Jet engine

A jet engine is a reaction engine discharging a fast-moving jet that generates thrust by jet propulsion. This broad definition includes turbojets, turbofans, rocket engines, ramjets, and pulse jets. In general, jet engines are combustion engines.

In common parlance, the term jet engine loosely refers to an internal combustion airbreathing jet engine. These typically feature a rotating air compressor powered by a turbine, with the leftover power providing thrust via a propelling nozzle — this process is known as the Brayton thermodynamic cycle. Jet aircraft use such engines for long-distance travel. Early jet aircraft used turbojet engines which were relatively inefficient for subsonic flight. Modern subsonic jet aircraft usually use more complex high-bypass turbofan engines. These engines offer high speed and greater fuel efficiency than piston and propeller aeroengines over long distances.

The thrust of a typical jetliner engine went from 5,000 lbf (22,000 N) (de Havilland Ghost turbojet ) in the 1950s to 115,000 lbf (510,000 N) (General Electric GE90 turbofan) in the 1990s, and their reliability went from 40 in-flight shutdowns per 100,000 engine flight hours to less than one in the late 1990s. This, combined with greatly decreased fuel consumption, permitted routine transatlantic flight by twin-engined airliners by the turn of the century, where before a similar journey would have required multiple fuel stops.[1]

History

Jet engines date back to the invention of the aeolipile before the first century AD. This device directed steam power through two nozzles to cause a sphere to spin rapidly on its axis. So far as is known, it did not supply mechanical power and the potential practical applications of this invention did not receive recognition. Instead, it was seen as a curiosity.

Jet propulsion only gained practical applications with the invention of the gunpowder-powered rocket by the Chinese in the 13th century as a type of firework, and gradually progressed to propel formidable weaponry. However, although very powerful, at reasonable flight speeds rockets are very inefficient and so jet propulsion technology stalled for hundreds of years.

The earliest attempts at airbreathing jet engines were hybrid designs in which an external power source first compressed air, which was then mixed with fuel and burned for jet thrust. In one such system, called a thermojet by Secondo Campini but more commonly, motorjet, the air was compressed by a fan driven by a conventional piston engine. Examples of this type of design were the Caproni Campini N.1, and the Japanese Tsu-11 engine intended to power Ohka kamikaze planes towards the end of World War II. None were entirely successful and the N.1 ended up being slower than the same design with a traditional engine and propeller combination.

Even before the start of World War II, engineers were beginning to realize that engines driving propellers were self-limiting in terms of the maximum performance which could be attained; the limit was due to issues related to propeller efficiency,[2] which declined as blade tips approached the speed of sound. If aircraft performance were ever to increase beyond such a barrier, a way would have to be found to use a different propulsion mechanism. This was the motivation behind the development of the gas turbine engine, commonly called a "jet" engine.

The key to a practical jet engine was the gas turbine, used to extract energy from the engine itself to drive the compressor. The gas turbine was not an idea developed in the 1930s: the patent for a stationary turbine was granted to John Barber in England in 1791. The first gas turbine to successfully run self-sustaining was built in 1903 by Norwegian engineer Ægidius Elling.[3] Limitations in design and practical engineering and metallurgy prevented such engines reaching manufacture. The main problems were safety, reliability, weight and, especially, sustained operation.

The first patent for using a gas turbine to power an aircraft was filed in 1921 by Frenchman Maxime Guillaume.[4] His engine was an axial-flow turbojet. Alan Arnold Griffith published An Aerodynamic Theory of Turbine Design in 1926 leading to experimental work at the RAE.

In 1928, RAF College Cranwell cadet[5] Frank Whittle formally submitted his ideas for a turbojet to his superiors. In October 1929 he developed his ideas further.[6] On 16 January 1930 in England, Whittle submitted his first patent (granted in 1932).[7] The patent showed a two-stage axial compressor feeding a single-sided centrifugal compressor. Practical axial compressors were made possible by ideas from A.A.Griffith in a seminal paper in 1926 ("An Aerodynamic Theory of Turbine Design"). Whittle would later concentrate on the simpler centrifugal compressor only, for a variety of practical reasons. Whittle had his first engine running in April 1937. It was liquid-fuelled, and included a self-contained fuel pump. Whittle's team experienced near-panic when the engine would not stop, accelerating even after the fuel was switched off. It turned out that fuel had leaked into the engine and accumulated in pools, so the engine would not stop until all the leaked fuel had burned off. Whittle was unable to interest the government in his invention, and development continued at a slow pace.

In 1935 Hans von Ohain started work on a similar design in Germany, initially unaware of Whittle's work.[8]

Von Ohain's first device was strictly experimental and could run only under external power, but he was able to demonstrate the basic concept. Ohain was then introduced to Ernst Heinkel, one of the larger aircraft industrialists of the day, who immediately saw the promise of the design. Heinkel had recently purchased the Hirth engine company, and Ohain and his master machinist Max Hahn were set up there as a new division of the Hirth company. They had their first HeS 1 centrifugal engine running by September 1937. Unlike Whittle's design, Ohain used hydrogen as fuel, supplied under external pressure. Their subsequent designs culminated in the gasoline-fuelled HeS 3 of 5 kN (1,100 lbf), which was fitted to Heinkel's simple and compact He 178 airframe and flown by Erich Warsitz in the early morning of August 27, 1939, from Rostock-Marienehe aerodrome, an impressively short time for development. The He 178 was the world's first jet plane.[9]

Austrian Anselm Franz of Junkers' engine division (Junkers Motoren or "Jumo") introduced the axial-flow compressor in their jet engine. Jumo was assigned the next engine number in the RLM 109-0xx numbering sequence for gas turbine aircraft powerplants, "004", and the result was the Jumo 004 engine. After many lesser technical difficulties were solved, mass production of this engine started in 1944 as a powerplant for the world's first jet-fighter aircraft, the Messerschmitt Me 262 (and later the world's first jet-bomber aircraft, the Arado Ar 234). A variety of reasons conspired to delay the engine's availability, causing the fighter to arrive too late to improve Germany's position in World War II, however this was the first jet engine to be used in service.

Meanwhile, in Britain the Gloster E28/39 had its maiden flight on 15 May 1941 and the Gloster Meteor finally entered service with the RAF in July 1944. These were powered by turbojet engines from Power Jets Ltd., set up by Frank Whittle.

Following the end of the war the German jet aircraft and jet engines were extensively studied by the victorious allies and contributed to work on early Soviet and US jet fighters. The legacy of the axial-flow engine is seen in the fact that practically all jet engines on fixed-wing aircraft have had some inspiration from this design.

By the 1950s the jet engine was almost universal in combat aircraft, with the exception of cargo, liaison and other specialty types. By this point some of the British designs were already cleared for civilian use, and had appeared on early models like the de Havilland Comet and Avro Canada Jetliner. By the 1960s all large civilian aircraft were also jet powered, leaving the piston engine in low-cost niche roles such as cargo flights.

The efficiency of turbojet engines was still rather worse than piston engines, but by the 1970s, with the advent of high-bypass turbofan jet engines (an innovation not foreseen by the early commentators such as Edgar Buckingham, at high speeds and high altitudes that seemed absurd to them), fuel efficiency was about the same as the best piston and propeller engines.[10]

Uses

Jet engines power jet aircraft, cruise missiles and unmanned aerial vehicles. In the form of rocket engines they power fireworks, model rocketry, spaceflight, and military missiles.

Jet engines have propelled high speed cars, particularly drag racers, with the all-time record held by a rocket car. A turbofan powered car, ThrustSSC, currently holds the land speed record.

Jet engine designs are frequently modified for non-aircraft applications, as industrial gas turbines or marine powerplants. These are used in electrical power generation, for powering water, natural gas, or oil pumps, and providing propulsion for ships and locomotives. Industrial gas turbines can create up to 50,000 shaft horsepower. Many of these engines are derived from older military turbojets such as the Pratt & Whitney J57 and J75 models. There is also a derivative of the P&W JT8D low-bypass turbofan that creates up to 35,000 HP.

Jet engines are also sometimes developed into, or share certain components such as engine cores, with turboshaft and turboprop engines, which are forms of gas turbine engines that are typically used to power helicopters and some propeller-driven aircraft..

Types

There are a large number of different types of jet engines, all of which achieve forward thrust from the principle of jet propulsion.

Airbreathing

Commonly aircraft are propelled by airbreathing jet engines. Most airbreathing jet engines that are in use are turbofan jet engines, which give good efficiency at speeds just below the speed of sound.

Turbine powered

Gas turbines are rotary engines that extract energy from a flow of combustion gas. They have an upstream compressor coupled to a downstream turbine with a combustion chamber in-between. In aircraft engines, those three core components are often called the "gas generator."[11] There are many different variations of gas turbines, but they all use a gas generator system of some type.

Turbojet

A turbojet engine is a gas turbine engine that works by compressing air with an inlet and a compressor (axial, centrifugal, or both), mixing fuel with the compressed air, burning the mixture in the combustor, and then passing the hot, high pressure air through a turbine and a nozzle. The compressor is powered by the turbine, which extracts energy from the expanding gas passing through it. The engine converts internal energy in the fuel to kinetic energy in the exhaust, producing thrust. All the air ingested by the inlet is passed through the compressor, combustor, and turbine, unlike the turbofan engine described below.[12]

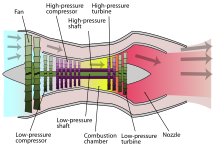

Turbofan

Turbofans differ from turbojets in that they have an additional fan at the front of the engine, which accelerates air in a duct bypassing the core gas turbine engine. Compared to a turbojet of identical thrust, a turbofan has a much larger air mass flow rate. Turbofans are the dominant engine type for medium and long-range airliners.

The comparatively large frontal fan has several effects. The main effect is that the output of the engine as a whole has a much higher mass per second, and therefore generates much more thrust, despite not having ignited much of its airflow. Also, because the additional air has not been ignited, no extra fuel is needed to provide this thrust. The slower average velocity of the mixed exhaust air (low specific thrust) is also less wasteful of energy for subsonic flight, and allows the engine to be more efficient and much quieter, while the fan also allows greater thrust to be available at slow speeds. Together, the thrust produced by the fan and core are much more fuel efficient, and provides a much higher output, than could be produced by the core alone.

Turbofans are usually more efficient than turbojets at subsonic speeds, but their large frontal area also generates more drag.[13] Therefore, in supersonic flight, and in military and other aircraft where absolute performance, weight, and drag have a higher priority than fuel efficiency, engines tend to either have smaller fans (or multiple smaller fans) or use other engine designs entirely. Typically, turbofans in civilian aircraft usually have a pronounced large front area to accommodate a very large fan, as their design involves a much larger mass of air bypassing the core so they can benefit from these effects, while in military aircraft, where noise and efficiency are less important compared to performance and drag, a smaller amount of air typically bypasses the core. Turbofans designed for subsonic civilian aircraft also usually have a just a single front fan, because their additional thrust is generated by a large additional mass of air which is only moderately compressed, rather than a smaller amount of air which is greatly compressed.

Because of these distinctions, turbofan engine designs are often categorized as low-bypass or high-bypass, depending upon the amount of air which bypasses the core of the engine. Low-bypass turbofans have a bypass ratio of around 2:1 or less, meaning that for each kilogram of air that passes through the core of the engine, two kilograms or less of air bypass the core.[citation needed] Low-bypass turbofans often use a mixed exhaust nozzle meaning that the bypassed flow and the core flow exit from the same nozzle.[14] High-bypass turbofans often have ratios from 4:1 up to 8:1, with the Rolls-Royce Trent XWB approaching 10:1.[15]

Turboprop and turboshaft

Turboprop engines are jet engine derivatives, still gas turbines, that extract work from the hot-exhaust jet to turn a rotating shaft, which is then used to produce thrust by some other means. While not strictly jet engines in that they rely on an auxiliary mechanism to produce thrust, turboprops are very similar to other turbine-based jet engines, and are often described as such.

In turboprop engines, a portion of the engine's thrust is produced by spinning a propeller, rather than relying solely on high-speed jet exhaust. As their jet thrust is augmented by a propeller, turboprops are occasionally referred to as a type of hybrid jet engine. They are quite similar to turbofans in many respects, except that they use a traditional propeller to provide the majority of thrust, rather than a ducted fan. Both fans and propellers are powered the same way, although most turboprops use gear-reduction between the turbine and the propeller (geared turbofans also feature gear reduction). While many turboprops generate the majority of their thrust with the propeller, the hot-jet exhaust is an important design point, and maximum thrust is obtained by matching thrust contributions of the propeller to the hot jet.[16] Turboprops generally have better performance than turbojets or turbofans at low speeds where propeller efficiency is high, but become increasingly noisy and inefficient at high speeds.[17]

Turboshaft engines are very similar to turboprops, differing in that nearly all energy in the exhaust is extracted to spin the rotating shaft, which is used to power machinery rather than a propeller, they therefore generate little to no jet thrust and are often used to power helicopters.[14]

Propfan

A propfan engine (also called "unducted fan", "open rotor", or "ultra-high bypass") is a jet engine that uses its gas generator to power an exposed fan, similar to turboprop engines. Like turboprop engines, propfans generate most of their thrust from the propeller and not the exhaust jet. The primary difference between turboprop and propfan design is that the propeller blades on a propfan are highly swept to allow them to operate at speeds around Mach 0.8, which is competitive with modern commercial turbofans. These engines have the fuel efficiency advantages of turboprops with the performance capability of commercial turbofans.[18] While significant research and testing (including flight testing) has been conducted on propfans, no propfan engines have entered production.

Ram powered

Ram powered jet engines are airbreathing engines similar to gas turbine engines and they both follow the Brayton cycle. Gas turbine and ram powered engines differ, however, in how they compress the incoming airflow. Whereas gas turbine engines use axial or centrifugal compressors to compress incoming air, ram engines rely only on air compressed through the inlet or diffuser.[19] Ram powered engines are considered the most simple type of air breathing jet engine because they can contain no moving parts.[20]

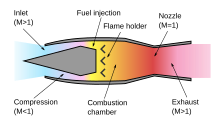

Ramjet

Ramjets are the most basic type of ram powered jet engines. They consist of three sections; an inlet to compress incoming air, a combustor to inject and combust fuel, and a nozzle to expel the hot gases and produce thrust. Ramjets require a relatively high speed to efficiently compress the incoming air, so ramjets cannot operate at a standstill and they are most efficient at supersonic speeds. A key trait of ramjet engines is that combustion is done at subsonic speeds. The supersonic incoming air is dramatically slowed through the inlet, where it is then combusted at the much slower, subsonic, speeds.[19] The faster the incoming air is, however, the less efficient it becomes to slow it to subsonic speeds. Therefore, ramjet engines are limited to approximately Mach 5.[21]

Scramjet

Scramjets are mechanically very similar to ramjets. Like a ramjet, they consist of an inlet, a combustor, and a nozzle. The primary difference between ramjets and scramjets is that scramjets do not slow the oncoming airflow to subsonic speeds for combustion, they use supersonic combustion instead. The name "scramjet" comes from "Supersonic Combusting Ramjet." Since scramjets use supersonic combustion they can operate at speeds above Mach 6 where traditional ramjets are too inefficient. Another difference between ramjets and scramjets comes from how each type of engine compresses the oncoming airflow: while the inlet provides most of the compression for ramjets, the high speeds at which scramjets operate allow them to take advantage of the compression generated by shock waves, primarily oblique shocks.[22]

Very few scramjet engines have ever been built and flown. In May 2010 the Boeing X-51 set the endurance record for the longest scramjet burn at over 200 seconds.[23]

Non-continuous combustion

| Type | Description | Advantages | Disadvantages |

|---|---|---|---|

| Motorjet | Obsolete type that worked like a turbojet but instead of a turbine driving the compressor a piston engine drives it. | Higher exhaust velocity than a propeller, offering better thrust at high speed | Heavy, inefficient and underpowered. Example: Caproni Campini N.1. |

| Pulsejet | Air is compressed and combusted intermittently instead of continuously. Some designs use valves. | Very simple design, commonly used on model aircraft | Noisy, inefficient (low compression ratio), works poorly on a large scale, valves on valved designs wear out quickly |

| Pulse detonation engine | Similar to a pulsejet, but combustion occurs as a detonation instead of a deflagration, may or may not need valves | Maximum theoretical engine efficiency | Extremely noisy, parts subject to extreme mechanical fatigue, hard to start detonation, not practical for current use |

Rocket

The rocket engine uses the same basic physical principles as the jet engine for propulsion via thrust, but is distinct in that it does not require atmospheric air to provide oxygen; the rocket carries all components of the reaction mass. This allows them to operate at arbitrary altitudes and in space.

This type of engine is used for launching satellites, space exploration and manned access, and permitted landing on the moon in 1969.

Rocket engines are used for high altitude flights, or anywhere where very high accelerations are needed since rocket engines themselves have a very high thrust-to-weight ratio.

However, the high exhaust speed and the heavier, oxidizer-rich propellant results in far more propellant use than turbofans. Even so, at extremely high speeds they become energy-efficient.

An approximate equation for the net thrust of a rocket engine is:

Where is the net thrust, is the specific impulse, is a standard gravity, is the propellant flow in kg/s, is the cross-sectional area at the exit of the exhaust nozzle, and is the atmospheric pressure.

| Type | Description | Advantages | Disadvantages |

|---|---|---|---|

| Rocket | Carries all propellants and oxidants on board, emits jet for propulsion[24] | Very few moving parts. Mach 0 to Mach 25+; efficient at very high speed (> Mach 5.0 or so). Thrust/weight ratio over 100. No complex air inlet. High compression ratio. Very high-speed (hypersonic) exhaust. Good cost/thrust ratio. Fairly easy to test. Works in a vacuum; indeed, works best outside the atmosphere, which is kinder on vehicle structure at high speed. Fairly small surface area to keep cool, and no turbine in hot exhaust stream. Very high-temperature combustion and high expansion-ratio nozzle gives very high efficiency, at very high speeds. | Needs lots of propellant. Very low specific impulse—typically 100–450 seconds. Extreme thermal stresses of combustion chamber can make reuse harder. Typically requires carrying oxidizer on-board which increases risks. Extraordinarily noisy. |

Hybrid

Combined cycle engines simultaneously use 2 or more different jet engine operating principles.

| Type | Description | Advantages | Disadvantages |

|---|---|---|---|

| Turborocket | A turbojet where an additional oxidizer such as oxygen is added to the airstream to increase maximum altitude | Very close to existing designs, operates in very high altitude, wide range of altitude and airspeed | Airspeed limited to same range as turbojet engine, carrying oxidizer like LOX can be dangerous. Much heavier than simple rockets. |

| Air-augmented rocket | Essentially a ramjet where intake air is compressed and burnt with the exhaust from a rocket | Mach 0 to Mach 4.5+ (can also run exoatmospheric), good efficiency at Mach 2 to 4 | Similar efficiency to rockets at low speed or exoatmospheric, inlet difficulties, a relatively undeveloped and unexplored type, cooling difficulties, very noisy, thrust/weight ratio is similar to ramjets. |

| Precooled jets / LACE | Intake air is chilled to very low temperatures at inlet in a heat exchanger before passing through a ramjet and/or turbojet and/or rocket engine. | Easily tested on ground. Very high thrust/weight ratios are possible (~14) together with good fuel efficiency over a wide range of airspeeds, Mach 0-5.5+; this combination of efficiencies may permit launching to orbit, single stage, or very rapid, very long distance intercontinental travel. | Exists only at the lab prototyping stage. Examples include RB545, Reaction Engines SABRE, ATREX. Requires liquid hydrogen fuel which has very low density and requires heavily insulated tankage. |

Water jet

A water jet, or pump jet, is a marine propulsion system that utilizes a jet of water. The mechanical arrangement may be a ducted propeller with nozzle, or a centrifugal compressor and nozzle.

| Type | Description | Advantages | Disadvantages |

|---|---|---|---|

| Water jet | For propelling water rockets and jetboats; squirts water out the back through a nozzle | In boats, can run in shallow water, high acceleration, no risk of engine overload (unlike propellers), less noise and vibration, highly maneuverable at all boat speeds, high speed efficiency, less vulnerable to damage from debris, very reliable, more load flexibility, less harmful to wildlife | Can be less efficient than a propeller at low speed, more expensive, higher weight in boat due to entrained water, will not perform well if boat is heavier than the jet is sized for |

General physical principles

All jet engines are reaction engines that generate thrust by emitting a jet of fluid rearwards at relatively high speed. The forces on the inside of the engine needed to create this jet give a strong thrust on the engine which pushes the craft forwards.

Jet engines make their jet from propellant from tankage that is attached to the engine (as in a 'rocket') as well as in duct engines (those commonly used on aircraft) by ingesting an external fluid (very typically air) and expelling it at higher speed.

Propelling nozzle

The propelling nozzle is the key component of all jet engines as it creates the exhaust jet. Propelling nozzles turn internal and pressure energy into high velocity kinetic energy.[25] The total pressure and temperature don't change through the nozzle but their static values drop as the gas speeds up.

The velocity of the air entering the nozzle is low, about Mach 0.4, a prerequisite for minimizing pressure losses in the duct leading to the nozzle. The temperature entering the nozzle may be as low as sea level ambient for a fan nozzle in the cold air at cruise altitudes. It may be as high as the 1000K exhaust gas temperature for a supersonic afterburning engine or 2200K with afterburner lit.[26] The pressure entering the nozzle may vary from 1.5 times the pressure outside the nozzle, for a single stage fan, to 30 times for the fastest manned aircraft at mach 3+.[27]

The velocity of the gas leaving a convergent nozzle may be subsonic or sonic (Mach 1) at low flight speeds or supersonic (Mach 3.0 at SR-71 cruise)[28] for a con-di nozzle at higher speeds where the nozzle pressure ratio is increased with the intake ram.[29] The nozzle thrust is highest if the static pressure of the gas reaches the ambient value as it leaves the nozzle. This only happens if the nozzle exit area is the correct value for the nozzle pressure ratio (npr). Since the npr changes with engine thrust setting and flight speed this is seldom the case. Also at supersonic speeds the divergent area is less than required to give complete internal expansion to ambient pressure as a trade-off with external body drag. Whitford[30] gives the F-16 as an example. Other underexpanded examples were the XB-70 and SR-71.

The nozzle size, together with the area of the turbine nozzles, determines the operating pressure of the compressor.[31]

Thrust

Origin of engine thrust

The familiar explanation for jet thrust is a "black box" description which only looks at what goes in to the engine, air and fuel, and what comes out, exhaust gas and an unbalanced force. This force, called thrust, is the sum of the momentum difference between entry and exit and any unbalanced pressure force between entry and exit, as explained in "Thrust calculation". As an example, an early turbojet, the Bristol Olympus Mk. 101, had a momentum thrust of 9300 lb. and a pressure thrust of 1800 lb. giving a total of 11,100 lb.[32] Looking inside the "black box" shows that the thrust results from all the unbalanced momentum and pressure forces created within the engine itself.[33] These forces, some forwards and some rearwards, are across all the internal parts, both stationary and rotating, such as ducts, compressors, etc., which are in the primary gas flow which flows through the engine from front to rear. The algebraic sum of all these forces is delivered to the airframe for propulsion.[34] "Flight" gives examples of these internal forces for two early jet engines, the Rolls-Royce Avon Ra.14[35] and the de Havilland Goblin[36]

Transferring thrust to the aircraft

The engine thrust acts along the engine centreline. The aircraft "holds" the engine on the outer casing of the engine at some distance from the engine centreline (at the engine mounts). This arrangement causes the engine casing to bend (known as backbone bending) and the round rotor casings to distort (ovalization). Distortion of the engine structure has to be controlled with suitable mount locations to maintain acceptable rotor and seal clearances and prevent rubbing. A well-publicized example of excessive structural deformation occurred with the original Pratt & Whitney JT9D engine installation in the Boeing 747 aircraft.[37] The engine mounting arrangement had to be revised with the addition of an extra thrust frame to reduce the casing deflections to an acceptable amount.[38][39]

Rotor thrust

The rotor thrust on a thrust bearing is not related to the engine thrust. It may even change direction at some RPM. The bearing load is determined by bearing life considerations. Although the aerodynamic loads on the compressor and turbine blades contribute to the rotor thrust they are small compared to cavity loads inside the rotor which result from the secondary air system pressures and sealing diameters on discs, etc. To keep the load within the bearing specification seal diameters are chosen accordingly as, many years ago, on the backface of the impeller[40] in the de Havilland Ghost engine. Sometimes an extra disc known as a balance piston has to be added inside the rotor. An early turbojet example with a balance piston[41] was the Rolls-Royce Avon.

Thrust calculation

The net thrust (FN) of a turbojet is given by:[42]

| where: | |

| ṁ air | = the mass rate of air flow through the engine |

| ṁ fuel | = the mass rate of fuel flow entering the engine |

| ve | = the velocity of the jet (the exhaust plume) and is assumed to be less than sonic velocity |

| v | = the velocity of the air intake = the true airspeed of the aircraft |

| (ṁ air + ṁ fuel)ve | = the nozzle gross thrust (FG) |

| ṁ air v | = the ram drag of the intake air |

The above equation applies only for air-breathing jet engines. It does not apply to rocket engines. Most types of jet engine have an air intake, which provides the bulk of the fluid exiting the exhaust. Conventional rocket engines, however, do not have an intake, the oxidizer and fuel both being carried within the vehicle. Therefore, rocket engines do not have ram drag and the gross thrust of the rocket engine nozzle is the net thrust of the engine. Consequently, the thrust characteristics of a rocket motor are different from that of an air breathing jet engine, and thrust is independent of velocity.

If the velocity of the jet from a jet engine is equal to sonic velocity, the jet engine's nozzle is said to be choked. If the nozzle is choked, the pressure at the nozzle exit plane is greater than atmospheric pressure, and extra terms must be added to the above equation to account for the pressure thrust.[42]

The rate of flow of fuel entering the engine is very small compared with the rate of flow of air.[42] If the contribution of fuel to the nozzle gross thrust is ignored, the net thrust is:

The velocity of the jet (ve) must exceed the true airspeed of the aircraft (v) if there is to be a net forward thrust on the aircraft. The velocity (ve) can be calculated thermodynamically based on adiabatic expansion.[43]

Thrust augmentation

Thrust augmentation has taken many forms, most commonly to supplement inadequate take-off thrust. Some early jet aircraft needed rocket assistance to take off from high altitude airfields or when the day temperature was high. A more recent aircraft, the Tupolev Tu-22 supersonic bomber, was fitted with four SPRD-63 boosters for take-off.[44] Possibly the most extreme requirement needing rocket assistance, and which was short-lived, was zero-length launching. Almost as extreme, but very common, is catapult assistance from aircraft carriers. Rocket assistance has also been used during flight. The SEPR 841 booster engine was used on the Dassault Mirage for high altitude interception.[45]

Early aft-fan arrangements which added bypass airflow to a turbojet were known as thrust augmentors.[46] The aft-fan fitted to the General Electric CJ805-3 turbojet augmented the take-off thrust from 11,650lb to 16,100lb.

Water, or other coolant,[47] injection into the compressor or combustion chamber and fuel injection into the jetpipe (afterburning/reheat) became standard ways to increase thrust, known as 'wet' thrust to differentiate with the no-augmentation 'dry' thrust.

Coolant injection (pre-compressor cooling) has been used, together with afterburning, to increase thrust at supersonic speeds. The 'Skyburner' McDonnell Douglas F-4 Phantom II set a world speed record using water injection in front of the engine.[48]

At high Mach numbers afterburners supply progressively more of the engine thrust as the thrust from the turbomachine drops off towards zero at which speed the engine pressure ratio (epr) has fallen to 1.0 and all the engine thrust comes from the afterburner. The afterburner also has to make up for the pressure loss across the turbomachine which is a drag item at higher speeds where the epr will be less than 1.0.[49][50]

Thrust augmentation of existing afterburning engine installations for special short-duration tasks has been the subject of studies for launching small payloads into low earth orbits using aircraft such as McDonnell Douglas F-4 Phantom II, McDonnell Douglas F-15 Eagle, Dassault Rafale and Mikoyan MiG-31,[51] and also for carrying experimental packages to high altitudes using a Lockheed SR-71.[52] In the first case an increase in the existing maximum speed capability is required for orbital launches. In the second case an increase in thrust within the existing speed capability is required. Compressor inlet cooling is used in the first case. A compressor map shows that the airflow reduces with increasing compressor inlet temperature although the compressor is still running at maximum RPM (but reduced aerodynamic speed). Compressor inlet cooling increases the aerodynamic speed and flow and thrust. In the second case a small increase in the maximum mechanical speed and turbine temperature were allowed, together with nitrous oxide injection into the afterburner and simultaneous increase in afterburner fuel flow.

Energy efficiency relating to aircraft jet engines

This overview highlights where energy losses occur in complete jet aircraft powerplants or engine installations. It includes mention of inlet and exhaust nozzle losses which become increasingly significant at the high flight speeds achieved by some manned aircraft since only a small proportion, 17% for the SR-71 powerplant and 8% for the Concorde powerplant, of the thrust transmitted to the airframe came from the engine.

A jet engine at rest, as on a test stand, sucks in fuel and tries to thrust itself forward. How well it does this is judged by how much fuel it uses and what force is required to restrain it. This is a measure of its efficiency. If something deteriorates inside the engine (known as performance deterioration[53]) it will be less efficient and this will show when the fuel produces less thrust. If a change is made to an internal part which allows the air/combustion gases to flow more smoothly the engine will be more efficient and use less fuel. A standard definition is used to assess how different things change engine efficiency and also to allow comparisons to be made between different engines. This definition is called specific fuel consumption, or how much fuel is needed to produce one unit of thrust. For example, it will be known for a particular engine design that if some bumps in a bypass duct are smoothed out the air will flow more smoothly giving a pressure loss reduction of x% and y% less fuel will be needed to get the take-off thrust, for example. This understanding comes under the engineering discipline Jet engine performance. How efficiency is affected by forward speed and by supplying energy to aircraft systems is mentioned later.

The efficiency of the engine is controlled primarily by the operating conditions inside the engine which are the pressure produced by the compressor and the temperature of the combustion gases at the first set of rotating turbine blades. The pressure is the highest air pressure in the engine. The turbine rotor temperature is not the highest in the engine but is the highest at which energy transfer takes place ( higher temperatures occur in the combustor). The above pressure and temperature are shown on a Thermodynamic cycle diagram.

The efficiency is further modified by how smoothly the air and the combustion gases flow through the engine, how well the flow is aligned (known as incidence angle) with the moving and stationary passages in the compressors and turbines.[54] Non-optimum angles, as well as non-optimum passage and blade shapes can cause thickening and separation of Boundary layers and formation of Shock waves as explained in Effects of Mach number and shock losses in turbomachines. It is important to slow the flow (lower speed means less pressure losses or Pressure drop) when it travels through ducts connecting the different parts. How well the individual components contribute to turning fuel into thrust is quantified by measures like efficiencies for the compressors, turbines and combustor and pressure losses for the ducts. These are shown as lines on a Thermodynamic cycle diagram.

The engine efficiency, or thermal efficiency,[55] known as . is dependent on the Thermodynamic cycle parameters, maximum pressure and temperature, and on component efficiencies, , and and duct pressure losses.

The engine needs compressed air for itself just to run successfully. This air comes from its own compressor and is called secondary air. It does not contribute to making thrust so makes the engine less efficient. It is used to preserve the mechanical integrity of the engine, to stop parts overheating and to prevent oil escaping from bearings for example. Only some of this air taken from the compressors returns to the turbine flow to contribute to thrust production. Any reduction in the amount needed improves the engine efficiency. Again, it will be known for a particular engine design that a reduced requirement for cooling flow of x% will reduce the specific fuel consumption by y%. In other words, less fuel will be required to give take-off thrust, for example. The engine is more efficient.

All of the above considerations are basic to the engine running on its own and, at the same time, doing nothing useful, i.e. it is not moving an aircraft or supplying energy for the aircraft's electrical, hydraulic and air systems. In the aircraft the engine gives away some of its thrust-producing potential, or fuel, to power these systems. These requirements, which cause installation losses,[56] reduce its efficiency. It is using some fuel that does not contribute to the engine's thrust.

Finally, when the aircraft is flying the propelling jet itself contains wasted kinetic energy after it has left the engine. This is quantified by the term propulsive, or Froude, efficiency and may be reduced by redesigning the engine to give it bypass flow and a lower speed for the propelling jet, for example as a turboprop or turbofan engine. At the same time forward speed increases the by increasing the Overall pressure ratio.

The overall efficiency of the engine at flight speed is defined as .[57]

The at flight speed depends on how well the intake compresses the air before it is handed over to the engine compressors. The intake compression ratio, which can be as high as 32:1 at Mach 3, adds to that of the engine compressor to give the Overall pressure ratio and for the Thermodynamic cycle. How well it does this is defined by its pressure recovery or measure of the losses in the intake. Mach 3 manned flight has provided an interesting illustration of how these losses can increase dramatically in an instant. The North American XB-70 Valkyrie and Lockheed SR-71 Blackbird at Mach 3 each had pressure recoveries of about 0.8,[58][59] due to relatively low losses during the compression process, i.e. through systems of multiple shocks. During an 'unstart' the efficient shock system would be replaced by a very inefficient single shock beyond the inlet and an intake pressure recovery of about 0.3 and a correspondingly low pressure ratio.

The propelling nozzle at speeds above about Mach 2 usually has extra internal thrust losses because the exit area is not big enough as a trade-off with external afterbody drag.[60]

Although a bypass engine improves propulsive efficiency it incurs losses of its own inside the engine itself. Machinery has to be added to transfer energy from the gas generator to a bypass airflow. The low loss from the propelling nozzle of a turbojet is added to with extra losses due to inefficiencies in the added turbine and fan.[61] These may be included in a transmission, or transfer, efficiency . However, these losses are more than made up [62] by the improvement in propulsive efficiency.[63] There are also extra pressure losses in the bypass duct and an extra propelling nozzle.

With the advent of turbofans with their loss-making machinery what goes on inside the engine has been separated by Bennett,[64] for example, between gas generator and transfer machinery giving .

The energy efficiency () of jet engines installed in vehicles has two main components:

- propulsive efficiency (): how much of the energy of the jet ends up in the vehicle body rather than being carried away as kinetic energy of the jet.

- cycle efficiency (): how efficiently the engine can accelerate the jet

Even though overall energy efficiency is:

for all jet engines the propulsive efficiency is highest as the exhaust jet velocity gets closer to the vehicle speed as this gives the smallest residual kinetic energy.[65] For an airbreathing engine an exhaust velocity equal to the vehicle velocity, or a equal to one, gives zero thrust with no net momentum change.[66] The formula for air-breathing engines moving at speed with an exhaust velocity , and neglecting fuel flow, is:[67]

And for a rocket:[68]

In addition to propulsive efficiency, another factor is cycle efficiency; a jet engine is a form of heat engine. Heat engine efficiency is determined by the ratio of temperatures reached in the engine to that exhausted at the nozzle. This has improved constantly over time as new materials have been introduced to allow higher maximum cycle temperatures. For example, composite materials, combining metals with ceramics, have been developed for HP turbine blades, which run at the maximum cycle temperature.[69] The efficiency is also limited by the overall pressure ratio that can be achieved. Cycle efficiency is highest in rocket engines (~60+%), as they can achieve extremely high combustion temperatures. Cycle efficiency in turbojet and similar is nearer to 30%, due to much lower peak cycle temperatures.

The combustion efficiency of most aircraft gas turbine engines at sea level takeoff conditions is almost 100%. It decreases nonlinearly to 98% at altitude cruise conditions. Air-fuel ratio ranges from 50:1 to 130:1. For any type of combustion chamber there is a rich and weak limit to the air-fuel ratio, beyond which the flame is extinguished. The range of air-fuel ratio between the rich and weak limits is reduced with an increase of air velocity. If the increasing air mass flow reduces the fuel ratio below certain value, flame extinction occurs.[70]

Consumption of fuel or propellant

A closely related (but different) concept to energy efficiency is the rate of consumption of propellant mass. Propellant consumption in jet engines is measured by Specific Fuel Consumption, Specific impulse or Effective exhaust velocity. They all measure the same thing. Specific impulse and effective exhaust velocity are strictly proportional, whereas specific fuel consumption is inversely proportional to the others.

For airbreathing engines such as turbojets, energy efficiency and propellant (fuel) efficiency are much the same thing, since the propellant is a fuel and the source of energy. In rocketry, the propellant is also the exhaust, and this means that a high energy propellant gives better propellant efficiency but can in some cases actually give lower energy efficiency.

It can be seen in the table (just below) that the subsonic turbofans such as General Electric's CF6 turbofan use a lot less fuel to generate thrust for a second than did the Concorde's Rolls-Royce/Snecma Olympus 593 turbojet. However, since energy is force times distance and the distance per second was greater for Concorde, the actual power generated by the engine for the same amount of fuel was higher for Concorde at Mach 2 than the CF6. Thus, the Concorde's engines were more efficient in terms of energy per mile.

| Rocket engines in vacuum | |||||||

|---|---|---|---|---|---|---|---|

| Model | Type | First run |

Application | TSFC | Isp (by weight) | Isp (by mass) | |

| lb/lbf·h | g/kN·s | s | m/s | ||||

| Avio P80 | solid fuel | 2006 | Vega stage 1 | 13 | 360 | 280 | 2700 |

| Avio Zefiro 23 | solid fuel | 2006 | Vega stage 2 | 12.52 | 354.7 | 287.5 | 2819 |

| Avio Zefiro 9A | solid fuel | 2008 | Vega stage 3 | 12.20 | 345.4 | 295.2 | 2895 |

| Merlin 1D | liquid fuel | 2013 | Falcon 9 | 12 | 330 | 310 | 3000 |

| RD-843 | liquid fuel | Vega upper stage | 11.41 | 323.2 | 315.5 | 3094 | |

| Kuznetsov NK-33 | liquid fuel | 1970s | N-1F, Soyuz-2-1v stage 1 | 10.9 | 308 | 331[71] | 3250 |

| NPO Energomash RD-171M | liquid fuel | Zenit-2M, -3SL, -3SLB, -3F stage 1 | 10.7 | 303 | 337 | 3300 | |

| LE-7A | cryogenic | H-IIA, H-IIB stage 1 | 8.22 | 233 | 438 | 4300 | |

| Snecma HM-7B | cryogenic | Ariane 2, 3, 4, 5 ECA upper stage | 8.097 | 229.4 | 444.6 | 4360 | |

| LE-5B-2 | cryogenic | H-IIA, H-IIB upper stage | 8.05 | 228 | 447 | 4380 | |

| Aerojet Rocketdyne RS-25 | cryogenic | 1981 | Space Shuttle, SLS stage 1 | 7.95 | 225 | 453[72] | 4440 |

| Aerojet Rocketdyne RL-10B-2 | cryogenic | Delta III, Delta IV, SLS upper stage | 7.734 | 219.1 | 465.5 | 4565 | |

| NERVA NRX A6 | nuclear | 1967 | 869 | ||||

| Jet engines with Reheat, static, sea level | |||||||

|---|---|---|---|---|---|---|---|

| Model | Type | First run |

Application | TSFC | Isp (by weight) | Isp (by mass) | |

| lb/lbf·h | g/kN·s | s | m/s | ||||

| Turbo-Union RB.199 | turbofan | Tornado | 2.5[73] | 70.8 | 1440 | 14120 | |

| GE F101-GE-102 | turbofan | 1970s | B-1B | 2.46 | 70 | 1460 | 14400 |

| Tumansky R-25-300 | turbojet | MIG-21bis | 2.206[73] | 62.5 | 1632 | 16000 | |

| GE J85-GE-21 | turbojet | F-5E/F | 2.13[73] | 60.3 | 1690 | 16570 | |

| GE F110-GE-132 | turbofan | F-16E/F | 2.09[73] | 59.2 | 1722 | 16890 | |

| Honeywell/ITEC F125 | turbofan | F-CK-1 | 2.06[73] | 58.4 | 1748 | 17140 | |

| Snecma M53-P2 | turbofan | Mirage 2000C/D/N | 2.05[73] | 58.1 | 1756 | 17220 | |

| Snecma Atar 09C | turbojet | Mirage III | 2.03[73] | 57.5 | 1770 | 17400 | |

| Snecma Atar 09K-50 | turbojet | Mirage IV, 50, F1 | 1.991[73] | 56.4 | 1808 | 17730 | |

| GE J79-GE-15 | turbojet | F-4E/EJ/F/G, RF-4E | 1.965 | 55.7 | 1832 | 17970 | |

| Saturn AL-31F | turbofan | Su-27/P/K | 1.96[74] | 55.5 | 1837 | 18010 | |

| GE F110-GE-129 | turbofan | F-16C/D, F-15EX | 1.9[73] | 53.8 | 1895 | 18580 | |

| Soloviev D-30F6 | turbofan | MiG-31, S-37/Su-47 | 1.863[73] | 52.8 | 1932 | 18950 | |

| Lyulka AL-21F-3 | turbojet | Su-17, Su-22 | 1.86[73] | 52.7 | 1935 | 18980 | |

| Klimov RD-33 | turbofan | 1974 | MiG-29 | 1.85 | 52.4 | 1946 | 19080 |

| Saturn AL-41F-1S | turbofan | Su-35S/T-10BM | 1.819 | 51.5 | 1979 | 19410 | |

| Volvo RM12 | turbofan | 1978 | Gripen A/B/C/D | 1.78[73] | 50.4 | 2022 | 19830 |

| GE F404-GE-402 | turbofan | F/A-18C/D | 1.74[73] | 49 | 2070 | 20300 | |

| Kuznetsov NK-32 | turbofan | 1980 | Tu-144LL, Tu-160 | 1.7 | 48 | 2100 | 21000 |

| Snecma M88-2 | turbofan | 1989 | Rafale | 1.663 | 47.11 | 2165 | 21230 |

| Eurojet EJ200 | turbofan | 1991 | Eurofighter | 1.66–1.73 | 47–49[75] | 2080–2170 | 20400–21300 |

| Dry jet engines, static, sea level | |||||||

|---|---|---|---|---|---|---|---|

| Model | Type | First run |

Application | TSFC | Isp (by weight) | Isp (by mass) | |

| lb/lbf·h | g/kN·s | s | m/s | ||||

| GE J85-GE-21 | turbojet | F-5E/F | 1.24[73] | 35.1 | 2900 | 28500 | |

| Snecma Atar 09C | turbojet | Mirage III | 1.01[73] | 28.6 | 3560 | 35000 | |

| Snecma Atar 09K-50 | turbojet | Mirage IV, 50, F1 | 0.981[73] | 27.8 | 3670 | 36000 | |

| Snecma Atar 08K-50 | turbojet | Super Étendard | 0.971[73] | 27.5 | 3710 | 36400 | |

| Tumansky R-25-300 | turbojet | MIG-21bis | 0.961[73] | 27.2 | 3750 | 36700 | |

| Lyulka AL-21F-3 | turbojet | Su-17, Su-22 | 0.86 | 24.4 | 4190 | 41100 | |

| GE J79-GE-15 | turbojet | F-4E/EJ/F/G, RF-4E | 0.85 | 24.1 | 4240 | 41500 | |

| Snecma M53-P2 | turbofan | Mirage 2000C/D/N | 0.85[73] | 24.1 | 4240 | 41500 | |

| Volvo RM12 | turbofan | 1978 | Gripen A/B/C/D | 0.824[73] | 23.3 | 4370 | 42800 |

| RR Turbomeca Adour | turbofan | 1999 | Jaguar retrofit | 0.81 | 23 | 4400 | 44000 |

| Honeywell/ITEC F124 | turbofan | 1979 | L-159, X-45 | 0.81[73] | 22.9 | 4440 | 43600 |

| Honeywell/ITEC F125 | turbofan | F-CK-1 | 0.8[73] | 22.7 | 4500 | 44100 | |

| PW J52-P-408 | turbojet | A-4M/N, TA-4KU, EA-6B | 0.79 | 22.4 | 4560 | 44700 | |

| Saturn AL-41F-1S | turbofan | Su-35S/T-10BM | 0.79 | 22.4 | 4560 | 44700 | |

| Snecma M88-2 | turbofan | 1989 | Rafale | 0.782 | 22.14 | 4600 | 45100 |

| Klimov RD-33 | turbofan | 1974 | MiG-29 | 0.77 | 21.8 | 4680 | 45800 |

| RR Pegasus 11-61 | turbofan | AV-8B+ | 0.76 | 21.5 | 4740 | 46500 | |

| Eurojet EJ200 | turbofan | 1991 | Eurofighter | 0.74–0.81 | 21–23[75] | 4400–4900 | 44000–48000 |

| GE F414-GE-400 | turbofan | 1993 | F/A-18E/F | 0.724[76] | 20.5 | 4970 | 48800 |

| Kuznetsov NK-32 | turbofan | 1980 | Tu-144LL, Tu-160 | 0.72-0.73 | 20–21 | 4900–5000 | 48000–49000 |

| Soloviev D-30F6 | turbofan | MiG-31, S-37/Su-47 | 0.716[73] | 20.3 | 5030 | 49300 | |

| Snecma Larzac | turbofan | 1972 | Alpha Jet | 0.716 | 20.3 | 5030 | 49300 |

| IHI F3 | turbofan | 1981 | Kawasaki T-4 | 0.7 | 19.8 | 5140 | 50400 |

| Saturn AL-31F | turbofan | Su-27 /P/K | 0.666-0.78[74][76] | 18.9–22.1 | 4620–5410 | 45300–53000 | |

| RR Spey RB.168 | turbofan | AMX | 0.66[73] | 18.7 | 5450 | 53500 | |

| GE F110-GE-129 | turbofan | F-16C/D, F-15 | 0.64[76] | 18 | 5600 | 55000 | |

| GE F110-GE-132 | turbofan | F-16E/F | 0.64[76] | 18 | 5600 | 55000 | |

| Turbo-Union RB.199 | turbofan | Tornado ECR | 0.637[73] | 18.0 | 5650 | 55400 | |

| PW F119-PW-100 | turbofan | 1992 | F-22 | 0.61[76] | 17.3 | 5900 | 57900 |

| Turbo-Union RB.199 | turbofan | Tornado | 0.598[73] | 16.9 | 6020 | 59000 | |

| GE F101-GE-102 | turbofan | 1970s | B-1B | 0.562 | 15.9 | 6410 | 62800 |

| PW TF33-P-3 | turbofan | B-52H, NB-52H | 0.52[73] | 14.7 | 6920 | 67900 | |

| RR AE 3007H | turbofan | RQ-4, MQ-4C | 0.39[73] | 11.0 | 9200 | 91000 | |

| GE F118-GE-100 | turbofan | 1980s | B-2 | 0.375[73] | 10.6 | 9600 | 94000 |

| GE F118-GE-101 | turbofan | 1980s | U-2S | 0.375[73] | 10.6 | 9600 | 94000 |

| General Electric CF6-50C2 | turbofan | A300, DC-10-30 | 0.371[73] | 10.5 | 9700 | 95000 | |

| GE TF34-GE-100 | turbofan | A-10 | 0.37[73] | 10.5 | 9700 | 95000 | |

| CFM CFM56-2B1 | turbofan | C-135, RC-135 | 0.36[77] | 10 | 10000 | 98000 | |

| Progress D-18T | turbofan | 1980 | An-124, An-225 | 0.345 | 9.8 | 10400 | 102000 |

| PW F117-PW-100 | turbofan | C-17 | 0.34[78] | 9.6 | 10600 | 104000 | |

| PW PW2040 | turbofan | Boeing 757 | 0.33[78] | 9.3 | 10900 | 107000 | |

| CFM CFM56-3C1 | turbofan | 737 Classic | 0.33 | 9.3 | 11000 | 110000 | |

| GE CF6-80C2 | turbofan | 744, 767, MD-11, A300/310, C-5M | 0.307-0.344 | 8.7–9.7 | 10500–11700 | 103000–115000 | |

| EA GP7270 | turbofan | A380-861 | 0.299[76] | 8.5 | 12000 | 118000 | |

| GE GE90-85B | turbofan | 777-200/200ER/300 | 0.298[76] | 8.44 | 12080 | 118500 | |

| GE GE90-94B | turbofan | 777-200/200ER/300 | 0.2974[76] | 8.42 | 12100 | 118700 | |

| RR Trent 970-84 | turbofan | 2003 | A380-841 | 0.295[76] | 8.36 | 12200 | 119700 |

| GE GEnx-1B70 | turbofan | 787-8 | 0.2845[76] | 8.06 | 12650 | 124100 | |

| RR Trent 1000C | turbofan | 2006 | 787-9 | 0.273[76] | 7.7 | 13200 | 129000 |

| Jet engines, cruise | |||||||

|---|---|---|---|---|---|---|---|

| Model | Type | First run |

Application | TSFC | Isp (by weight) | Isp (by mass) | |

| lb/lbf·h | g/kN·s | s | m/s | ||||

| Ramjet | Mach 1 | 4.5 | 130 | 800 | 7800 | ||

| J-58 | turbojet | 1958 | SR-71 at Mach 3.2 (Reheat) | 1.9[73] | 53.8 | 1895 | 18580 |

| RR/Snecma Olympus | turbojet | 1966 | Concorde at Mach 2 | 1.195[79] | 33.8 | 3010 | 29500 |

| PW JT8D-9 | turbofan | 737 Original | 0.8[80] | 22.7 | 4500 | 44100 | |

| Honeywell ALF502R-5 | GTF | BAe 146 | 0.72[78] | 20.4 | 5000 | 49000 | |

| Soloviev D-30KP-2 | turbofan | Il-76, Il-78 | 0.715 | 20.3 | 5030 | 49400 | |

| Soloviev D-30KU-154 | turbofan | Tu-154M | 0.705 | 20.0 | 5110 | 50100 | |

| RR Tay RB.183 | turbofan | 1984 | Fokker 70, Fokker 100 | 0.69 | 19.5 | 5220 | 51200 |

| GE CF34-3 | turbofan | 1982 | Challenger, CRJ100/200 | 0.69 | 19.5 | 5220 | 51200 |

| GE CF34-8E | turbofan | E170/175 | 0.68 | 19.3 | 5290 | 51900 | |

| Honeywell TFE731-60 | GTF | Falcon 900 | 0.679[81] | 19.2 | 5300 | 52000 | |

| CFM CFM56-2C1 | turbofan | DC-8 Super 70 | 0.671[78] | 19.0 | 5370 | 52600 | |

| GE CF34-8C | turbofan | CRJ700/900/1000 | 0.67-0.68 | 19–19 | 5300–5400 | 52000–53000 | |

| CFM CFM56-3C1 | turbofan | 737 Classic | 0.667 | 18.9 | 5400 | 52900 | |

| CFM CFM56-2A2 | turbofan | 1974 | E-3, E-6 | 0.66[77] | 18.7 | 5450 | 53500 |

| RR BR725 | turbofan | 2008 | G650/ER | 0.657 | 18.6 | 5480 | 53700 |

| CFM CFM56-2B1 | turbofan | C-135, RC-135 | 0.65[77] | 18.4 | 5540 | 54300 | |

| GE CF34-10A | turbofan | ARJ21 | 0.65 | 18.4 | 5540 | 54300 | |

| CFE CFE738-1-1B | turbofan | 1990 | Falcon 2000 | 0.645[78] | 18.3 | 5580 | 54700 |

| RR BR710 | turbofan | 1995 | G. V/G550, Global Express | 0.64 | 18 | 5600 | 55000 |

| GE CF34-10E | turbofan | E190/195 | 0.64 | 18 | 5600 | 55000 | |

| General Electric CF6-50C2 | turbofan | A300B2/B4/C4/F4, DC-10-30 | 0.63[78] | 17.8 | 5710 | 56000 | |

| PowerJet SaM146 | turbofan | Superjet LR | 0.629 | 17.8 | 5720 | 56100 | |

| CFM CFM56-7B24 | turbofan | 737 NG | 0.627[78] | 17.8 | 5740 | 56300 | |

| RR BR715 | turbofan | 1997 | 717 | 0.62 | 17.6 | 5810 | 56900 |

| GE CF6-80C2-B1F | turbofan | 747-400 | 0.605[79] | 17.1 | 5950 | 58400 | |

| CFM CFM56-5A1 | turbofan | A320 | 0.596 | 16.9 | 6040 | 59200 | |

| Aviadvigatel PS-90A1 | turbofan | Il-96-400 | 0.595 | 16.9 | 6050 | 59300 | |

| PW PW2040 | turbofan | 757-200 | 0.582[78] | 16.5 | 6190 | 60700 | |

| PW PW4098 | turbofan | 777-300 | 0.581[78] | 16.5 | 6200 | 60800 | |

| GE CF6-80C2-B2 | turbofan | 767 | 0.576[78] | 16.3 | 6250 | 61300 | |

| IAE V2525-D5 | turbofan | MD-90 | 0.574[82] | 16.3 | 6270 | 61500 | |

| IAE V2533-A5 | turbofan | A321-231 | 0.574[82] | 16.3 | 6270 | 61500 | |

| RR Trent 700 | turbofan | 1992 | A330 | 0.562[83] | 15.9 | 6410 | 62800 |

| RR Trent 800 | turbofan | 1993 | 777-200/200ER/300 | 0.560[83] | 15.9 | 6430 | 63000 |

| Progress D-18T | turbofan | 1980 | An-124, An-225 | 0.546 | 15.5 | 6590 | 64700 |

| CFM CFM56-5B4 | turbofan | A320-214 | 0.545 | 15.4 | 6610 | 64800 | |

| CFM CFM56-5C2 | turbofan | A340-211 | 0.545 | 15.4 | 6610 | 64800 | |

| RR Trent 500 | turbofan | 1999 | A340-500/600 | 0.542[83] | 15.4 | 6640 | 65100 |

| CFM LEAP-1B | turbofan | 2014 | 737 MAX | 0.53-0.56 | 15–16 | 6400–6800 | 63000–67000 |

| Aviadvigatel PD-14 | turbofan | 2014 | MC-21-310 | 0.526 | 14.9 | 6840 | 67100 |

| RR Trent 900 | turbofan | 2003 | A380 | 0.522[83] | 14.8 | 6900 | 67600 |

| GE GE90-85B | turbofan | 777-200/200ER | 0.52[78][84] | 14.7 | 6920 | 67900 | |

| GE GEnx-1B76 | turbofan | 2006 | 787-10 | 0.512[80] | 14.5 | 7030 | 69000 |

| PW PW1400G | GTF | MC-21 | 0.51[85] | 14.4 | 7100 | 69000 | |

| CFM LEAP-1C | turbofan | 2013 | C919 | 0.51 | 14.4 | 7100 | 69000 |

| CFM LEAP-1A | turbofan | 2013 | A320neo family | 0.51[85] | 14.4 | 7100 | 69000 |

| RR Trent 7000 | turbofan | 2015 | A330neo | 0.506[a] | 14.3 | 7110 | 69800 |

| RR Trent 1000 | turbofan | 2006 | 787 | 0.506[b] | 14.3 | 7110 | 69800 |

| RR Trent XWB-97 | turbofan | 2014 | A350-1000 | 0.478[c] | 13.5 | 7530 | 73900 |

| PW 1127G | GTF | 2012 | A320neo | 0.463[80] | 13.1 | 7780 | 76300 |

Thrust-to-weight ratio

The thrust-to-weight ratio of jet engines with similar configurations varies with scale, but is mostly a function of engine construction technology. For a given engine, the lighter the engine, the better the thrust-to-weight is, the less fuel is used to compensate for drag due to the lift needed to carry the engine weight, or to accelerate the mass of the engine.

As can be seen in the following table, rocket engines generally achieve much higher thrust-to-weight ratios than duct engines such as turbojet and turbofan engines. This is primarily because rockets almost universally use dense liquid or solid reaction mass which gives a much smaller volume and hence the pressurization system that supplies the nozzle is much smaller and lighter for the same performance. Duct engines have to deal with air which is two to three orders of magnitude less dense and this gives pressures over much larger areas, which in turn results in more engineering materials being needed to hold the engine together and for the air compressor.

| Jet or rocket engine | Mass | Thrust | Thrust-to- weight ratio | ||

|---|---|---|---|---|---|

| (kg) | (lb) | (kN) | (lbf) | ||

| RD-0410 nuclear rocket engine[86][87] | 2,000 | 4,400 | 35.2 | 7,900 | 1.8 |

| J58 jet engine (SR-71 Blackbird)[88][89] | 2,722 | 6,001 | 150 | 34,000 | 5.2 |

| Rolls-Royce/Snecma Olympus 593 turbojet with reheat (Concorde)[90] |

3,175 | 7,000 | 169.2 | 38,000 | 5.4 |

| Pratt & Whitney F119[91] | 1,800 | 3,900 | 91 | 20,500 | 7.95 |

| RD-0750 rocket engine, three-propellant mode[92] | 4,621 | 10,188 | 1,413 | 318,000 | 31.2 |

| RD-0146 rocket engine[93] | 260 | 570 | 98 | 22,000 | 38.4 |

| Rocketdyne RS-25 rocket engine[94] | 3,177 | 7,004 | 2,278 | 512,000 | 73.1 |

| RD-180 rocket engine[95] | 5,393 | 11,890 | 4,152 | 933,000 | 78.5 |

| RD-170 rocket engine | 9,750 | 21,500 | 7,887 | 1,773,000 | 82.5 |

| F-1 (Saturn V first stage)[96] | 8,391 | 18,499 | 7,740.5 | 1,740,100 | 94.1 |

| NK-33 rocket engine[97] | 1,222 | 2,694 | 1,638 | 368,000 | 136.7 |

| Merlin 1D rocket engine, full-thrust version | 467 | 1,030 | 825 | 185,000 | 180.1 |

Comparison of types

Propeller engines handle larger air mass flows, and give them smaller acceleration, than jet engines. Since the increase in air speed is small, at high flight speeds the thrust available to propeller-driven aeroplanes is small. However, at low speeds, these engines benefit from relatively high propulsive efficiency.

On the other hand, turbojets accelerate a much smaller mass flow of intake air and burned fuel, but they then reject it at very high speed. When a de Laval nozzle is used to accelerate a hot engine exhaust, the outlet velocity may be locally supersonic. Turbojets are particularly suitable for aircraft travelling at very high speeds.

Turbofans have a mixed exhaust consisting of the bypass air and the hot combustion product gas from the core engine. The amount of air that bypasses the core engine compared to the amount flowing into the engine determines what is called a turbofan's bypass ratio (BPR).

While a turbojet engine uses all of the engine's output to produce thrust in the form of a hot high-velocity exhaust gas jet, a turbofan's cool low-velocity bypass air yields between 30% and 70% of the total thrust produced by a turbofan system.[98]

The net thrust (FN) generated by a turbofan is:[99]

where:

| ṁ e | = the mass rate of hot combustion exhaust flow from the core engine |

| ṁo | = the mass rate of total air flow entering the turbofan = ṁc + ṁf |

| ṁc | = the mass rate of intake air that flows to the core engine |

| ṁf | = the mass rate of intake air that bypasses the core engine |

| vf | = the velocity of the air flow bypassed around the core engine |

| ve | = the velocity of the hot exhaust gas from the core engine |

| vo | = the velocity of the total air intake = the true airspeed of the aircraft |

| BPR | = Bypass Ratio |

Rocket engines have extremely high exhaust velocity and thus are best suited for high speeds (hypersonic) and great altitudes. At any given throttle, the thrust and efficiency of a rocket motor improves slightly with increasing altitude (because the back-pressure falls thus increasing net thrust at the nozzle exit plane), whereas with a turbojet (or turbofan) the falling density of the air entering the intake (and the hot gases leaving the nozzle) causes the net thrust to decrease with increasing altitude. Rocket engines are more efficient than even scramjets above roughly Mach 15.[100]

Altitude and speed

With the exception of scramjets, jet engines, deprived of their inlet systems can only accept air at around half the speed of sound. The inlet system's job for transonic and supersonic aircraft is to slow the air and perform some of the compression.

The limit on maximum altitude for engines is set by flammability- at very high altitudes the air becomes too thin to burn, or after compression, too hot. For turbojet engines altitudes of about 40 km appear to be possible, whereas for ramjet engines 55 km may be achievable. Scramjets may theoretically manage 75 km.[101] Rocket engines of course have no upper limit.

At more modest altitudes, flying faster compresses the air at the front of the engine, and this greatly heats the air. The upper limit is usually thought to be about Mach 5-8, as above about Mach 5.5, the atmospheric nitrogen tends to react due to the high temperatures at the inlet and this consumes significant energy. The exception to this is scramjets which may be able to achieve about Mach 15 or more[citation needed], as they avoid slowing the air, and rockets again have no particular speed limit.

Noise

The noise emitted by a jet engine has many sources. These include, in the case of gas turbine engines, the fan, compressor, combustor, turbine and propelling jet/s.[102]

The propelling jet produces jet noise which is caused by the violent mixing action of the high speed jet with the surrounding air. In the subsonic case the noise is produced by eddies and in the supersonic case by Mach waves.[103] The sound power radiated from a jet varies with the jet velocity raised to the eighth power for velocities up to 2,000 ft/sec and varies with the velocity cubed above 2,000 ft/sec.[104] Thus, the lower speed exhaust jets emitted from engines such as high bypass turbofans are the quietest, whereas the fastest jets, such as rockets, turbojets, and ramjets, are the loudest. For commercial jet aircraft the jet noise has reduced from the turbojet through bypass engines to turbofans as a result of a progressive reduction in propelling jet velocities. For example, the JT8D, a bypass engine, has a jet velocity of 1450 ft/sec whereas the JT9D, a turbofan, has jet velocities of 885 ft/sec (cold) and 1190 ft/sec (hot).[105]

The advent of the turbofan replaced the very distinctive jet noise with another sound known as "buzz saw" noise. The origin is the shockwaves originating at the supersonic fan blades at takeoff thrust.[106]

See also

- Air turboramjet

- Balancing machine

- Components of jet engines

- Gas turbine

- Jet engine performance

- Jetboat

- Pulsejet

- Rocket engine nozzle

- Rocket turbine engine

- Spacecraft propulsion

- Thrust reversal

- Turbofan

- Turbojet

- Turbojet development at the RAE

- Turboprop

- Turboshaft

- Variable cycle engine

- Water injection (engine)

References

Notes

- ^ "Flight Operations Briefing Notes - Supplementary Techniques : Handling Engine Malfunctions" (PDF). Airbus.

- ^ propeller efficiency Archived 2008-05-25 at the Wayback Machine

- ^ "Centenary of the First Gas Turbine to Give Net Power Output: A Tribute to Ægidius Elling". The American Society of Mechanical Engineers. 14 June 2004. Retrieved 26 April 2015.

- ^ Maxime Guillaume, "Propulseur par réaction sur l'air," French patent no. 534,801 (filed: 3 May 1921; issued: 13 January 1922). Available on-line (in French) at: http://v3.espacenet.com/origdoc?DB=EPODOC&IDX=FR534801&F=0&QPN=FR534801 .

- ^ "Chasing the Sun - Frank Whittle". PBS. Retrieved 2010-03-26.

- ^ "History - Frank Whittle (1907 - 1996)". BBC. Retrieved 2010-03-26.

- ^ Frank Whittle, "Improvements relating to the propulsion of aircraft and other vehicles," British patent no. 347,206 (filed: 16 January 1930). Available on-line at: http://v3.espacenet.com/origdoc?DB=EPODOC&IDX=GB347206&F=0&QPN=GB347206 .

- ^ The History of the Jet Engine - Sir Frank Whittle - Hans Von Ohain Ohain said that he had not read Whittle's patent and Whittle believed him. (Frank Whittle 1907-1996).

- ^ Warsitz, Lutz: THE FIRST JET PILOT - The Story of German Test Pilot Erich Warsitz (p. 125), Pen and Sword Books Ltd., England, 2009

- ^ "ch10-3". Hq.nasa.gov. Retrieved 2010-03-26.

- ^ Mattingly, Jack D. (2006). Elements of Propulsion: Gas Turbines and Rockets. AIAA Education Series. Reston, VA: American Institute of Aeronautics and Astronautics. p. 6. ISBN 1-56347-779-3.

- ^ Mattingly, pp. 6-8

- ^ Mattingly, pp. 9-11

- ^ a b Mattingly, p. 12

- ^ "Trent XWB infographic". Retrieved 2015-10-15.

- ^ Hill & Peterson 1992, pp. 190.

- ^ Mattingly 2006, pp. 12–14.

- ^ Sweetman, Bill (2005). The Short, Happy Life of the Prop-fan. Air & Space Magazine. 1 September 2005.

- ^ a b Mattingly, p. 14

- ^ *Flack, Ronald D. (2005). Fundamentals of Jet Propulsion with Applications. Cambridge Aerospace Series. New York, NY: Cambridge University Press. p. 16. ISBN 978-0-521-81983-1.

- ^ Benson, Tom. Ramjet Propulsion. NASA Glenn Research Center. Updated: 11 July 2008. Retrieved: 23 July 2010.

- ^ Heiser, William H.; Pratt, David T. (1994). Hypersonic Airbreathing Propulsion. AIAA Education Series. Washington, D.C.: American Institute of Aeronautics and Astronautics. pp. 23–4. ISBN 1-56347-035-7.

- ^ X-51 Waverider makes historic hypersonic flight. United States Air Force. 26 May 2010. Retrieved: 23 July 2010.

- ^ "Rocket Thrust Equation". Grc.nasa.gov. 2008-07-11. Retrieved 2010-03-26.

- ^ Jet Propulsion for Aerospace Applications Second Edition 1964, Hesse and Mumford, Pitman Publishing Corporation, Library of Congress Catalog Card Number 64-18757,p.48

- ^ "Jet Propulsion" Nicholas Cumpsty 1997, Cambridge University Press, ISBN 0 521 59674 2, p.197

- ^ http://www.enginehistory.org/Convention/convention1.shtml SR-71 overview part2 Fig.17

- ^ AEHS Conventions 1

- ^ http://arc.aiaa.org/doi/abs/10.2514/6.2004-3923 Fig.11

- ^ Design For Air Combat" Ray Whitford Jane's Publishing Company Ltd. 1987, ISBN 0 7106 0426 2, p.203

- ^ "Jet Propulsion" Nicholas Cumpsty 1997, Cambridge University Press, ISBN 0 521 59674 2, p.141

- ^ "The Avro Type 698 Vulcan" David W. Fildes, Pen & Sword Aviation 2012, ISBN 978 1 84884 284 7, p.301, Gas Floow Diagram

- ^ The Aircraft Gas Turbine and its operation December 1982, P&W Oper. Instr. 200, United Technologies Pratt & Whitney

- ^ Jet Propulsion For Aerospace Applications" Second Edition 1964, Pitman Publishing Corp., Library of Congress Catalog card Number 64-18757, p.262

- ^ flight | flight pdf | pdf archive | 1957 | 1484 | Flight Archive

- ^ goblin | lb | flight | 1946 | 0353 | Flight Archive

- ^ https://www.flightglobal.com/pdfarchive/view/1969/1969%20-%203201.html

- ^ https://www.google.com/patents/US3675418

- ^ "747 Creating the world's first jumbo jet and other adventures from a life in aviation" Joe Sutter, Smithsonian Books, ISBN 978-0-06-088241-9, p.185-188

- ^ de havilland | 1947 | 0202 | Flight Archive

- ^ rolls-royce avon | 1955 | 1778 | Flight Archive

- ^ a b c Nicholas Cumpsty (2003). Jet Propulsion (2nd ed.). Cambridge University Press. ISBN 0-521-54144-1.

- ^ 16.Unified: Thermodynamics and Propulsion, Prof. Z. S. Spakovszky. Scroll down to "Performance of Turbojet Engines, Section 11.6.4. (Obtained from the website of the Massachusetts Institute of Technology)

- ^ "Tupolev Tu-22 Blinder" Sergey Burdin & Alan E Dawes 2006, Pen & Sword Aviation, ISBN 1 84415 241 3, p.130

- ^ atar | snecma | pressure ratio | 1960 | 0376 | Flight Archive

- ^ Gas turbine aero-thermodynamics : with special reference to aircraft propulsion Sir Frank Whittle, Pergamon Press Ltd. 1981, ISBN 9780080267197. p.220

- ^ gas turbines | flight boosting | boosting gas | 1952 | 0092 | Flight Archive

- ^ Flightdeck Friday: The YF4H-1 Phantom II – Operations Skyburner and Sageburner | Steeljaw Scribe

- ^ "Jet Propulsion For Aerospace Applications" Second Edition 1964, Hesse and Mumford, Pitman Publishing Corporation, Library of Congress Catalog Card Number 64-18757, p.375

- ^ "F-12 Series Aircraft Propulsion System Performance and Development, David H. Campbell, J. Aircraft Vol.II, No.11, November 1974, p.672

- ^ "Water injection pre-compressor cooling assist space access" Mehta, Huynh, Hagseth, The Aeronautical Journal, February 2015, Volume 19, Number 1212, p.147

- ^ http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19970019923.pdf

- ^ Gas Turbine Performance Deterioration, Meher-Homji, Chaker and Motiwala, Proceedings Of The 30th Turbomachinery Symposium, ASME, p.139-175

- ^ "Jet Propulsion' Nicholas Cumpsty, Cambridge University Press 2001, ISBN 0 521 59674 2, Figure 9.1 shows losses with incidence

- ^ "Jet Propulsion' Nicholas Cumpsty, Cambridge University Press 2001, ISBN 0 521 59674 2, p.35

- ^ Gas Turbine Performance' Second Edition, Walsh and Fletcher, Blackwell Science Ltd., ISBN 0-632-06434-X, p.64

- ^ "Jet Propulsion' Nicholas Cumpsty, Cambridge University Press 2001, ISBN 0 521 59674 2, p.26

- ^ http://www.enginehistory.org/Convention/2013/HowInletsWork8-19-13.pdf Figure 22 Inlet Pressure Recovery

- ^ B-70 Aircraft Study Final Report Volume IV, SD 72-SH-0003 April 1972, L.J.Taube, Space Division North American Rockwell, p.IV-11

- ^ "Design For Air Combat" ray Whitford, Jane's Publishing Company Limited 1987, ISBN 0 7106 0426 2, p.203 'Area ratio for optimum expansion'

- ^ Gas Turbine Performance' Second Edition, Walsh and Fletcher, Blackwell Science Ltd., ISBN 0-632-06535-4, p.305

- ^ Aero engine development for the future, Bennett, Proc Instn Mech Engrs Vol 197A, IMechE July 1983, Fig.5 Overall spectrum of engine losses

- ^ Gas Turbine Theory Second Edition, Cohen, Rogers and Saravanamuttoo, Longman Group Limited 1972, ISBN 0 582 44927 8, p.

- ^ Aero engine development for the future, Bennett, Proc Instn Mech Engrs Vol 197A, IMechE July 1983, p.150

- ^ Note: In Newtonian mechanics kinetic energy is frame dependent. The kinetic energy is easiest to calculate when the speed is measured in the center of mass frame of the vehicle and (less obviously) its reaction mass / air (i.e., the stationary frame before takeoff begins.

- ^ "Jet Propulsion for Aerospace Applications' Second Edition, Hesse and Mumford, Piman Publishing Corporation 1964, Library of Concress Catalog Number 64-18757, p.39

- ^ "Jet Propulsion" Nicholas Cumpsty ISBN 0 521 59674 2 p24

- ^ George P. Sutton and Oscar Biblarz (2001). Rocket Propulsion Elements (7th ed.). John Wiley & Sons. pp. 37–38. ISBN 0-471-32642-9.

- ^ S. Walston, A. Cetel, R. MacKay, K. O’Hara, D. Duhl, and R. Dreshfield (2004). Joint Development of a Fourth Generation Single Crystal Superalloy. NASA TM—2004-213062. December 2004. Retrieved: 16 June 2010.

- ^ Claire Soares, "Gas Turbines: A Handbook of Air, Land and Sea Applications", pp. 140.

- ^ "NK33". Encyclopedia Astronautica.

- ^ "SSME". Encyclopedia Astronautica.

- ^ a b c d e f g h i j k l m n o p q r s t u v w x y z aa ab ac ad ae af ag Nathan Meier (21 Mar 2005). "Military Turbojet/Turbofan Specifications". Archived from the original on 11 February 2021.

- ^ a b "Flanker". AIR International Magazine. 23 March 2017.

- ^ a b "EJ200 turbofan engine" (PDF). MTU Aero Engines. April 2016.

- ^ a b c d e f g h i j k Kottas, Angelos T.; Bozoudis, Michail N.; Madas, Michael A. "Turbofan Aero-Engine Efficiency Evaluation: An Integrated Approach Using VSBM Two-Stage Network DEA" (PDF). doi:10.1016/j.omega.2019.102167.

- ^ a b c Élodie Roux (2007). "Turbofan and Turbojet Engines: Database Handbook" (PDF). p. 126. ISBN 9782952938013.

- ^ a b c d e f g h i j k Nathan Meier (3 Apr 2005). "Civil Turbojet/Turbofan Specifications". Archived from the original on 17 August 2021.

- ^ a b Ilan Kroo. "Data on Large Turbofan Engines". Aircraft Design: Synthesis and Analysis. Stanford University. Archived from the original on 11 January 2017.

- ^ a b c David Kalwar (2015). "Integration of turbofan engines into the preliminary design of a high-capacity short-and medium-haul passenger aircraft and fuel efficiency analysis with a further developed parametric aircraft design software" (PDF).

- ^ "Purdue School of Aeronautics and Astronautics Propulsion Web Page - TFE731".

- ^ a b Lloyd R. Jenkinson & al. (30 Jul 1999). "Civil Jet Aircraft Design: Engine Data File". Elsevier/Butterworth-Heinemann.

- ^ a b c d "Gas Turbine Engines" (PDF). Aviation Week. 28 January 2008. pp. 137–138.

- ^ Élodie Roux (2007). "Turbofan and Turbojet Engines: Database Handbook". ISBN 9782952938013.

- ^ a b Vladimir Karnozov (August 19, 2019). "Aviadvigatel Mulls Higher-thrust PD-14s To Replace PS-90A". AIN Online.

- ^ Wade, Mark. "RD-0410". Encyclopedia Astronautica. Retrieved 2009-09-25.

- ^ РД0410. Ядерный ракетный двигатель. Перспективные космические аппараты [RD0410. Nuclear Rocket Engine. Advanced launch vehicles]. KBKhA - Chemical Automatics Design Bureau. Archived from the original on 30 November 2010.

- ^ "Aircraft: Lockheed SR-71A Blackbird". Archived from the original on 2012-07-29. Retrieved 2010-04-16.

- ^ "Factsheets : Pratt & Whitney J58 Turbojet". National Museum of the United States Air Force. Archived from the original on 2015-04-04. Retrieved 2010-04-15.

- ^ "Rolls-Royce SNECMA Olympus - Jane's Transport News". Archived from the original on 2010-08-06. Retrieved 2009-09-25.

With afterburner, reverser and nozzle ... 3,175 kg ... Afterburner ... 169.2 kN

- ^ Military Jet Engine Acquisition, RAND, 2002.

- ^ "Конструкторское бюро химавтоматики" - Научно-исследовательский комплекс / РД0750. [«Konstruktorskoe Buro Khimavtomatiky» - Scientific-Research Complex / RD0750.]. KBKhA - Chemical Automatics Design Bureau. Archived from the original on 26 July 2011.

- ^ Wade, Mark. "RD-0146". Encyclopedia Astronautica. Retrieved 2009-09-25.

- ^ SSME

- ^ "RD-180". Retrieved 2009-09-25.

- ^ Encyclopedia Astronautica: F-1

- ^ Astronautix NK-33 entry

- ^ Federal Aviation Administration (FAA) (2004). FAA-H-8083-3B Airplane Flying Handbook Handbook (PDF). Federal Aviation Administration.

- ^ Turbofan Thrust, Glenn Research Center, National Aeronautics and Space Administration (NASA)

- ^ "Microsoft PowerPoint - KTHhigspeed08.ppt" (PDF). Retrieved 2010-03-26.

- ^ "Scramjet". Orbitalvector.com. 2002-07-30. Retrieved 2010-03-26.

- ^ "Softly, softly towards the quiet jet" Michael J. T. Smith New Scientist 19 February 1970 p350

- ^ "Silencing the sources of jet noise" Dr David Crighton New Scientist 27 July 1972 p185

- ^ "Noise" I.C. Cheeseman Flight International 16 April 1970 p639

- ^ "The Aircraft Gas Turbine Engine and its operation" United Technologies Pratt & Whitney Part No. P&W 182408 December 1982 Sea level static internal pressures and temperatures p219/220

- ^ 'Quietening a Quiet Engine- The RB211 Demonstrator Programme" M. J. T. Smith SAE paper 760897 "Intake Noise Suppression" p5

Bibliography

- Brooks, David S. (1997). Vikings at Waterloo: Wartime Work on the Whittle Jet Engine by the Rover Company. Rolls-Royce Heritage Trust. ISBN 1-872922-08-2.

- Golley, John (1997). Genesis of the Jet: Frank Whittle and the Invention of the Jet Engine. Crowood Press. ISBN 1-85310-860-X.

- Hill, Philip; Peterson, Carl (1992), Mechanics and Thermodynamics of Propulsion (2nd ed.), New York: Addison-Wesley, ISBN 0-201-14659-2

- Kerrebrock, Jack L. (1992). Aircraft Engines and Gas Turbines (2nd ed.). Cambridge, MA: The MIT Press. ISBN 978-0-262-11162-1.

External links

- Media about jet engines from Rolls-Royce

- How Stuff Works article on how a Gas Turbine Engine works

- Influence of the Jet Engine on the Aerospace Industry

- An Overview of Military Jet Engine History, Appendix B, pp. 97–120, in Military Jet Engine Acquisition (Rand Corp., 24 pgs, PDF)

- Basic jet engine tutorial (QuickTime Video)

Cite error: There are <ref group=lower-alpha> tags or {{efn}} templates on this page, but the references will not show without a {{reflist|group=lower-alpha}} template or {{notelist}} template (see the help page).