Printing

| Part of a series on the |

| History of printing |

|---|

|

| Marketing |

|---|

Printing is a process for mass reproducing text and images using a master form or template. The earliest non-paper products involving printing include cylinder seals and objects such as the Cyrus Cylinder and the Cylinders of Nabonidus. The earliest known form of printing evolved from ink rubbings made on paper or cloth from texts on stone tablets, used during the sixth century.[1][a] Printing by pressing an inked image onto paper (using woodblock printing) appeared later that century.[3] Later developments in printing technology include the movable type invented by Bi Sheng around 1040 AD[4][5] and the printing press invented by Johannes Gutenberg in the 15th century. The technology of printing played a key role in the development of the Renaissance and the Scientific Revolution and laid the material basis for the modern knowledge-based economy and the spread of learning to the masses.[6]

History

Woodblock printing

Woodblock printing is a technique for printing text, images or patterns that was used widely throughout East Asia. It originated in China in antiquity as a method of printing on textiles and later on paper.[3]

In East Asia

The earliest examples of ink-squeeze rubbings and potential stone printing blocks appear in the mid-sixth century in China. A type of printing called mechanical woodblock printing on paper started during the 7th century in the Tang dynasty,[3][1] and subsequently spread throughout East Asia. Nara Japan printed the Hyakumantō Darani en masse around 770, and distributed them to temples throughout Japan. In Korea, an example of woodblock printing from the eighth century was discovered in 1966. A copy of the Buddhist Dharani Sutra called the Pure Light Dharani Sutra (Korean: 무구정광대다라니경; Hanja: 無垢淨光大陀羅尼經; RR: Mugu jeonggwang dae darani-gyeong), discovered in Gyeongju, in a Silla dynasty pagoda that was repaired in AD 751,[8] was undated but must have been created sometime before the reconstruction of the Shakyamuni Pagoda of Bulguk Temple, Kyongju Province in AD 751.[9][10][11][12][13] The document is estimated to have been created no later than AD 704.[8]

By the ninth century, printing on paper had taken off, and the first completely surviving printed book is the Diamond Sutra (British Library) of 868, uncovered from Dunhuang.[14] By the tenth century, 400,000 copies of some sutras and pictures were printed, and the Confucian classics were in print. A skilled printer could print up to 2,000 double-page sheets per day.[15]

Printing spread early to Korea and Japan, which also used Chinese logograms, but the technique was also used in Turpan and Vietnam using a number of other scripts. This technique then spread to Persia and Russia.[16] This technique was transmitted to Europe by around 1400 and was used on paper for old master prints and playing cards.[17]

In the Middle East

Block printing, called tarsh in Arabic, developed in Arabic Egypt during the ninth and tenth centuries, mostly for prayers and amulets. There is some evidence to suggest that these print blocks were made from non-wood materials, possibly tin, lead, or clay. The techniques employed are uncertain. Block printing later went out of use during the Timurid Renaissance.[18] The printing technique in Egypt was embraced by reproducing texts on paper strips and supplying them in different copies to meet the demand.[19][20]

In Europe

Block printing first came to Europe as a method for printing on cloth, where it was common by 1300. Images printed on cloth for religious purposes could be quite large and elaborate. When paper became relatively easily available, around 1400, the technique transferred very quickly to small woodcut religious images and playing cards printed on paper. These prints were produced in very large numbers from about 1425 onward.

Around the mid-fifteenth-century, block-books, woodcut books with both text and images, usually carved in the same block, emerged as a cheaper alternative to manuscripts and books printed with movable type. These were all short, heavily illustrated works, the bestsellers of the day, repeated in many different block-book versions: the Ars moriendi and the Biblia pauperum were the most common. There is still some controversy among scholars as to whether their introduction preceded or, in the majority view, followed the introduction of movable type, with the estimated range of dates being between about 1440 and 1460.[21]

Movable-type printing

Movable type is the system of printing and typography using movable pieces of metal type, made by casting from matrices struck by letterpunches. Movable type allowed for much more flexible processes than hand copying or block printing.

Around 1040, the first known movable type system was created in China by Bi Sheng out of porcelain.[5] Bi Sheng used clay type, which broke easily, but Wang Zhen by 1298 had carved a more durable type from wood. He also developed a complex system of revolving tables and number-association with written Chinese characters that made typesetting and printing more efficient. Still, the main method in use there remained woodblock printing (xylography), which "proved to be cheaper and more efficient for printing Chinese, with its thousands of characters".[22]

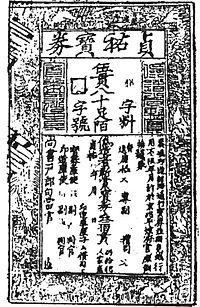

Copper movable type printing originated in China at the beginning of the 12th century. It was used in large-scale printing of paper money issued by the Northern Song dynasty. Movable type spread to Korea during the Goryeo dynasty.

Around 1230, Koreans invented a metal type movable printing using bronze. The Jikji, published in 1377, is the earliest known metal printed book. Type-casting was used, adapted from the method of casting coins. The character was cut in beech wood, which was then pressed into a soft clay to form a mould, and bronze poured into the mould, and finally the type was polished.[23] Eastern metal movable type was spread to Europe between the late 14th and early 15th centuries.[24][25][26][27][28] The Korean form of metal movable type was described by the French scholar Henri-Jean Martin as "extremely similar to Gutenberg's".[29] Authoritative historians Frances Gies and Joseph Gies claimed that "The Asian priority of invention movable type is now firmly established, and that Chinese-Korean technique, or a report of it traveled westward is almost certain."[30]

The printing press

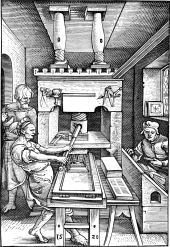

Around 1450, Johannes Gutenberg introduced the first movable type printing system in Europe. He advanced innovations in casting type based on a matrix and hand mould, adaptations to the screw-press, the use of an oil-based ink, and the creation of a softer and more absorbent paper.[31] Gutenberg was the first to create his type pieces from an alloy of lead, tin, antimony, copper and bismuth – the same components still used today.[32] Johannes Gutenberg started work on his printing press around 1436, in partnership with Andreas Dritzehen – whom he had previously instructed in gem-cutting – and Andreas Heilmann, the owner of a paper mill.[33][page needed]

Compared to woodblock printing, movable type page setting and printing using a press was faster and more durable. Also, the metal type pieces were sturdier and the lettering more uniform, leading to typography and fonts. The high quality and relatively low price of the Gutenberg Bible (1455) established the superiority of movable type for Western languages. The printing press rapidly spread across Europe, leading up to the Renaissance, and later all around the world.[34]

Time Life magazine called Gutenberg's innovations in movable type printing the most important invention of the second millennium.[35]

Rotary printing press

The steam-powered rotary printing press, invented in 1843 in the United States by Richard M. Hoe,[36] ultimately allowed millions of copies of a page in a single day. Mass production of printed works flourished after the transition to rolled paper, as continuous feed allowed the presses to run at a much faster pace. Hoe's original design operated at up to 2,000 revolutions per hour where each revolution deposited 4 page images, giving the press a throughput of 8,000 pages per hour.[37] By 1891, The New York World and Philadelphia Item were operating presses producing either 90,000 4-page sheets per hour or 48,000 8-page sheets.[38]

The rotary printing press uses impressions curved around a cylinder to print on long continuous rolls of paper or other substrates. Rotary drum printing was later significantly improved by William Bullock. There are multiple types of rotary printing press technologies that are still used today: sheetfed offset, rotogravure, and flexographic printing.[39]

Printing capacity

The table lists the maximum number of pages which various press designs could print per hour.

| Hand-operated presses | Steam-powered presses | |||||

|---|---|---|---|---|---|---|

| Gutenberg-style c. 1600 |

Stanhope press c. 1800 |

Koenig press 1812 |

Koenig press 1813 |

Koenig press 1814 |

Koenig press 1818 | |

| Impressions per hour | 200[40] | 480[41] | 800[42] | 1,100[43] | 2,000[44] | 2,400[44] |

Conventional printing technology

All printing process are concerned with two kinds of areas on the final output:

- Image area (printing areas)

- Non-image area (non-printing areas)

After the information has been prepared for production (the prepress step), each printing process has definitive means of separating the image from the non-image areas.

Conventional printing has four types of process:

- Planographics, in which the printing and non-printing areas are on the same plane surface and the difference between them is maintained chemically or by physical properties, the examples are: offset lithography, collotype, and screenless printing.

- Relief, in which the printing areas are on a plane surface and the non printing areas are below the surface, examples: flexography and letterpress.

- Intaglio, in which the non-printing areas are on a plane surface and the printing area are etched or engraved below the surface, examples: steel die engraving, gravure, etching, collagraph.

- Porous or Stencil, in which the printing areas are on fine mesh screens through which ink can penetrate, and the non-printing areas are a stencil over the screen to block the flow of ink in those areas, examples: screen printing, stencil duplicator, risograph.

Crop marks

To print an image without a blank area around the image, the non-printing areas must be trimmed after printing. Crop marks can be used to show the printer where the printing area ends, and the non-printing area begins.[45] The part of the image which is trimmed off is called bleed.

Letterpress

Letterpress printing is a technique of relief printing. A worker composes and locks movable type into the bed of a press, inks it, and presses paper against it to transfer the ink from the type which creates an impression on the paper. There is different paper for different works the quality of paper shows different ink to use.

Letterpress printing was the normal form of printing text from its invention by Johannes Gutenberg in the mid-15th century and remained in wide use for books and other uses until the second half of the 20th century, when offset printing was developed. More recently, letterpress printing has seen a revival in an artisanal form.

Offset

Offset printing is a widely used modern printing process. This technology is best described as when a positive (right-reading) image on a printing plate is inked and transferred (or "offset") from the plate to a rubber blanket. The blanket image becomes a mirror image of the plate image. An offset transfer moves the image to a printing substrate (typically paper), making the image right-reading again. Offset printing uses a lithographic process which is based on the repulsion of oil and water. The offset process employs a flat (planographic) image carrier (plate) which is mounted on a press cylinder. The image to be printed obtains ink from ink rollers, while the non-printing area attracts an (acidic) film of water, keeping the non-image areas ink-free. Most offset presses use three cylinders: Plate, blanket, impression. Currently, most books and newspapers are printed using offset lithography.

Gravure

Gravure printing is an intaglio printing technique, where the image being printed is made up of small depressions in the surface of the printing plate. The cells are filled with ink, and the excess is scraped off the surface with a doctor blade. Then a rubber-covered roller presses paper onto the surface of the plate and into contact with the ink in the cells. The printing cylinders are usually made from copper plated steel, which is subsequently chromed, and may be produced by diamond engraving; etching, or laser ablation.

Gravure printing is known for its ability to produce high-quality, high-resolution images with accurate color reproduction and using viscosity control equipment during production. Ink evaporation control affects the change in the color of the printed image.

Gravure printing is used for long, high-quality print runs such as magazines, mail-order catalogues, packaging and printing onto fabric and wallpaper. It is also used for printing postage stamps and decorative plastic laminates, such as kitchen worktops.

Flexography

Flexography is a type of relief printing. The relief plates are typically made from photopolymers. The process is used for flexible packaging, corrugated board, labels, newspapers and more. In this market it competes with gravure printing by holding 80% of the market in US, 50% in Europe but only 20% in Asia.[46]

Other printing techniques

The other significant printing techniques include:

- Dye-sublimation printer

- Inkjet, used typically to print a small number of books or packaging, and also to print a variety of materials: from high quality papers simulating offset printing, to floor tiles. Inkjet is also used to apply mailing addresses to direct mail pieces

- Laser printing (toner printing) mainly used in offices and for transactional printing (bills, bank documents). Laser printing is commonly used by direct mail companies to create variable data letters or coupons.

- Pad printing, popular for its ability to print on complex three-dimensional surfaces

- Relief print, mainly used for catalogues

- Screen printing for a variety of applications ranging from T-shirts to floor tiles, and on uneven surfaces

- Intaglio, used mainly for high value documents such as currencies.

- Thermal printing, popular in the 1990s for fax printing. Used today for printing labels such as airline baggage tags and individual price labels in supermarket deli counters.

Impact of German movable type printing press

Quantitative aspects

It is estimated that following the innovation of Gutenberg's printing press, the European book output rose from a few million to around one billion copies within a span of less than four centuries.[47]

Religious impact

Samuel Hartlib, who was exiled in Britain and enthusiastic about social and cultural reforms, wrote in 1641 that "the art of printing will so spread knowledge that the common people, knowing their own rights and liberties, will not be governed by way of oppression".[48][49]

In the Muslim world, printing, especially in Arabic scripts, was strongly opposed throughout the early modern period, partially due to the high artistic renown of the art of traditional calligraphy. However, printing in Hebrew or Armenian script was often permitted. Thus, the first movable type printing in the Ottoman Empire was in Hebrew in 1493, after which both religious and non-religious texts were able to be printed in Hebrew.[50] According to an imperial ambassador to Istanbul in the middle of the sixteenth century, it was a sin for the Turks, particularly Turkish Muslims, to print religious books. In 1515, Sultan Selim I issued a decree under which the practice of printing would be punishable by death. At the end of the sixteenth century, Sultan Murad III permitted the sale of non-religious printed books in Arabic characters, yet the majority were imported from Italy. Ibrahim Muteferrika established the first press for printing in Arabic in the Ottoman Empire, against opposition from the calligraphers and parts of the Ulama. It operated until 1742, producing altogether seventeen works, all of which were concerned with non-religious, utilitarian matters. Printing did not become common in the Islamic world until the 19th century.[51]

Hebrew language printers were banned from printing guilds in some Germanic states; as a result, Hebrew printing flourished in Italy, beginning in 1470 in Rome, then spreading to other cities including Bari, Pisa, Livorno, and Mantua. Local rulers had the authority to grant or revoke licenses to publish Hebrew books,[52] and many of those printed during this period carry the words 'con licenza de superiori' (indicating their printing having been officially licensed) on their title pages.

It was thought that the introduction of printing 'would strengthen religion and enhance the power of monarchs.'[53] The majority of books were of a religious nature, with the church and crown regulating the content. The consequences of printing 'wrong' material were extreme. Meyrowitz[53] used the example of William Carter who in 1584 printed a pro-Catholic pamphlet in Protestant-dominated England. The consequence of his action was hanging.

Social impact

Print gave a broader range of readers access to knowledge and enabled later generations to build directly on the intellectual achievements of earlier ones without the changes arising within verbal traditions. Print, according to Acton in his 1895 lecture On the Study of History, gave "assurance that the work of the Renaissance would last, that what was written would be accessible to all, that such an occultation of knowledge and ideas as had depressed the Middle Ages would never recur, that not an idea would be lost".[48]

Print was instrumental in changing the social nature of reading.

Elizabeth Eisenstein identifies two long-term effects of the invention of printing. She claims that print created a sustained and uniform reference for knowledge and allowed comparisons of incompatible views.[54]

Asa Briggs and Peter Burke identify five kinds of reading that developed in relation to the introduction of print:

- Critical reading: Because texts finally became accessible to the general population, critical reading emerged as people were able to form their own opinions on texts.

- Dangerous reading: Reading was seen as a dangerous pursuit because it was considered rebellious and unsociable, especially in the case of women, because reading could stir up dangerous emotions such as love, and if women could read, they could read love notes.

- Creative reading: Printing allowed people to read texts and interpret them creatively, often in very different ways than the author intended.

- Extensive reading: Once print made a wide range of texts available, earlier habits of intensive reading of texts from start to finish began to change, and people began reading selected excerpts, allowing much more extensive reading on a wider range of topics.

- Private reading: Reading was linked to the rise of individualism because, before print, reading was often a group event in which one person would read to a group. With print, both literacy and the availability of texts increased, and solitary reading became the norm.

The invention of printing also changed the occupational structure of European cities. Printers emerged as a new group of artisans for whom literacy was essential, while the much more labour-intensive occupation of the scribe naturally declined. Proof-correcting arose as a new occupation, while a rise in the numbers of booksellers and librarians naturally followed the explosion in the numbers of books.

Educational impact

Gutenberg's printing press had profound impacts on universities as well. Universities were influenced in their "language of scholarship, libraries, curriculum, [and] pedagogy"[55]

The language of scholarship

Before the invention of the printing press, most written material was in Latin. However, after the invention of printing the number of books printed expanded as well as the vernacular. Latin was not replaced completely, but remained an international language until the eighteenth century.[55]

University libraries

At this time, universities began establishing accompanying libraries. "Cambridge made the chaplain responsible for the library in the fifteenth century but this position was abolished in 1570 and in 1577 Cambridge established the new office of university librarian. Although, the University of Leuven did not see a need for a university library based on the idea that professor were the library. Libraries also began receiving so many books from gifts and purchases that they began to run out of room. However, the issue was solved in 1589 by a man named Merton who decided books should be stored on horizontal shelves rather than lecterns.[55]

Curriculum

The printed press changed university libraries in many ways. Professors were finally able to compare the opinions of different authors rather than being forced to look at only one or two specific authors. Textbooks themselves were also being printed in different levels of difficulty, rather than just one introductory text being made available.[55]

Comparison of printing methods

| Printing process | Transfer method | Pressure applied | Drop size | Dynamic viscosity | Ink thickness on substrate | Notes | Cost-effective run length |

|---|---|---|---|---|---|---|---|

| Offset printing | rollers | 1 MPa | 40–100 Pa·s | 0.5–1.5 μm | high print quality | > 5,000 (A3 trim size, sheet-fed)[57]

> 30,000 (A3 trim size, web-fed)[57] | |

| Rotogravure | rollers | 3 MPa | 50–200 mPa·s | 0.8–8 μm | thick ink layers possible, excellent image reproduction, edges of letters and lines are jagged[58] |

> 500,000[58] | |

| Flexography | rollers | 0.3 MPa | 50–500 mPa·s | 0.8–2.5 μm | high quality (now HD) | ||

| Letterpress printing | platen | 10 MPa | 50–150 Pa·s | 0.5–1.5 μm | slow drying | ||

| Screen-printing | pressing ink through holes in screen | 1000–10,000 mPa·s[59] | < 12 μm | versatile method, low quality |

|||

| Electrophotography | electrostatics | 5–10 μm | thick ink | ||||

| Liquid electrophotography | image formation by Electrostatics and transfer while fixing | High PQ, excellent image reproduction, wide range of media, very thin image | |||||

| Inkjet printer | thermal | 5–30 picolitres (pl) | 1–5 mPa·s[60] | < 0.5 μm | special paper required to reduce bleeding | < 350 (A3 trim size)[57] | |

| Inkjet printer | piezoelectric | 4–30 pl | 5–20 mPa s | < 0.5 μm | special paper required to reduce bleeding | < 350 (A3 trim size)[57] | |

| Inkjet printer | continuous | 5–100 pl | 1–5 mPa·s | < 0.5 μm | special paper required to reduce bleeding | < 350 (A3 trim size)[57] | |

| Transfer-print | thermal transfer film or water release decal | mass-production method of applying an image to a curved or uneven surface | |||||

| Aerosol-jet printer | Aerosolized inks carried by gas | 2–5 microns in diameter | 1–1000 mPa s | < 1 μm | Good printing resolution, High quality[59][61] |

Digital printing

By 2005, digital printing accounted for approximately 9% of the 45 trillion pages printed annually around the world.[62]

Printing at home, an office, or an engineering environment is subdivided into:

- small format (up to ledger size paper sheets), as used in business offices and libraries

- wide format (up to 3' or 914mm wide rolls of paper), as used in drafting and design establishments.

Some of the more common printing technologies are:

- blueprint – and related chemical technologies

- daisy wheel – where pre-formed characters are applied individually

- dot-matrix – which produces arbitrary patterns of dots with an array of printing studs

- line printing – where formed characters are applied to the paper by lines

- heat transfer – such as early fax machines or modern receipt printers that apply heat to special paper, which turns black to form the printed image

- inkjet – including bubble-jet, where ink is sprayed onto the paper to create the desired image

- electrophotography – where toner is attracted to a charged image and then developed

- laser – a type of xerography where the charged image is written pixel by pixel using a laser

- solid ink printer – where solid sticks of ink are melted to make liquid ink or toner

Vendors typically stress the total cost to operate the equipment, involving complex calculations that include all cost factors involved in the operation as well as the capital equipment costs, amortization, etc. For the most part, toner systems are more economical than inkjet in the long run, even though inkjets are less expensive in the initial purchase price.

Professional digital printing (using toner) primarily uses an electrical charge to transfer toner or liquid ink to the substrate onto which it is printed. Digital print quality has steadily improved from early color and black and white copiers to sophisticated colour digital presses such as the Xerox iGen3, the Kodak Nexpress, the HP Indigo Digital Press series, and the InfoPrint 5000. The iGen3 and Nexpress use toner particles and the Indigo uses liquid ink. The InfoPrint 5000 is a full-color, continuous forms inkjet drop-on-demand printing system. All handle variable data, and rival offset in quality. Digital offset presses are also called direct imaging presses, although these presses can receive computer files and automatically turn them into print-ready plates, they cannot insert variable data.

Small press and fanzines generally use digital printing. Prior to the introduction of cheap photocopying, the use of machines such as the spirit duplicator, hectograph, and mimeograph was common.

3D printing

3D printing is a form of manufacturing technology where physical objects are created from three-dimensional digital models using 3D printers. The objects are created by laying down or building up many thin layers of material in succession. The technique is also known as additive manufacturing, rapid prototyping, or fabricating.[63]

In the 1980s, 3D printing techniques were considered suitable only for the production of functional or aesthetic prototypes, and a more appropriate term for it at the time was rapid prototyping.[64][65] As of 2019[update], the precision, repeatability, and material range of 3D printing have increased to the point that some 3D printing processes are considered viable as an industrial-production technology, whereby the term additive manufacturing can be used synonymously with 3D printing.[66][67][68] One of the key advantages of 3D printing[69][70] is the ability to produce very complex shapes or geometries that would be otherwise infeasible to construct by hand, including hollow parts or parts with internal truss structures to reduce weight. Fused deposition modeling (FDM), which uses a continuous filament of a thermoplastic material, is the most common 3D printing process in use as of 2020[update].[71][72]

Gang run printing

Gang run printing is a method in which multiple printing projects are placed on a common paper sheet in an effort to reduce printing costs and paper waste. Gang runs are generally used with sheet-fed printing presses and process color jobs, which require four or eight separate plates that are hung on the plate cylinder of the press. Printers use the term "gang run" or "gang" to describe the practice of placing many print projects on the same oversized sheet. Basically, instead of running one postcard that is 4 x 6 as an individual job the printer would place 15 different postcards on 20 x 18 sheet, therefore using the same amount of press time the printer will get 15 jobs done in roughly the same amount of time as one job.

Printed electronics

Printed electronics is the manufacturing of electronic devices using standard printing processes. Printed electronics technology can be produced on cheap materials such as paper or flexible film, which makes it an extremely cost-effective method of production. Since early 2010, the printable electronics industry has been gaining momentum and several large companies, including Bemis Company and Illinois Tool Works have made investments in printed electronics and industry associations including OE-A and FlexTech Alliance are contributing heavily to the advancement of the printed electronics industry.[73][74]

Printing terminologies

Printing terminologies are the specific terms used in the printing industry.

- Airshaft – Device used in manufacturing

- Anilox – Method to provide a measured amount of ink

- Basis weight – The mass per unit of area of paper

- Ben-Day dots – Printing and photoengraving technique

- Bleed (printing) – Type of printing technique

- Broadsheet – Largest newspaper format

- California Job Case – Case with compartments to store the movable type used in letterpress printing

- Camera-ready – Document technically ready to print

- Card stock – Paper, thicker and more durable than normal writing or printing paper

- Catchword – word placed at the foot of a page that anticipates the first word of the following page

- CcMmYK color model – Six-color printing process

- CMYK color model – Subtractive color model, used in color printing

- Colophon (publishing) – Brief statement of a book's own information, such as publisher, location, and date of publication

- Color bleeding (printing) – effect of areas of colored inks or dyes spreading into unwanted areas

- Composing stick – Tool used in printing to assemble metal type into words and lines

- Computer to film – Printing process

- Computer to plate – Imaging technology used in printing

- Continuous tone – Image in which each point can transition smoothly between shades

- Die (philately) – Engraved image of a stamp on metal

- Dot gain – Phenomenon in offset lithography

- Dots per centimeter – Measure of dot density

- Dots per inch – Measure of dot density

- Double truck – A pair of facing pages

- Dry transfer – Type of decal

- Dultgen – Printing technique

- Duotone – Superimposition of one contrasting colour halftone over another color halftone

- Duplex printing – Automatic double-sided printing

- Edition (printmaking) – number of prints struck from one plate

- Error diffusion – Type of halftoning

- Flong – Temporary negative paper mould made from an impression

- Folio (printing) – Technical term describing the format or size of a book

- For position only – Materials used as placeholders in a layout

- Frisket – Protective sheet on a printing hand press

- Galley proof – First proofs printed from type, usually before breaking into pages

- Gang run printing – Printing multiple projects on a common paper sheet

- Grammage – The mass per unit of area of paper

- Grey component replacement – a part of color separation process

- Halftone – Printing process

- Hand mould – Tool used in injection molding and printing

- Hellbox – Bin for cast metal sorts after printing

- Hexachrome – Six-color printing process designed by Pantone Inc

- Hot stamping – Method of relief printing

- Imposition – Step in the prepress printing process

- Inkometer – Instrument for measuring the adhesiveness of ink

- Iris printer – Color inkjet printer for prepress proofing

- Iron-on – Image that can be transferred to fabric by the application of heat and pressure

- Job Definition Format – technical standard

- Key plate – Plate that prints the detail in an image

- Keyline – Line that separates color and monochromatic areas

- Kodak Proofing Software

- Mezzotint – Printmaking technique

- Nanotransfer printing – Additive and high resolution metal printing technique

- Non-photo blue – Shade of blue not detected by film

- Overprinting – Process of printing one color over another

- Pagination – Process of dividing content into discrete pages

- Paste up – Method of preparing copy for photographing to make a printing plate

- Pre-flight (printing) – Process of reviewing digital files before publication

- Prepress – Processes and procedures that occur between the creation of a print layout and the final printing

- Prepress proofing – usually serves as an agreement between customer and printer and as a color reference guide for adjusting the press before the final press run

- Press check (printing) – Verifies color on press v. color proof.

- Registration black – Correct layering of colors in printed documents

- Rich black – Black ink mixed with other colors for a darker tone

- Set-off (printing) – ink passing from one printed sheet to another because the ink has not had the chance to dry, which causes the sheets of paper to stick together

- Spot color – Type of ink or pigment used in printing

- Stochastic screening

- Transfer-print – method of decorating ceramics by transferring an engraved printed design

- Trap (printing) – printing technique to overcome registration problems

- Under color removal – Color separation process in printing

See also

- Color printing – Reproductive printing with color

- Cloud printing – printing using cloud computing

- Converters (industry) – Specialist in combining raw materials to create new products

- Dickerson combination press – Printing press invented mid 1950s

- Electrotyping – Chemical method for forming metal parts

- Flexography – Form of printing process

- In-mould decoration – method of decorating moulded plastics

- In-mould labelling – Plastic production process

- Jang Yeong-sil – Korean inventor (1390–1442)

- Laurens Janszoon Coster – Dutch purported inventor of printing press

- Letterpress printing – Technique of relief printing using a printing press

- Music engraving – Process of drawing music notation at high quality for reproduction

- Music printing

- Print on demand – Printing business process

- Printed T-shirt – Style of inexpensive fabric shirt

- Printing press check – Verifies color on press v. color proof.

- Security printing – Field of the printing industry for banknotes and other security products

- Textile printing – Method for applying patterns to cloth using printing techniques

- Waterless printing – Lithographic printing process that uses silicone plates instead of water to control ink placement

- Wetting – Ability of a liquid to maintain contact with a solid surface

- Early American publishers and printers

- The influence of the internet on the printing industry

Major sources

- Bolza, Hans (1967). "Friedrich Koenig und die Erfindung der Druckmaschine". Technikgeschichte. 34 (1): 79–89.

- Tsien, Tsuen-Hsuin (1985). Paper and Printing. Needham, Joseph Science and Civilization in China. Vol. 5 part 1. Cambridge University Press. ISBN 0-521-08690-6.; also published in Taipei: Caves Books, Ltd., 1986.

Notes

- ^ An early method of reproduction that has been traced to the second century is the practice of using needles pushed through a stencil onto the target paper, fabric or plaster, to provide guidelines for subsequent artwork:[2] this cannot reasonably be described as printing.

References

- ^ a b Tsien 1985, p. 8.

- ^ Tsien 1985, p. 146.

- ^ a b c Suarez, Michael F.; Woudhuysen, H. R., eds. (2013). The Book: A Global History. Oxford: Oxford University Press. p. 574–576. ISBN 9780191668746.

- ^ Needham, Joseph; Tsien, Tsuen-hsuin, eds. (2001) [1985]. Science and civilisation in China: Paper and printing. Vol. V:1 (Reprint ed.). Cambridge: Cambridge University Press. pp. 159, 201–205. ISBN 978-0-521-08690-5.

At the present time, the only known authoritative account of the invention of movable type by a commoner named Pi Sheng (c. 990–1051) is the contemporary record of Shen Kua (1031–[1095]) [...] Although the process went into eclipse after its inception, it was a complete invention and fully four hundred years ahead of Gutenberg.

- ^ a b "Great Chinese Inventions". Minnesota-china.com. Archived from the original on December 3, 2010. Retrieved July 29, 2010.

- ^ Rees, Fran. Johannes Gutenberg: Inventor of the Printing Press Archived April 6, 2023, at the Wayback Machine

- ^ "Cat 262: Printed dated copy of the Diamond Sutra". idp.bl.uk. Archived from the original on December 8, 2022. Retrieved December 8, 2022.

- ^ a b Tsien 1985, pp. 149, 150

- ^ Pratt, Keith (August 15, 2007). Everlasting Flower: A History of Korea. Reaktion Books. p. 74. ISBN 978-1861893352.

- ^ Early Printing in Korea. Korea Cultural Center Archived 2009-02-08 at the Wayback Machine

- ^ Gutenberg and the Koreans: Asian Woodblock Books. Rightreading.com

- ^ Gutenberg and the Koreans: Cast-Type Printing in Korea's Goryeo Dynasty (918–1392). Rightreading.com

- ^ North Korea – Silla. Country Studies

- ^ "Oneline Gallery: Sacred Texts". British Library. Archived from the original on November 10, 2013. Retrieved March 10, 2012.

- ^ Tsuen-Hsuin, Tsien; Needham, Joseph (1985). Paper and Printing. Science and Civilisation in China. Vol. 5 part 1. Cambridge University Press. pp. 158, 201.

- ^ Thomas Franklin Carter, The Invention of Printing in China and its Spread Westward, The Ronald Press, NY 2nd ed. 1955, pp. 176–78

- ^ Mayor, A Hyatt (1980). Prints and People. Vol. 5–18. Princeton: Metropolitan Museum of Art. ISBN 978-0-691-00326-9.

- ^ Richard W. Bulliet (1987), "Medieval Arabic Tarsh: A Forgotten Chapter in the History of Printing Archived September 21, 2017, at the Wayback Machine". Journal of the American Oriental Society 107 (3), pp. 427–38.

- ^ See Geoffrey Roper, Muslim Printing Before Gutenberg and the references cited therein.

- ^ Bloom, Jonathan (2001). Paper Before Print: The History and Impact of Paper in the Islamic World. New Haven: Yale University Press. pp. 8–10, 42–45. ISBN 0-300-08955-4.

- ^ Shestack, Alan (1967). Master E S, five hundredth anniversary exhibition, September fifth through October third, Philadelphia Museum of Art. Philadelphia Museum of Art. OCLC 1976512.

- ^ Beckwith, Christopher I., Empires of the Silk Road: A History of Central Eurasia from the Bronze Age to the Present, Princeton University Press, 2009, ISBN 978-0-691-15034-5

- ^ Tsien 1985, p. 330

- ^ Polenz, Peter von. (1991). Deutsche Sprachgeschichte vom Spätmittelalter bis zur Gegenwart: I. Einführung, Grundbegriffe, Deutsch in der frühbürgerlichen Zeit (in German). New York/Berlin: Gruyter, Walter de GmbH.

- ^ Thomas Christensen (2007). "Did East Asian Printing Traditions Influence the European Renaissance?". Arts of Asia Magazine (to appear). Archived from the original on August 11, 2019. Retrieved October 18, 2006.

- ^ Juan González de Mendoza (1585). Historia de las cosas más notables, ritos y costumbres del gran reyno de la China (in Spanish).

- ^ Thomas Franklin Carter, The Invention of Printing in China and its Spread Westward, The Ronald Press, NY 2nd ed. 1955, pp. 176–178

- ^ L. S. Stavrianos (1998) [1970]. A Global History: From Prehistory to the 21st Century (7th ed.). Upper Saddle River, New Jersey: Prentice Hall. ISBN 978-0-13-923897-0.

- ^ Briggs, Asa and Burke, Peter (2002) However, more correctly it should be described as the other way around. Gutenberg's form of metal movable type was extremely similar to the Korean Jikji's, which was printed 78 years prior to the Gutenberg Bible. A Social History of the Media: from Gutenberg to the Internet, Polity, Cambridge, pp. 15–23, 61–73.

- ^ Gies, Frances and Gies, Joseph (1994) Cathedral, Forge, and Waterwheel: Technology and Invention in the Middle Age, New York : HarperCollins, ISBN 0-06-016590-1, p. 241.

- ^ Steinberg, S. H. (1974). Five Hundred Years of Printing (3rd ed.). Harmondsworth, Middlesex: Penguin. ISBN 978-0-14-020343-1.

- ^ Encyclopædia Britannica. Retrieved November 27, 2006, from Encyclopædia Britannica Ultimate Reference Suite DVD – entry "printing"

- ^ Polenz, Peter von. (1991). Deutsche Sprachgeschichte vom Spätmittelalter bis zur Gegenwart: I. Einführung, Grundbegriffe, Deutsch in der frühbürgerlichen Zeit (in German). New York/Berlin: Gruyter, Walter de GmbH.

- ^ "Gutenberg Bible Published". education.nationalgeographic.org. Retrieved May 19, 2024.

- ^ In 1997, Time–Life magazine picked Gutenberg's invention to be the most important of the second millennium. In 1999, the A&E Network voted Johannes Gutenberg "Man of the Millennium". See also 1,000 Years, 1,000 People: Ranking The Men and Women Who Shaped The Millennium Archived October 12, 2007, at the Wayback Machine which was composed by four prominent US journalists in 1998.

- ^ Meggs, Philip B. (1998). A History of Graphic Design (Third ed.). John Wiley & Sons, Inc. p. 147. ISBN 978-0-471-29198-5.

- ^ "Richard March Hoe | American inventor and manufacturer". Encyclopedia Britannica.

- ^ Peck, Harry Thurston. (1895). The International Cyclopædia A Compendium of Human Knowledge, Revised with Large Additions · Volume 12. Dodd, Mead & Company. p. 168. Retrieved June 28, 2020.

- ^ "JMC 107 Design and Graphics- Printing Process (Gravure & Screen)" (PDF). www.davuniversity.org. Retrieved May 19, 2024.

- ^ Pollak, Michael (1972). "The performance of the wooden printing press". The Library Quarterly. 42 (2): 218–64. doi:10.1086/620028. JSTOR 4306163. S2CID 144726990.

- ^ Bolza 1967, p. 80.

- ^ Bolza 1967, p. 83.

- ^ Bolza 1967, p. 87.

- ^ a b Bolza 1967, p. 88.

- ^ Bob deLaubenfels (February 9, 2011). "What are crop marks and why would you want to print them?". Microsoft. Archived from the original on April 24, 2022.

- ^ Joanna Izdebska; Sabu Thomas (September 24, 2015). Printing on Polymers: Fundamentals and Applications. Elsevier Science. p. 199. ISBN 978-0-323-37500-9.

- ^ a b Buringh, Eltjo; van Zanden, Jan Luiten: "Charting the 'Rise of the West': Manuscripts and Printed Books in Europe, A Long-Term Perspective from the Sixth through Eighteenth Centuries", The Journal of Economic History, Vol. 69, No. 2 (2009), pp. 409–45 (417, table 2)

- ^ a b Ref: Briggs, Asa and Burke, Peter (2002) A Social History of the Media: from Gutenberg to the Internet, Polity, Cambridge, pp. 15–23, 61–73.

- ^ A Description of the Famous Kingdome of Macaria. London. 1641.

- ^ or soon after; Naim A. Güleryüz, Bizans'tan 20. Yüzyıla – Türk Yahudileri, Gözlem Gazetecilik Basın ve Yayın A.Ş., İstanbul, January 2012, p. 90 ISBN 978-9944-994-54-5

- ^ Watson, William J., "İbrāhīm Müteferriḳa and Turkish Incunabula", Journal of the American Oriental Society, 1968, volume 88, issue 3, p. 436

- ^ "A Lifetime's Collection of Texts in Hebrew, at Sotheby's Archived January 22, 2019, at the Wayback Machine", Edward Rothstein, New York Times, February 11, 2009

- ^ a b Meyrowitz: "Mediating Communication: What Happens?" in "Questioning the Media", p. 41.

- ^ Eisenstein in Briggs and Burke, 2002: p. 21

- ^ a b c d Modie, G (2014). "Gutenberg's Effects on Universities". History of Education. 43 (4): 17. doi:10.1080/0046760X.2014.930186. S2CID 145093891.

- ^ Kipphan, Helmut (2001). Handbook of print media: technologies and production methods (Illustrated ed.). Springer. pp. 130–44. ISBN 978-3-540-67326-2.

- ^ a b c d e Kipphan, Helmut (2001). Handbook of print media: technologies and production methods (Illustrated ed.). Springer. pp. 976–79. ISBN 978-3-540-67326-2.

- ^ a b Kipphan, Helmut (2001). Handbook of print media: technologies and production methods (Illustrated ed.). Springer. pp. 48–52. ISBN 978-3-540-67326-2.

- ^ a b Zeng, Minxiang; Zhang, Yanliang (October 22, 2019). "Colloidal nanoparticle inks for printing functional devices: emerging trends and future prospects". Journal of Materials Chemistry A. 7 (41): 23301–23336. doi:10.1039/C9TA07552F. ISSN 2050-7496. OSTI 1801277. S2CID 203945576. Archived from the original on April 12, 2020. Retrieved April 21, 2020.

- ^ Hu, Guohua; Kang, Joohoon; Ng, Leonard W. T.; Zhu, Xiaoxi; Howe, Richard C. T.; Jones, Christopher G.; Hersam, Mark C.; Hasan, Tawfique (May 8, 2018). "Functional inks and printing of two-dimensional materials". Chemical Society Reviews. 47 (9): 3265–3300. doi:10.1039/C8CS00084K. ISSN 1460-4744. PMID 29667676. S2CID 4937349. Archived from the original on April 13, 2020. Retrieved April 13, 2020.

- ^ Paulsen, Jason A.; Renn, Michael; Christenson, Kurt; Plourde, Richard (October 2012). "Printing conformal electronics on 3D structures with Aerosol Jet technology". 2012 Future of Instrumentation International Workshop (FIIW) Proceedings. pp. 1–4. doi:10.1109/FIIW.2012.6378343. ISBN 978-1-4673-2482-3. S2CID 21924851.

- ^ "When 2% Leads to a Major Industry Shift Archived February 16, 2008, at the Wayback Machine" Patrick Scaglia, August 30, 2007.

- ^ "Rapid Prototyping - an overview | ScienceDirect Topics". www.sciencedirect.com. Archived from the original on October 26, 2022. Retrieved October 26, 2022.

- ^ "Learning Course: Additive Manufacturing – Additive Fertigung". tmg-muenchen.de.

- ^ "3-D Printing Steps into the Spotlight". Upstate Business Journal. April 11, 2013. Archived from the original on December 20, 2019. Retrieved December 20, 2019.

- ^ Lam, Hugo K.S.; Ding, Li; Cheng, T.C.E.; Zhou, Honggeng (January 1, 2019). "The impact of 3D printing implementation on stock returns: A contingent dynamic capabilities perspective". International Journal of Operations & Production Management. 39 (6/7/8): 935–961. doi:10.1108/IJOPM-01-2019-0075. ISSN 0144-3577. S2CID 211386031.

- ^ "Ariadne". New Scientist. Vol. 64, no. 917. October 3, 1974. p. 80. ISSN 0262-4079. Archived from the original on July 24, 2020.

- ^ Ellam, Richard (February 26, 2019). "3D printing: you read it here first". New Scientist. Retrieved August 23, 2019.

- ^ "3D Printing: All You Need To Know". explainedideas.com. Archived from the original on August 20, 2022. Retrieved August 11, 2022.

- ^ Zelinski, Peter (August 4, 2017), "Additive manufacturing and 3D printing are two different things", Additive Manufacturing, retrieved August 11, 2017.

- ^ "ISO/ASTM 52900:2015 – Additive manufacturing – General principles – Terminology". iso.org. Retrieved June 15, 2017.

- ^ JP-S56-144478, "JP Patent: S56-144478 - 3D figure production device", issued 10 November 1981

- ^ "Recent Announcements Show Gains Being Made by PE Industry". Printed Electronics Now. Archived from the original on April 7, 2014. Retrieved September 21, 2012.

- ^ "Printable transistors usher in 'internet of things'". The Register. Archived from the original on May 17, 2017. Retrieved September 21, 2012.

Further reading

- Barker, Nicholas. (1978). "Invention of Printing." U.S. Library of Congress Quarterly Journal 35 (March): 64–76.

- Edwards, Eiluned (December 2015). Block Printed Textiles of India. Niyogi Books. ISBN 978-93-85285-03-5.

- Elizabeth L. Eisenstein, The Printing Press as an Agent of Change, Cambridge University Press, September 1980, Paperback, 832 p. ISBN 0-521-29955-1

- Egan, Grace, and Colin Johnston. “‘Serving the Turn’: Collaboration and Proof in Illegal Hand-Press Period Books.” Ilha do Desterro 71.2 (2018): 129–152.

- Gaskell, Philip (1995). A New Introduction to Bibliography. Winchester and Newcastle: St Paul's Bibliographies and Oak Knoll Press.

- Hargrave, J. (2013). Disruptive Technological History: Papermaking to Digital Printing. Journal of Scholarly Publishing, 44(3). 221–227.

- Lafontaine, Gerard S. (1958). Dictionary of Terms Used in the Paper, Printing, and Allied Industries. Toronto: H. Smith Paper Mills. 110 p.

- Marshall McLuhan, The Gutenberg Galaxy: The Making of Typographic Man (1962) Univ. of Toronto Press (1st ed.); reissued by Routledge & Kegan Paul ISBN 0-7100-1818-5

- Nesbitt, Alexander (1957). The History and Technique of Lettering. Dover Books.

- Saunders, Gill; Miles, Rosie (May 1, 2006). Prints Now: Directions and Definitions. Victoria and Albert Museum. ISBN 978-1-85177-480-7.

- Steinberg, S.H. (1996). Five Hundred Years of Printing. London and Newcastle: The British Library and Oak Knoll Press.

- Tam, Pui-Wing The New Paper Trail, The Wall Street Journal Online, February 13, 2006 p. R8

- Werner, S. (2018). Studying Early Printed Books, 1450-1800: A Practical Guide. Wiley.

- Woong-Jin-Wee-In-Jun-Gi No. 11 Jang Young Sil by Baek Sauk Gi. 1987 Woongjin Publishing Co., Ltd. p. 61. On the effects of Gutenberg's printing

Early printers manuals

The classic manual of early hand-press technology is

- Moxon, Joseph (1962) [1683–1684]. Herbert, Davies; Carter, Harry (eds.). Mechanick Exercises on the Whole Art of Printing (reprint ed.). New York: Dover Publications.

- A somewhat later one, showing 18th century developments is

- Stower, Caleb (1965) [1808]. The Printer's Grammar (reprint ed.). London: Gregg Press.

External links

- . Encyclopædia Britannica. Vol. 22 (11th ed.). 1911.

- . New International Encyclopedia. 1905.

- Prints & People: A Social History of Printed Pictures – an exhibition catalog from The Metropolitan Museum of Art (fully available online as PDF)

- Centre for the History of the Book

- Printing Industries of the Americas – trade association for printers and companies in the graphic arts

- The development of book and printing. English website of the Gutenberg-Museum Mainz (Germany)

- BPSnet British Printing Society

- Taiwan Culture Portal: Ri Xing Type Foundry – preserving the true character of Chinese type

- A collection of printing materials from the 19th Century – Documents printed by R. Mathison Jr., The Job Printer, in Vancouver, B.C. – UBC Library Digital Collections

- International Printing Museum, Carson, CA, Web site

- Museum of Printing, Andover, MA, Web site

- American Printing History Association, NY, Web site

- Hamilton Wood Type and Printing Museum, WI, Web site

- History of Printing – Timeline