Fuel cell

A fuel cell is a device that converts the chemical energy from a fuel into electricity through a chemical reaction with oxygen or another oxidizing agent.[1]

Hydrogen produced from the steam methane reforming of natural gas is the most common fuel, but for greater efficiency hydrocarbons can be used directly such as natural gas and alcohols like methanol. Fuel cells are different from batteries in that they require a continuous source of fuel and oxygen/air to sustain the chemical reaction whereas in a battery the chemicals present in the battery react with each other to generate an electromotive force (emf). Fuel cells can produce electricity continuously for as long as these inputs are supplied.

The first fuel cells were invented in 1838. The first commercial use of fuel cells came more than a century later in NASA space programs to generate power for probes, satellites and space capsules. Since then, fuel cells have been used in many other applications. Fuel cells are used for primary and backup power for commercial, industrial and residential buildings and in remote or inaccessible areas. They are also used to power fuel-cell vehicles, including forklifts, automobiles, buses, boats, motorcycles and submarines.

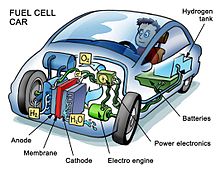

There are many types of fuel cells, but they all consist of an anode, a cathode and an electrolyte that allows charges to move between the two sides of the fuel cell. Electrons are drawn from the anode to the cathode through an external circuit, producing direct current electricity. As the main difference among fuel cell types is the electrolyte, fuel cells are classified by the type of electrolyte they use followed by the difference in startup time ranging from 1 sec for PEMFC to 10 min for SOFC. Fuel cells come in a variety of sizes. Individual fuel cells produce relatively small electrical potentials, about 0.7 volts, so cells are "stacked", or placed in series, to increase the voltage and meet an application's requirements.[2] In addition to electricity, fuel cells produce water, heat and, depending on the fuel source, very small amounts of nitrogen dioxide and other emissions. The energy efficiency of a fuel cell is generally between 40–60%, or up to 85% efficient in cogeneration if waste heat is captured for use.

The fuel cell market is growing, and Pike Research has estimated that the stationary fuel cell market will reach 50 GW by 2020.[3]

History

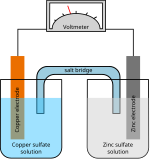

The first references to hydrogen fuel cells appeared in 1838. In a letter dated October 1838 but published in the December 1838 edition of The London and Edinburgh Philosophical Magazine and Journal of Science, Welsh physicist and barrister William Grove wrote about the development of his first crude fuel cells. He used a combination of sheet iron, copper and porcelain plates, and a solution of sulphate of copper and dilute acid.[4][5] In a letter to the same publication written in December 1838 but published in June 1839, German physicist Christian Friedrich Schönbein discussed the first crude fuel cell that he had invented. His letter discussed current generated from hydrogen and oxygen dissolved in water.[6] Grove later sketched his design, in 1842, in the same journal. The fuel cell he made used similar materials to today's phosphoric-acid fuel cell.[7]

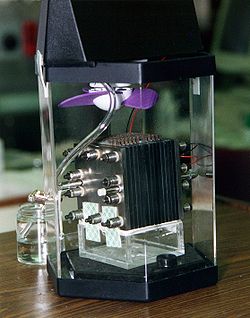

In 1939, British engineer Francis Thomas Bacon successfully developed a 5 kW stationary fuel cell. In 1955, W. Thomas Grubb, a chemist working for the General Electric Company (GE), further modified the original fuel cell design by using a sulphonated polystyrene ion-exchange membrane as the electrolyte. Three years later another GE chemist, Leonard Niedrach, devised a way of depositing platinum onto the membrane, which served as catalyst for the necessary hydrogen oxidation and oxygen reduction reactions. This became known as the "Grubb-Niedrach fuel cell".[8][9] GE went on to develop this technology with NASA and McDonnell Aircraft, leading to its use during Project Gemini. This was the first commercial use of a fuel cell. In 1959, a team led by Harry Ihrig built a 15 kW fuel cell tractor for Allis-Chalmers, which was demonstrated across the U.S. at state fairs. This system used potassium hydroxide as the electrolyte and compressed hydrogen and oxygen as the reactants. Later in 1959, Bacon and his colleagues demonstrated a practical five-kilowatt unit capable of powering a welding machine. In the 1960s, Pratt and Whitney licensed Bacon's U.S. patents for use in the U.S. space program to supply electricity and drinking water (hydrogen and oxygen being readily available from the spacecraft tanks). In 1991, the first hydrogen fuel cell automobile was developed by Roger Billings.[10]

UTC Power was the first company to manufacture and commercialize a large, stationary fuel cell system for use as a co-generation power plant in hospitals, universities and large office buildings.[11] UTC Power continues to be the sole supplier of fuel cells to NASA for use in space vehicles, having supplied fuel cells for the Apollo missions,[12] and the Space Shuttle program, and is developing fuel cells for cell phone towers and other applications.

Types of fuel cells; design

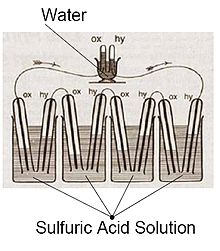

Fuel cells come in many varieties; however, they all work in the same general manner. They are made up of three adjacent segments: the anode, the electrolyte, and the cathode. Two chemical reactions occur at the interfaces of the three different segments. The net result of the two reactions is that fuel is consumed, water or carbon dioxide is created, and an electric current is created, which can be used to power electrical devices, normally referred to as the load.

At the anode a catalyst oxidizes the fuel, usually hydrogen, turning the fuel into a positively charged ion and a negatively charged electron. The electrolyte is a substance specifically designed so ions can pass through it, but the electrons cannot. The freed electrons travel through a wire creating the electric current. The ions travel through the electrolyte to the cathode. Once reaching the cathode, the ions are reunited with the electrons and the two react with a third chemical, usually oxygen, to create water or carbon dioxide.

The most important design features in a fuel cell are[citation needed]:

- The electrolyte substance. The electrolyte substance usually defines the type of fuel cell.

- The fuel that is used. The most common fuel is hydrogen.

- The anode catalyst breaks down the fuel into electrons and ions. The anode catalyst is usually made up of very fine platinum powder.

- The cathode catalyst turns the ions into the waste chemicals like water or carbon dioxide. The cathode catalyst is often made up of nickel but it can also be a nanomaterial-based catalyst.

A typical fuel cell produces a voltage from 0.6 V to 0.7 V at full rated load. Voltage decreases as current increases, due to several factors:

- Activation loss

- Ohmic loss (voltage drop due to resistance of the cell components and interconnections)

- Mass transport loss (depletion of reactants at catalyst sites under high loads, causing rapid loss of voltage).[13]

To deliver the desired amount of energy, the fuel cells can be combined in series and parallel circuits to yield higher voltage, and parallel-channel of configurations allow a higher current to be supplied. Such a design is called a fuel cell stack. The cell surface area can be increased, to allow stronger current from each cell. In the stack, reactant gases must be distributed uniformly over all of the cells to maximize the power output.[14][15][16]

Proton exchange membrane fuel cells (PEMFCs)

In the archetypical hydrogen–oxide proton exchange membrane fuel cell design, a proton-conducting polymer membrane (the electrolyte) separates the anode and cathode sides.[17][18] This was called a "solid polymer electrolyte fuel cell" (SPEFC) in the early 1970s, before the proton exchange mechanism was well-understood. (Notice that the synonyms "polymer electrolyte membrane" and "proton exchange mechanism" result in the same acronym.)

On the anode side, hydrogen diffuses to the anode catalyst where it later dissociates into protons and electrons. These protons often react with oxidants causing them to become what are commonly referred to as multi-facilitated proton membranes. The protons are conducted through the membrane to the cathode, but the electrons are forced to travel in an external circuit (supplying power) because the membrane is electrically insulating. On the cathode catalyst, oxygen molecules react with the electrons (which have traveled through the external circuit) and protons to form water.

In addition to this pure hydrogen type, there are hydrocarbon fuels for fuel cells, including diesel, methanol (see: direct-methanol fuel cells and indirect methanol fuel cells) and chemical hydrides. The waste products with these types of fuel are carbon dioxide and water, when hydrogen is used the CO2 is released when methane from natural gas is combined with steam in a process called steam methane reforming to produce the hydrogen, this can take place in a different location to the fuel cell potentially allowing the hydrogen fuel cell to be used indoors for example in fork lifts.

The different components of a PEMFC are;

- bipolar plates,

- electrodes,

- catalyst,

- membrane, and

- the necessary hardware.[21]

The materials used for different parts of the fuel cells differ by type. The bipolar plates may be made of different types of materials, such as, metal, coated metal, graphite, flexible graphite, C–C composite, carbon–polymer composites etc.[22] The membrane electrode assembly (MEA) is referred as the heart of the PEMFC and is usually made of a proton exchange membrane sandwiched between two catalyst-coated carbon papers. Platinum and/or similar type of noble metals are usually used as the catalyst for PEMFC. The electrolyte could be a polymer membrane.

Proton exchange membrane fuel cell design issues

- Costs. In 2013, the Department of Energy estimated that 80-kW automotive fuel cell system costs of US$67 per kilowatt could be achieved, assuming volume production of 100,000 automotive units per year and US$55 per kilowatt could be achieved, assuming volume production of 500,000 units per year.[23] In 2008, professor Jeremy P. Meyers estimated that cost reductions over a production ramp-up period will take about 20 years after fuel-cell cars are introduced before they will be able to compete commercially with current market technologies, including gasoline internal combustion engines.[24] Many companies are working on techniques to reduce cost in a variety of ways including reducing the amount of platinum needed in each individual cell. Ballard Power Systems has experimented with a catalyst enhanced with carbon silk, which allows a 30% reduction (1 mg/cm² to 0.7 mg/cm²) in platinum usage without reduction in performance.[25] Monash University, Melbourne uses PEDOT as a cathode.[26] A 2011 published study[27] documented the first metal-free electrocatalyst using relatively inexpensive doped carbon nanotubes, which are less than 1% the cost of platinum and are of equal or superior performance.

- Water and air management[28] (in PEMFCs). In this type of fuel cell, the membrane must be hydrated, requiring water to be evaporated at precisely the same rate that it is produced. If water is evaporated too quickly, the membrane dries, resistance across it increases, and eventually it will crack, creating a gas "short circuit" where hydrogen and oxygen combine directly, generating heat that will damage the fuel cell. If the water is evaporated too slowly, the electrodes will flood, preventing the reactants from reaching the catalyst and stopping the reaction. Methods to manage water in cells are being developed like electroosmotic pumps focusing on flow control. Just as in a combustion engine, a steady ratio between the reactant and oxygen is necessary to keep the fuel cell operating efficiently.

- Temperature management. The same temperature must be maintained throughout the cell in order to prevent destruction of the cell through thermal loading. This is particularly challenging as the 2H2 + O2 -> 2H2O reaction is highly exothermic, so a large quantity of heat is generated within the fuel cell.

- Durability, service life, and special requirements for some type of cells. Stationary fuel cell applications typically require more than 40,000 hours of reliable operation at a temperature of −35 °C to 40 °C (−31 °F to 104 °F), while automotive fuel cells require a 5,000-hour lifespan (the equivalent of 240,000 km (150,000 miles)) under extreme temperatures. Current service life is 7,300 hours under cycling conditions.[29] Automotive engines must also be able to start reliably at −30 °C (−22 °F) and have a high power-to-volume ratio (typically 2.5 kW per liter).

- Limited carbon monoxide tolerance of some (non-PEDOT) cathodes.

Phosphoric acid fuel cell (PAFC)

Phosphoric acid fuel cells (PAFC) were first designed and introduced in 1961 by G. V. Elmore and H. A. Tanner. In these cells phosphoric acid is used as a non-conductive electrolyte to pass positive hydrogen ions from the anode to the cathode. These cells commonly work in temperatures of 150 to 200 degrees Celsius. This high temperature will cause heat and energy loss if the heat is not removed and used properly. This heat can be used to produce steam for air conditioning systems or any other thermal energy consuming system.[30] Using this heat in cogeneration can enhance the efficiency of phosphoric acid fuel cells from 40–50% to about 80%.[31] Phosphoric acid, the electrolyte used in PAFCs, is a non-conductive liquid acid which forces electrons to travel from anode to cathode through an external electrical circuit. Since the hydrogen ion production rate on the anode is small, platinum is used as catalyst to increase this ionization rate. A key disadvantage of these cells is the use of an acidic electrolyte. This increases the corrosion or oxidation of components exposed to phosphoric acid.[32]

High-temperature fuel cells

SOFC

Solid oxide fuel cells (SOFCs) use a solid material, most commonly a ceramic material called yttria-stabilized zirconia (YSZ), as the electrolyte. Because SOFCs are made entirely of solid materials, they are not limited to the flat plane configuration of other types of fuel cells and are often designed as rolled tubes. They require high operating temperatures (800–1000 °C) and can be run on a variety of fuels including natural gas.[33]

SOFCs are unique in that negatively charged oxygen ions travel from the cathode (positive side of the fuel cell) to the anode (negative side of the fuel cell) instead of positively charged hydrogen ions travelling from the anode to the cathode, as is the case in all other types of fuel cells. Oxygen gas is fed through the cathode, where it absorbs electrons to create oxygen ions. The oxygen ions then travel through the electrolyte to react with hydrogen gas at the anode. The reaction at the anode produces electricity and water as by-products. Carbon dioxide may also be a by-product depending on the fuel, but the carbon emissions from an SOFC system are less than those from a fossil fuel combustion plant.[34] The chemical reactions for the SOFC system can be expressed as follows:[35]

- Anode Reaction: 2H2 + 2O2− → 2H2O + 4e−

- Cathode Reaction: O2 + 4e– → 2O2−

- Overall Cell Reaction: 2H2 + O2 → 2H2O

SOFC systems can run on fuels other than pure hydrogen gas. However, since hydrogen is necessary for the reactions listed above, the fuel selected must contain hydrogen atoms. For the fuel cell to operate, the fuel must be converted into pure hydrogen gas. SOFCs are capable of internally reforming light hydrocarbons such as methane (natural gas),[36] propane and butane.[37] These fuel cells are at an early stage of development.[38]

Challenges exist in SOFC systems due to their high operating temperatures. One such challenge is the potential for carbon dust to build up on the anode, which slows down the internal reforming process. Research to address this "carbon coking" issue at the University of Pennsylvania has shown that the use of copper-based cermet (heat-resistant materials made of ceramic and metal) can reduce coking and the loss of performance.[39] Another disadvantage of SOFC systems is slow start-up time, making SOFCs less useful for mobile applications. Despite these disadvantages, a high operating temperature provides an advantage by removing the need for a precious metal catalyst like platinum, thereby reducing cost. Additionally, waste heat from SOFC systems may be captured and reused, increasing the theoretical overall efficiency to as high as 80%–85%.[33]

The high operating temperature is largely due to the physical properties of the YSZ electrolyte. As temperature decreases, so does the ionic conductivity of YSZ. Therefore, to obtain optimum performance of the fuel cell, a high operating temperature is required. According to their website, Ceres Power, a UK SOFC fuel cell manufacturer, has developed a method of reducing the operating temperature of their SOFC system to 500–600 degrees Celsius. They replaced the commonly used YSZ electrolyte with a CGO (cerium gadolinium oxide) electrolyte. The lower operating temperature allows them to use stainless steel instead of ceramic as the cell substrate, which reduces cost and start-up time of the system.[40]

MCFC

Molten carbonate fuel cells (MCFCs) require a high operating temperature, 650 °C (1,200 °F), similar to SOFCs. MCFCs use lithium potassium carbonate salt as an electrolyte, and this salt liquefies at high temperatures, allowing for the movement of charge within the cell – in this case, negative carbonate ions.[41]

Like SOFCs, MCFCs are capable of converting fossil fuel to a hydrogen-rich gas in the anode, eliminating the need to produce hydrogen externally. The reforming process creates CO2 emissions. MCFC-compatible fuels include natural gas, biogas and gas produced from coal. The hydrogen in the gas reacts with carbonate ions from the electrolyte to produce water, carbon dioxide, electrons and small amounts of other chemicals. The electrons travel through an external circuit creating electricity and return to the cathode. There, oxygen from the air and carbon dioxide recycled from the anode react with the electrons to form carbonate ions that replenish the electrolyte, completing the circuit.[41] The chemical reactions for an MCFC system can be expressed as follows:[42]

- Anode Reaction: CO32− + H2 → H2O + CO2 + 2e−

- Cathode Reaction: CO2 + ½O2 + 2e− → CO32−

- Overall Cell Reaction: H2 + ½O2 → H2O

As with SOFCs, MCFC disadvantages include slow start-up times because of their high operating temperature. This makes MCFC systems not suitable for mobile applications, and this technology will most likely be used for stationary fuel cell purposes. The main challenge of MCFC technology is the cells' short life span. The high-temperature and carbonate electrolyte lead to corrosion of the anode and cathode. These factors accelerate the degradation of MCFC components, decreasing the durability and cell life. Researchers are addressing this problem by exploring corrosion-resistant materials for components as well as fuel cell designs that may increase cell life without decreasing performance.[33]

MCFCs hold several advantages over other fuel cell technologies, including their resistance to impurities. They are not prone to "carbon coking", which refers to carbon build-up on the anode that results in reduced performance by slowing down the internal fuel reforming process. Therefore, carbon-rich fuels like gases made from coal are compatible with the system. The Department of Energy claims that coal, itself, might even be a fuel option in the future, assuming the system can be made resistant to impurities such as sulfur and particulates that result from converting coal into hydrogen.[33] MCFCs also have relatively high efficiencies. They can reach a fuel-to-electricity efficiency of 50%, considerably higher than the 37–42% efficiency of a phosphoric acid fuel cell plant. Efficiencies can be as high as 65% when the fuel cell is paired with a turbine, and 85% if heat is captured and used in a Combined Heat and Power (CHP) system.[41]

FuelCell Energy, a Connecticut-based fuel cell manufacturer, develops and sells MCFC fuel cells. The company says that their MCFC products range from 300 kW to 2.8 MW systems that achieve 47% electrical efficiency and can utilize CHP technology to obtain higher overall efficiencies. One product, the DFC-ERG, is combined with a gas turbine and, according to the company, it achieves an electrical efficiency of 65%.[43]

Comparison of fuel cell types

| Fuel cell name | Electrolyte | Qualified power (W) | Working temperature (°C) | Efficiency (cell) | Efficiency (system) | Status | Cost (USD/W) |

|---|---|---|---|---|---|---|---|

| Metal hydride fuel cell | Aqueous alkaline solution | > -20 (50% Ppeak @ 0 °C) |

Commercial / Research | ||||

| Electro-galvanic fuel cell | Aqueous alkaline solution | < 40 | Commercial / Research | ||||

| Direct formic acid fuel cell (DFAFC) | Polymer membrane (ionomer) | < 50 W | < 40 | Commercial / Research | |||

| Zinc-air battery | Aqueous alkaline solution | < 40 | Mass production | ||||

| Microbial fuel cell | Polymer membrane or humic acid | < 40 | Research | ||||

| Upflow microbial fuel cell (UMFC) | < 40 | Research | |||||

| Regenerative fuel cell | Polymer membrane (ionomer) | < 50 | Commercial / Research | ||||

| Direct borohydride fuel cell | Aqueous alkaline solution | 70 | Commercial | ||||

| Alkaline fuel cell | Aqueous alkaline solution | 10 – 100 kW | < 80 | 60–70% | 62% | Commercial / Research | |

| Direct methanol fuel cell | Polymer membrane (ionomer) | 100 mW – 1 kW | 90–120 | 20–30% | 10–20% | Commercial / Research | 125 |

| Reformed methanol fuel cell | Polymer membrane (ionomer) | 5 W – 100 kW | 250–300 (Reformer) 125–200 (PBI) |

50–60% | 25–40% | Commercial / Research | |

| Direct-ethanol fuel cell | Polymer membrane (ionomer) | < 140 mW/cm² | > 25 ? 90–120 |

Research | |||

| Proton exchange membrane fuel cell | Polymer membrane (ionomer) | 100 W – 500 kW | 50–100 (Nafion)[44] 125–220 (PBI) |

50–70% | 30–50% | Commercial / Research | 50–100 |

| RFC – Redox | Liquid electrolytes with redox shuttle and polymer membrane (Ionomer) | 1 kW – 10 MW | Research | ||||

| Phosphoric acid fuel cell | Molten phosphoric acid (H3PO4) | < 10 MW | 150-200 | 55% | 40% Co-Gen: 90% |

Commercial / Research | 4–4.50 |

| Solid acid fuel cell | H+-conducting oxyanion salt (solid acid) | 10 W - 1 kW | 200-300 | 55-60% | 40-45% | Commercial / Research | |

| Molten carbonate fuel cell | Molten alkaline carbonate | 100 MW | 600–650 | 55% | 47% | Commercial / Research | |

| Tubular solid oxide fuel cell (TSOFC) | O2--conducting ceramic oxide | < 100 MW | 850–1100 | 60–65% | 55–60% | Commercial / Research | |

| Protonic ceramic fuel cell | H+-conducting ceramic oxide | 700 | Research | ||||

| Direct carbon fuel cell | Several different | 700–850 | 80% | 70% | Commercial / Research | ||

| Planar Solid oxide fuel cell | O2--conducting ceramic oxide | < 100 MW | 500–1100 | 60–65% | 55–60% | Commercial / Research | |

| Enzymatic Biofuel Cells | Any that will not denature the enzyme | < 40 | Research | ||||

| Magnesium-Air Fuel Cell | Salt water | −20 to 55 | 90% | Commercial / Research |

Efficiency of leading fuel cell types

Glossary of Terms in table:

- Anode: The electrode at which oxidation (a loss of electrons) takes place. For fuel cells and other galvanic cells, the anode is the negative terminal; for electrolytic cells (where electrolysis occurs), the anode is the positive terminal.[45]

- Aqueous solution: a: of, relating to, or resembling water b : made from, with, or by water.[46]

- Catalyst: A chemical substance that increases the rate of a reaction without being consumed; after the reaction, it can potentially be recovered from the reaction mixture and is chemically unchanged. The catalyst lowers the activation energy required, allowing the reaction to proceed more quickly or at a lower temperature. In a fuel cell, the catalyst facilitates the reaction of oxygen and hydrogen. It is usually made of platinum powder very thinly coated onto carbon paper or cloth. The catalyst is rough and porous so the maximum surface area of the platinum can be exposed to the hydrogen or oxygen. The platinum-coated side of the catalyst faces the membrane in the fuel cell.[45]

- Cathode: The electrode at which reduction (a gain of electrons) occurs. For fuel cells and other galvanic cells, the cathode is the positive terminal; for electrolytic cells (where electrolysis occurs), the cathode is the negative terminal.[45]

- Electrolyte: A substance that conducts charged ions from one electrode to the other in a fuel cell, battery, or electrolyzer.[45]

- Fuel Cell Stack: Individual fuel cells connected in a series. Fuel cells are stacked to increase voltage.[45]

- Matrix: something within or from which something else originates, develops, or takes form.[47]

- Membrane: The separating layer in a fuel cell that acts as electrolyte (an ion-exchanger) as well as a barrier film separating the gases in the anode and cathode compartments of the fuel cell.[45]

- Molten Carbonate Fuel Cell (MCFC): A type of fuel cell that contains a molten carbonate electrolyte. Carbonate ions (CO32−) are transported from the cathode to the anode. Operating temperatures are typically near 650 °C.[45]

- Phosphoric acid fuel cell (PAFC): A type of fuel cell in which the electrolyte consists of concentrated phosphoric acid (H3PO4). Protons (H+) are transported from the anode to the cathode. The operating temperature range is generally 160–220 °C.[45]

- Polymer Electrolyte Membrane (PEM): A fuel cell incorporating a solid polymer membrane used as its electrolyte. Protons (H+) are transported from the anode to the cathode. The operating temperature range is generally 60–100 °C.[45]

- Solid Oxide Fuel Cell (SOFC): A type of fuel cell in which the electrolyte is a solid, nonporous metal oxide, typically zirconium oxide (ZrO2) treated with Y2O3, and O2− is transported from the cathode to the anode. Any CO in the reformate gas is oxidized to CO2 at the anode. Temperatures of operation are typically 800–1,000 °C.[45]

- Solution: a: an act or the process by which a solid, liquid, or gaseous substance is homogeneously mixed with a liquid or sometimes a gas or solid, b : a homogeneous mixture formed by this process; especially : a single-phase liquid system, c : the condition of being dissolved[48]

For more information see Glossary of fuel cell terms

Theoretical maximum efficiency

The energy efficiency of a system or device that converts energy is measured by the ratio of the amount of useful energy put out by the system ("output energy") to the total amount of energy that is put in ("input energy") or by useful output energy as a percentage of the total input energy. In the case of fuel cells, useful output energy is measured in electrical energy produced by the system. Input energy is the energy stored in the fuel. According to the U.S. Department of Energy, fuel cells are generally between 40–60% energy efficient.[49] This is higher than some other systems for energy generation. For example, the typical internal combustion engine of a car is about 25% energy efficient.[50] In combined heat and power (CHP) systems, the heat produced by the fuel cell is captured and put to use, increasing the efficiency of the system to up to 85–90%.[33]

The theoretical maximum efficiency of any type of power generation system is never reached in practice, and it does not consider other steps in power generation, such as production, transportation and storage of fuel and conversion of the electricity into mechanical power. However, this calculation allows the comparison of different types of power generation. The maximum theoretical energy efficiency of a fuel cell is 83%, operating at low power density and using pure hydrogen and oxygen as reactants (assuming no heat recapture)[51] According to the World Energy Council, this compares with a maximum theoretical efficiency of 58% for internal combustion engines.[51] While these efficiencies are not approached in most real world applications, high-temperature fuel cells (solid oxide fuel cells or molten carbonate fuel cells) can theoretically be combined with gas turbines to allow stationary fuel cells to come closer to the theoretical limit. A gas turbine would capture heat from the fuel cell and turn it into mechanical energy to increase the fuel cell's operational efficiency. This solution has been predicted to increase total efficiency to as much as 70%.[52]

In practice

The tank-to-wheel efficiency of a fuel-cell vehicle is greater than 45% at low loads[53] and shows average values of about 36% when a driving cycle like the NEDC (New European Driving Cycle) is used as test procedure.[54] The comparable NEDC value for a Diesel vehicle is 22%. In 2008 Honda released a demonstration fuel cell electric vehicle (the Honda FCX Clarity) with fuel stack claiming a 60% tank-to-wheel efficiency.[55]

It is also important to take losses due to fuel production, transportation, and storage into account. Fuel cell vehicles running on compressed hydrogen may have a power-plant-to-wheel efficiency of 22% if the hydrogen is stored as high-pressure gas, and 17% if it is stored as liquid hydrogen.[56] Fuel cells cannot store energy like a battery,[57] except as hydrogen, but in some applications, such as stand-alone power plants based on discontinuous sources such as solar or wind power, they are combined with electrolyzers and storage systems to form an energy storage system. Most hydrogen, however, is produced by steam methane reforming, and so most hydrogen production emits carbon dioxide.[58] The overall efficiency (electricity to hydrogen and back to electricity) of such plants (known as round-trip efficiency), using pure hydrogen and pure oxygen can be "from 35 up to 50 percent", depending on gas density and other conditions.[59] While a much cheaper lead–acid battery might return about 90%, the electrolyzer/fuel cell system can store indefinite quantities of hydrogen, and is therefore better suited for long-term storage.

Solid-oxide fuel cells produce exothermic heat from the recombination of the oxygen and hydrogen. The ceramic can run as hot as 800 degrees Celsius. This heat can be captured and used to heat water in a micro combined heat and power (m-CHP) application. When the heat is captured, total efficiency can reach 80–90% at the unit, but does not consider production and distribution losses. CHP units are being developed today for the European home market.

Professor Jeremy P. Meyers, in the Electrochemical Society journal Interface in 2008, wrote, "While fuel cells are efficient relative to combustion engines, they are not as efficient as batteries, due primarily to the inefficiency of the oxygen reduction reaction (and ... the oxygen evolution reaction, should the hydrogen be formed by electrolysis of water).... [T]hey make the most sense for operation disconnected from the grid, or when fuel can be provided continuously. For applications that require frequent and relatively rapid start-ups ... where zero emissions are a requirement, as in enclosed spaces such as warehouses, and where hydrogen is considered an acceptable reactant, a [PEM fuel cell] is becoming an increasingly attractive choice [if exchanging batteries is inconvenient]".[24] In 2013 military organisations are evaluating fuel cells to significantly reduce the battery weight carried by soldiers.[60]

Applications

Power

Stationary fuel cells are used for commercial, industrial and residential primary and backup power generation. Fuel cells are very useful as power sources in remote locations, such as spacecraft, remote weather stations, large parks, communications centers, rural locations including research stations, and in certain military applications. A fuel cell system running on hydrogen can be compact and lightweight, and have no major moving parts. Because fuel cells have no moving parts and do not involve combustion, in ideal conditions they can achieve up to 99.9999% reliability.[61] This equates to less than one minute of downtime in a six-year period.[61]

Since fuel cell electrolyzer systems do not store fuel in themselves, but rather rely on external storage units, they can be successfully applied in large-scale energy storage, rural areas being one example.[62] There are many different types of stationary fuel cells so efficiencies vary, but most are between 40% and 60% energy efficient.[33] However, when the fuel cell's waste heat is used to heat a building in a cogeneration system this efficiency can increase to 85%.[33] This is significantly more efficient than traditional coal power plants, which are only about one third energy efficient.[63] Assuming production at scale, fuel cells could save 20–40% on energy costs when used in cogeneration systems.[64] Fuel cells are also much cleaner than traditional power generation; a fuel cell power plant using natural gas as a hydrogen source would create less than one ounce of pollution (other than CO2) for every 1,000 kW·h produced, compared to 25 pounds of pollutants generated by conventional combustion systems.[65] Fuel Cells also produce 97% less nitrogen oxide emissions than conventional coal-fired power plants.

One such pilot program is operating on Stuart Island in Washington State. There the Stuart Island Energy Initiative[66] has built a complete, closed-loop system: Solar panels power an electrolyzer, which makes hydrogen. The hydrogen is stored in a 500-U.S.-gallon (1,900 L) tank at 200 pounds per square inch (1,400 kPa), and runs a ReliOn fuel cell to provide full electric back-up to the off-the-grid residence. Another closed system loop was unveiled in late 2011 in Hempstead, NY.[67]

Fuel cells can be used with low-quality gas from landfills or waste-water treatment plants to generate power and lower methane emissions. A 2.8 MW fuel cell plant in California is said to be the largest of the type.[68]

Cogeneration

Combined heat and power (CHP) fuel cell systems, including Micro combined heat and power (MicroCHP) systems are used to generate both electricity and heat for homes (see home fuel cell), office building and factories. The system generates constant electric power (selling excess power back to the grid when it is not consumed), and at the same time produces hot air and water from the waste heat. As the result CHP systems have the potential to save primary energy as they can make use of waste heat which is generally rejected by thermal energy conversion systems.[69] A typical capacity range of home fuel cell is 1–3 kWel / 4–8 kWth.[70][71] CHP systems linked to absorption chillers use their waste heat for refrigeration.[72]

The waste heat from fuel cells can be diverted during the summer directly into the ground providing further cooling while the waste heat during winter can be pumped directly into the building. The University of Minnesota owns the patent rights to this type of system[73][74]

Co-generation systems can reach 85% efficiency (40–60% electric + remainder as thermal).[33] Phosphoric-acid fuel cells (PAFC) comprise the largest segment of existing CHP products worldwide and can provide combined efficiencies close to 90%.[75][76] Molten Carbonate (MCFC) and Solid Oxide Fuel Cells (SOFC) are also used for combined heat and power generation and have electrical energy efficiences around 60%.[77] Disadvantages of co-generation systems include slow ramping up and down rates, high cost and short lifetime.[78][79] Also their need to have a hot water storage tank to smooth out the thermal heat production was a serious disadvantage in the domestic market place where space in domestic properties is at a great premium.[80]

Fuel cell electric vehicles (FCEVs)

Automobiles

Although there are currently no fuel cell vehicles available for commercial sale, over 20 fuel cell electric vehicle (FCEV) prototypes and demonstration cars have been released since 2009. Demonstration models include the Honda FCX Clarity, Toyota FCHV-adv, and Mercedes-Benz F-Cell.[82] As of June 2011 demonstration FCEVs had driven more than 4,800,000 km (3,000,000 miles), with more than 27,000 refuelings.[83] Demonstration fuel cell vehicles have been produced with "a driving range of more than 400 km (250 miles) between refueling".[84] They can be refueled in less than 5 minutes.[85] The U.S. Department of Energy's Fuel Cell Technology Program claims that, as of 2011, fuel cells achieved 53–59% efficiency at one-quarter power and 42–53% vehicle efficiency at full power,[86] and a durability of over 120,000 km (75,000 miles) with less than 10% degradation.[84] In a Well-to-Wheels simulation analysis, that "did not address the economics and market constraints", General Motors and its partners estimated that per mile traveled, a fuel cell electric vehicle running on compressed gaseous hydrogen produced from natural gas could use about 40% less energy and emit 45% less greenhouse gasses than an internal combustion vehicle.[87] A lead engineer from the Department of Energy whose team is testing fuel cell cars said in 2011 that the potential appeal is that "these are full-function vehicles with no limitations on range or refueling rate so they are a direct replacement for any vehicle. For instance, if you drive a full sized SUV and pull a boat up into the mountains, you can do that with this technology and you can't with current battery-only vehicles, which are more geared toward city driving."[88]

Some experts believe, however, that fuel cell cars will never become economically competitive with other technologies[89][90] or that it will take decades for them to become profitable.[91][92] In July 2011, the chairman and CEO of General Motors, Daniel Akerson, stated that while the cost of hydrogen fuel cell cars is decreasing: "The car is still too expensive and probably won't be practical until the 2020-plus period, I don't know."[93]

In 2012, Lux Research, Inc. issued a report that stated: "The dream of a hydrogen economy ... is no nearer". It concluded that "Capital cost ... will limit adoption to a mere 5.9 GW" by 2030, providing "a nearly insurmountable barrier to adoption, except in niche applications". The analysis concluded that, by 2030, PEM stationary market will reach $1 billion, while the vehicle market, including forklifts, will reach a total of $2 billion.[94] Other analyses cite the lack of an extensive hydrogen infrastructure in the U.S. as an ongoing challenge to Fuel Cell Electric Vehicle commercialization. In 2006, a study for the IEEE showed that for hydrogen produced via electrolysis of water: "Only about 25% of the power generated from wind, water, or sun is converted to practical use." The study further noted that "Electricity obtained from hydrogen fuel cells appears to be four times as expensive as electricity drawn from the electrical transmission grid. ... Because of the high energy losses [hydrogen] cannot compete with electricity."[95] Furthermore, the study found: "Natural gas reforming is not a sustainable solution".[95] "The large amount of energy required to isolate hydrogen from natural compounds (water, natural gas, biomass), package the light gas by compression or liquefaction, transfer the energy carrier to the user, plus the energy lost when it is converted to useful electricity with fuel cells, leaves around 25% for practical use."[24][53][96]

Despite this, several major car manufacturers have announced plans to introduce a production model of a fuel cell car in 2015. In 2013, Toyota has stated that it plans to introduce such a vehicle at a price of less than US$100,000.[97] Mercedes-Benz announced that they would move the scheduled production date of their fuel cell car from 2015 up to 2014, asserting that "The product is ready for the market technically. ... The issue is infrastructure."[98] At the Paris Auto Show in September 2012, Hyundai announced that it plans to begin producing a commercial production fuel cell model (based on the ix35) in December 2012 and hopes to deliver 1,000 of them by 2015.[99] Other manufacturers planning to sell fuel cell electric vehicles commercially by 2016 or earlier include General Motors (2015),[100] Honda (2015 in Japan),[101] and Nissan (2016).[102]

The Obama Administration sought to reduce funding for the development of fuel cell vehicles, concluding that other vehicle technologies will lead to quicker reduction in emissions in a shorter time.[103] Steven Chu, the United States Secretary of Energy, stated in 2009 that hydrogen vehicles "will not be practical over the next 10 to 20 years".[104][105] In 2012, however, Chu stated that he saw fuel cell cars as more economically feasible as natural gas prices have fallen and hydrogen reforming technologies have improved.[106][107]

Buses

As of August 2011[update], there were a total of approximately 100 fuel cell buses deployed around the world. Most buses are produced by UTC Power, Toyota, Ballard, Hydrogenics, and Proton Motor. UTC Buses had accumulated over 970,000 km (600,000 miles) of driving by 2011.[108] Fuel cell buses have a 39–141% higher fuel economy than diesel buses and natural gas buses.[109] Fuel cell buses have been deployed around the world including in Whistler, Canada; San Francisco, United States; Hamburg, Germany; Shanghai, China; London, England; São Paulo, Brazil; as well as several others.[110] The Fuel Cell Bus Club is a global cooperative effort in trial fuel cell buses. Notable Projects Include:

- 12 Fuel cell buses are being deployed in the Oakland and San Francisco Bay area of California.[110]

- Daimler AG, with thirty-six experimental buses powered by Ballard Power Systems fuel cells completed a successful three-year trial, in eleven cities, in January 2007.[111][112]

- A fleet of Thor buses with UTC Power fuel cells was deployed in California, operated by SunLine Transit Agency.[113]

The first Brazilian hydrogen fuel cell bus prototype in Brazil was deployed in São Paulo. The bus was manufactured in Caxias do Sul and the hydrogen fuel will be produced in São Bernardo do Campo from water through electrolysis. The program, called "Ônibus Brasileiro a Hidrogênio" (Brazilian Hydrogen Autobus), includes three additional buses.[114][115]

Forklifts

A fuel cell forklift (also called a fuel cell lift truck) is a fuel cell powered industrial forklift truck used to lift and transport materials. Most fuel cells used for material handling purposes are powered by PEM fuel cells.[citation needed]

In 2013 there were over 4,000 fuel cell forklifts used in material handling in the USA,[116] of which only 500 received funding from DOE (2012).[117][118] Fuel cell fleets are operated by a large number of companies, including Sysco Foods, FedEx Freight, GENCO (at Wegmans, Coca-Cola, Kimberly Clark, and Whole Foods), and H-E-B Grocers.[119] Europe demonstrated 30 Fuel cell forklifts with Hylift and extended it with HyLIFT-EUROPE to 200 units,[120] with other projects in France [121][122] and Austria.[123] Pike Research stated in 2011 that fuel-cell-powered forklifts will be the largest driver of hydrogen fuel demand by 2020.[124]

PEM fuel-cell-powered forklifts provide significant benefits over both petroleum and battery powered forklifts as they produce no local emissions, can work for a full 8-hour shift on a single tank of hydrogen, can be refueled in 3 minutes and have a lifetime of 8–10 years. Fuel cell-powered forklifts are often used in refrigerated warehouses, as their performance is not degraded by lower temperatures. Many companies do not use petroleum powered forklifts, as these vehicles work indoors where emissions must be controlled and instead are turning to electric forklifts.[125] In design the FC units are often made as drop-in replacements.[126][127]

Motorcycles and bicycles

In 2005 a British manufacturer of hydrogen-powered fuel cells, Intelligent Energy (IE), produced the first working hydrogen run motorcycle called the ENV (Emission Neutral Vehicle). The motorcycle holds enough fuel to run for four hours, and to travel 160 km (100 miles) in an urban area, at a top speed of 80 km/h (50 mph).[128] In 2004 Honda developed a fuel-cell motorcycle that utilized the Honda FC Stack.[129][130]

Other examples of motorbikes[131] and bicycles[132] that use hydrogen fuel cells include the Taiwanese company APFCT's scooter[133] using the fueling system from Italy's Acta SpA[134] and the Suzuki Burgman scooter with an IE fuel cell that received EU Whole Vehicle Type Approval in 2011.[135] Suzuki Motor Corp. and IE have announced a joint venture to accelerate the commercialization of zero-emission vehicles.[136]

Airplanes

Boeing researchers and industry partners throughout Europe conducted experimental flight tests in February 2008 of a manned airplane powered only by a fuel cell and lightweight batteries. The fuel cell demonstrator airplane, as it was called, used a proton exchange membrane (PEM) fuel cell/lithium-ion battery hybrid system to power an electric motor, which was coupled to a conventional propeller.[137] In 2003, the world's first propeller-driven airplane to be powered entirely by a fuel cell was flown. The fuel cell was a unique FlatStackTM stack design, which allowed the fuel cell to be integrated with the aerodynamic surfaces of the plane.[138]

There have been several fuel-cell-powered unmanned aerial vehicles (UAV). A Horizon fuel cell UAV set the record distance flown for a small UAV in 2007.[139] The military is especially interested in this application because of the low noise, low thermal signature and ability to attain high altitude. In 2009 the Naval Research Laboratory's (NRL's) Ion Tiger utilized a hydrogen-powered fuel cell and flew for 23 hours and 17 minutes.[140] Fuel cells are also being used to provide auxiliary power in aircraft, replacing fossil fuel generators that were previously used to start the engines and power on board electrical needs.[141][failed verification] Fuel cells can help airplanes reduce CO2 and other pollutant emissions and noise.

Boats

The world's first fuel-cell boat HYDRA used an AFC system with 6.5 kW net output. Iceland has committed to converting its vast fishing fleet to use fuel cells to provide auxiliary power by 2015 and, eventually, to provide primary power in its boats. Amsterdam recently introduced its first fuel-cell-powered boat that ferries people around the city's famous and beautiful canals.[142]

Submarines

The Type 212 submarines of the German and Italian navies use fuel cells to remain submerged for weeks without the need to surface.

The U212A is a non-nuclear submarine developed by German naval shipyard Howaldtswerke Deutsche Werft.[143] The system consists of nine PEM fuel cells, providing between 30 kW and 50 kW each. The ship is silent giving it an advantage in the detection of other submarines.[144]

Portable power systems

Portable power systems that use fuel cells can be used in the leisure sector (i.e. RV's, Cabins, Marine), the industrial sector (i.e. power for remote locations including gas/oil wellsites, communication towers, security, weather stations etc.), and in the military sector. SFC Energy is a German manufacturer of direct methanol fuel cells for a variety of portable power systems.[145] Ensol Systems Inc. is an integrator of portable power systems, using the SFC Energy DMFC.[146]

Other applications

- Providing power for base stations or cell sites[147][148]

- Distributed generation

- Emergency power systems are a type of fuel cell system, which may include lighting, generators and other apparatus, to provide backup resources in a crisis or when regular systems fail. They find uses in a wide variety of settings from residential homes to hospitals, scientific laboratories, data centers,[149]

- telecommunication[150] equipment and modern naval ships.

- An uninterrupted power supply (UPS) provides emergency power and, depending on the topology, provide line regulation as well to connected equipment by supplying power from a separate source when utility power is not available. Unlike a standby generator, it can provide instant protection from a momentary power interruption.

- Base load power plants

- Solar Hydrogen Fuel Cell Water Heating

- Hybrid vehicles, pairing the fuel cell with either an ICE or a battery.

- Notebook computers for applications where AC charging may not be readily available.

- Portable charging docks for small electronics (e.g. a belt clip that charges your cell phone or PDA).

- Smartphones, laptops and tablets.

- Small heating appliances[151]

- Food preservation, achieved by exhausting the oxygen and automatically maintaining oxygen exhaustion in a shipping container, containing, for example, fresh fish.[152]

- Breathalyzers, where the amount of voltage generated by a fuel cell is used to determine the concentration of fuel (alcohol) in the sample.[153]

- Carbon monoxide detector, electrochemical sensor.

Fueling stations

There were over 85 hydrogen refueling stations in the U.S. in 2010.[154]

As of June 2012 California had 23 hydrogen refueling stations in operation.[154][155] Honda announced plans in March 2011 to open the first station that would generate hydrogen through solar-powered renewable electrolysis.[citation needed] South Carolina also has two hydrogen fueling stations, in Aiken and Columbia, SC. The University of South Carolina, a founding member of the South Carolina Hydrogen & Fuel Cell Alliance, received 12.5 million dollars from the United States Department of Energy for its Future Fuels Program.[156]

The first public hydrogen refueling station in Iceland was opened in Reykjavík in 2003. This station serves three buses built by DaimlerChrysler that are in service in the public transport net of Reykjavík. The station produces the hydrogen it needs by itself, with an electrolyzing unit (produced by Norsk Hydro), and does not need refilling: all that enters is electricity and water. Royal Dutch Shell is also a partner in the project. The station has no roof, in order to allow any leaked hydrogen to escape to the atmosphere.[citation needed]

The current 14 stations nationwide in Germany are planned to be expanded to 50 by 2015[157] through its public private partnership Now GMBH.[158] Japan also has a hydrogen highway, as part of the Japan hydrogen fuel cell project. Twelve hydrogen fueling stations have been built in 11 cities in Japan, and additional hydrogen stations could potentially be operational by 2015.[159] Canada, Sweden and Norway also have hydrogen highways being implemented.[citation needed]

Markets and economics

In 2012, fuel cell industry revenues exceeded $1 billion market value worldwide, with Asian pacific countries shipping more than 3/4 of the fuel cell systems worldwide.[160] However, as of October 2013, no public company in the industry had yet become profitable.[161] There were 140,000 fuel cell stacks shipped globally in 2010, up from 11 thousand shipments in 2007, and from 2011 to 2012 worldwide fuel cell shipments had an annual growth rate of 85%.[162] Tanaka Kikinzoku Kogyo K.K. expanded its production facilities for fuel cell catalysts in 2013 to meet anticipated demand as the Japanese ENE Farm scheme expects to install 50,000 units in 2013[163] and the company is experiencing rapid market growth.[164][165]

Approximately 50% of fuel cell shipments in 2010 were stationary fuel cells, up from about a third in 2009, and the four dominant producers in the Fuel Cell Industry were the United States, Germany, Japan and South Korea.[166] The Department of Energy Solid State Energy Conversion Alliance found that, as of January 2011, stationary fuel cells generated power at approximately $724 to $775 per kilowatt installed.[167] In 2011, Bloom Energy, a major fuel cell supplier, said that its fuel cells generated power at 9–11 cents per kilowatt-hour, including the price of fuel, maintenance, and hardware.[168][169]

Industry groups predict that there are sufficient platinum resources for future demand,[170] and in 2007, research at Brookhaven National Laboratory suggested that platinum could be replaced by a gold-palladium coating, which may be less susceptible to poisoning and thereby improve fuel cell lifetime.[171] Another method would use iron and sulphur instead of platinum. This would lower the cost of a fuel cell (as the platinum in a regular fuel cell costs around US$1,500, and the same amount of iron costs only around US$1.50). The concept was being developed by a coalition of the John Innes Centre and the University of Milan-Bicocca.[172] PEDOT cathodes are immune to monoxide poisoning.[173]

Research and development

- August 2005: Georgia Institute of Technology researchers use triazole to raise the operating temperature of PEM fuel cells from below 100 °C to over 125 °C, claiming this will require less carbon-monoxide purification of the hydrogen fuel.[174]

- 2008 Monash University, Melbourne uses PEDOT as a cathode.[26]

- 2009 Researchers at the University of Dayton, in Ohio, show that arrays of vertically grown carbon nanotubes could be used as the catalyst in fuel cells.[175]

- 2009: Y-Carbon began to develop a carbide-derived-carbon-based ultracapacitor, which they hoped would lead to fuel cells with higher energy density.[176][177]

- 2009: A nickel bisdiphosphine-based catalyst for fuel cells is demonstrated.[178]

- 2013: British firm ACAL Energy develops a fuel cell that it says runs for 10,000 hours in simulated driving conditions.[179] It asserts that the cost of fuel cell construction can be reduced to $40/kW (roughly $9,000 for 300 HP).[180]

See also

- Alkaline Anion Exchange Membrane Fuel Cells

- Bio-nano generator

- Cryptophane

- Energy development

- Fuel Cell Development Information Center

- Fuel Cells and Hydrogen Joint Technology Initiative (in Europe)

- Glossary of fuel cell terms

- Grid energy storage

- Hydrogen reformer

- Hydrogen storage

- Hydrogen technologies

- Microgeneration

- Water splitting

- PEM electrolysis

References

- ^ Khurmi, R. S. Material Science.

- ^ Nice, Karim and Strickland, Jonathan. "How Fuel Cells Work: Polymer Exchange Membrane Fuel Cells". How Stuff Works, accessed 4 August 2011

- ^ Prabhu, Rahul R. (13 January 2013). "Stationary Fuel Cells Market size to reach 350,000 Shipments by 2022". Renew India Campaign. Retrieved 14 January 2013.

- ^ "Mr. W. R. Grove on a new Voltaic Combination". The London and Edinburgh Philosophical Magazine and Journal of Science. 1838. Retrieved 2 October 2013.

- ^ Grove, William Robert. "On Voltaic Series and the Combination of Gases by Platinum", Philosophical Magazine and Journal of Science vol. XIV (1839), pp. 127–130

- ^ "On the Voltaic Polarization of Certain Solid and Fluid Substances" (PDF). The London and Edinburgh Philosophical Magazine and Journal of Science. 1839. Retrieved 2 October 2013.

- ^ Grove, William Robert. "On a Gaseous Voltaic Battery", Philosophical Magazine and Journal of Science vol. XXI (1842), pp. 417–420

- ^ GE's Thomas Grubb (right) and Leonard Niedrach run a fan with a diesel powered PEM fuel cell in April 1963

- ^ PEM Fuel Cell Technology

- ^ "Roger Billings Biography". International Association for Hydrogen Energy. Retrieved 8 March 2011.

- ^ "The PureCell Model 400 – Product Overview". UTC Power. Retrieved 22 December 2011.

- ^ "Apollo Space Program Hydrogen Fuel Cells". Spaceaholic.com. Retrieved 21 September 2009.

- ^ Larminie, James (1 May 2003). Fuel Cell Systems Explained, Second Edition. SAE International. ISBN 0-7680-1259-7.

- ^ Wang, J.Y. (2008). "Pressure drop and flow distribution in parallel-channel of configurations of fuel cell stacks: U-type arrangement". Int. J. of Hydrogen Energy. 33 (21): 6339–6350. doi:10.1016/j.ijhydene.2008.08.020.

- ^ Wang, J.Y.; Wang, H.L. (2012). "Flow field designs of bipolar plates in PEM fuel cells: theory and applications, Fuel Cells,". 12 (6): 989–1003. doi:10.1002/fuce.201200074.

{{cite journal}}: Cite journal requires|journal=(help) - ^ Wang, J.Y.; Wang, H.L. (2012). "Discrete approach for flow-field designs of parallel channel configurations in fuel cells". Int. J. of Hydrogen Energy. 37 (14): 10881–10897. doi:10.1016/j.ijhydene.2012.04.034.

- ^ Anne-Claire Dupuis, Progress in Materials Science, Volume 56, Issue 3, March 2011, pp. 289–327

- ^ Measuring the relative efficiency of hydrogen energy technologies for implementing the hydrogen economy 2010

- ^ Kakati, B. K., Deka, D., "Effect of resin matrix precursor on the properties of graphite composite bipolar plate for PEM fuel cell", Energy & Fuels 2007, 21 (3):1681–1687.

- ^ "LEMTA – Our fuel cells". Perso.ensem.inpl-nancy.fr. Retrieved 21 September 2009.

- ^ Kakati B. K., Mohan V., "Development of low cost advanced composite bipolar plate for P.E.M. fuel cell", Fuel Cells 2008, 08(1): 45–51

- ^ Kakati B. K., Deka D., "Differences in physico-mechanical behaviors of resol and novolac type phenolic resin based composite bipolar plate for proton exchange membrane (PEM) fuel cell", Electrochimica Acta 2007, 52 (25): 7330–7336.

- ^ Spendelow, Jacob and Jason Marcinkoski. "Fuel Cell System Cost – 2013", DOE Fuel Cell Technologies Office, October 16, 2013

- ^ a b c Meyers, Jeremy P. "Getting Back Into Gear: Fuel Cell Development After the Hype". The Electrochemical Society Interface, Winter 2008, pp. 36–39, accessed 7 August 2011

- ^ "Ballard Power Systems: Commercially Viable Fuel Cell Stack Technology Ready by 2010". 29 March 2005. Archived from the original on 27 September 2007. Retrieved 27 May 2007.

{{cite news}}: Unknown parameter|deadurl=ignored (|url-status=suggested) (help) - ^ a b Online, Science (2 August 2008). "2008 – Cathodes in fuel cells". Abc.net.au. Retrieved 21 September 2009.

- ^ http://pubs.acs.org/doi/abs/10.1021/ja1112904?journalCode=jacsat

- ^ "Water_and_Air_Management". Ika.rwth-aachen.de. Retrieved 21 September 2009.

- ^ "Fuel Cell School Buses: Report to Congress" (PDF). Retrieved 21 September 2009.

- ^ http://americanhistory.si.edu/fuelcells/phos/pafcmain.htm

- ^ Phosphoric acid fuel cell technology

- ^ http://scopewe.com/phosphoric-acid-fuel-cells

- ^ a b c d e f g h "Types of Fuel Cells". Department of Energy EERE website, accessed 4 August 2011

- ^ Stambouli, A. Boudghene. "Solid oxide fuel cells (SOFCs): a review of an environmentally clean and efficient source of energy". Renewable and Sustainable Energy Reviews, Vol. 6, Issue 5, pp. 433–455, October 2002.

- ^ "Solid Oxide Fuel Cell (SOFC)". FCTec website', accessed 4 August 2011

- ^ "Methane Fuel Cell Subgroup". University of Virginia. 2012. Retrieved 13 February 2014.

- ^ A Kulkarni, FT Ciacchi, S Giddey, C Munnings, SPS Badwal, JA Kimpton, D Fini (2012). "International Journal of Hydrogen Energy". International Journal of Hydrogen Energy. 37 (24): 19092–19102. doi:10.1016/j.ijhydene.2012.09.141.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - ^ S. Giddey, S.P.S. Badwal, A. Kulkarni, C. Munnings (2012). "A comprehensive review of direct carbon fuel cell technology". Progress in Energy and Combustion Science. 38 (3): 360–399. doi:10.1016/j.pecs.2012.01.003.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - ^ Hill, Michael. "Ceramic Energy: Material Trends in SOFC Systems". Ceramic Industry, 1 September 2005.

- ^ "The Ceres Cell". Ceres Power website, accessed 4 August 2011

- ^ a b c "Molten Carbonate Fuel Cell Technology". U.S. Department of Energy, accessed 9 August 2011

- ^ "Molten Carbonate Fuel Cells (MCFC)". FCTec.com, accessed 9 August 2011

- ^ "Products". FuelCell Energy, accessed 9 August 2011

- ^ "Fuel Cell Comparison Chart" (PDF). Retrieved 10 February 2013.

- ^ a b c d e f g h i j "Fuel Cell Technologies Program: Glossary". Department of Energy Energy Efficiency and Renewable Energy Fuel Cell Technologies Program. 7 July 2011. Accessed 3 August 2011.

- ^ "Aqueous Solution". Merriam-Webster Free Online Dictionary

- ^ "Matrix". Merriam-Webster Free Online Dictionary

- ^ "Solution". Merriam-Webster Free Online Dictionary

- ^ "Comparison of Fuel Cell Technologies". U.S. Department of Energy, Energy Efficiency and Fuel Cell Technologies Program, February 2011, accessed 4 August 2011

- ^ "Fuel Economy: Where The Energy Goes". U.S. Department of Energy, Energy Effciency and Renewable Energy, accessed 3 August 2011

- ^ a b "Fuel Cell Efficiency". World Energy Council, 17 July 2007, accessed 4 August 2011

- ^ Milewski, J., A. Miller and K. Badyda. "The Control Strategy for High Temperature Fuel Cell Hybrid Systems". The Online Journal on Electronics and Electrical Engineering, Vol. 2, No. 4, p. 331, 2009, accessed 4 August 2011

- ^ a b Eberle, Ulrich and Rittmar von Helmolt. "Sustainable transportation based on electric vehicle concepts: a brief overview". Energy & Environmental Science, Royal Society of Chemistry, 14 May 2010, accessed 2 August 2011

- ^ Von Helmolt, R.; Eberle, U (20 March 2007). "Fuel Cell Vehicles:Status 2007". Journal of Power Sources. 165 (2): 833. doi:10.1016/j.jpowsour.2006.12.073.

- ^ "Honda FCX Clarity – Fuel cell comparison". Honda. Retrieved 2 January 2009.

- ^ "Efficiency of Hydrogen PEFC, Diesel-SOFC-Hybrid and Battery Electric Vehicles" (PDF). 15 July 2003. Retrieved 23 May 2007.

- ^ "Batteries, Supercapacitors, and Fuel Cells: Scope". Science Reference Services. 20 August 2007. Retrieved 11 February 2009.

- ^ Nice, Karim. "How Fuel Processors Work". HowStuffWorks, accessed 3 August 2011

- ^ Garcia, Christopher P.; et al. (January 2006). "Round Trip Energy Efficiency of NASA Glenn Regenerative Fuel Cell System". Preprint: 5. Retrieved 4 August 2011.

{{cite journal}}: Cite journal requires|journal=(help); Unknown parameter|author-separator=ignored (help) - ^ The fuel cell industry review 2013

- ^ a b "Fuel Cell Basics: Benefits". Fuel Cells 2000. Retrieved 27 May 2007.

- ^ "Fuel Cell Basics: Applications". Fuel Cells 2000. Accessed 2 August 2011.

- ^ "Energy Sources: Electric Power". U.S. Department of Energy. Accessed 2 August 2011.

- ^ "2008 Fuel Cell Technologies Market Report". Bill Vincent of the Breakthrough Technologies Institute, Jennifer Gangi, Sandra Curtin, and Elizabeth Delmont. Department of Energy Energy Efficiency and Renewable Energy. June 2010.

- ^ U.S. Fuel Cell Council Industry Overview 2010, p. 12. U.S. Fuel Cell Council. 2010.

- ^ "Stuart Island Energy Initiative". Siei.org. Retrieved 21 September 2009. – gives extensive technical details

- ^ "Town's Answer to Clean Energy is Blowin' in the Wind: New Wind Turbine Powers Hydrogen Car Fuel Station". Town of Hempstead. Retrieved 13 January 2012.

- ^ World's Largest Carbon Neutral Fuel Cell Power Plant, 16 October 2012

- ^ "Reduction of residential carbon dioxide emissions through the use of small cogeneration fuel cell systems – Combined heat and power systems". IEA Greenhouse Gas R&D Programme (IEAGHG). 11 November 2008. Retrieved 1 July 2013.

- ^ "Reduction of residential carbon dioxide emissions through the use of small cogeneration fuel cell systems – Scenario calculations". IEA Greenhouse Gas R&D Programme (IEAGHG). 11 November 2008. Retrieved 1 July 2013.

- ^ COGEN EUROPE

- ^ Fuel Cells and CHP

- ^ "Patent 7,334,406". Retrieved 25 August 2011.

- ^ "Geothermal Heat, Hybrid Energy Storage System". Retrieved 25 August 2011.

- ^ "Reduction of residential carbon dioxide emissions through the use of small cogeneration fuel cell systems – Commercial sector". IEA Greenhouse Gas R&D Programme (IEAGHG). 11 November 2008. Retrieved 1 July 2013.

- ^ "PureCell Model 400: Overview". UTC Power. Accessed 2 August 2011.

- ^ "Comparison of Fuel Cell Technologies". Departement of Energy Energy Efficiency and Renewable Energy Fuel Cell Technologies Program. February 2011.

- ^ H.I. Onovwiona and V.I. Ugursal. Residential cogeneration systems: review of the current technology. Renewable and Sustainable Energy Reviews, 10(5):389 – 431, 2006.

- ^ AD. Hawkes, L. Exarchakos, D. Hart, MA. Leach, D. Haeseldonckx, L. Cosijns and W. D’haeseleer. EUSUSTEL work package 3: Fuell cells, 2006.

- ^ "Reduction of residential carbon dioxide emissions through the use of small cogeneration fuel cell systems". IEA Greenhouse Gas R&D Programme (IEAGHG). 11 November 2008. Retrieved 1 July 2013.

- ^ Richard Truett (21 November 2013). "Fuel cell nearing leap from lab to highway". Automotive News. Retrieved 1 December 2013.

- ^ "Hydrogen and Fuel Cell Vehicles Worldwide". TÜV SÜD Industrie Service GmbH, accessed on 2 August 2011

- ^ Wipke, Keith, Sam Sprik, Jennifer Kurtz and Todd Ramsden. "Controlled Hydrogen Fleet and Infrastructure Demonstration and Validation Project". National Renewable Energy Laboratory, 11 September 2009, accessed on 2 August 2011

- ^ a b "Accomplishments and Progress". Fuel Cell Technology Program, U.S. Dept. of Energy, 24 June 2011

- ^ Wipke, Keith, Sam Sprik, Jennifer Kurtz and Todd Ramsden. "National FCEV Learning Demonstration". National Renewable Energy Laboratory, April 2011, accessed 2 August 2011

- ^ Garbak, John. "VIII.0 Technology Validation Sub-Program Overview". DOE Fuel Cell Technologies Program, FY 2010 Annual Progress Report, accessed 2 August 2011

- ^ Brinkman, Norma, Michael Wang, Trudy Weber and Thomas Darlington. "Well-To-Wheels Analysis of Advanced Fuel/Vehicle Systems – A North American Study of Energy Use, Greenhouse Gas Emissions, and Criteria Pollutant Emissions". General Motors Corporation, Argonne National Laboratory and Air Improvement Resource, Inc., May 2005, accessed 9 August 2011

- ^ Lammers, Heather (17 August 2011). "Low Emission Cars Under NREL's Microscope". NREL Newsroom. Retrieved 21 August 2011.

- ^ "From TechnologyReview.com "Hell and Hydrogen", March 2007". Technologyreview.com. Retrieved 31 January 2011.

- ^ White, Charlie. "Hydrogen fuel cell vehicles are a fraud" Dvice TV, 31 July 2008

- ^ Squatriglia, Chuck. "Hydrogen Cars Won't Make a Difference for 40 Years", Wired, 12 May 2008

- ^ Boyd, Robert S. "Hydrogen cars may be a long time coming". McClatchy Newspapers, 15 May 2007, accessed 13 August 2011

- ^ "GM CEO: Fuel cell vehicles not yet practical", The Detroit News, 30 July 2011; and Chin, Chris. "GM's Dan Akerson: Fuel-cell vehicles aren't practical… yet". egmCarTech, 1 August 2011, accessed 27 February 2012

- ^ Brian Warshay, Brian. "The Great Compression: the Future of the Hydrogen Economy", Lux Research, Inc. January 2013

- ^ a b Bossel, Ulf. "Does a Hydrogen Economy Make Sense? Proceedings of the IEEE Vol. 94, No. 10, October 2006.

- ^ Zyga, Lisa. "Why a hydrogen economy doesn't make sense". physorg.com, 11 December 2006, accessed 2 August 2011, citing Bossel, Ulf. "Does a Hydrogen Economy Make Sense?" Proceedings of the IEEE. Vol. 94, No. 10, October 2006

- ^ Kubota, Yoko. "Toyota says slashes fuel cell costs by nearly $1 million for new hydrogen car". Reuters, Oct 10, 2013

- ^ Lienert, Anita. "Mercedes-Benz Fuel-Cell Car Ready for Market in 2014". Edmunds Inside Line, 21 June 2011

- ^ Korzeniewski, Jeremy (27 September 2012). "Hyundai ix35 lays claim to world's first production fuel cell vehicle title". autoblog.com. Retrieved 7 October 2012.

- ^ "GM's Fuel Cell System Shrinks in Size, Weight, Cost". General Motors. 16 March 2010. Retrieved 5 March 2012.

- ^ "Honda unveils FCX Clarity advanced fuel cell electric vehicle at motor show in US". Honda Worldwide. Retrieved 5 March 2012.

- ^ "Environmental Activities: Nissan Green Program 2016". Nissan. Retrieved 5 March 2012.

- ^ Chu, Steven. "Winning the Future with a Responsible Budget". U.S. Dept. of Energy, 11 February 2011

- ^ Matthew L. Wald (7 May 2009). "U.S. Drops Research into Fuel Cells for Cars". The New York Times. Retrieved 9 May 2009.

- ^ Bullis, Kevin. "Q & A: Steven Chu", Technology Review, 14 May 2009

- ^ Steven Chu turns out to be a supporter of Hydrogen Technologies – on 2.10 min

- ^ Motavalli, Jim. "Cheap Natural Gas Prompts Energy Department to Soften Its Line on Fuel Cells", The New York Times, 29 May 2012

- ^ "Transportation Fleet Vehicles: Overview". UTC Power. Accessed 2 August 2011.

- ^ "FY 2010 annual progress report: VIII.0 Technology Validation Sub-Program Overview".John Garbak. Department of Energy Hydrogen Program.

- ^ a b "National Fuel Cell Bus Program Awards". Calstart. Accessed 12 August 2011

- ^ "European Fuel Cell Bus Project Extended by One Year". DaimlerChrysler. Retrieved 31 March 2007.[dead link]

- ^ "Fuel cell buses". Transport for London. Archived from the original on 13 May 2007. Retrieved 1 April 2007.

{{cite web}}: Unknown parameter|deadurl=ignored (|url-status=suggested) (help) - ^ "UTC Power – Fuel Cell Fleet Vehicles".[dead link]

- ^ "Ônibus brasileiro movido a hidrogênio começa a rodar em São Paulo" (in Portuguese). Inovação Tecnológica. 8 April 2009. Retrieved 3 May 2009.

- ^ "Ônibus a Hidrogênio vira realidade no Brasil" (in Portuguese). Inovação Tecnológica. April 2009. Retrieved 3 May 2009. [dead link]

- ^ Fuel Cell Forklifts Gain Ground

- ^ Fuel cell technologies program overview

- ^ Economic Impact of Fuel Cell Deployment in Forklifts and for Backup Power under the American Recovery and Reinvestment Act

- ^ "Fact Sheet: Materials Handling and Fuel Cells"

- ^ Hylift

- ^ First hydrogen station for fuel cell forklift trucks in France, for IKEA

- ^ HyPulsion

- ^ HyGear delivers hydrogen system for fuel cell based forklift trucks

- ^ "Hydrogen Fueling Stations Could Reach 5,200 by 2020". Environmental Leader: Environmental & Energy Management News,20 July 2011, accessed 2 August 2011

- ^ Full Fuel-Cycle Comparison of Forklift Propulsion Systems

- ^ Fuel cell technology

- ^ Fuel cell forklift

- ^ "The ENV Bike". Intelligent Energy. Retrieved 27 May 2007.

- ^ "Honda Develops Fuel Cell Scooter Equipped with Honda FC Stack". Honda Motor Co. 24 August 2004. Retrieved 27 May 2007.

- ^ Bryant, Eric (21 July 2005). "Honda to offer fuel-cell motorcycle". autoblog.com. Retrieved 27 May 2007.

- ^ 15. Dezember 2007. "Hydrogen Fuel Cell electric bike". Youtube.com. Retrieved 21 September 2009.

{{cite web}}: CS1 maint: numeric names: authors list (link) - ^ "Horizon fuel cell vehicles: Transportation: Light Mobility". Horizon Fuel Cell Technologies. 2010. Accessed 2 August 2011.

- ^ APFCT won Taiwan BOE project contract for 80 FC scooters fleet demonstration

- ^ The fuel cell industry review 2012

- ^ Burgman_Fuel-Cell_Scooter; "Products History 2000s". Global Suzuki. Suzuki Motor Corporation. Retrieved 25 October 2013.

- ^ "Eco energy firm in Suzuki deal". Leicester Mercury. 6 February 2012. Retrieved 26 October 2013.; "Suzuki and IE to commercialize FC cars and bikes". Gizmag. 8 February 2012. Retrieved 26 October 2013.

- ^ "Boeing Successfully Flies Fuel Cell-Powered Airplane".. Boeing. 3 April 2008. Accessed 2 August 2011.

- ^ "First Fuel Cell Microaircraft" [dead link]

- ^ "Horizon Fuel Cell Powers New World Record in UAV Flight". Horizon Fuel Cell Technologies. 1 November 2007.

- ^ "Fuel Cell Powered UAV Completes 23-hour Flight". Alternative Energy: News. 22 October 2009. Accessed 2 August 2011.

- ^ "Hydrogen-powered unmanned aircraft completes set of tests".www.theengineer.co.uk. 20 June 2011. Accessed 2 August 2011.

- ^ "Lovers introduces zero-emission boat" (in Dutch). NemoH2. 28 March 2011. Accessed 2 August 2011.

- ^ "Super-stealth sub powered by fuel cell". Frederik Pleitgen. CNN Tech: Nuclear Weapons. 22 February 2011. Accessed 2 August 2011.

- ^ "U212 / U214 Attack Submarines, Germany". Navel-Technology.com. Accessed 2 August 2011.

- ^ SFC Energy

- ^ Ensol Systems Inc.

- ^ "Ballard fuel cells to power telecom backup power units for motorola". Association Canadienne de l'hydrogene et des piles a combustible. 13 July 2009. Accessed 2 August 2011.

- ^ India telecoms to get fuel cell power [dead link]

- ^ "Cottbus receives new local data center". T Systems. 21 March 2011.

- ^ "Fuel Cell Applications". Fuel Cells 2000. Accessed 2 August 2011

- ^ DVGW VP 119 Brennstoffzellen-Gasgeräte bis 70 kW. DVGW. (German)

- ^ Laine Welch (18 May 2013). "Laine Welch: Fuel cell technology boosts long-distance fish shipping". Anchorage Daily News. Retrieved 19 May 2013.

- ^ "Fuel Cell Technology Applied to Alcohol Breath Testing". Intoximeters, Inc. Retrieved 24 October 2013.

- ^ a b "Alternative Fueling Station Locator". U.S. Department of Energy Energy Efficiency and Renewable Energy Alternative Fuel & Advance Vehicle Center. 14 January 2010.

- ^ Ingram, Antony. "RIP Hydrogen Highway? California Takes Back Grant Dollars", Green Car Reports, 5 June 2012

- ^ "Cluster Successes in South Carolina". South Carolina Hydrogen & Fuel Cell Alliance. 200

- ^ German Government announces support for 50 urban hydrogen refuelling stations

- ^ Bundesverkehrsministerium und Industriepartner bauen überregionales Tankstellennetz (German)

- ^ Higashi, Tadashi. "Initiative to Promote a Diffusion of Hydrogen Fuel Cell Vehicles", Fukuoka Strategy Conference for Hydrogen Energy, February 1, 2012, accessed November 16, 2013

- ^ "Navigant: fuel cell industry passed $1-billion revenue mark in 2012", Green Car Congress, 12 August 2013

- ^ Wesoff, Eric. "Will Plug Power Be the First Profitable Fuel Cell Company?". Greentech Media, October 21, 2013

- ^ Fuel cell report highlights continued growth in material handling applications

- ^ Latest developments in the Ene-Farm scheme

- ^ Tanaka Precious Metals Records Highest Shipment Volume of Fuel Cell Catalysts in FY2011

- ^ "Tanaka precious metals constructs dedicated plant for the development and manufacture of fuel cell catalysts", FuelCellToday.com, February 26, 2013, accessed November 16, 2013

- ^ Adamson, Karry-Ann and Clint Wheelock. "Fuel Cell Annual Report 2011". 2Q 2011, Pike Research, accessed 1 August 2011

- ^ "Solid State Energy Conversion Alliance SECA Cost Reduction". U.S. Dept. of Energy, 31 January 2011, accessed 1 August 2011

- ^ "Lower & Lock-In Energy Costs". Bloom Energy, accessed 3 August 2011

- ^ Wesoff, Eric. "Bloom Energy Plays the Subsidy Game Like a Pro", April 13, 2011, accessed August 1, 2011

- ^ International Platinum Group Metals Association-FAQ

- ^ Johnson, R. Colin (22 January 2007). "Gold is key to ending platinum dissolution in fuel cells". EETimes.com. Retrieved 27 May 2007.

- ^ Replacement of platinum by iron-sulpher

- ^ Fuel cell improvements raise hopes for clean, cheap energy

- ^ "Chemical Could Revolutionize Polymer Fuel Cells". Georgia Institute of Technology. 24 August 2005. Retrieved 27 May 2007.

- ^ Cheaper fuel cells

- ^ Lane, K. (September 2009). Y-carbon? because it has so many applications! NanoMaterials Quarterly, Retrieved from http://www.y-carbon.us/Portals/0/docs/Media/Newsletter_september_2009.pdf

- ^ Savage, N. (October 2009). Nanoporous carbon could help power hybrid cars. Technology Review, 112(5), 51, Retrieved from http://www.y-carbon.us/Portals/0/docs/Media/TR35.pdf

- ^ Bio-inspired catalyst design could rival platinum

- ^ ACAL Energy System Breaks The 10,000 Hour Endurance Barrier

- ^ ACAL poster on Fuel Cell costs and efficiency

Further reading

- Handbook of fuel cells: advances in electrocatalysis, materials, diagnostics and durability. Hoboken: John Wiley and Sons. 2009.

{{cite book}}: Unknown parameter|editors=ignored (|editor=suggested) (help) - Gregor Hoogers (2003). Fuel Cell Technology – Handbook. CRC Press.

- James Larminie; Andrew Dicks (2003). Fuel Cell Systems Explained (Second ed.). Hoboken: John Wiley and Sons.

- Subash C. Singhal; Kevin Kendall (2003). High Temperature Solid Oxide Fuel Cells-Fundamentals, Design and Applications. Elsevier Academic Press.

- Frano Barbir (2005). PEM Fuel Cells-Theory and Practice. Elsevier Academic Press.

- EG&G Technical Services, Inc. (2004). Fuel Cell Technology-Handbook, 7th Edition. U.S. Department of Energy.

- Matthew M. Mench (2008). Fuel Cell Engines. Hoboken: John Wiley & Sons, Inc.

- Noriko Hikosaka Behling (2012). Fuel Cells: Current Technology Challenges and Future Research Needs (First ed.). Elsevier Academic Press.

{{cite book}}: CS1 maint: location missing publisher (link)

External links

- Fuel Cell Today – Market-based intelligence on the fuel cell industry

- Fuel starvation in a hydrogen fuel cell animation

- Animation how a fuel cell works and applications

- Fuel Cell Origins: 1840–1890

- TC 105 IEC Technical standard for Fuel Cells

- EERE: Hydrogen, Fuel Cells and Infrastructure Technologies Program

- Thermodynamics of electrolysis of water and hydrogen fuel cells

- 2002-Portable Power Applications of Fuel Cells

- US Fuel Cell Council

- DoITPoMS Teaching and Learning Package- "Fuel Cells"

- Solar Hydrogen Fuel Cell Water Heating