Mirror: Difference between revisions

m Reverted edits by Melodydreamj (talk) to last version by ClueBot NG |

Typo fixing, MOS:DASH, link maintenance, refine ref details, typo(s) fixed: wave-length → wavelength using AWB |

||

| Line 2: | Line 2: | ||

{{Redirect|Looking glass||Looking Glass (disambiguation)}} |

{{Redirect|Looking glass||Looking Glass (disambiguation)}} |

||

{{Redirect|Mirrors}} |

{{Redirect|Mirrors}} |

||

{{pp-move-indef}} |

{{pp-move-indef}} |

||

| Line 43: | Line 42: | ||

* In a '''[[concave mirror]]''', parallel beams of light become a convergent beam, whose rays intersect in the [[Focus (optics)|focus]] of the mirror. Also known as converging mirror |

* In a '''[[concave mirror]]''', parallel beams of light become a convergent beam, whose rays intersect in the [[Focus (optics)|focus]] of the mirror. Also known as converging mirror |

||

* In a '''[[convex mirror]]''', parallel beams become divergent, with the [[ray (optics)|rays]] appearing to diverge from a common point of intersection "behind" the mirror. |

* In a '''[[convex mirror]]''', parallel beams become divergent, with the [[ray (optics)|rays]] appearing to diverge from a common point of intersection "behind" the mirror. |

||

* '''Spherical concave and convex mirrors''' do not focus parallel rays to a single point due to [[spherical aberration]].<ref>{{Cite book|url=https://books.google.com/books?id=5y9_CgAAQBAJ&pg=PA1211 |

* '''Spherical concave and convex mirrors''' do not focus parallel rays to a single point due to [[spherical aberration]].<ref>{{Cite book|url=https://books.google.com/books?id=5y9_CgAAQBAJ&pg=PA1211|title=Physics for Scientists and Engineers: Foundations and Connections|last=Katz|first=Debora M.|date=2016-01-01|publisher=Cengage Learning|isbn=9781337026369|language=en}}</ref> However, the ideal of focusing to a point is a commonly used approximation. '''[[Parabolic reflector]]s''' resolve this, allowing incoming parallel rays (for example, light from a distant star) to be focused to a small spot; almost an ideal point. Parabolic reflectors are not suitable for imaging nearby objects because the light rays are not parallel. |

||

=== Mirror image === |

=== Mirror image === |

||

{{More citations needed |

|||

{{Refimprove |

|||

| date = June 2017 |

| date = June 2017 |

||

}} |

}} |

||

[[File:Mirror statue - Győr, 2015.10.31.JPG|thumb|A large convex mirror. Distortions in the image increase with the viewing distance.]] |

[[File:Mirror statue - Győr, 2015.10.31.JPG|thumb|A large convex mirror. Distortions in the image increase with the viewing distance.]] |

||

{{Main |

{{Main|Mirror image}} |

||

Objects viewed in a (plane) mirror will appear laterally inverted (e.g., if one raises one's right hand, the image's left hand will appear to go up in the mirror), but not vertically inverted (in the image a person's head still appears above his body).<ref>{{Cite book|url=https://books.google.com/books?id=q-MMAAAAYAAJ&pg=PA5 |

Objects viewed in a (plane) mirror will appear laterally inverted (e.g., if one raises one's right hand, the image's left hand will appear to go up in the mirror), but not vertically inverted (in the image a person's head still appears above his body).<ref>{{Cite book|url=https://books.google.com/books?id=q-MMAAAAYAAJ&pg=PA5|title=Popular Lectures on Astronomy: Delivered at the Royal Observatory of Paris|last=Arago|first=François|last2=Lardner|first2=Dionysius|date=1845|publisher=Greeley & McElrath|language=en}}</ref> However, a mirror does not usually "swap" left and right any more than it swaps top and bottom. A mirror typically reverses the forward/backward axis. To be precise, it reverses the object in the direction perpendicular to the mirror surface (the normal). Because left and right are defined relative to front-back and top-bottom, the "flipping" of front and back results in the perception of a left-right reversal in the image. (If you stand side-on to a mirror, the mirror really does reverse your left and right, because that's the direction perpendicular to the mirror.) |

||

Looking at an image of oneself with the front-back axis flipped results in the perception of an image with its left-right axis flipped. When reflected in the mirror, your right hand remains directly opposite your real right hand, but it is perceived as the left hand of your image. When a person looks into a mirror, the image is actually front-back reversed, which is an effect similar to the [[hollow-mask illusion]]. Notice that a mirror image is fundamentally different from the object and cannot be reproduced by simply rotating the object. |

Looking at an image of oneself with the front-back axis flipped results in the perception of an image with its left-right axis flipped. When reflected in the mirror, your right hand remains directly opposite your real right hand, but it is perceived as the left hand of your image. When a person looks into a mirror, the image is actually front-back reversed, which is an effect similar to the [[hollow-mask illusion]]. Notice that a mirror image is fundamentally different from the object and cannot be reproduced by simply rotating the object. |

||

| Line 62: | Line 61: | ||

[[File:Histoire de femme Gu Kai Zhi.jpg|thumb|'Adorning Oneself', detail from 'Admonitions of the Instructress to the Palace Ladies', [[Tang dynasty]] copy of an original by [[Chinese painting|Chinese painter]] [[Gu Kaizhi]], c. 344–405 AD]] |

[[File:Histoire de femme Gu Kai Zhi.jpg|thumb|'Adorning Oneself', detail from 'Admonitions of the Instructress to the Palace Ladies', [[Tang dynasty]] copy of an original by [[Chinese painting|Chinese painter]] [[Gu Kaizhi]], c. 344–405 AD]] |

||

[[File:Lady looking into mirror Belur Halebidu.jpg|thumb|upright|A sculpture of a lady looking into a mirror, from [[Halebidu]], [[India]], 12th century]] |

[[File:Lady looking into mirror Belur Halebidu.jpg|thumb|upright|A sculpture of a lady looking into a mirror, from [[Halebidu]], [[India]], 12th century]] |

||

The first mirrors used by humans were most likely pools of dark, still water, or water collected in a primitive vessel of some sort. The requirements for making a good mirror are a surface with a very high degree of [[Flatness (mathematics)|flatness]] (preferably but not necessarily with high [[reflectivity]]), and a [[surface roughness]] smaller than the |

The first mirrors used by humans were most likely pools of dark, still water, or water collected in a primitive vessel of some sort. The requirements for making a good mirror are a surface with a very high degree of [[Flatness (mathematics)|flatness]] (preferably but not necessarily with high [[reflectivity]]), and a [[surface roughness]] smaller than the wavelength of the light. The earliest manufactured mirrors were pieces of polished stone such as [[obsidian]], a naturally occurring [[volcanic glass]]. Examples of obsidian mirrors found in [[Anatolia]] (modern-day Turkey) have been dated to around 6000 B.C.<ref name="Enoch" /> Mirrors of polished copper were crafted in [[Mesopotamia]] from 4000 B.C.,<ref name="Enoch" /> and in ancient Egypt from around 3000 B.C.<ref>[http://www.tekniskamuseet.se/templates/Page.aspx?id=12447 The National Museum of Science and Technology, Stockholm] {{webarchive |url=https://web.archive.org/web/20090703101416/http://www.tekniskamuseet.se/templates/Page.aspx?id=12447 |date=3 July 2009 }}</ref> Polished stone mirrors from Central and South America date from around 2000 B.C. onwards.<ref name="Enoch">[http://www.optvissci.com/pt/re/ovs/pdfhandler.00006324-200610000-00017.pdf History of Mirrors Dating Back 8000 Years], Jay M. Enoch, School of Optometry, University of California at Berkeley</ref> In China, [[bronze mirror]]s were manufactured from around 2000 B.C.,<ref>{{cite web |url=http://www.chinavoc.com/arts/handicraft/bronze/patternchange.asp |title=Chinavoc.com |publisher=Chinavoc.com |accessdate=2014-06-03 |deadurl=yes |archiveurl=https://web.archive.org/web/20131019042142/http://www.chinavoc.com/arts/handicraft/bronze/patternchange.asp |archivedate=19 October 2013 |df=dmy-all }}</ref> some of the earliest bronze and copper examples being produced by the [[Qijia culture]]. Mirrors made of other metal mixtures ([[alloy]]s) such as copper and tin [[speculum metal]] may have also been produced in China and India.<ref>{{cite book|author=Joseph Needham|title=Science and Civilisation in China|url=https://books.google.com/books?id=BYixSmXUCuMC&pg=PA238|year=1974|publisher=Cambridge University Press|isbn=978-0-521-08571-7|page=238}}</ref> Mirrors of speculum metal or any precious metal were hard to produce and were only owned by the wealthy.<ref>{{cite book|author=Albert Allis Hopkins|title=The Scientific American cyclopedia of formulas: partly based upon the 28th ed. of Scientific American cyclopedia of receipts, notes and queries|url=https://books.google.com/books?id=ioNOAAAAMAAJ&pg=PA89|year=1910|publisher=Munn & co., inc.|page=89}}</ref> These stone and metal mirrors could be made in very large sizes, but were difficult to polish and get perfectly flat; a process that became more difficult with increased size; so they often produced warped or blurred images. Stone mirrors often had poor reflectivity compared to metals, yet metals scratch or tarnish easily, so they frequently needed polishing. Depending upon the color, both often yielded reflections with poor [[color rendering]].<ref>''The Mirror: A History'' by Sabine Melchoir-Bonnet – Routledge 2011 Page 11–13</ref> The poor image quality of ancient mirrors explains [[1 Corinthians 13]]'s reference to seeing "as in a mirror, darkly." |

||

In her history of the mirror, [[Sabine Melchior-Bonnet]] draws significant attention to the relation of the mirror to Greek philosophy, specifically [[Socrates]]:<blockquote>If well used, however, the mirror can aid moral meditation between man and himself. Socrates, we are told by [[Diogenes]], urged young people to look at themselves in mirrors so that, if they were beautiful, they would become worthy of their beauty, and if they were ugly, they would know how to hide their disgrace through learning. The mirror, a tool by which to "[[know thyself]]," invited man to ''not'' mistake himself for God, to avoid pride by knowing his limits, and to improve himself. His was thus not a passive mirror of imitation but an active mirror of transformation. (p.106)<ref>{{Cite web|url=https://www.amazon.com/Mirror-History-Sabine-Melchoir-Bonnet/dp/0415924480|title=The Mirror: A History: Sabine Melchoir-Bonnet: 9780415924481: Amazon.com: Books|website=www.amazon.com|access-date=2017-12-12}}</ref></blockquote>[[Glass]] was a desirable material for mirrors. Because the surface of glass is naturally smooth, it produces reflections with very little blur. In addition, glass is very hard and scratch-resistant. However, glass by itself has little reflectivity, so people began coating it with metals to increase the reflectivity. Metal-coated glass mirrors are said by the Roman scholar [[Pliny the Elder]] to have been invented in [[Sidon]] (modern-day Lebanon) in the first century A.D., although no archeological evidence of them date from before the third century.<ref>[http://www.digitalegypt.ucl.ac.uk/metal/mirrors.html Mirrors in Egypt], Digital Egypt for Universities</ref> According to Pliny, the people of Sidon developed a technique for creating crude mirrors by coating blown glass with molten lead.<ref>[http://www.c-s-p.org/Flyers/9781847181930-sample.pdf The Book of the Mirror] {{webarchive|url=https://web.archive.org/web/20080411060903/http://www.c-s-p.org/Flyers/9781847181930-sample.pdf |date=11 April 2008 }}, Cambridge Scholars Publishing, edited by Miranda Anderson</ref><ref>''The Mirror: A History'' by Sabine Melchoir-Bonnet – Routledge 2011 Page 12</ref> Glass mirrors backed with [[gold leaf]] are mentioned by Pliny in his ''[[Natural History (Pliny)|Natural History]]'', written in about 77 A.D.<ref>[http://www.umich.edu/~kelseydb/Exhibits/WondrousGlass/RomanGlass-Wondrous.html Wondrous Glass: Images and Allegories], Kelsey Museum of Archaeology</ref> Because there were few ways to make a smooth piece of glass with a uniform thickness, these ancient glass-mirrors were made by blowing a glass bubble, and then cutting off a small, circular section, producing mirrors that were either concave or convex. These circular mirrors were typically small, from only a fraction of an inch to as much as eight inches in diameter.<ref>''The Mirror: A History'' by Sabine Melchoir-Bonnet – Routledge 2011 Page 11–12</ref> These small mirrors produced distorted images, yet were prized objects of high value. These ancient glass mirrors were very thin, thus very fragile, because the glass needed to be extremely thin to prevent cracking when coated with a hot, molten metal. Due to the poor quality, high cost, and small size of these ancient glass mirrors, solid metal-mirrors primarily of steel were usually preferred until the late nineteenth century.<ref>''The Mirror: A History'' by Sabine Melchoir-Bonnet – Routledge 2011 Page 13</ref> |

In her history of the mirror, [[Sabine Melchior-Bonnet]] draws significant attention to the relation of the mirror to Greek philosophy, specifically [[Socrates]]:<blockquote>If well used, however, the mirror can aid moral meditation between man and himself. Socrates, we are told by [[Diogenes]], urged young people to look at themselves in mirrors so that, if they were beautiful, they would become worthy of their beauty, and if they were ugly, they would know how to hide their disgrace through learning. The mirror, a tool by which to "[[know thyself]]," invited man to ''not'' mistake himself for God, to avoid pride by knowing his limits, and to improve himself. His was thus not a passive mirror of imitation but an active mirror of transformation. (p.106)<ref>{{Cite web|url=https://www.amazon.com/Mirror-History-Sabine-Melchoir-Bonnet/dp/0415924480|title=The Mirror: A History: Sabine Melchoir-Bonnet: 9780415924481: Amazon.com: Books|website=www.amazon.com|access-date=2017-12-12}}</ref></blockquote>[[Glass]] was a desirable material for mirrors. Because the surface of glass is naturally smooth, it produces reflections with very little blur. In addition, glass is very hard and scratch-resistant. However, glass by itself has little reflectivity, so people began coating it with metals to increase the reflectivity. Metal-coated glass mirrors are said by the Roman scholar [[Pliny the Elder]] to have been invented in [[Sidon]] (modern-day Lebanon) in the first century A.D., although no archeological evidence of them date from before the third century.<ref>[http://www.digitalegypt.ucl.ac.uk/metal/mirrors.html Mirrors in Egypt], Digital Egypt for Universities</ref> According to Pliny, the people of Sidon developed a technique for creating crude mirrors by coating blown glass with molten lead.<ref>[http://www.c-s-p.org/Flyers/9781847181930-sample.pdf The Book of the Mirror] {{webarchive|url=https://web.archive.org/web/20080411060903/http://www.c-s-p.org/Flyers/9781847181930-sample.pdf |date=11 April 2008 }}, Cambridge Scholars Publishing, edited by Miranda Anderson</ref><ref>''The Mirror: A History'' by Sabine Melchoir-Bonnet – Routledge 2011 Page 12</ref> Glass mirrors backed with [[gold leaf]] are mentioned by Pliny in his ''[[Natural History (Pliny)|Natural History]]'', written in about 77 A.D.<ref>[http://www.umich.edu/~kelseydb/Exhibits/WondrousGlass/RomanGlass-Wondrous.html Wondrous Glass: Images and Allegories], Kelsey Museum of Archaeology</ref> Because there were few ways to make a smooth piece of glass with a uniform thickness, these ancient glass-mirrors were made by blowing a glass bubble, and then cutting off a small, circular section, producing mirrors that were either concave or convex. These circular mirrors were typically small, from only a fraction of an inch to as much as eight inches in diameter.<ref>''The Mirror: A History'' by Sabine Melchoir-Bonnet – Routledge 2011 Page 11–12</ref> These small mirrors produced distorted images, yet were prized objects of high value. These ancient glass mirrors were very thin, thus very fragile, because the glass needed to be extremely thin to prevent cracking when coated with a hot, molten metal. Due to the poor quality, high cost, and small size of these ancient glass mirrors, solid metal-mirrors primarily of steel were usually preferred until the late nineteenth century.<ref>''The Mirror: A History'' by Sabine Melchoir-Bonnet – Routledge 2011 Page 13</ref> |

||

[[Parabolic mirror]]s were described and studied in [[classical antiquity]] by the mathematician [[Diocles (mathematician)|Diocles]] in his work ''On Burning Mirrors''.<ref>pp. 162–164, ''Apollonius of Perga's Conica: text, context, subtext'', Michael N. Fried and Sabetai Unguru, Brill, 2001, {{ISBN|90-04-11977-9}}.</ref> [[Ptolemy]] conducted a number of experiments with curved polished iron mirrors,<ref>p. 64, ''[[Mirror Mirror: A History of the Human Love Affair With Reflection]]'', Mark Pendergrast, Basic Books, 2004, {{ISBN|0-465-05471-4}}</ref> and discussed plane, convex spherical, and concave spherical mirrors in his ''Optics''.<ref>{{cite journal | last1 = Smith | first1 = A. Mark | year = 1996 | title = Ptolemy's Theory of Visual Perception: An English Translation of the "Optics" with Introduction and Commentary | url = | journal = Transactions of the American Philosophical Society, new series | volume = 86 | issue = 2| page = iii-300 [38 ff] | doi=10.2307/3231951}}</ref> [[Parabolic mirror]]s were also described by the physicist [[Ibn Sahl (mathematician)|Ibn Sahl]] in the tenth century,<ref>{{cite journal | last1 = Rashed | first1 = Roshdi | year = 1990 | title = A Pioneer in Anaclastics: Ibn Sahl on Burning Mirrors and Lenses | url = | journal = Isis | volume = 81 | issue = 3| pages = 464–491 [465, 468, 469] | doi = 10.1086/355456 }}</ref> and [[Ibn al-Haytham]] discussed [[Curved mirror|concave and convex mirrors]] in both [[Cylinder (geometry)|cylindrical]] and [[Spherical geometry|spherical geometries]],<ref>R. S. Elliott (1966). ''Electromagnetics'', Chapter 1. [[McGraw-Hill]].</ref> carried out a number of experiments with mirrors, and solved the problem of finding the point on a convex mirror at which a ray coming from one point is reflected to another point.<ref name=Deek>Dr. Mahmoud Al Deek. "Ibn Al-Haitham: Master of Optics, Mathematics, Physics and Medicine", ''Al Shindagah'', November–December 2004.</ref> By the 11th century, glass mirrors were being produced in [[Al-Andalus|Moorish Spain]].<ref name=Ajram>{{cite book|author= Kasem Ajram|title=The Miracle of Islam Science|edition=2nd|publisher=Knowledge House Publishers|year=1992|page=171|isbn=0-911119-43-4}}</ref> |

[[Parabolic mirror]]s were described and studied in [[classical antiquity]] by the mathematician [[Diocles (mathematician)|Diocles]] in his work ''On Burning Mirrors''.<ref>pp. 162–164, ''Apollonius of Perga's Conica: text, context, subtext'', Michael N. Fried and Sabetai Unguru, Brill, 2001, {{ISBN|90-04-11977-9}}.</ref> [[Ptolemy]] conducted a number of experiments with curved polished iron mirrors,<ref>p. 64, ''[[Mirror Mirror: A History of the Human Love Affair With Reflection]]'', Mark Pendergrast, Basic Books, 2004, {{ISBN|0-465-05471-4}}</ref> and discussed plane, convex spherical, and concave spherical mirrors in his ''Optics''.<ref>{{cite journal | last1 = Smith | first1 = A. Mark | year = 1996 | title = Ptolemy's Theory of Visual Perception: An English Translation of the "Optics" with Introduction and Commentary | url = | journal = Transactions of the American Philosophical Society, new series | volume = 86 | issue = 2| page = iii-300 [38 ff] | doi=10.2307/3231951| jstor = 3231951 }}</ref> [[Parabolic mirror]]s were also described by the physicist [[Ibn Sahl (mathematician)|Ibn Sahl]] in the tenth century,<ref>{{cite journal | last1 = Rashed | first1 = Roshdi | year = 1990 | title = A Pioneer in Anaclastics: Ibn Sahl on Burning Mirrors and Lenses | url = | journal = Isis | volume = 81 | issue = 3| pages = 464–491 [465, 468, 469] | doi = 10.1086/355456 }}</ref> and [[Ibn al-Haytham]] discussed [[Curved mirror|concave and convex mirrors]] in both [[Cylinder (geometry)|cylindrical]] and [[Spherical geometry|spherical geometries]],<ref>R. S. Elliott (1966). ''Electromagnetics'', Chapter 1. [[McGraw-Hill]].</ref> carried out a number of experiments with mirrors, and solved the problem of finding the point on a convex mirror at which a ray coming from one point is reflected to another point.<ref name=Deek>Dr. Mahmoud Al Deek. "Ibn Al-Haitham: Master of Optics, Mathematics, Physics and Medicine", ''Al Shindagah'', November–December 2004.</ref> By the 11th century, glass mirrors were being produced in [[Al-Andalus|Moorish Spain]].<ref name=Ajram>{{cite book|author= Kasem Ajram|title=The Miracle of Islam Science|edition=2nd|publisher=Knowledge House Publishers|year=1992|page=171|isbn=0-911119-43-4}}</ref> |

||

In China, people began making mirrors by coating metallic objects with silver-mercury [[amalgam (chemistry)|amalgams]] as early as 500 A.D. This was accomplished by coating the mirror with the amalgam, and then heating it until the mercury boiled away, leaving only the silver behind.<ref>Archaeominerology By George Rapp – Springer Verlag Berlin Heidelberg 2009 page 180</ref> |

In China, people began making mirrors by coating metallic objects with silver-mercury [[amalgam (chemistry)|amalgams]] as early as 500 A.D. This was accomplished by coating the mirror with the amalgam, and then heating it until the mercury boiled away, leaving only the silver behind.<ref>Archaeominerology By George Rapp – Springer Verlag Berlin Heidelberg 2009 page 180</ref> |

||

| Line 76: | Line 75: | ||

The invention of the [[silvering|silvered-glass]] mirror is credited to German chemist [[Justus von Liebig]] in 1835.<ref>{{cite journal| doi = 10.1002/jlac.18560980112 | title = Ueber Versilberung und Vergoldung von Glas | journal = Annalen der Chemie und Pharmacie | volume = 98 | issue = 1 | year = 1856 | pages = 132–139 | first = Justus | last = Liebig}}</ref> His process involved the deposition of a thin layer of metallic silver onto glass through the chemical reduction of [[silver nitrate]]. This [[silvering]] process was adapted for mass manufacturing and led to the greater availability of affordable mirrors. In the modern age, mirrors are often produced by the [[wet deposition]] of silver, or sometimes nickel or chromium (the latter used most often in automotive mirrors) via [[electroplating]] directly onto the glass substrate.<ref>{{cite web|url=http://www.mirrorlink.org/tech/manufacture.htm |title=Welcome to |publisher=Mirrorlink.org |accessdate=2014-06-03}}</ref> |

The invention of the [[silvering|silvered-glass]] mirror is credited to German chemist [[Justus von Liebig]] in 1835.<ref>{{cite journal| doi = 10.1002/jlac.18560980112 | title = Ueber Versilberung und Vergoldung von Glas | journal = Annalen der Chemie und Pharmacie | volume = 98 | issue = 1 | year = 1856 | pages = 132–139 | first = Justus | last = Liebig}}</ref> His process involved the deposition of a thin layer of metallic silver onto glass through the chemical reduction of [[silver nitrate]]. This [[silvering]] process was adapted for mass manufacturing and led to the greater availability of affordable mirrors. In the modern age, mirrors are often produced by the [[wet deposition]] of silver, or sometimes nickel or chromium (the latter used most often in automotive mirrors) via [[electroplating]] directly onto the glass substrate.<ref>{{cite web|url=http://www.mirrorlink.org/tech/manufacture.htm |title=Welcome to |publisher=Mirrorlink.org |accessdate=2014-06-03}}</ref> |

||

[[Vacuum deposition]] began with the study of the [[sputtering]] phenomenon during the 1920s and 1930s, which was a common problem in lighting in which metal ejected from the electrodes coated the glass, blocking output. However, turning sputtering into a reliable method of coating a mirror did not occur until the invention of [[semiconductor]]s in the 1970s. [[Evaporation (deposition)|Evaporation coating]] was pioneered by John Strong in 1912. Aluminum was a desirable material for mirrors, but was too dangerous to apply with electroplating. Strong used evaporation coating to make the first aluminum telescope mirrors in the 1930s.<ref>''The Foundations of Vacuum Coating Technology'' By D. M. Mattox -- Springer 2004 Page 37</ref> The first [[dielectric mirror]] was created in 1937 by Auwarter using evaporated [[rhodium]], while the first metallic mirror to be enhanced with a dielectric coating of [[silicon dioxide]] was created by Hass the same year. In 1939 at the [[Schott Glass]] company, Walter Geffcken invented the first dielectric mirrors to use multilayer coatings (stacks).<ref>''Coatings on Glass'' By H. Pulker, H.K. Pulker -- Elsevier 1999 Page |

[[Vacuum deposition]] began with the study of the [[sputtering]] phenomenon during the 1920s and 1930s, which was a common problem in lighting in which metal ejected from the electrodes coated the glass, blocking output. However, turning sputtering into a reliable method of coating a mirror did not occur until the invention of [[semiconductor]]s in the 1970s. [[Evaporation (deposition)|Evaporation coating]] was pioneered by John Strong in 1912. Aluminum was a desirable material for mirrors, but was too dangerous to apply with electroplating. Strong used evaporation coating to make the first aluminum telescope mirrors in the 1930s.<ref>''The Foundations of Vacuum Coating Technology'' By D. M. Mattox -- Springer 2004 Page 37</ref> The first [[dielectric mirror]] was created in 1937 by Auwarter using evaporated [[rhodium]], while the first metallic mirror to be enhanced with a dielectric coating of [[silicon dioxide]] was created by Hass the same year. In 1939 at the [[Schott Glass]] company, Walter Geffcken invented the first dielectric mirrors to use multilayer coatings (stacks).<ref name="ReferenceA">''Coatings on Glass'' By H. Pulker, H.K. Pulker -- Elsevier 1999 Page 3–4</ref> |

||

== Manufacturing == |

== Manufacturing == |

||

| Line 82: | Line 81: | ||

[[File:Dielectric mirror diagram.svg|thumb|A dielectric mirror-stack works on the principle of [[thin-film interference]]. Each layer has a different [[refractive index]], allowing each interface to produce a small amount of reflection. When the thickness of the layers is proportional to the chosen wavelength, the multiple reflections [[constructive interference|constructively interfere]]. Stacks may consist of a few to hundreds of individual coats.]] |

[[File:Dielectric mirror diagram.svg|thumb|A dielectric mirror-stack works on the principle of [[thin-film interference]]. Each layer has a different [[refractive index]], allowing each interface to produce a small amount of reflection. When the thickness of the layers is proportional to the chosen wavelength, the multiple reflections [[constructive interference|constructively interfere]]. Stacks may consist of a few to hundreds of individual coats.]] |

||

Mirrors are manufactured by applying a [[silvering|reflective coating]] to a suitable [[substrate (materials science)|substrate]].<ref>{{Cite book|url=https://books.google.com/books?id=71dgCaECxcQC&pg=PA40 |

Mirrors are manufactured by applying a [[silvering|reflective coating]] to a suitable [[substrate (materials science)|substrate]].<ref>{{Cite book|url=https://books.google.com/books?id=71dgCaECxcQC&pg=PA40|title=Quantum Radar|last=Lanzagorta|first=Marco|date=2012|publisher=Morgan & Claypool Publishers|isbn=9781608458264|language=en}}</ref> The most common substrate is glass, due to its transparency, ease of fabrication, rigidity, hardness, and ability to take a smooth finish. The reflective coating is typically applied to the back surface of the glass, so that the reflecting side of the coating is protected from corrosion and accidental damage by the glass on one side and the coating itself and optional paint for further protection on the other. |

||

In classical antiquity, mirrors were made of solid metal (bronze, later silver)<ref>{{Cite book|url=https://books.google.com/books?id=XkV9CgAAQBAJ&pg=PT92 |

In classical antiquity, mirrors were made of solid metal (bronze, later silver)<ref>{{Cite book|url=https://books.google.com/books?id=XkV9CgAAQBAJ&pg=PT92|title=Elements Of Interior Design And Decoration|last=Whiton|first=Sherrill|date=2013-04-16|publisher=Read Books Ltd|isbn=9781447498230|language=en}}</ref> and were too expensive for widespread use by common people; they were also prone to [[corrosion]]. Due to the low [[reflectivity]] of polished metal, these mirrors also gave a darker image than modern ones, making them unsuitable for indoor use with the artificial lighting of the time ([[candle]]s or [[lantern]]s).{{Citation needed|date=September 2009}} |

||

The method of making mirrors out of [[flat glass|plate glass]] was invented by 13th-century Venetian glassmakers on the island of [[Murano]], who covered the back of the glass with an [[amorphous]] coat of [[tin]] using a [[Gilding#Fire-gilding|fire-gilding]] technique, obtaining near-perfect and undistorted reflection. For over one hundred years, Venetian mirrors installed in richly decorated frames served as luxury decorations for palaces throughout Europe, but the secret of the mercury process eventually arrived in London and Paris during the 17th century, due to industrial espionage. French workshops succeeded in large-scale industrialization of the process, eventually making mirrors affordable to the masses, although mercury's [[toxicity]] (a primary ingredient in gilding, which was boiled away forming noxious vapors) remained a problem.{{Citation needed|date=June 2009|reason=was mercury's toxicity recognised then? I think it was considered innocuous until the mid-twentieth century|answer=likely not, although that didn't negate its toxicity}} |

The method of making mirrors out of [[flat glass|plate glass]] was invented by 13th-century Venetian glassmakers on the island of [[Murano]], who covered the back of the glass with an [[amorphous]] coat of [[tin]] using a [[Gilding#Fire-gilding|fire-gilding]] technique, obtaining near-perfect and undistorted reflection. For over one hundred years, Venetian mirrors installed in richly decorated frames served as luxury decorations for palaces throughout Europe, but the secret of the mercury process eventually arrived in London and Paris during the 17th century, due to industrial espionage. French workshops succeeded in large-scale industrialization of the process, eventually making mirrors affordable to the masses, although mercury's [[toxicity]] (a primary ingredient in gilding, which was boiled away forming noxious vapors) remained a problem.{{Citation needed|date=June 2009|reason=was mercury's toxicity recognised then? I think it was considered innocuous until the mid-twentieth century|answer=likely not, although that didn't negate its toxicity}} |

||

In modern times, the mirror substrate is shaped, polished and cleaned, and is then coated. Glass mirrors are most often coated with silver<ref>{{cite web|url=http://www.mirrorlink.org/tech/manufacture.htm |title=Mirror Manufacturing and Composition |publisher=Mirrorlink.org |accessdate=2014-06-03 |archiveurl=https://web.archive.org/web/20150214231103/http://mirrorlink.org/tech/manufacture.htm |archivedate=February 14, 2015}}</ref> or aluminium,<ref>{{Cite book|url=https://books.google.com/books?id=GSKSJdpt4HAC&pg=PT33 |

In modern times, the mirror substrate is shaped, polished and cleaned, and is then coated. Glass mirrors are most often coated with silver<ref>{{cite web|url=http://www.mirrorlink.org/tech/manufacture.htm |title=Mirror Manufacturing and Composition |publisher=Mirrorlink.org |accessdate=2014-06-03 |archiveurl=https://web.archive.org/web/20150214231103/http://mirrorlink.org/tech/manufacture.htm |archivedate=February 14, 2015}}</ref> or aluminium,<ref>{{Cite book|url=https://books.google.com/books?id=GSKSJdpt4HAC&pg=PT33|title=Aluminum and the Elements of Group 13|last=Saunders|first=Nigel|date=2004-02-06|publisher=Capstone Classroom|isbn=9781403454959|language=en}}</ref> implemented by a series of coatings:{{Citation needed|date=September 2009}} |

||

# [[Tin(II) chloride]] |

# [[Tin(II) chloride]] |

||

| Line 96: | Line 95: | ||

# [[Paint]] |

# [[Paint]] |

||

The [[tin(II) chloride]] is applied because silver will not bond with the glass. The activator causes the tin/silver to harden. Copper is added for long-term durability.<ref name="How It's Made ep 305">Episode 305 of [[How It's Made]], filmed at [http://www.laverreriewalker.com/ verrerie-walker.com] in [[Anjou, Quebec]], Canada</ref> The [[paint]] protects the coating on the back of the mirror from scratches<ref>{{Cite book|url=https://books.google.com/books?id=NKVRAAAAMAAJ |

The [[tin(II) chloride]] is applied because silver will not bond with the glass. The activator causes the tin/silver to harden. Copper is added for long-term durability.<ref name="How It's Made ep 305">Episode 305 of [[How It's Made]], filmed at [http://www.laverreriewalker.com/ verrerie-walker.com] in [[Anjou, Quebec]], Canada</ref> The [[paint]] protects the coating on the back of the mirror from scratches<ref>{{Cite book|url=https://books.google.com/books?id=NKVRAAAAMAAJ|title=Construction Materials and Processes|last=Watson|first=Don Arthur|date=January 1986|publisher=Gregg Division, McGraw-Hill|isbn=9780070684768|language=en}}</ref> and other accidental damage.{{Citation needed|date=September 2009}} |

||

In some applications, generally those that are cost-sensitive or that require great durability, such as for mounting in a prison cell, mirrors may be made from a single, bulk material such as polished metal. However, metals consist of small crystals (grains) separated by grain boundaries. Thus, crystalline metals do not reflect with perfect uniformity.<ref>''Coatings on Glass'' By H. Pulker, H.K. Pulker -- Elsevier 1999 Page |

In some applications, generally those that are cost-sensitive or that require great durability, such as for mounting in a prison cell, mirrors may be made from a single, bulk material such as polished metal. However, metals consist of small crystals (grains) separated by grain boundaries. Thus, crystalline metals do not reflect with perfect uniformity.<ref>''Coatings on Glass'' By H. Pulker, H.K. Pulker -- Elsevier 1999 Page 2–3, 8</ref> Other methods like wet-deposition or electroplating produce a non-crystalline coating of [[amorphous metal]] (metallic glass). Lacking any grain boundaries, the amorphous coatings have higher reflectivity than crystalline metals of the same type. Electroplating must be performed by first coating the glass with carbon, to make the surface electrically conductive, thus the adhesion is often not as good as with wet-deposition. Both lack the ability to produce perfectly uniform thicknesses with high precision.<ref>''Coatings on Glass'' By H. Pulker, H.K. Pulker -- Elsevier 1999 Page 3, 107</ref> When high precision or reflectivity is not a requirement, the coating may be placed on the back of the mirror so that the light passes through the glass, and the coating is the second surface it encounters. Therefore, these are called second-surface mirrors, which have the added benefit of high durability, because the glass substrate can protect the coating from damage.<ref>''Coatings on Glass'' By H. Pulker, H.K. Pulker -- Elsevier 1999 Page 2, 107</ref> |

||

For technical applications such as [[laser]] mirrors, the reflective coating is typically applied by [[vacuum deposition]]. Vacuum deposition provides an effective means of producing a very uniform coating, and controlling the thickness with high precision.<ref |

For technical applications such as [[laser]] mirrors, the reflective coating is typically applied by [[vacuum deposition]]. Vacuum deposition provides an effective means of producing a very uniform coating, and controlling the thickness with high precision.<ref name="ReferenceA"/> In applications where great precision and low losses are required, the coated side of the mirror may be the first material encountered by the light, referred to as a first-surface mirror. This eliminates [[refraction]] and double reflections, also called "ghost reflections" (a weak reflection from the surface of the glass, and a stronger one from the reflecting metal), and reduces absorption of light by the mirror.<ref>''Molded Optics: Design and Manufacture'' By Michael Schaub, Jim Schwiegerling, Eric Fest, R. Hamilton Shepard, Alan Symmons -- CRC Press 2011 Page 88–89</ref> Technical mirrors may use a silver, aluminium, or gold coating (the latter typically for [[infrared]] mirrors), and achieve reflectivities of 90–95% when new. A hard, protective, transparent overcoat may be applied to prevent [[oxidation]] of the reflective layer and scratching of the soft metal. Applications requiring higher reflectivity or greater durability, where wide [[bandwidth (signal processing)|bandwidth]] is not essential, use [[dielectric mirror|dielectric coatings]], which can achieve reflectivities as high as 99.997% over a limited range of wavelengths. Because the coatings are usually transparent, absorption losses are negligible. Unlike with metals, the reflectivity of the individual dielectric-coatings is a function of [[Snell's law]] known as the [[Fresnel equations]], determined by the difference in [[refractive index]] between layers. Therefore, the thickness and material of the coatings can be adjusted to be centered on any wavelength. Vacuum deposition can be achieved in a number of ways, including sputtering, evaporation deposition, arc deposition, reactive-gas deposition, and ion plating, among many others.<ref>''Coatings on Glass'' By H. Pulker, H.K. Pulker -- Elsevier 1999 Page 103, 107</ref> |

||

=== Tolerances === |

=== Tolerances === |

||

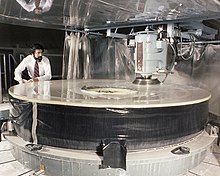

[[File:Hubble mirror polishing.jpg|thumb|Polishing the primary mirror for the [[Hubble space telescope]]. A deviation in the surface quality of approximately 4λ resulted in poor images initially, which was eventually compensated for using [[Corrective Optics Space Telescope Axial Replacement|corrective optics]].]] |

[[File:Hubble mirror polishing.jpg|thumb|Polishing the primary mirror for the [[Hubble space telescope]]. A deviation in the surface quality of approximately 4λ resulted in poor images initially, which was eventually compensated for using [[Corrective Optics Space Telescope Axial Replacement|corrective optics]].]] |

||

[[File:Laser dielectric output coupler centered @ 550nm.png|thumb|A dielectric, laser output-coupler that is |

[[File:Laser dielectric output coupler centered @ 550nm.png|thumb|A dielectric, laser output-coupler that is 75–80% reflective between 500 and 600 nm. Left: The mirror is highly reflective to yellow and green but highly transmissive to red and blue. Right: The mirror transmits 25% of the 589 nm laser light. Because the smoke particles [[Diffraction|diffract]] more light than they reflect, the beam appears much brighter when reflecting back toward the observer.]] |

||

[[File:Mirror distortion and artifacts due to flatness errors.png|thumb|Flatness errors, like rippled dunes across the surface, produced these artifacts, distortion, and low image quality in the [[far field]] reflection of a household mirror.]] |

[[File:Mirror distortion and artifacts due to flatness errors.png|thumb|Flatness errors, like rippled dunes across the surface, produced these artifacts, distortion, and low image quality in the [[far field]] reflection of a household mirror.]] |

||

| Line 110: | Line 109: | ||

====Reflectivity==== |

====Reflectivity==== |

||

The reflectivity of a mirror is determined by the percentage of reflected light per the total of the incident light. The reflectivity may vary with wavelength. All or a portion of the light not reflected is [[Absorption (electromagnetic radiation)|absorbed]] by the mirror, while in some cases a portion may also transmit through. Although some small portion of the light will be absorbed by the coating, the reflectivity is usually higher for first-surface mirrors, eliminating both reflection and absorption losses from the substrate. The reflectivity is often determined by the type and thickness of the coating. When the thickness of the coating is sufficient to prevent transmission, all of the losses occur due to absorption. Aluminum is harder, less expensive, and more resistant to tarnishing than silver, and will reflect 85 to 90% of the light in the visible to near-ultraviolet range, but is a poor reflector of infrared wavelengths longer than 800 |

The reflectivity of a mirror is determined by the percentage of reflected light per the total of the incident light. The reflectivity may vary with wavelength. All or a portion of the light not reflected is [[Absorption (electromagnetic radiation)|absorbed]] by the mirror, while in some cases a portion may also transmit through. Although some small portion of the light will be absorbed by the coating, the reflectivity is usually higher for first-surface mirrors, eliminating both reflection and absorption losses from the substrate. The reflectivity is often determined by the type and thickness of the coating. When the thickness of the coating is sufficient to prevent transmission, all of the losses occur due to absorption. Aluminum is harder, less expensive, and more resistant to tarnishing than silver, and will reflect 85 to 90% of the light in the visible to near-ultraviolet range, but is a poor reflector of infrared wavelengths longer than 800 nm. Gold is very soft and easily scratched, costly, yet does not tarnish. Gold is greater than 96% reflective to near and far-infrared light between 800 and 12000 nm, but poorly reflects visible light with wavelengths shorter than 600 nm (yellow). Silver is expensive, soft, and quickly tarnishes, but has the highest reflectivity in the visual to near-infrared of any metal. Silver can reflect up to 98 or 99% of light to wavelengths as long as 2000 nm, but loses nearly all reflectivity at wavelengths shorter than 350 nm. Dielectric mirrors can reflect greater than 99.99% of light, but only for a narrow range of wavelengths, ranging from a bandwidth of only 10 nm to as wide as 100 nm for [[tunable laser]]s. However, dielectric coatings can also enhance the reflectivity of metallic coatings and protect them from scratching or tarnishing. Dielectric materials are typically very hard and relatively cheap, however the number of coats needed generally makes it an expensive process. In mirrors with low tolerances, the coating thickness may be reduced to save cost, and simply covered with paint to absorb transmission.<ref name="ReferenceB">''Optical Engineering Fundamentals'' By Bruce H. Walker -- The International Society for Optical Engineering 1998 Page 163–164</ref> |

||

====Surface quality==== |

====Surface quality==== |

||

Surface quality, or surface accuracy, measures the deviations from a perfect, ideal surface shape. Increasing the surface quality reduces distortion, artifacts, and [[Aberration (optics)|aberration]] in images, and helps increase [[Coherence (physics)|coherence]], [[collimation]], and reduce unwanted [[beam divergence|divergence]] in beams. For plane mirrors, this is often described in terms of [[Flatness (manufacturing)|flatness]], while other surface shapes are compared to an ideal shape. The surface quality is typically measured with items like [[interferometer]]s or [[optical flat]]s, and are usually measured in wavelengths of light (λ). These deviations can be much larger or much smaller than the surface roughness. A normal household-mirror made with [[float glass]] may have flatness tolerances as low as |

Surface quality, or surface accuracy, measures the deviations from a perfect, ideal surface shape. Increasing the surface quality reduces distortion, artifacts, and [[Aberration (optics)|aberration]] in images, and helps increase [[Coherence (physics)|coherence]], [[collimation]], and reduce unwanted [[beam divergence|divergence]] in beams. For plane mirrors, this is often described in terms of [[Flatness (manufacturing)|flatness]], while other surface shapes are compared to an ideal shape. The surface quality is typically measured with items like [[interferometer]]s or [[optical flat]]s, and are usually measured in wavelengths of light (λ). These deviations can be much larger or much smaller than the surface roughness. A normal household-mirror made with [[float glass]] may have flatness tolerances as low as 9–14λ per inch, equating to a deviation of 5600 through 8800 [[nanometer]]s from perfect flatness. Precision ground and polished mirrors intended for lasers or telescopes may have tolerances as high as λ/50 (1/50 of the wavelength of the light, or around 12 nm).<ref>''The Principles of Astronomical Telescope Design'' By Jingquan Cheng -- Springer 2009 Page 87</ref><ref name="ReferenceB"/> The surface quality can be affected by factors such as temperature changes, internal stress in the substrate, or even bending effects that occur when combining materials with different coefficients of [[thermal expansion]], similar to a [[bimetallic strip]].<ref>''Mems/Nems: Volume 1 Handbook Techniques and Applications Design Methods'' By Cornelius T. Leondes -- Springer 2006 Page 203</ref> |

||

====Surface roughness==== |

====Surface roughness==== |

||

Surface roughness describes the texture of the surface, often in terms of the depth of the microscopic scratches left by the polishing operations. Surface roughness determines how much of the reflection is specular and how much diffuses, controlling how sharp or blurry the image will be. For perfectly specular reflection, the surface roughness must be kept smaller than the wavelength of the light. Microwaves, which sometimes have a wavelength greater than an inch (2.5 |

Surface roughness describes the texture of the surface, often in terms of the depth of the microscopic scratches left by the polishing operations. Surface roughness determines how much of the reflection is specular and how much diffuses, controlling how sharp or blurry the image will be. For perfectly specular reflection, the surface roughness must be kept smaller than the wavelength of the light. Microwaves, which sometimes have a wavelength greater than an inch (2.5 cm) can reflect specularly off a metal screen-door, continental ice-sheets, or desert sand, while visible light, having wavelengths of only a few hundred nanometers (a few hundred-thousandths of an inch), must meet a very smooth surface to produce specular reflection. For wavelengths that are approaching or are even shorter than the [[Atomic radius|diameter of the atoms]], such as [[X-ray]]s, specular reflection can only be produced by surfaces that are at a [[grazing incidence]] from the rays. Surface roughness is typically measured in [[micron]]s, wavelength, or [[Sandpaper#Grit size table|grit size]] (with ~ 80,000 to 100,000 grit (λ/2--λ/4) being "optical quality").<ref>''Remote Sensing of the Mine Environment'' By H. Şebnem Düzgün, Nuray Demirel -- CRC Press 2011 Page 24</ref><ref name="ReferenceB"/><ref>''The SAGE Handbook of Remote Sensing'' By Timothy A Warner, M Duane Nellis, Giles M Foody -- Page 349–350</ref> |

||

====Transmissivity==== |

====Transmissivity==== |

||

Transmissivity is determined by the percentage of light transmitted per the incident light. Transmissivity is usually the same from both first and second surfaces. The combined transmitted and reflected light, subtracted from the incident light, measures the amount absorbed by both the coating and substrate. For transmissive mirrors, such as one-way mirrors, [[beam splitter]]s, or laser [[output coupler]]s, the transmissivity of the mirror is an important consideration. The transmissivity of metallic coatings are often determined by their thickness. For precision beam-splitters or output couplers, the thickness of the coating must be kept at very high tolerances to transmit the proper amount of light. For dielectric mirrors, the thickness of the coat must always be kept to high tolerances, but it is often more the number of individual coats that determine the transmissivity. For the substrate, the material used must also have good transmissivity to the chosen wavelengths. Glass is a suitable substrate for most visible-light applications, but other substrates such as [[zinc selenide]] or [[synthetic sapphire]] may be used for infrared or ultraviolet wavelengths.<ref>''Synchrotron Radiation Sources and Applications'' By G.N Greaves, I.H Munro -- Sussp Publishing 1989 Page |

Transmissivity is determined by the percentage of light transmitted per the incident light. Transmissivity is usually the same from both first and second surfaces. The combined transmitted and reflected light, subtracted from the incident light, measures the amount absorbed by both the coating and substrate. For transmissive mirrors, such as one-way mirrors, [[beam splitter]]s, or laser [[output coupler]]s, the transmissivity of the mirror is an important consideration. The transmissivity of metallic coatings are often determined by their thickness. For precision beam-splitters or output couplers, the thickness of the coating must be kept at very high tolerances to transmit the proper amount of light. For dielectric mirrors, the thickness of the coat must always be kept to high tolerances, but it is often more the number of individual coats that determine the transmissivity. For the substrate, the material used must also have good transmissivity to the chosen wavelengths. Glass is a suitable substrate for most visible-light applications, but other substrates such as [[zinc selenide]] or [[synthetic sapphire]] may be used for infrared or ultraviolet wavelengths.<ref>''Synchrotron Radiation Sources and Applications'' By G.N Greaves, I.H Munro -- Sussp Publishing 1989 Page 104–108</ref> |

||

== Applications == |

== Applications == |

||

| Line 127: | Line 126: | ||

=== Personal grooming === |

=== Personal grooming === |

||

Mirrors are commonly used as aids to [[personal grooming]].<ref>{{Cite book|url=https://books.google.com/books?id=GnN6aHe7Xn8C |

Mirrors are commonly used as aids to [[personal grooming]].<ref>{{Cite book|url=https://books.google.com/books?id=GnN6aHe7Xn8C|title=Planning & remodeling bathrooms|last=Schram|first=Joseph F.|date=1969-01-01|publisher=Lane Books|isbn=9780376013224|language=en}}</ref> They may range from small sizes, good to carry with oneself, to full body sized; they may be handheld, mobile, fixed or adjustable. A classic example of the latter is the [[wikt:cheval glass#English|cheval glass]], which may be tilted. |

||

A classic example of the latter is the [[wikt:cheval glass#English|cheval glass]], which may be tilted. |

|||

=== Safety and easier viewing === |

=== Safety and easier viewing === |

||

;Convex mirrors |

;Convex mirrors |

||

:Convex mirrors provide a wider [[field of view]] than flat mirrors,<ref>{{Cite book|url=https://books.google.com/books?id=daKPJ7T8FhIC&pg=PA266 |

:Convex mirrors provide a wider [[field of view]] than flat mirrors,<ref>{{Cite book|url=https://books.google.com/books?id=daKPJ7T8FhIC&pg=PA266|title=The Kingfisher Science Encyclopedia|last=Taylor|first=Charles|date=2000|publisher=Kingfisher|isbn=9780753452691|language=en}}</ref> and are often used on vehicles,<ref>{{Cite book|url=https://books.google.com/books?id=MZuEsb9Xk5kC|title=Assessment of Vehicle Safety Problems for Special Driving Populations: Final Report|date=1979|publisher=U.S. National Highway Traffic Safety Administration|language=en}}</ref> especially large trucks, to minimize [[Blind spot (automobile)|blind spots]]. They are sometimes placed at [[road junction]]s, and corners of sites such as [[parking lot]]s to allow people to see around corners to avoid crashing into other vehicles or [[shopping cart]]s. They are also sometimes used as part of security systems, so that a single [[video camera]] can show more than one [[angle]] at a time.{{Citation needed|date=November 2010}} . Convex mirrors as decoration are used in interior design to provide a predominantly experiential effect.<ref>https://www.reflectingdesign.com/design_classics_convex-mirrors/</ref> |

||

;[[Mouth mirror]]s or "dental mirrors" |

;[[Mouth mirror]]s or "dental mirrors" |

||

:Mouth mirrors or "dental mirrors" are used by dentists to allow indirect vision and lighting within the mouth. Their reflective surfaces may be either flat or curved.<ref>{{Cite book|url=https://books.google.com/books?id=IEhJpyEBKYIC&pg=PA263 |

:Mouth mirrors or "dental mirrors" are used by dentists to allow indirect vision and lighting within the mouth. Their reflective surfaces may be either flat or curved.<ref>{{Cite book|url=https://books.google.com/books?id=IEhJpyEBKYIC&pg=PA263|title=The Dental Assistant|last=Anderson|first=Pauline Carter|last2=Pendleton|first2=Alice E.|date=2000|publisher=Cengage Learning|isbn=0766811131|language=en}}</ref> Mouth mirrors are also commonly used by [[mechanic]]s to allow vision in tight spaces and around corners in equipment. |

||

;[[Rear-view mirror]]s |

;[[Rear-view mirror]]s |

||

:Rear-view mirrors are widely used in and on vehicles (such as automobiles, or bicycles), to allow drivers to see other vehicles coming up behind them.<ref>{{Cite book|url=https://books.google.com/books?id=5ha9BgAAQBAJ&pg=PA6 |

:Rear-view mirrors are widely used in and on vehicles (such as automobiles, or bicycles), to allow drivers to see other vehicles coming up behind them.<ref>{{Cite book|url=https://books.google.com/books?id=5ha9BgAAQBAJ&pg=PA6|title=The Gist of NCERT -- GENERAL SCIENCE|last=Board|first=Editorial|publisher=Kalinjar Publications|isbn=9789351720188|language=en}}</ref> On rear-view sunglasses, the left end of the left glass and the right end of the right glass work as mirrors. |

||

=== One-way mirrors and windows === |

=== One-way mirrors and windows === |

||

{{Main |

{{Main|One-way mirror}} |

||

;One-way mirrors |

;One-way mirrors |

||

:One-way mirrors (also called two-way mirrors) work by overwhelming dim transmitted light with bright reflected light.<ref>{{Cite news|url=http://mentalfloss.com/article/12969/how-do-two-way-mirrors-work|title=How Do Two-Way Mirrors Work?|date=2012-11-02|access-date=2017-07-31|language=en}}</ref> A true one-way mirror that actually allows light to be transmitted in one direction only without requiring external energy is not possible as it violates the [[second law of thermodynamics]]{{Citation needed|reason=A common sense explanation is not sufficient. A source that discusses this more in depth is needed.|date=November 2015}}: if one placed a cold object on the transmitting side and a hot one on the blocked side, [[radiant energy]] would be transferred from the cold to the hot object. Thus, though a one-way mirror can be made to appear to work in only one direction at a time, it is actually reflective from either side. |

:One-way mirrors (also called two-way mirrors) work by overwhelming dim transmitted light with bright reflected light.<ref>{{Cite news|url=http://mentalfloss.com/article/12969/how-do-two-way-mirrors-work|title=How Do Two-Way Mirrors Work?|date=2012-11-02|access-date=2017-07-31|language=en}}</ref> A true one-way mirror that actually allows light to be transmitted in one direction only without requiring external energy is not possible as it violates the [[second law of thermodynamics]]{{Citation needed|reason=A common sense explanation is not sufficient. A source that discusses this more in depth is needed.|date=November 2015}}: if one placed a cold object on the transmitting side and a hot one on the blocked side, [[radiant energy]] would be transferred from the cold to the hot object. Thus, though a one-way mirror can be made to appear to work in only one direction at a time, it is actually reflective from either side. |

||

| Line 147: | Line 145: | ||

=== Signalling === |

=== Signalling === |

||

{{Main |

{{Main|Heliograph}} |

||

With the sun as light source, a mirror can be used to signal by variations in the orientation of the mirror. The signal can be used over long distances, possibly up to 60 |

With the sun as light source, a mirror can be used to signal by variations in the orientation of the mirror. The signal can be used over long distances, possibly up to 60 km on a clear day. This technique was used by [[Indigenous peoples of the Americas|Native American]] tribes and numerous [[military|militaries]] to transmit information between distant outposts. |

||

Mirrors can also be used for search to attract the attention of [[search and rescue]] helicopters. Specialized type of mirrors are available and are often included in military [[survival kit]]s. |

Mirrors can also be used for search to attract the attention of [[search and rescue]] helicopters. Specialized type of mirrors are available and are often included in military [[survival kit]]s. |

||

| Line 164: | Line 162: | ||

==== Solar power ==== |

==== Solar power ==== |

||

[[File:Parabolic trough near Harper Lake in California front and back.jpg|thumb|Parabolic troughs near [[Harper Lake]] in [[California]]]] |

[[File:Parabolic trough near Harper Lake in California front and back.jpg|thumb|Parabolic troughs near [[Harper Lake]] in [[California]]]] |

||

Mirrors are integral parts of a [[solar power]] plant. The one shown in the adjacent picture uses [[concentrated solar power]] from an array of [[parabolic trough]]s.<ref>{{Cite book|url=https://books.google.com/books?id=oAC5CgAAQBAJ&pg=PA35 |

Mirrors are integral parts of a [[solar power]] plant. The one shown in the adjacent picture uses [[concentrated solar power]] from an array of [[parabolic trough]]s.<ref>{{Cite book|url=https://books.google.com/books?id=oAC5CgAAQBAJ&pg=PA35|title=Concentrating Solar Power and Desalination Plants: Engineering and Economics of Coupling Multi-Effect Distillation and Solar Plants|last=Palenzuela|first=Patricia|last2=Alarcón-Padilla|first2=Diego-César|last3=Zaragoza|first3=Guillermo|date=2015-10-09|publisher=Springer|isbn=9783319205359|language=en}}</ref> |

||

==== Instruments ==== |

==== Instruments ==== |

||

| Line 229: | Line 227: | ||

Mirrors have been used by artists to create works and hone their craft: |

Mirrors have been used by artists to create works and hone their craft: |

||

* [[Filippo Brunelleschi]] discovered linear perspective with the help of the mirror.<ref>{{Cite book|url=https://books.google.com/books?id=EfpMBQAAQBAJ&pg=PA40 |

* [[Filippo Brunelleschi]] discovered linear perspective with the help of the mirror.<ref>{{Cite book|url=https://books.google.com/books?id=EfpMBQAAQBAJ&pg=PA40|title=The First Frame|last=Camp|first=Pannill|date=2014-12-04|publisher=Cambridge University Press|isbn=9781107079168|language=en}}</ref> |

||

* [[Leonardo da Vinci]] called the mirror the "master of painters". He recommended, "When you wish to see whether your whole picture accords with what you have portrayed from nature take a mirror and reflect the actual object in it. Compare what is reflected with your painting and carefully consider whether both likenesses of the subject correspond, particularly in regard to the mirror."<ref>Leonardo da Vinci, ''The Notebooks of Leonardo Da Vinci'', XXIX : Precepts of the Painter, Tr. Edward MacCurdy (1938)</ref> |

* [[Leonardo da Vinci]] called the mirror the "master of painters". He recommended, "When you wish to see whether your whole picture accords with what you have portrayed from nature take a mirror and reflect the actual object in it. Compare what is reflected with your painting and carefully consider whether both likenesses of the subject correspond, particularly in regard to the mirror."<ref>Leonardo da Vinci, ''The Notebooks of Leonardo Da Vinci'', XXIX : Precepts of the Painter, Tr. Edward MacCurdy (1938)</ref> |

||

* Many [[self-portraits]] are made possible through the use of mirrors, such as the great self-portraits by [[Dürer]], [[Frida Kahlo]], [[Rembrandt]], and [[Van Gogh]]. [[M. C. Escher]] used special shapes of mirrors in order to achieve a much more complete view of his surroundings than by direct observation in ''[[Hand with Reflecting Sphere]]'' (also known as ''Self-Portrait in Spherical Mirror''). |

* Many [[self-portraits]] are made possible through the use of mirrors, such as the great self-portraits by [[Dürer]], [[Frida Kahlo]], [[Rembrandt]], and [[Van Gogh]]. [[M. C. Escher]] used special shapes of mirrors in order to achieve a much more complete view of his surroundings than by direct observation in ''[[Hand with Reflecting Sphere]]'' (also known as ''Self-Portrait in Spherical Mirror''). |

||

| Line 296: | Line 294: | ||

== Mirrors and animals == |

== Mirrors and animals == |

||

{{Main |

{{Main|Mirror Test}} |

||

Only a few animal species have been shown to have the ability to recognize themselves in a mirror, most of them [[mammal]]s. Experiments have found that the following animals can pass the [[mirror test]]: |

Only a few animal species have been shown to have the ability to recognize themselves in a mirror, most of them [[mammal]]s. Experiments have found that the following animals can pass the [[mirror test]]: |

||

| Line 396: | Line 394: | ||

* [http://www.mirrorlink.org/tech/manufacture.htm ''Mirror Manufacturing and Composition'', Mirrorlink] |

* [http://www.mirrorlink.org/tech/manufacture.htm ''Mirror Manufacturing and Composition'', Mirrorlink] |

||

* {{YouTube|8Y-kWGe01jE|Video of Mirror Making}} |

* {{YouTube|8Y-kWGe01jE|Video of Mirror Making}} |

||

* [https://books.google.com/books?hl=en&id=P-c1g6QIPHIC |

* [https://books.google.com/books?hl=en&id=P-c1g6QIPHIC The Mirror: A History by Sabine Melchior-Bonnet at Google Books] |

||

* [https://web.archive.org/web/20071130004837/http://www.glasswebsite.com/video/mirror.asp How Mirrors Are Made (video)], Glass Association of North America (GANA) |

* [https://web.archive.org/web/20071130004837/http://www.glasswebsite.com/video/mirror.asp How Mirrors Are Made (video)], Glass Association of North America (GANA) |

||

{{Use dmy dates|date=May 2012}} |

{{Use dmy dates|date=May 2012}} |

||

Revision as of 23:50, 8 May 2018

A mirror is an object that reflects light in such a way that, for incident light in some range of wavelengths, the reflected light preserves many or most of the detailed physical characteristics of the original light, called specular reflection. This is different from other light-reflecting objects that do not preserve much of the original wave signal other than color and diffuse reflected light, such as flat-white paint.

The most familiar type of mirror is the plane mirror, which has a flat surface. Curved mirrors are also used, to produce magnified or diminished images or focus light or simply distort the reflected image.

Mirrors are commonly used for personal grooming or admiring oneself (where they are also called looking-glasses), for viewing the area behind and on the sides on motor vehicles while driving, for decoration, and architecture. Mirrors are also used in scientific apparatus such as telescopes and lasers, cameras, and industrial machinery. Most mirrors are designed for visible light; however, mirrors designed for other wavelengths of electromagnetic radiation are also used.

Types of glass mirrors

There are many types of glass mirrors, each representing a different manufacturing process and reflection type.

An aluminium glass mirror is made of a float glass manufactured using vacuum coating, i.e. aluminium powder is evaporated (or "sputtered") onto the exposed surface of the glass in a vacuum chamber and then coated with two or more layers of waterproof protective paint. [citation needed]

A low aluminium glass mirror is manufactured by coating silver and two layers of protective paint on the back surface of glass. A low aluminium glass mirror is very clear, light transmissive, smooth, and reflects accurate natural colors. This type of glass is widely used for framing presentations and exhibitions in which a precise color representation of the artwork is truly essential or when the background color of the frame is predominantly white.[citation needed]

A safety glass mirror is made by adhering a special protective film to the back surface of a silver glass mirror, which prevents injuries in case the mirror is broken. This kind of mirror is used for furniture, doors, glass walls, commercial shelves, or public areas.[citation needed]

A silkscreen printed glass mirror is produced using inorganic color ink that prints patterns through a special screen onto glass. Various colors, patterns, and glass shapes are available. Such a glass mirror is durable and more moisture resistant than ordinary printed glass and can serve for over 20 years. This type of glass is widely used for decorative purposes (e.g., on mirrors, table tops, doors, windows, kitchen chop boards, etc.).[citation needed]

A silver glass mirror is an ordinary mirror, coated on its back surface with silver, which produces images by reflection. This kind of glass mirror is produced by coating a silver, copper film and two or more layers of waterproof paint on the back surface of float glass, which perfectly resists acid and moisture. A silver glass mirror provides clear and actual images, is quite durable, and is widely used for furniture, bathroom and other decorative purposes.[citation needed]

Decorative glass mirrors are usually handcrafted. A variety of shades, shapes and glass thickness are often available.[citation needed]

Effects

Shape of a mirror's surface

A beam of light reflects off a mirror at an angle of reflection equal to its angle of incidence (if the size of a mirror is much larger than the wavelength of light). That is, if the beam of light is shining on a mirror's surface, at a ° angle vertically, then it reflects from the point of incidence at a ° angle from vertically in the opposite direction. This law mathematically follows from the interference of a plane wave on a flat boundary (of much larger size than the wavelength).

- In a plane mirror, a parallel beam of light changes its direction as a whole, while still remaining parallel; the images formed by a plane mirror are virtual images, of the same size as the original object (see mirror image).

- In a concave mirror, parallel beams of light become a convergent beam, whose rays intersect in the focus of the mirror. Also known as converging mirror

- In a convex mirror, parallel beams become divergent, with the rays appearing to diverge from a common point of intersection "behind" the mirror.

- Spherical concave and convex mirrors do not focus parallel rays to a single point due to spherical aberration.[1] However, the ideal of focusing to a point is a commonly used approximation. Parabolic reflectors resolve this, allowing incoming parallel rays (for example, light from a distant star) to be focused to a small spot; almost an ideal point. Parabolic reflectors are not suitable for imaging nearby objects because the light rays are not parallel.

Mirror image

This article needs additional citations for verification. (June 2017) |

Objects viewed in a (plane) mirror will appear laterally inverted (e.g., if one raises one's right hand, the image's left hand will appear to go up in the mirror), but not vertically inverted (in the image a person's head still appears above his body).[2] However, a mirror does not usually "swap" left and right any more than it swaps top and bottom. A mirror typically reverses the forward/backward axis. To be precise, it reverses the object in the direction perpendicular to the mirror surface (the normal). Because left and right are defined relative to front-back and top-bottom, the "flipping" of front and back results in the perception of a left-right reversal in the image. (If you stand side-on to a mirror, the mirror really does reverse your left and right, because that's the direction perpendicular to the mirror.)

Looking at an image of oneself with the front-back axis flipped results in the perception of an image with its left-right axis flipped. When reflected in the mirror, your right hand remains directly opposite your real right hand, but it is perceived as the left hand of your image. When a person looks into a mirror, the image is actually front-back reversed, which is an effect similar to the hollow-mask illusion. Notice that a mirror image is fundamentally different from the object and cannot be reproduced by simply rotating the object.

For things that may be considered as two-dimensional objects (like text), front-back reversal cannot usually explain the observed reversal. In the same way that text on a piece of paper appears reversed if held up to a light and viewed from behind, text held facing a mirror will appear reversed, because the observer is behind the text. Another way to understand the reversals observed in images of objects that are effectively two-dimensional is that the inversion of left and right in a mirror is due to the way human beings turn their bodies. To turn from viewing the side of the object facing the mirror to view the reflection in the mirror requires the observer to look in the opposite direction. To look in another direction, human beings turn their heads about a vertical axis. This causes a left-right reversal in the image but not an up-down reversal. If a person instead turns by bending over and looking at the mirror image between his/her legs, up-down will appear reversed but not left-right. This sort of reversal is simply a change relative to the observer and not a change intrinsic to the image itself, as with a three-dimensional object.

History

The first mirrors used by humans were most likely pools of dark, still water, or water collected in a primitive vessel of some sort. The requirements for making a good mirror are a surface with a very high degree of flatness (preferably but not necessarily with high reflectivity), and a surface roughness smaller than the wavelength of the light. The earliest manufactured mirrors were pieces of polished stone such as obsidian, a naturally occurring volcanic glass. Examples of obsidian mirrors found in Anatolia (modern-day Turkey) have been dated to around 6000 B.C.[3] Mirrors of polished copper were crafted in Mesopotamia from 4000 B.C.,[3] and in ancient Egypt from around 3000 B.C.[4] Polished stone mirrors from Central and South America date from around 2000 B.C. onwards.[3] In China, bronze mirrors were manufactured from around 2000 B.C.,[5] some of the earliest bronze and copper examples being produced by the Qijia culture. Mirrors made of other metal mixtures (alloys) such as copper and tin speculum metal may have also been produced in China and India.[6] Mirrors of speculum metal or any precious metal were hard to produce and were only owned by the wealthy.[7] These stone and metal mirrors could be made in very large sizes, but were difficult to polish and get perfectly flat; a process that became more difficult with increased size; so they often produced warped or blurred images. Stone mirrors often had poor reflectivity compared to metals, yet metals scratch or tarnish easily, so they frequently needed polishing. Depending upon the color, both often yielded reflections with poor color rendering.[8] The poor image quality of ancient mirrors explains 1 Corinthians 13's reference to seeing "as in a mirror, darkly."

In her history of the mirror, Sabine Melchior-Bonnet draws significant attention to the relation of the mirror to Greek philosophy, specifically Socrates:

If well used, however, the mirror can aid moral meditation between man and himself. Socrates, we are told by Diogenes, urged young people to look at themselves in mirrors so that, if they were beautiful, they would become worthy of their beauty, and if they were ugly, they would know how to hide their disgrace through learning. The mirror, a tool by which to "know thyself," invited man to not mistake himself for God, to avoid pride by knowing his limits, and to improve himself. His was thus not a passive mirror of imitation but an active mirror of transformation. (p.106)[9]

Glass was a desirable material for mirrors. Because the surface of glass is naturally smooth, it produces reflections with very little blur. In addition, glass is very hard and scratch-resistant. However, glass by itself has little reflectivity, so people began coating it with metals to increase the reflectivity. Metal-coated glass mirrors are said by the Roman scholar Pliny the Elder to have been invented in Sidon (modern-day Lebanon) in the first century A.D., although no archeological evidence of them date from before the third century.[10] According to Pliny, the people of Sidon developed a technique for creating crude mirrors by coating blown glass with molten lead.[11][12] Glass mirrors backed with gold leaf are mentioned by Pliny in his Natural History, written in about 77 A.D.[13] Because there were few ways to make a smooth piece of glass with a uniform thickness, these ancient glass-mirrors were made by blowing a glass bubble, and then cutting off a small, circular section, producing mirrors that were either concave or convex. These circular mirrors were typically small, from only a fraction of an inch to as much as eight inches in diameter.[14] These small mirrors produced distorted images, yet were prized objects of high value. These ancient glass mirrors were very thin, thus very fragile, because the glass needed to be extremely thin to prevent cracking when coated with a hot, molten metal. Due to the poor quality, high cost, and small size of these ancient glass mirrors, solid metal-mirrors primarily of steel were usually preferred until the late nineteenth century.[15]

Parabolic mirrors were described and studied in classical antiquity by the mathematician Diocles in his work On Burning Mirrors.[16] Ptolemy conducted a number of experiments with curved polished iron mirrors,[17] and discussed plane, convex spherical, and concave spherical mirrors in his Optics.[18] Parabolic mirrors were also described by the physicist Ibn Sahl in the tenth century,[19] and Ibn al-Haytham discussed concave and convex mirrors in both cylindrical and spherical geometries,[20] carried out a number of experiments with mirrors, and solved the problem of finding the point on a convex mirror at which a ray coming from one point is reflected to another point.[21] By the 11th century, glass mirrors were being produced in Moorish Spain.[22]

In China, people began making mirrors by coating metallic objects with silver-mercury amalgams as early as 500 A.D. This was accomplished by coating the mirror with the amalgam, and then heating it until the mercury boiled away, leaving only the silver behind.[23]

The problems of making metal-coated, glass mirrors was due to the difficulties in making glass that was very clear, as most ancient glass was tinted green with iron. This was overcome when people began mixing soda, limestone, potash, manganese, and fern ashes with the glass. There was also no way for the ancients to make flat panes of glass with uniform thicknesses. The earliest methods for producing glass panes began in France, when people began blowing glass bubbles, and then spinning them rapidly to flatten them out into plates from which pieces could be cut. However, these pieces were still not uniform in thickness, so produced distorted images as well. A better method was to blow a cylinder of glass, cut off the ends, slice it down the center, and unroll it onto a flat hearth. This method produced the first mirror-quality glass panes, but it was very difficult and resulted in a lot of breakage. Even windows were primarily made of oiled paper or stained glass, until the mid-nineteenth century, due to the high cost of making clear, flat panes of glass.[24]

The method of making flat panes of clear glass from blown cylinders began in Germany and evolved through the Middle Ages, until being perfected by the Venetians in the sixteenth century. The Venetians began using lead glass for its crystal-clarity and its easier workability. Some time during the early Renaissance, European manufacturers perfected a superior method of coating glass with a tin-mercury amalgam, producing an amorphous coating with better reflectivity than crystalline metals and causing little thermal shock to the glass.[25] The exact date and location of the discovery is unknown, but in the sixteenth century, Venice, a city famed for its glass-making expertise, became a center of mirror production using this new technique. Glass mirrors from this period were extremely expensive luxuries.[26] For example, in the late seventeenth century, the Countess de Fiesque was reported to have traded an entire wheat farm for a mirror, considering it a bargain. These Venetian mirrors were limited in size to a maximum area of around 40 inches (100 cm) square, until modern glass panes began to be produced during the Industrial Revolution.[27] The Saint-Gobain factory, founded by royal initiative in France, was an important manufacturer, and Bohemian and German glass, often rather cheaper, was also important.

The invention of the silvered-glass mirror is credited to German chemist Justus von Liebig in 1835.[28] His process involved the deposition of a thin layer of metallic silver onto glass through the chemical reduction of silver nitrate. This silvering process was adapted for mass manufacturing and led to the greater availability of affordable mirrors. In the modern age, mirrors are often produced by the wet deposition of silver, or sometimes nickel or chromium (the latter used most often in automotive mirrors) via electroplating directly onto the glass substrate.[29]