible for the lift fan which will provide the F-35B variants with a STOVL capability. The F100 engine was first used on the F-15 Eagle and F-16 Fighting Falcon. Newer Eagles and Falcons also come with GE F110 as an option, and the two are in competition.

Aviadvigatel

Aviadvigatel (Russian:Авиационный Двиѓатель) is a Russian manufacturer of aircraft engines that succeeded the Soviet Soloviev Design Bureau. The company currently offers[7] several versions of the Aviadvigatel PS-90 engine that powers Ilyushin Il-96-300/400/400T, Tupolev Tu-204, Tu-214 series and the Ilyushin Il-76-MD-90. The company is also developing the new Aviadvigatel PD-14 engine for the new Russian MS-21 airliner.[8]

Ivchenko-Progress

Ivchenko-Progress is the Ukrainian aircraft engine company that succeeded the Soviet Ivchenko Design Bureau. Some of their engine models include Progress D-436 available on the Antonov An-72/74, Yakovlev Yak-42, Beriev Be-200, Antonov An-148 and Tupolev Tu-334 and Progress D-18T that powers two of the world largest airplanes, Antonov An-124 and Antonov An-225.

Extreme bypass jet engines

In the 1970s, Rolls-Royce/SNECMA tested a M45SD-02 turbofan fitted with variable pitch fan blades to improve handling at ultra low fan pressure ratios and to provide thrust reverse down to zero aircraft speed. The engine was aimed at ultra quiet STOL aircraft operating from city centre airports.

In a bid for increased efficiency with speed, a development of the turbofan and turboprop known as a propfan engine was created that had an unducted fan. The fan blades are situated outside of the duct, so that it appears like a turboprop with wide scimitar-like blades. Both General Electric and Pratt & Whitney/Allison demonstrated propfan engines in the 1980s. Excessive cabin noise and relatively cheap jet fuel prevented the engines being put into service.

Terminology

- Afterburner

- extra combustor immediately upstream of final nozzle (also called reheat)

- Average stage loading

- constant × (delta temperature)/[(blade speed) × (blade speed) × (number of stages)]

- Bypass

- airstream that completely bypasses the core compression system, combustor and turbine system

- Bypass ratio

- bypass airflow /core compression inlet airflow

- Core

- turbomachinery handling the airstream that passes through the combustor.

- Core power

- residual shaft power from ideal turbine expansion to ambient pressure after deducting core compression power

- Core thermal efficiency

- core power/power equivalent of fuel flow

- Dry

- afterburner (if fitted) not lit

- EGT

- Exhaust Gas Temperature

- EPR

- Engine Pressure Ratio

- Fan

- turbofan LP compressor

- Fan pressure ratio

- fan outlet total pressure/intake delivery total pressure

- Flex temp

- use of artificially high apparent air temperature to reduce engine wear

- Gas generator

- engine core

- HPC

- high pressure compressor

- HP compressor

- high pressure compressor

- HPT

- high pressure turbine

- HP turbine

- high pressure turbine

- Intake ram drag

- penalty associated with jet engines picking up air from the atmosphere (conventional rocket motors do not have this drag term, because the oxidiser travels with the vehicle)

- IEPR

- Integrated engine pressure ratio

- IPC

- intermediate pressure compressor

- IP compressor

- intermediate pressure compressor

- IPT

- intermediate pressure turbine

- IP turbine

- intermediate pressure turbine

- LPC

- low pressure compressor

- LP compressor

- low pressure compressor

- LPT

- low pressure turbine

- LP turbine

- low pressure turbine

- Net thrust

- nozzle total gross thrust - intake ram drag (excluding nacelle drag, etc., this is the basic thrust acting on the airframe)

- Overall pressure ratio

- combustor inlet total pressure/intake delivery total pressure

- Overall thermal efficiency

- thermal efficiency * propulsive efficiency

- Propulsive efficiency

- propulsive power/rate of production of propulsive kinetic energy (maximum propulsive efficiency occurs when jet velocity equals flight velocity, which implies zero net thrust!)

- SFC

- Specific fuel consumption

- Specific fuel consumption

- total fuel flow/net thrust (proportional to flight velocity/overall thermal efficiency)

- Static pressure

- normal meaning of pressure. Excludes any kinetic energy effects

- Specific thrust

- net thrust/intake airflow

- Thermal efficiency

- rate of production of propulsive kinetic energy/fuel power

- Total fuel flow

- combustor (plus any afterburner) fuel flow rate (e.g., lb/s or g/s)

- Total pressure

- static pressure plus kinetic energy term

- Turbine rotor inlet temperature

- gas absolute mean temperature at principal (e.g., HP) turbine rotor entry

See also

- Jet engine

- Turbojet

- Turboprop

- Turboshaft

- Propfan

- Variable cycle engine

- Jet engine performance

- Gas turbine

Notes and references

- ^ Marshall Brain. "How Gas Turbine Engines Work". howstuffworks.com. Retrieved 2010-11-24.

- ^ "Turbofan Engine". www.grc.nasa.gov. Retrieved 2010-11-24.

- ^ a b Neumann, Gerhard (2004) [1984], Herman the German: Just Lucky I Guess, Bloomington, IN, USA: Authorhouse, ISBN 1-4184-7925-X. First published by Morrow in 1984 as Herman the German: Enemy Alien U.S. Army Master Sergeant. Republished with a new title in 2004 by Authorhouse, with minor or no changes.

{{citation}}: CS1 maint: postscript (link), pp. 228–230. - ^ http://www.rolls-royce.com/Images/RB211-535E4%20_tcm92-11348.pdf

- ^ [1] C. Riegler, C. Bichlmaier: "The geared turbofan technology - Opportunities, challenges and readiness status", 1st CEAS European Air and Space Conference, 10–13 September 2007, Berlin, Germany

- ^ Actually a Bristol engine design taken on by Rolls-Royce when they took over Bristol

- ^ PS-90A turbofan, Aviadvigatel, 2011-01-17

- ^ Turbofan Engine Family for Regional Jet, Aviadvigatel, 2011-01-17