Rubber tapping

This article has multiple issues. Please help improve it or discuss these issues on the talk page. (Learn how and when to remove these messages)

|

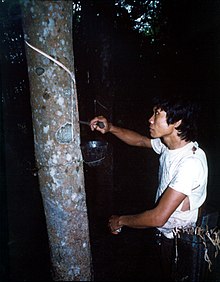

Rubber tapping is the process by which the latex is collected from a rubber tree. An incision is made in the tree's bark, which cuts through the latex vessels, from which the product then flows. Timing of the incision must be planned within the planting cycle to optimise the latex yield.

Rubber tapping is an environmentally attractive land use. Jungle rubber is essentially old secondary forest, strongly resembling the primary forest. Its species' richness is about half that of the primary forest. Michon and de Foresta (1994) found that sample jungle rubber sites contained 92 tree species, 97 lianas, and 28 epiphytes compared to 171, 89, and 63, respectively, in the primary forest, and compared to 1, 1, and 2 in monoculture estates. Thiollay (1995) estimated that jungle rubber supports about 137 bird species, against 241 in the primary forest itself. Jungle rubber is expected to resemble primary forest in its hydrological functions.[1] Monoculture rubber tree plantations have far less of an environmental impact than other crops, such as coffee or especially oil palm.

Process

Each night a rubber tapper must remove a thin layer of bark along a downward half spiral on the tree trunk. If done carefully and with skill, this tapping panel will yield latex for up to five years. Then the opposite side will be tapped, allowing this side to heal over. The spiral allows the latex to run down to a collecting cup. The work is done at night or in the early morning before the day's temperature rises,[2] so the latex will drip longer before coagulating and sealing the cut.

Depending on the final product, additional chemicals can be added to the latex cup to preserve the latex longer. Ammonia solution helps prevent natural coagulation and allows the latex to remain in its liquid state. Plastic bags containing a coagulant have replaced cups in many plantations in Malaysia. This form of latex is used as the raw material for latex concentrate, which is used for dipped rubber products or for the manufacture of ribbed smoke sheet grades.

Naturally coagulated latex, sometimes referred to as cup lump, is collected for processing into block rubbers, which are referred to as technically specified rubbers (TSRs). The serum left after latex coagulation is rich in quebrachitol, a cyclitol or cyclic polyol.

In information technology

In information technology the term 'Rubber tapping' is sometimes used as a lampoon for planned Production deployments, where the timing of the deployment is crucial. Such deployments are generally done late in the night when customer activity is minimum.

For high availability information technology services such as data centres, telecommunications, Internet service providers etc., a time period is stated in advance to the customer to prepare for any possible service disruption to bring about any change to the service. Such a disclosure is typically guaranteed as part of a service level agreement.

A maintenance window is scheduled between 02:00 AM to 06:00 AM which is the possible low traffic and customer usage time frame. As such, the IT or network engineer who is responsible in such service change and/or upgrade activity are called "Rubber Tappers"; for which they are required to wake up early in the morning to complete their deployment, testing and commissioning before sunrise.

See also

References

- ^ [1]

- ^ My unforgettable rubber tapping experience, KTemoc Kongsamkok, August 21, 2007.